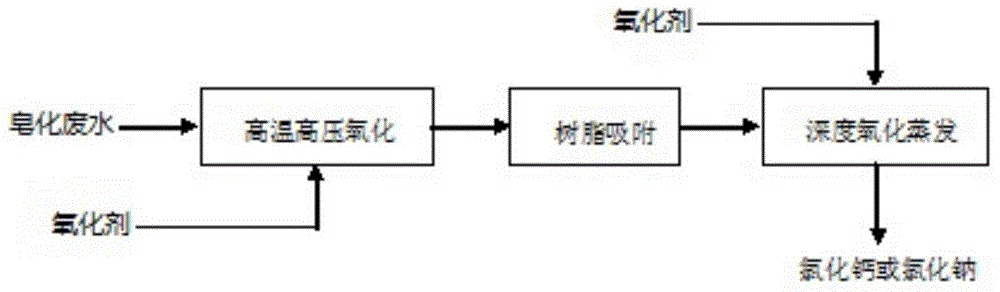

Method for treating glycerin-based epoxy chloropropane saponification wastewater

A technology of epichlorohydrin and saponification wastewater, which is applied in chemical instruments and methods, natural water treatment, multi-stage water treatment, etc., and can solve problems such as unclear residence time of activated carbon adsorption, complex composition, and increased organic oxygen demand. , to achieve the effect of short residence time, lower COD value and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concentration of calcium chloride-containing calcium chloride in the glycerol process epichlorohydrin saponification wastewater is 15% (weight ratio), the COD content is 8890ppm, and it is light yellow wastewater.

[0032] Through step 1: by adding pure oxygen generated by the oxygen generator, add the fully mixed flow bubbling bed reactor at 200°C for gas-liquid reaction, the reaction pressure is 10barG, and the residence time is 1 hour. After the reaction, the COD is reduced to 4680ppm. The reaction wastewater was transformed from light yellow to light yellow, and the pH value remained constant at 9 during the reaction.

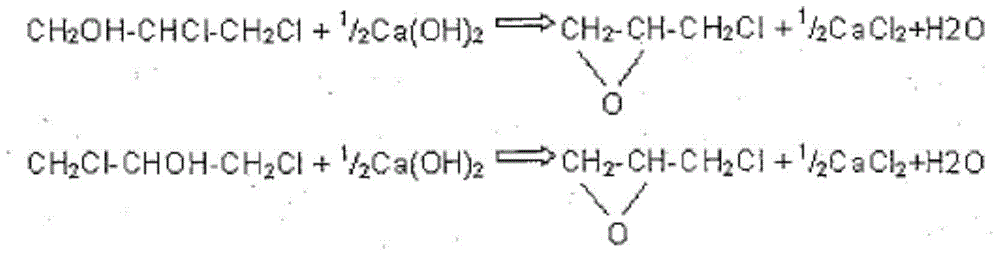

[0033] After the treatment, the color of the treated wastewater changes from light yellow to light yellow. For the first type of substances, they are formed during the chlorination of glycerin, including chlorinated hydrocarbons, chlorohydrins and chlorinated ketones. Some substances are yellow, and high temperature High-pressure oxygen is oxidiz...

Embodiment 2

[0038] The concentration of calcium chloride-containing calcium chloride in the glycerol process epichlorohydrin saponification wastewater is 15% (weight ratio), the COD content is 8890ppm, and it is light yellow wastewater.

[0039] Through step 1: by adding the oxidant hydrogen peroxide, spraying into the reactor, adding a fully mixed flow bubbling bed reactor at 140°C for gas-liquid reaction, the reaction pressure is 5barG, and the residence time is 5 hours. After the reaction, the COD is reduced to 5280ppm. The reaction wastewater was transformed from light yellow to light yellow, and the pH value was constant at 10 during the reaction.

[0040] After the treatment, the color of the treated wastewater is transformed from light yellow to light yellow. For the first type of substance, it is formed during the chlorination of glycerin. The subsequent separation cannot guarantee the purity of dichloropropanol. For the first type of substance, it includes Chlorinated hydrocarbon...

Embodiment 3

[0045] The concentration of calcium chloride-containing calcium chloride in the glycerol process epichlorohydrin saponification wastewater is 15% (weight ratio), the COD content is 8890ppm, and it is light yellow wastewater.

[0046] Through step 1: by adding oxidant air, add fully mixed flow bubbling bed reactor at 300°C for gas-liquid reaction, the reaction pressure is 36barG, and the residence time is 1 hour. After the reaction, the COD is reduced to 4150ppm, and the reaction wastewater changes from light yellow It turns pale yellow and the pH is constant at 9 during the reaction.

[0047] After the treatment, the color of the treated wastewater is transformed from light yellow to light yellow. For the first type of substance, it is formed during the chlorination of glycerin. The subsequent separation cannot guarantee the purity of dichloropropanol. For the first type of substance, it includes Chlorinated hydrocarbons and chlorohydrins, some of which are yellow in color, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com