Hydraulic system applied to multi-spud leg lifting mechanism

A lifting mechanism and hydraulic system technology, applied in the field of hydraulic system, can solve the problem that only one row can be raised or lowered, and achieve the effects of fast lifting speed, stable operation and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

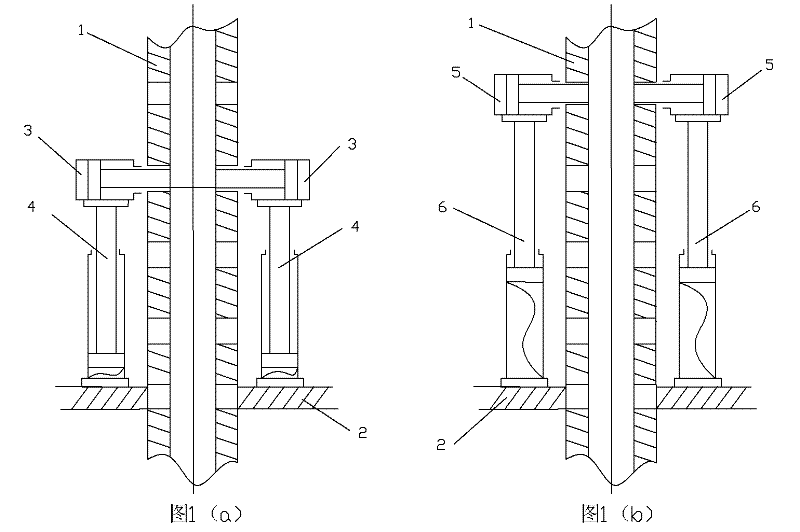

[0027] A specific embodiment of the present invention will be further described in detail below with reference to the accompanying drawings:

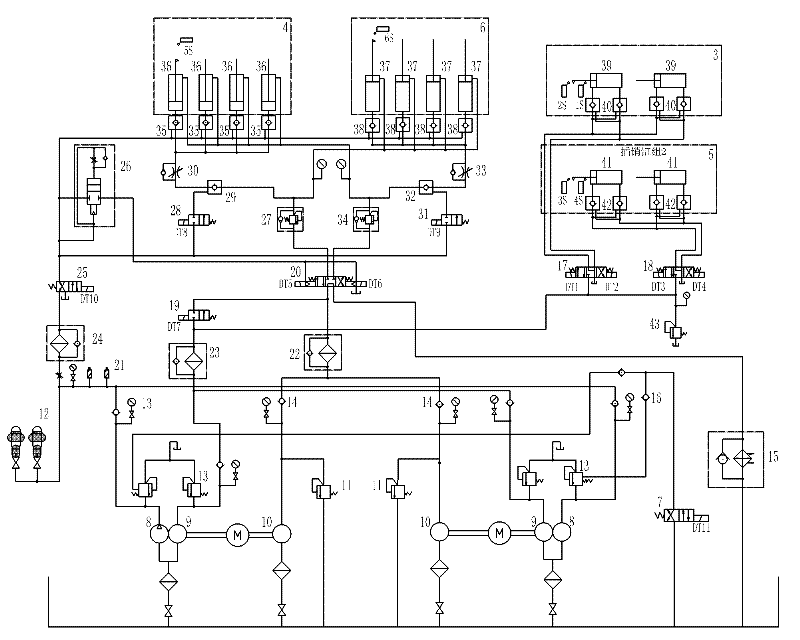

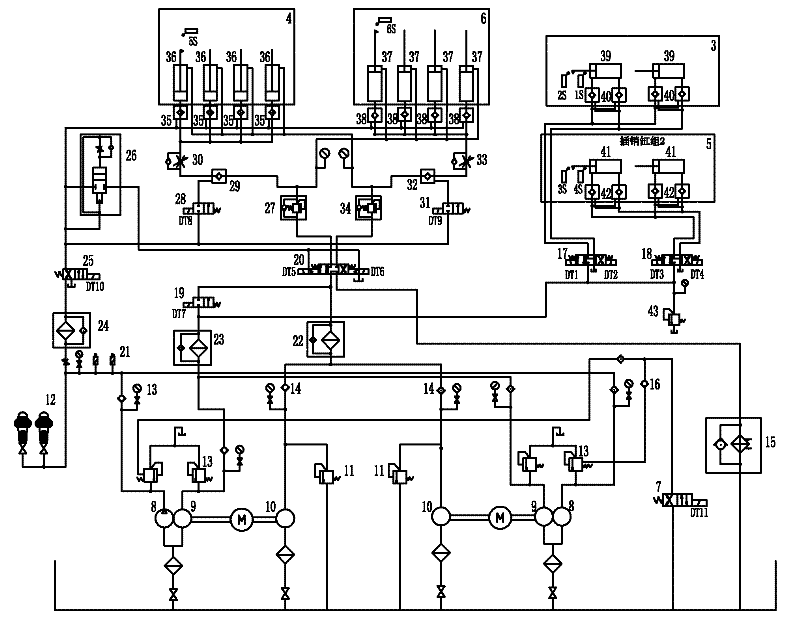

[0028] Such as figure 2 As shown, a hydraulic system of the present invention applied to a multi-leg lifting mechanism includes a main oil circuit, a bolt oil circuit and a control oil circuit, wherein:

[0029] The main oil circuit includes high-pressure pump 10, M-type functional three-position four-way electro-hydraulic directional valve 20, balance valves 27, 34, reverse-connected hydraulic control check valves 29, 32, one-way throttle valves 30, 33, A lifting cylinder group 4 and a second lifting cylinder group 6. The input end of the high pressure pump 10 is in communication with the oil tank, and the output end is in communication with the P port of the M-type functional three-position four-way electro-hydraulic directional valve 20. The T port of the M-type functional three-position four-way electro-hydraulic directional valve 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com