Engineering pile foundation static load detection resistance anchor hoe

A technology for static load detection and engineering piles, which is applied in basic structure engineering, basic structure testing, construction, etc., can solve problems such as long maintenance time, difficulty in recycling, and overall collapse of ballast bodies, so as to improve work efficiency and safety. The operation process is simple and convenient, and the effect of improving the safety and controllability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

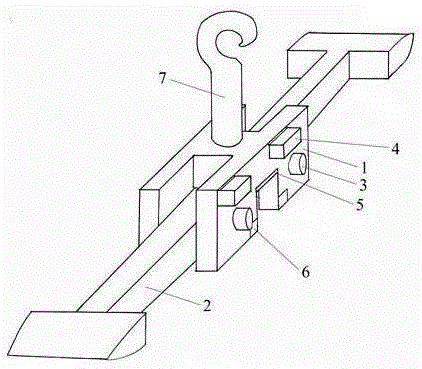

[0039] Such as figure 1 As shown, the engineering pile foundation static load detection resistance anchor hoe of the present invention includes a support base 1, a resistance rod plate 2, a support shaft 3, an off-axis device 4, a support top plate 5, a recovery device 6, and a suspension ring 7. The support base 1 is provided with a support shaft 3, the resistance bar plate 2 is connected with the support base 1 through the support shaft 3, the resistance bar plate 2 can rotate along the support shaft 3 in a circle, and the decoupling device 4 is arranged on the support base 1 and Connected with the support base 1, the suspension ring 7 is set at the middle position of the top of the support base 1, and the bottom of the support base 1 is provided with a recovery device 6;

[0040] Further, the resistance rod plate 2 and the support shaft 3 are arranged at the lower part of the support seat 1;

[0041] Further, the resistance bar plate 2 is horizontally located on both sides...

Embodiment 2

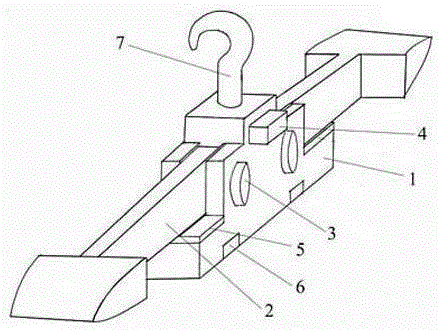

[0050] Such as figure 2 As shown, the engineering pile foundation static load detection resistance anchor hoe of the present invention includes a support base 1, a resistance rod plate 2, a support shaft 3, an off-axis device 4, a support top plate 5, a recovery device 6, and a suspension ring 7. The support base 1 is provided with a support shaft 3, the resistance bar plate 2 is connected with the support base 1 through the support shaft 3, the resistance bar plate 2 can rotate along the support shaft 3 in a circle, and the decoupling device 4 is arranged on the support base 1 and Connected with the support base 1, the suspension ring 7 is set at the middle position of the top of the support base 1, and the bottom of the support base 1 is provided with a recovery device 6;

[0051] Further, the resistance rod plate 2 and the support shaft 3 are arranged on the upper part of the support seat 1;

[0052] Further, the resistance bar plate 2 is horizontally located on both side...

Embodiment 3

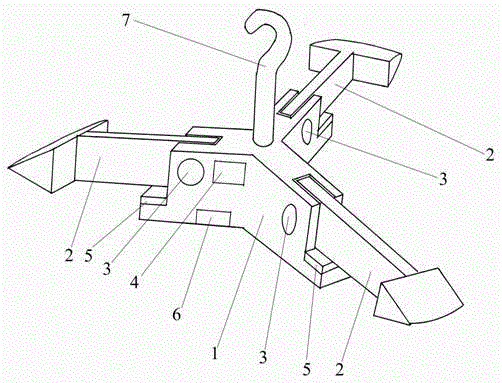

[0058] Such as image 3 As shown, the engineering pile foundation static load detection resistance anchor hoe of the present invention includes a support base 1, a resistance rod plate 2, a support shaft 3, an off-axis device 4, a support top plate 5, a recovery device 6, and a suspension ring 7. The support base 1 is provided with a support shaft 3, the resistance bar plate 2 is connected with the support base 1 through the support shaft 3, the resistance bar plate 2 can rotate along the support shaft 3 in a circle, and the decoupling device 4 is arranged on the support base 1 and Connected with the support base 1, the suspension ring 7 is set at the middle position of the top of the support base 1, and the bottom of the support base 1 is provided with a recovery device 6;

[0059] Further, the resistance rod plate 2 and the support shaft 3 are arranged on the upper part of the support seat 1;

[0060] Further, the resistance bar plate 2 is horizontally located on the three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com