Method for recovering organic matters in polyester wastewater

A technology of polyester wastewater and organic matter, which is applied in the recycling of organic matter in polyester wastewater, the recycling and reuse of polyester wastewater, can solve the problems of increased processing costs, high equipment requirements, and low concentration of acetaldehyde solution, and achieves the goal of overcoming Safety issues, reduction of handling process, effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

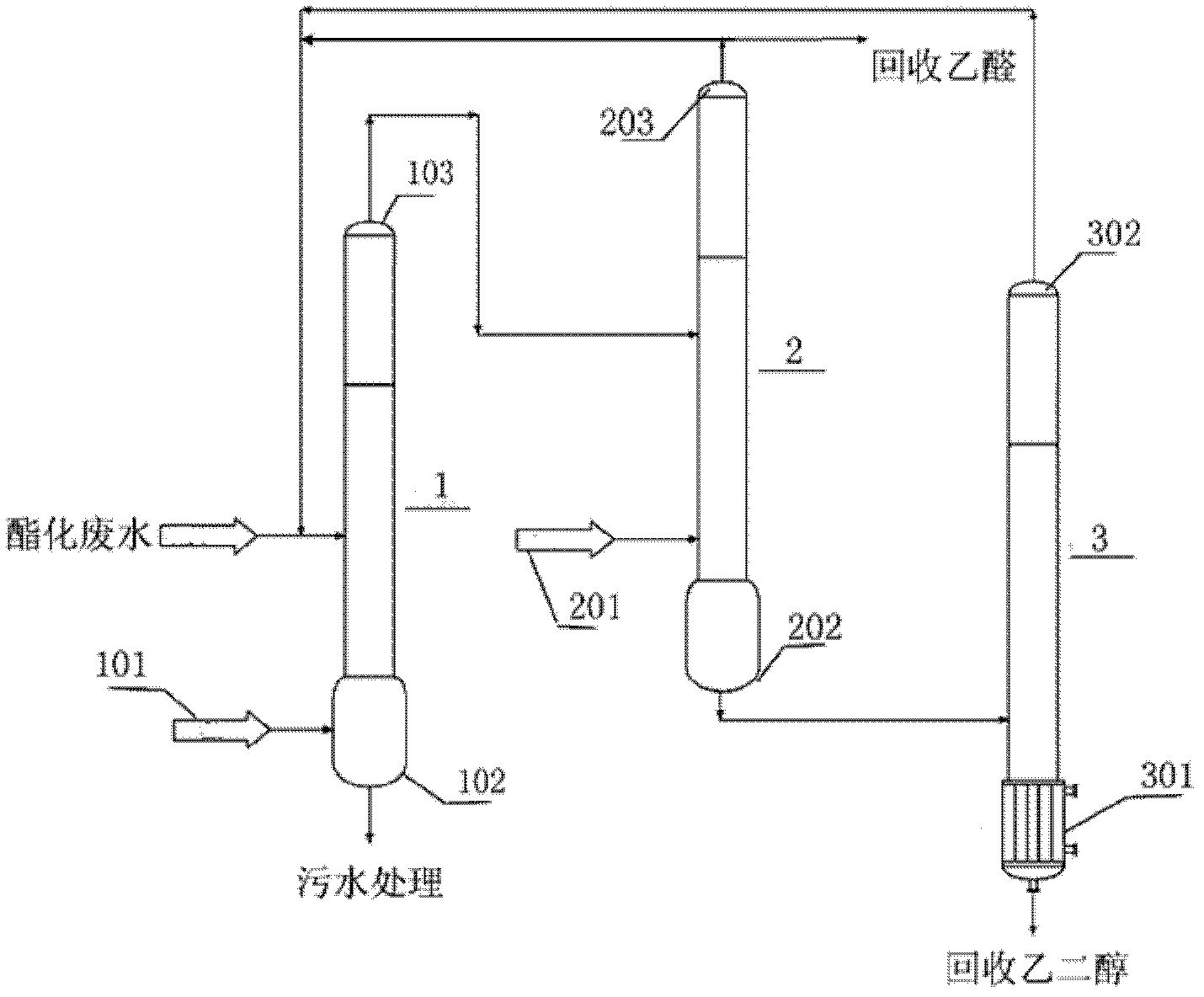

[0036] The specific implementation is carried out by using the treatment process flow without adding a waste water separation tower, and the specific implementation results are as follows:

[0037]Mix the esterification waste water with a flow rate of 42012kg / hr and a stream of acetaldehyde from the acetaldehyde rectification tower 2 at a flow rate of 150kg / hr, and mix them evenly for a residence time of 40min, then charge them into the stripping tower 1, and simultaneously feed them into the tower The kettle steam 101 is passed into heat source water vapor, the flow rate of water vapor is 3000kg / hr, and the temperature is 110°C. After being treated by the stripping tower 1, the ethylene glycol with an EG content of only 0.02% is collected from the waste water collection device 102 at the bottom of the tower kettle. Alcohol, carry out sewage treatment, collect the flow of the mixture of ethylene glycol and acetaldehyde and 2-MD from stripping tower top vapor recovery unit 103 b...

Embodiment 2

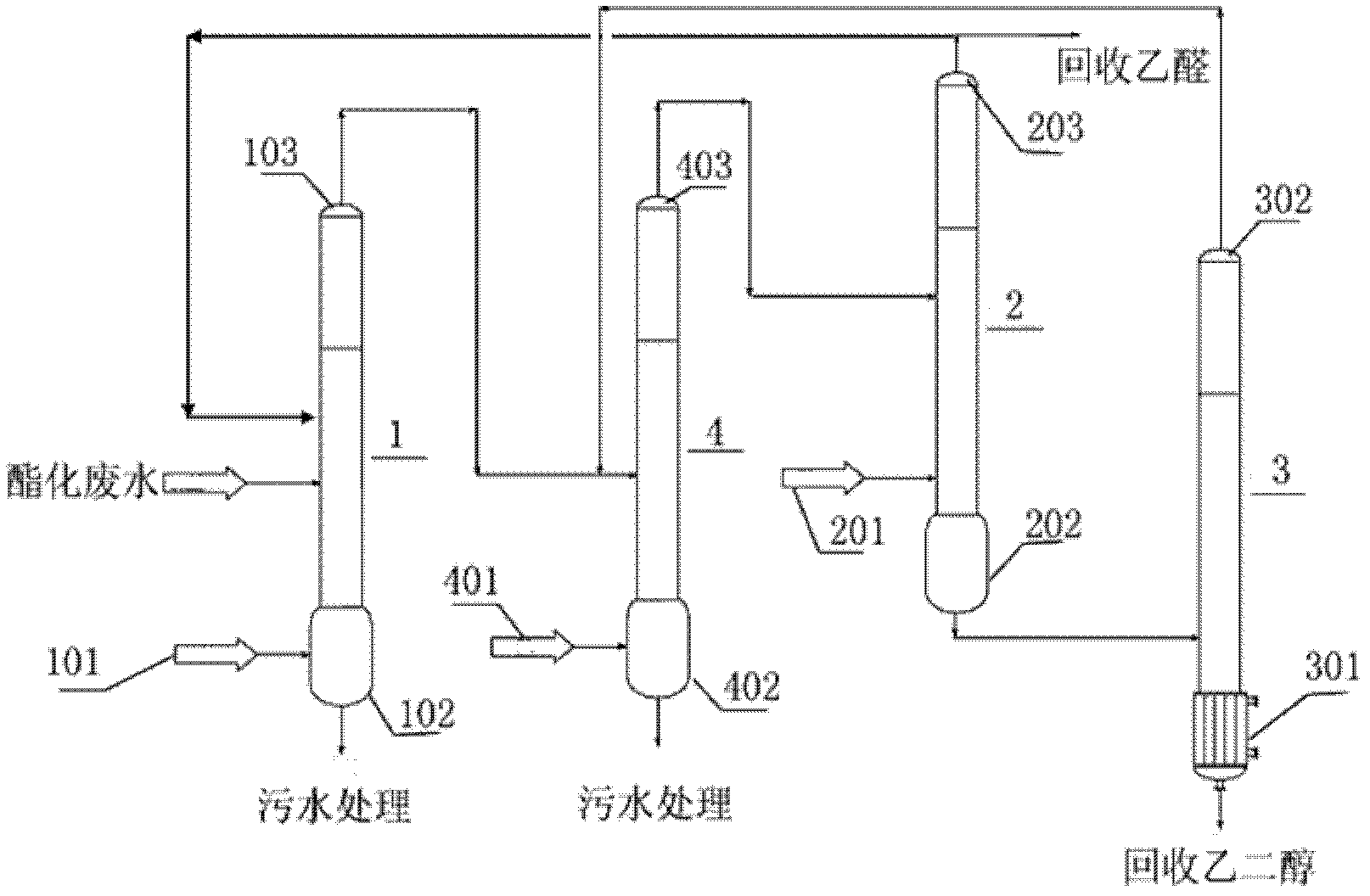

[0043] The specific implementation is carried out by using the treatment process of adding a waste water separation tower, and the specific implementation results are as follows:

[0044] Mix the esterification waste water with a flow rate of 34255kg / hr and a stream of acetaldehyde from the acetaldehyde rectification tower 2 at a flow rate of 100kg / hr, and mix them evenly for a residence time of 35min. The kettle steam 101 is passed into heat source water vapor, the flow rate of water vapor is 2600kg / hr, and the temperature is 120°C. After being treated by the stripping tower 1, ethylene glycol with an EG content of only 0.02% is collected from the waste water collection device 102 at the bottom of the tower kettle. Alcohol, carry out sewage treatment, the flow that collects the mixture of ethylene glycol and acetaldehyde and 2-MD from stripping tower top vapor recovery unit 103 is 700kg / hr, and this part material enters waste water separation tower 4, in waste water separation...

specific Embodiment approach

[0087] Below in conjunction with embodiment, the present invention is described further.

[0088] Example 1

[0089] The specific implementation is carried out by using the treatment process flow without adding a waste water separation tower, and the specific implementation results are as follows:

[0090] Mix the esterification waste water with a flow rate of 42012kg / hr and a stream of acetaldehyde from the acetaldehyde rectification tower 2 at a flow rate of 150kg / hr, and mix them evenly for a residence time of 40min, then charge them into the stripping tower 1, and simultaneously feed them into the tower The kettle steam 101 is passed into heat source water vapor, the flow rate of water vapor is 3000kg / hr, and the temperature is 110°C. After being treated by the stripping tower 1, the ethylene glycol with an EG content of only 0.02% is collected from the waste water collection device 102 at the bottom of the tower kettle. Alcohol, carry out sewage treatment, collect the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com