Measuring system and measuring method for determining wear of brake lining of friction brake

A technology of friction brakes and measurement systems, applied in the direction of brake types, mechanical equipment, etc., can solve problems such as reduced service life, and achieve the effect of low cost and subsequent cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

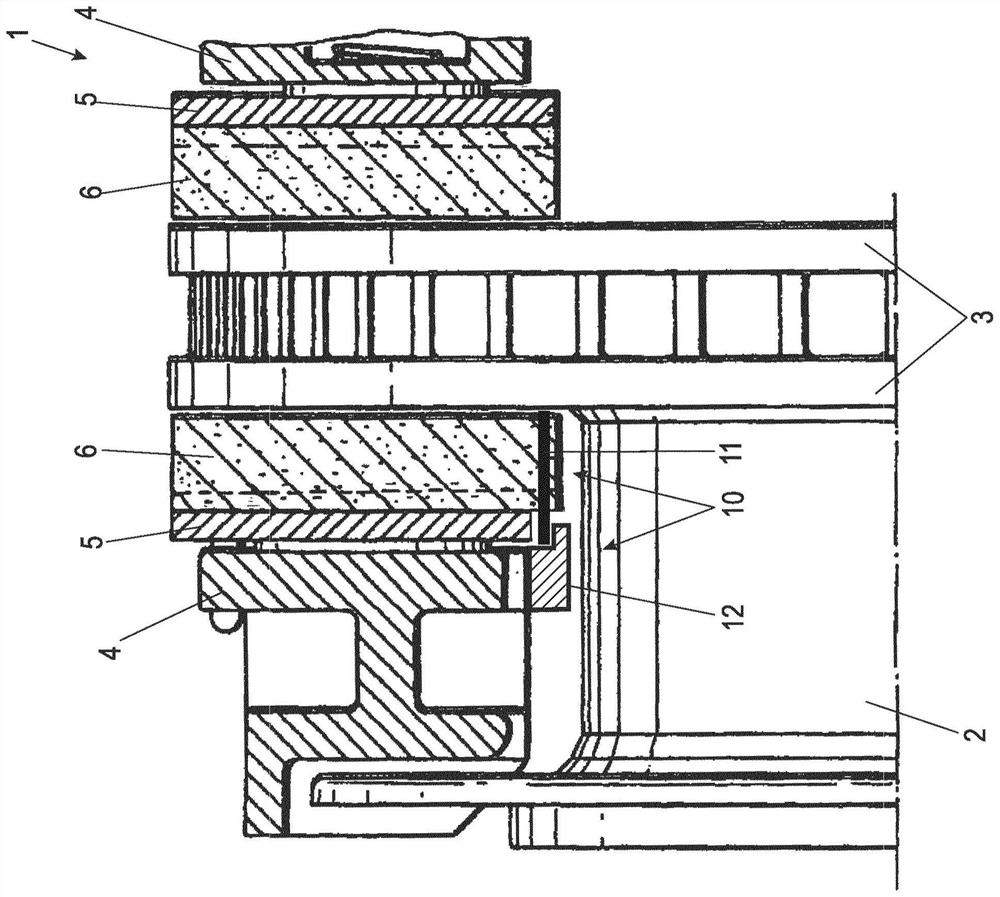

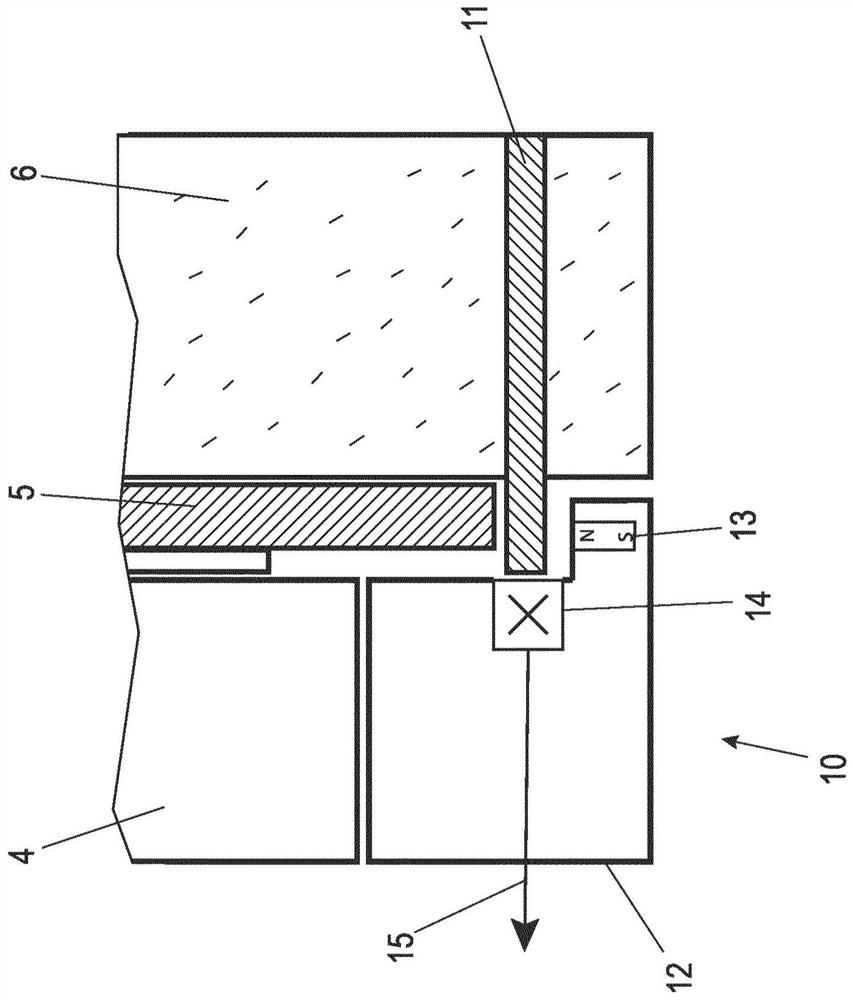

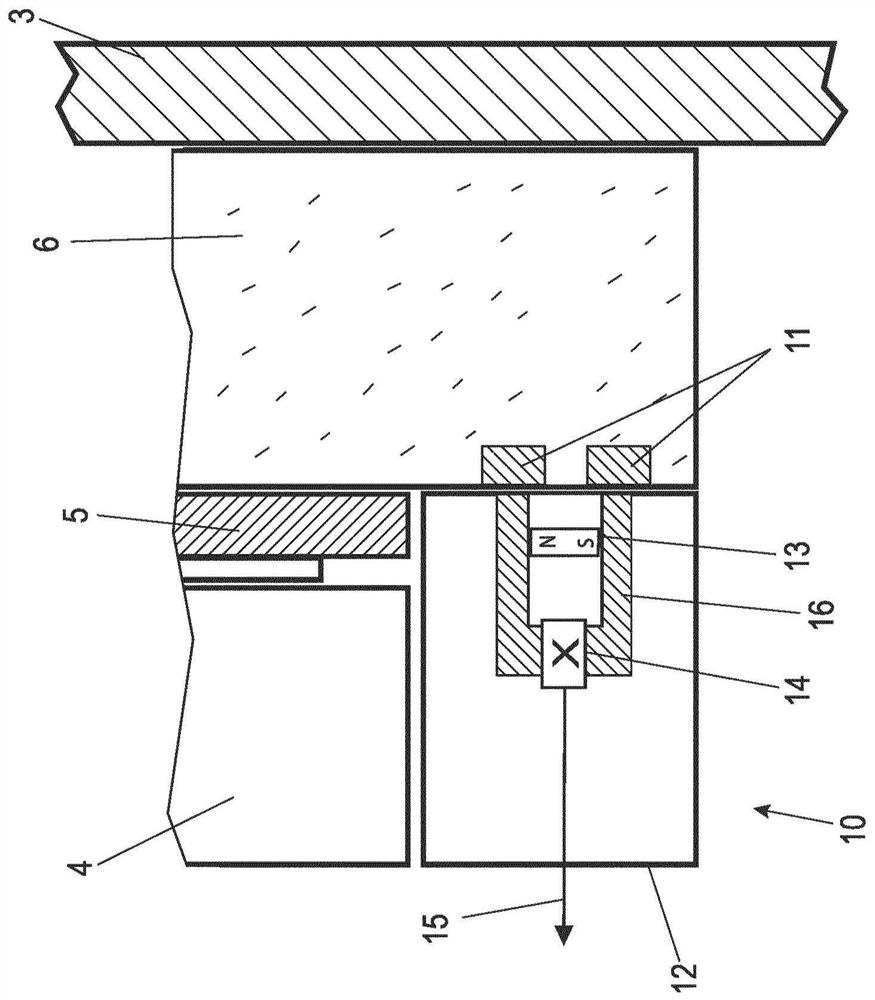

[0032] exist figure 1 The middle section again shows a part of the friction brake 1 of a rail vehicle, for example a freight car.

[0033] The friction brake 1 is a disc brake in which a brake disc 3 , here an internally ventilated disc, is fastened on a hub 2 of the vehicle. There is a pressing mechanism 4 , not further shown here, which acts on two brake linings 6 , which are each supported by a lining carrier 5 . The pressing mechanism 4 is not shown in detail here. The pressing mechanism can be actuated pneumatically, hydraulically or electrically in a known manner. When the friction brake 1 is actuated, the brake lining 6 is pressed against the brake disk 3 by the pressing mechanism 4 and thus brought into frictional engagement with the brake disk 3 .

[0034] As the brake is used, not only the brake disc 3 but also the brake lining 6 wears out in that the lining thickness (lining thickness) decreases. In order to avoid a direct frictional contact of the brake lining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com