Sound wave detection control method and device

A control method and sonic detection technology, which are used in the analysis of solids, infrastructure tests, buildings, etc. using sonic/ultrasonic/infrasonic waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

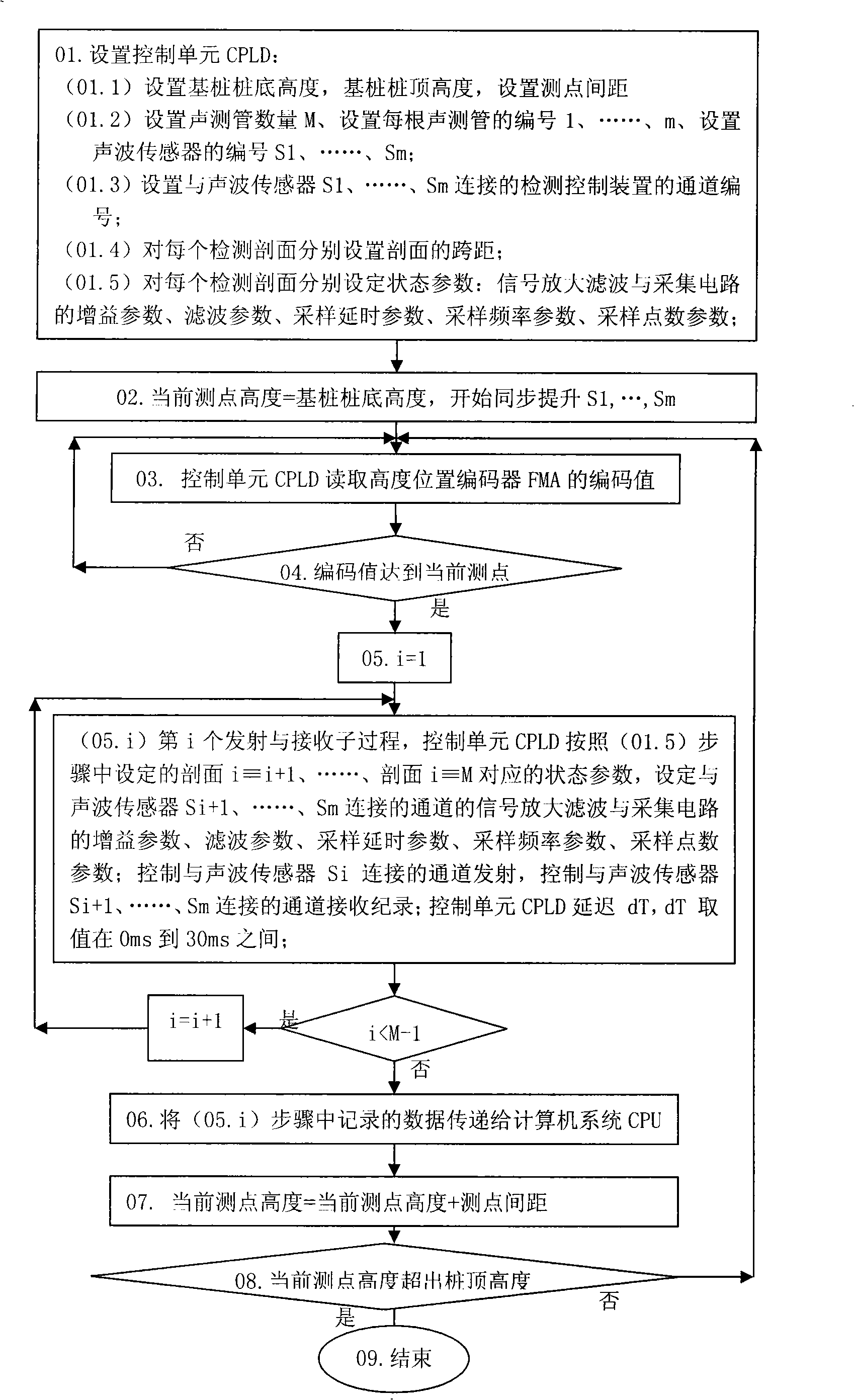

[0100] Embodiment 1: a 4-channel sound wave detection control method, the steps of which are as follows:

[0101] For foundation piles with 4 acoustic tubes buried,

[0102] The jth (1≤j≤4) channel Chj in the 4 channels of the detection control device is composed of the transmitting terminal Aj of the acoustic wave transmitter A, the transceiver half-duplex circuit Tj, and the signal amplification filter and acquisition circuit Ij;

[0103] A dual-purpose acoustic wave sensor is placed in the acoustic tubes numbered 1, 2, 3, and 4, respectively, and the dual-purpose acoustic wave sensor placed in the acoustic tube i (1≤i≤4) is marked as Si;

[0104] The height positions of the four dual-purpose acoustic wave sensors S1, S2, S3, and S4 are the same, and the cables of the acoustic wave sensors S1, S2, S3, and S4 can drive the height position encoder FMA to roll during the lifting process;

[0105] The 4 acoustic wave sensors S1, S2, S3 and S4 for transceivers are respectively c...

Embodiment 2

[0126] Embodiment 2: a kind of device that realizes 4-channel sound wave detection control method, it has following components to form:

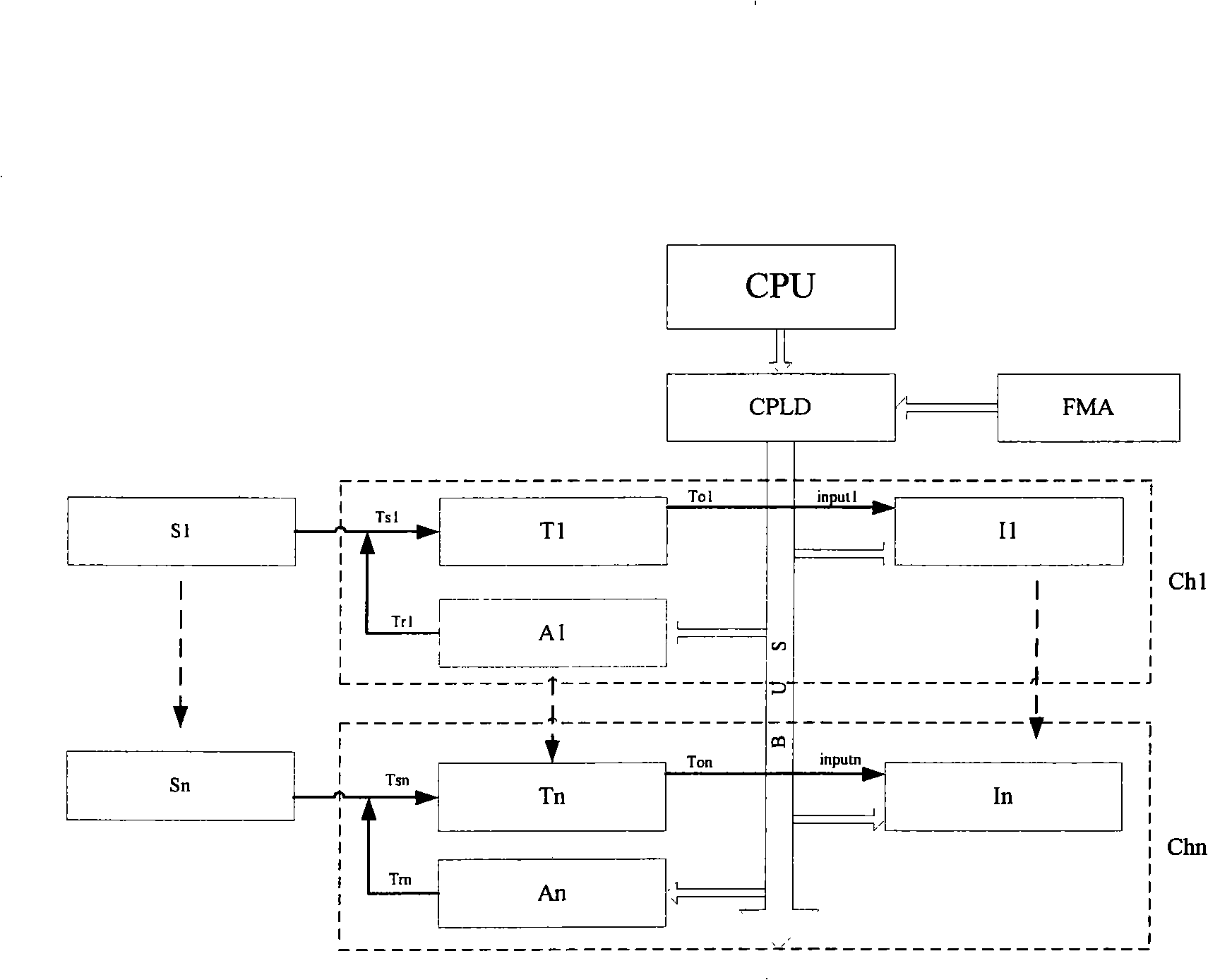

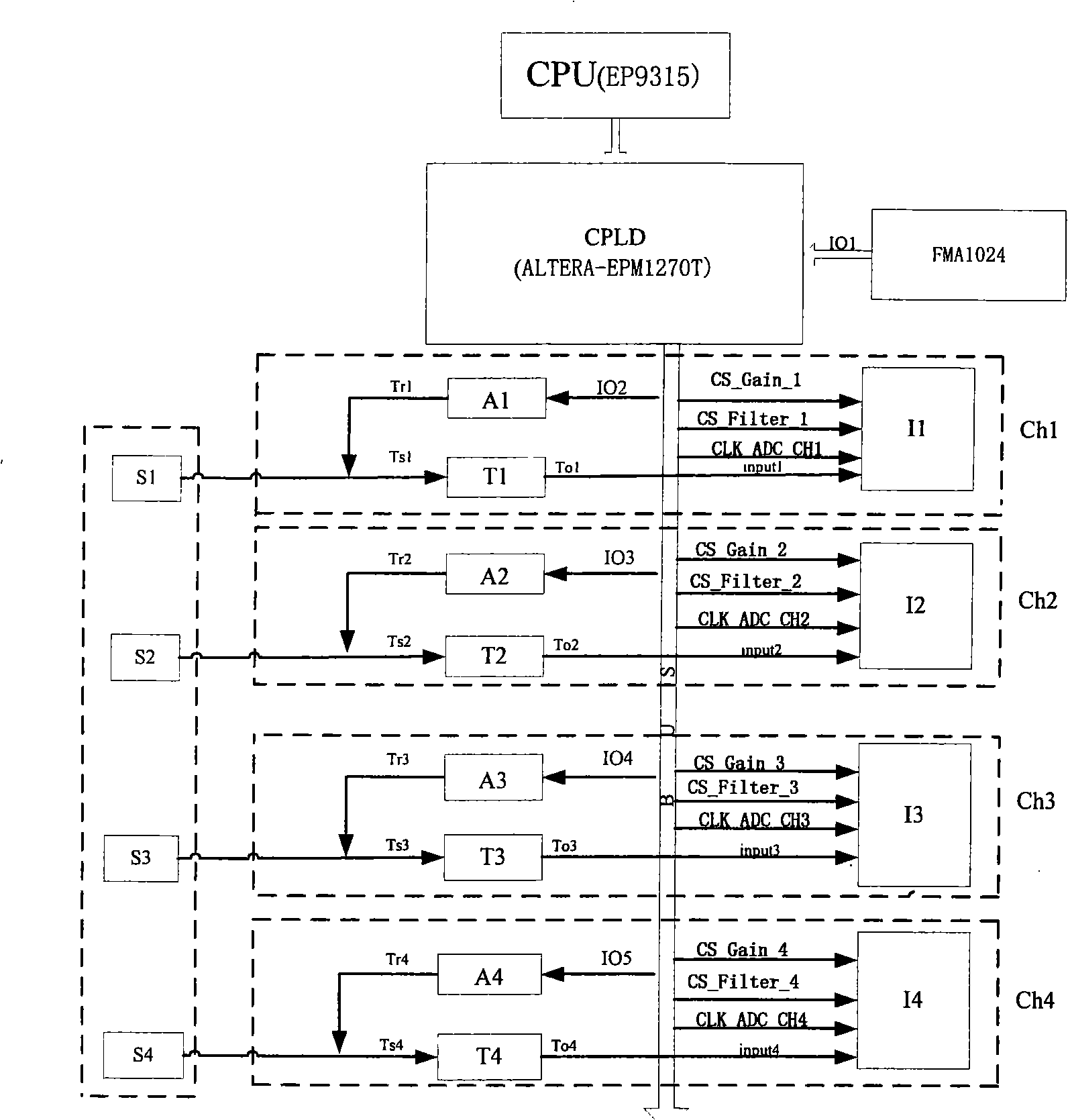

[0127] according to figure 2 , image 3 It can be seen that the sound wave detection control device consists of 4 YGD-45KHz transceiver dual-purpose acoustic wave sensors S1, S2, S3, S4, 4 transceiver dual-purpose channels Ch1, Ch2, Ch3, Ch4 (one wonhere1.4 type has 4 transmitting terminals Acoustic wave transmitter A of A1, A2, A3, A4, 4 transceiver half-duplex circuits T1, T2, T3, T4, 4 signal amplification filtering and acquisition circuits I1, I2, I3, I4), 1 computer system EP9315CPU , a control unit ALTERA-EPM1270T CPLD, a FMA 1024 photoelectric encoder.

[0128] according to figure 2 , image 3 It can be seen that the i-th transceiver channel Chi is composed of the i-th transceiver half-duplex circuit Ti, the i-th signal amplification filter and acquisition circuit Ii, the i-th transmitting terminal Ai of the wonhere1.4 acoustic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com