Cutting type filling method for optimal layout of rectangular parts

A filling method and technology for rectangular parts, which are applied in data processing applications, predictions, calculations, etc., can solve problems such as difficulty in coexistence of simplicity and high efficiency of nesting algorithms, complex nesting programming, and fewer specifications of rectangular parts, etc., to improve The core competitiveness of the enterprise, the saving of raw materials, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

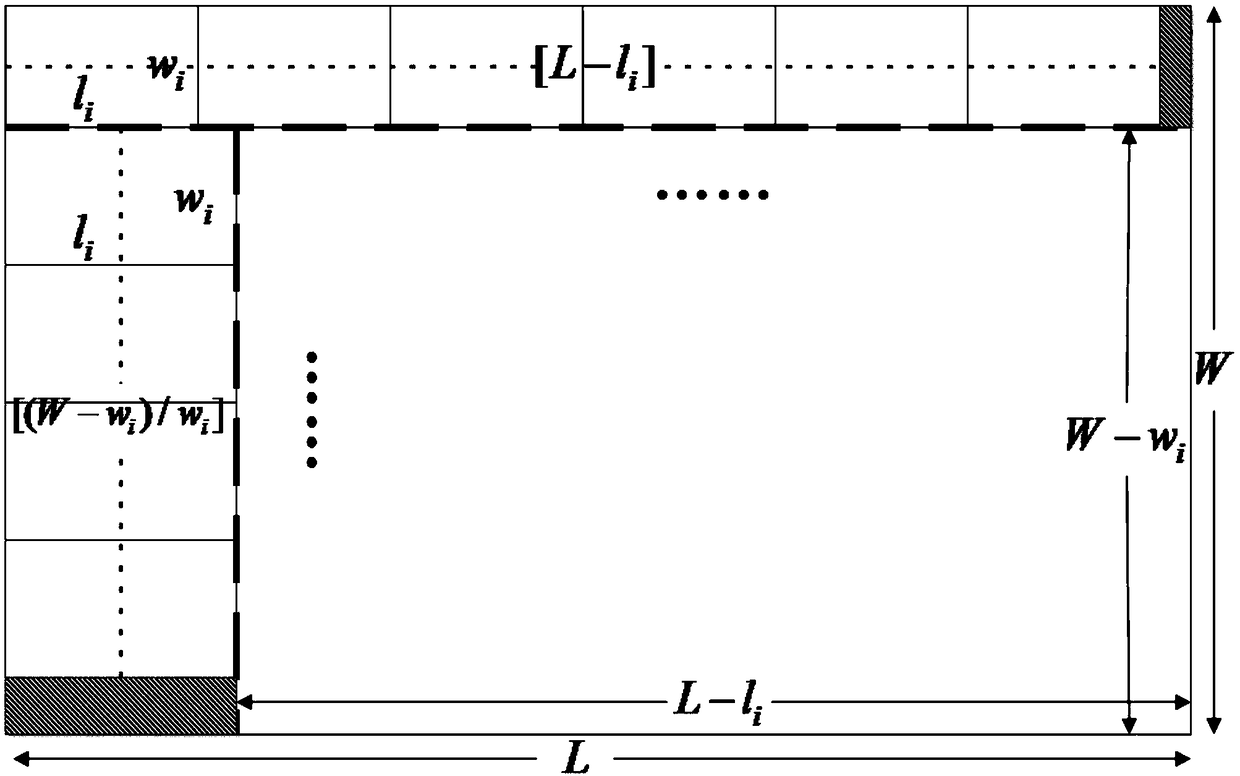

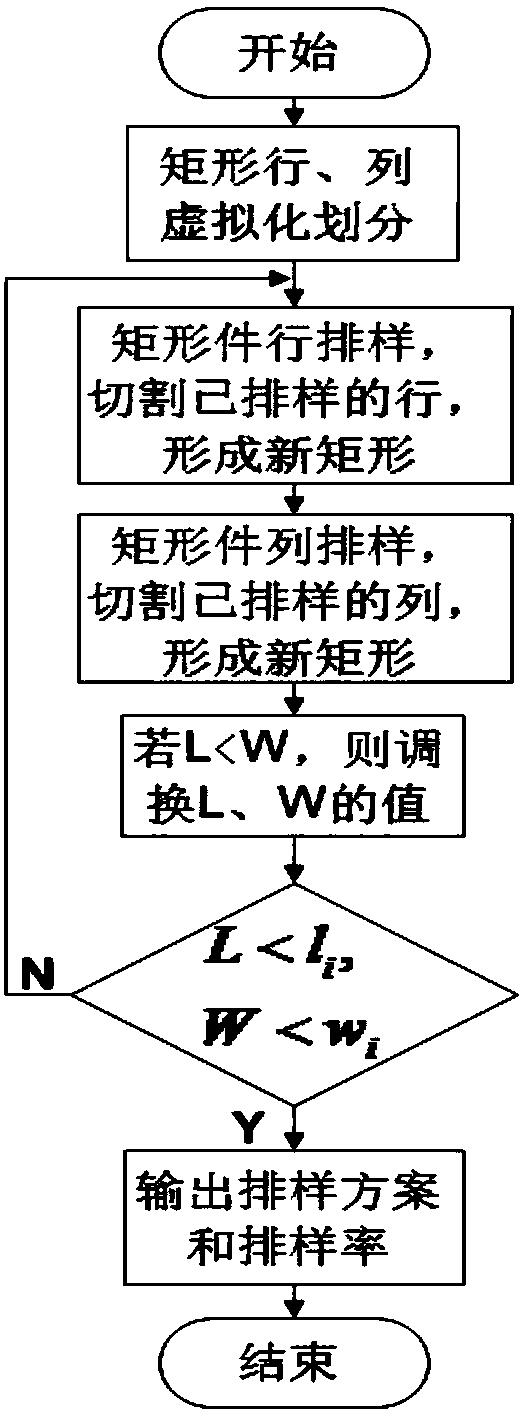

[0024] Such as Figure 1~4 As shown, a cutting filling method for optimized layout of rectangular pieces comprises the following steps:

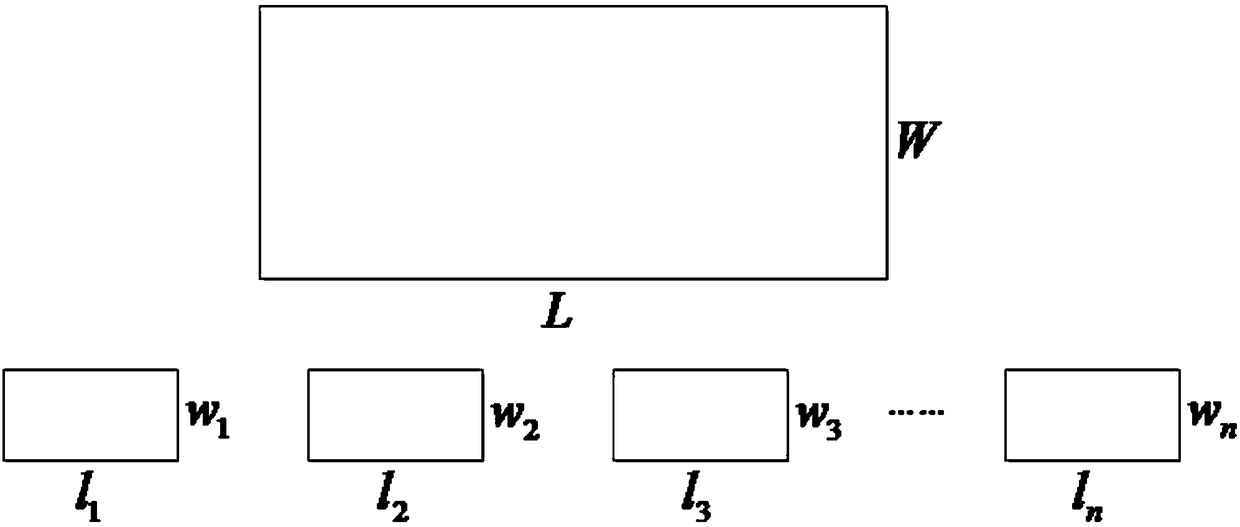

[0025] Step 1, establish a mathematical programming model; for the layout of two-dimensional rectangular parts such as steel, paper, ceramic tiles and clothing, first formalize the two-dimensional rectangular parts into simple rectangular areas and rectangular parts, and then establish a mathematical programming model for them :Such as figure 1 As shown, assuming a rectangular area whose length is L and width is W, a sufficient number of lengths will be l 1 width is w 1 , length is l 2 width is w 2 , ..., length is l n width is w n The n kinds of rectangular pieces fill the rectangular area; then it is stipulated that the rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com