Plastic, modular and self-engaging bristle brush

一种模块化、鬃毛的技术,应用在鬃毛刷领域,达到更换容易、降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

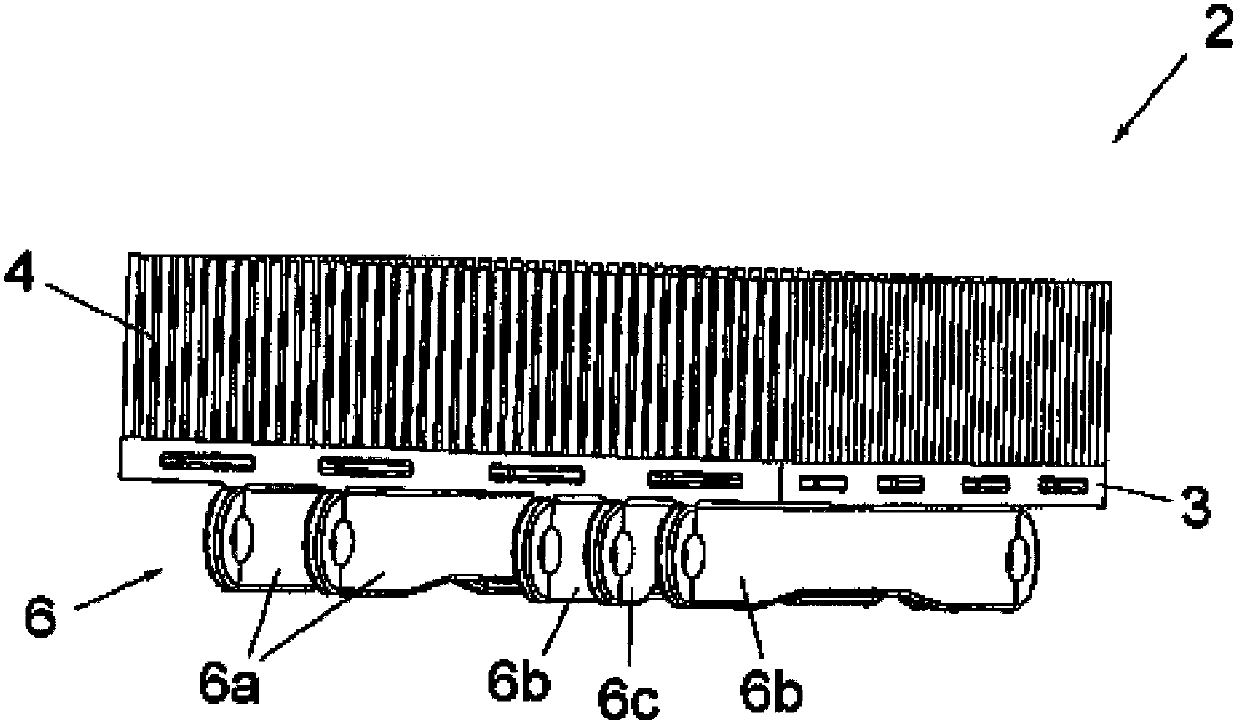

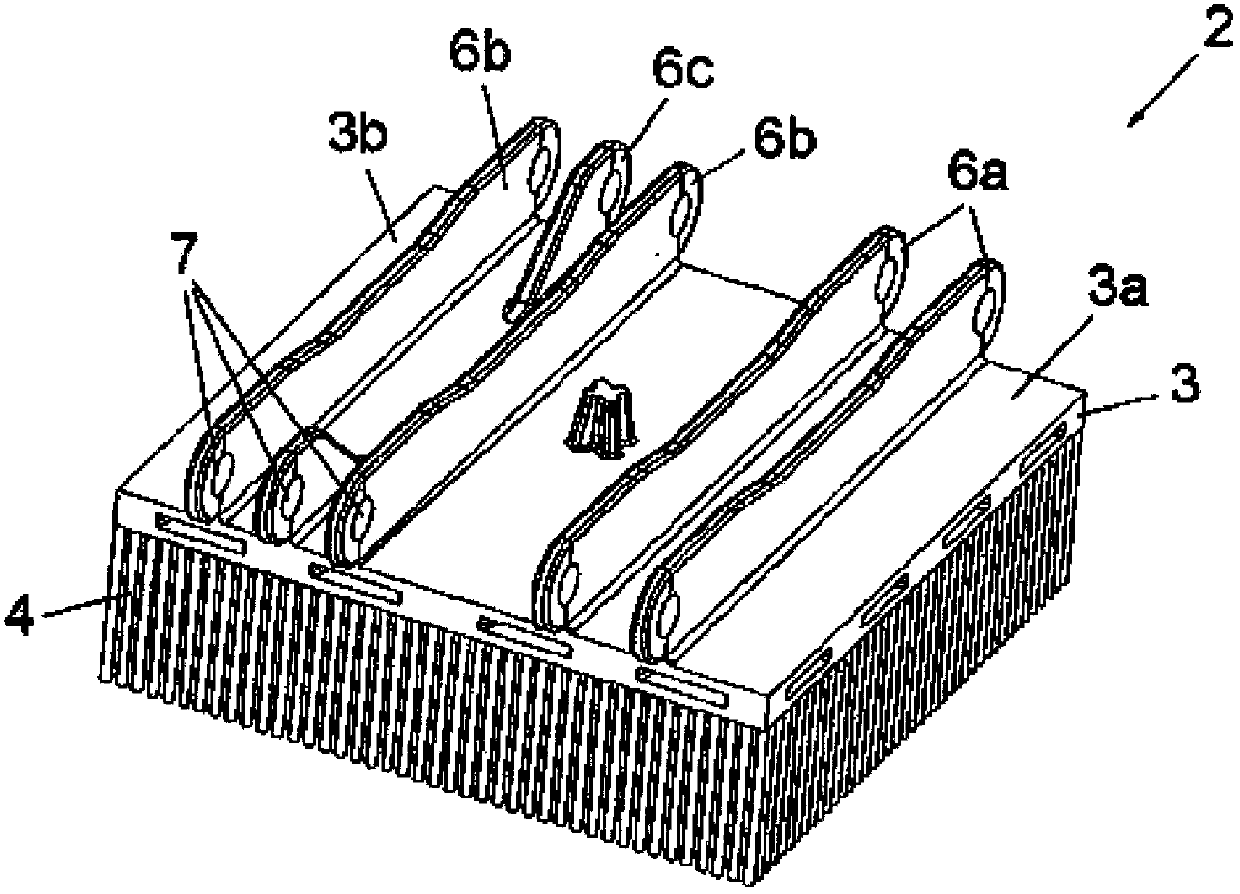

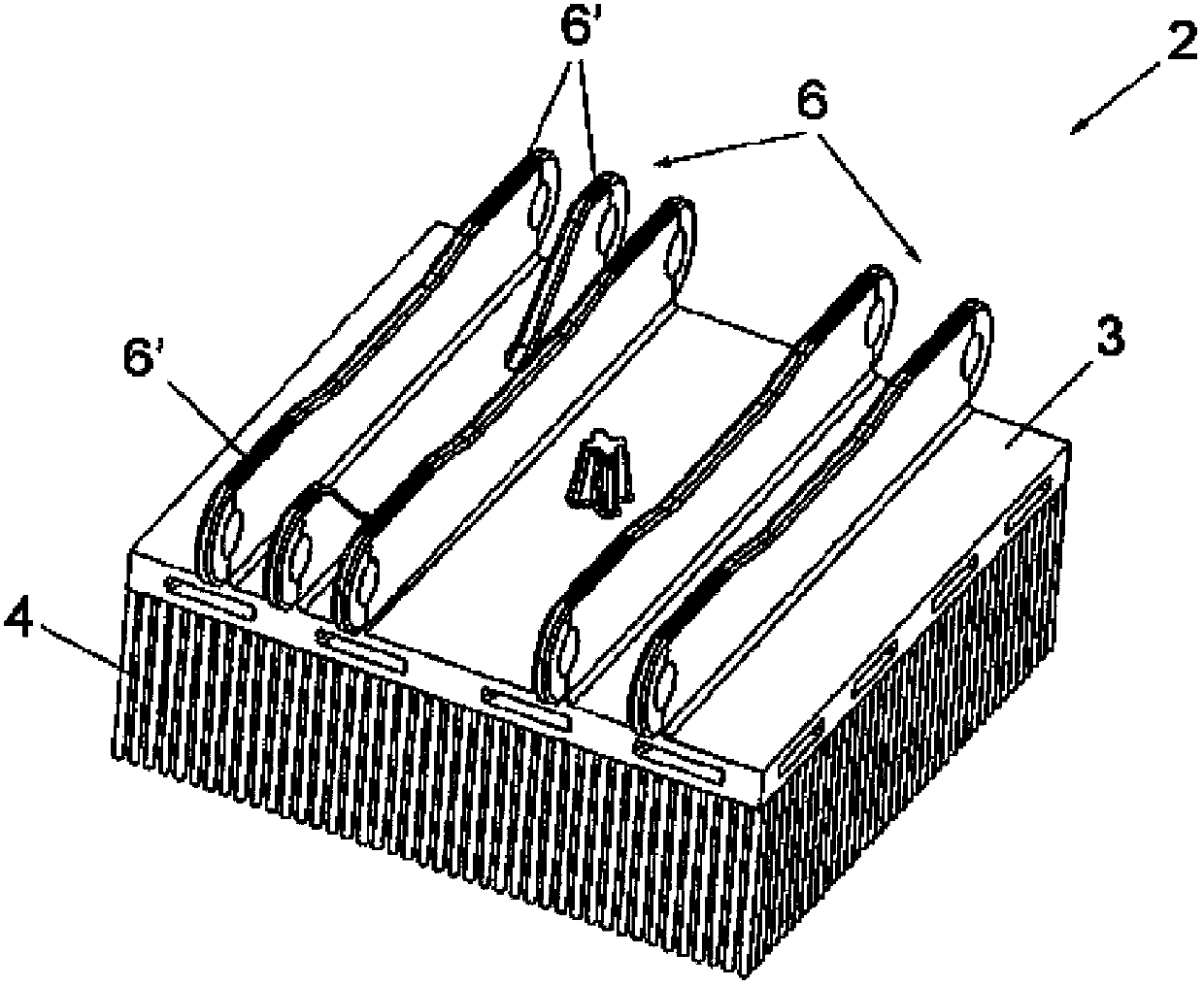

[0048] Such as figure 1 , 2 As shown in and 14, a cutting mat 1 comprises a plurality of bristle brushes 2 coupled adjacent to each other according to the present invention, each brush 2 comprising a support plate 3 having a top with a plurality of flexible bristles 4 extending vertically therefrom. The surface and the bottom surface provided with coupling means for coupling to drive means for driving the bristle brush 2 on the support table 5, the free ends of the bristles 4 define the The support surface for the cut part.

[0049] The coupling means for each brush 2 comprises a set of slides 6 projecting perpendicularly from the bottom surface of the support plate 3, said slides 6 comprising a pair of opposite guiding self-centering ends projecting from the periphery of the brush 2 , the slides 6 are distributed so that the ends of the slides 6 of adjacent brushes 2 can be assembled together by overlapping each other.

[0050] Said slideway 6 also includes, at its leading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com