A kind of binding system and binding method of concrete hollow block wall piece of aggregate building

A technology of hollow blocks and concrete, which is applied in construction, building structure, and processing of building materials, etc. It can solve the problems of inconvenient construction and inability to realize the hoisting of hollow block wall pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

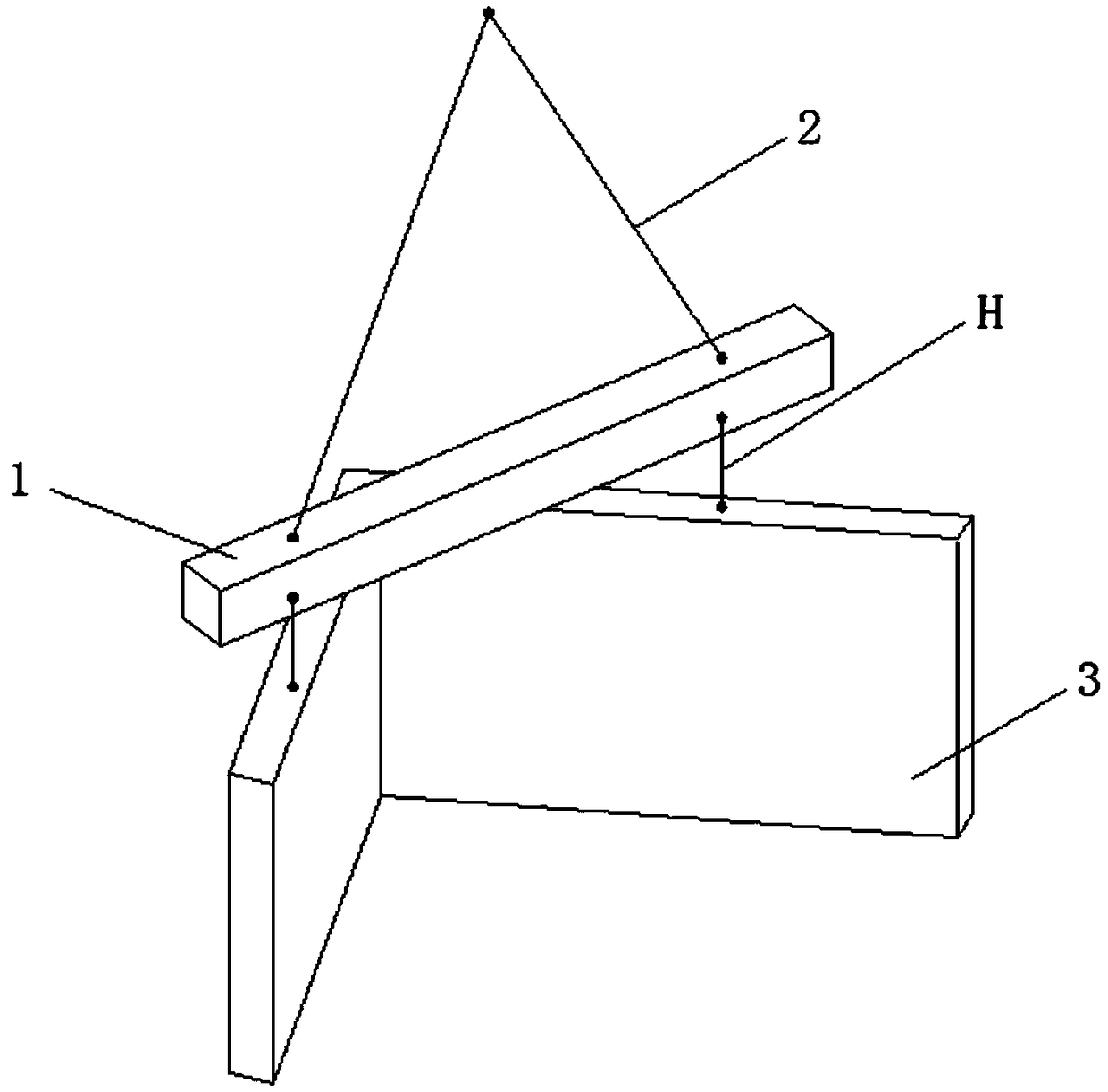

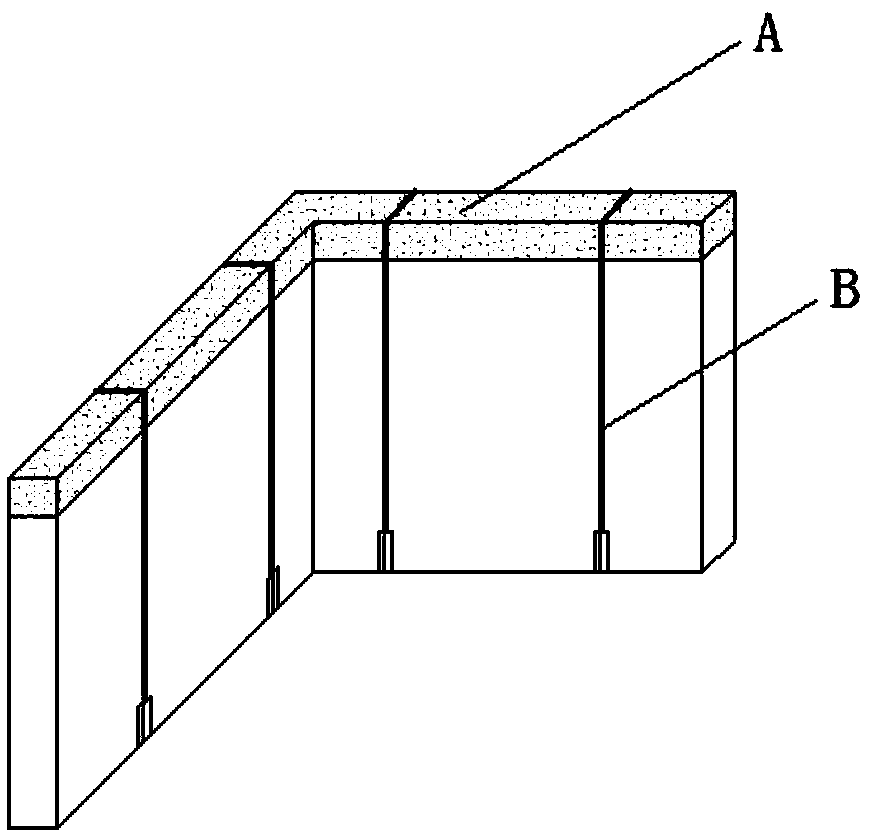

[0029] Specific implementation mode one: combine Figure 1 to Figure 13 Describe this embodiment, a kind of concrete hollow block wall piece binding system of agglomerate building in this embodiment includes binding beam A, multiple binding pieces B, slider C, balance beam 1 and hoisting rope 2, binding beam A passes through multiple A binding part B is bound on the wall piece 3, the balance beam 1 is located above the binding beam A and the balance beam 1 and the binding beam A are connected by a lifting rope H, and one end of the lifting rope 2 is connected to one side of the binding beam A, The other end of the lifting rope 2 is connected to the other side of the binding beam A, and the connection between the lifting rope H2 and the binding beam A is slidably connected through a slider C.

[0030] The binding system of this embodiment adopts a balance beam on the top, and the entire wall piece is bound on the balance beam with a hoisting rope, and the wall piece can be hois...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination Figure 3 to Figure 7 To illustrate this embodiment, the binding beam A of this embodiment includes an in-line binding beam, an L-shaped binding beam, a Z-shaped binding beam or a T-shaped binding beam formed by connecting a plurality of standard sections. With such a setting, it is convenient to select a binding beam of a suitable shape according to different conditions in the actual construction process, and can be connected with various prefabricated parts of different shapes, so as to realize smooth and safe hoisting in various situations. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

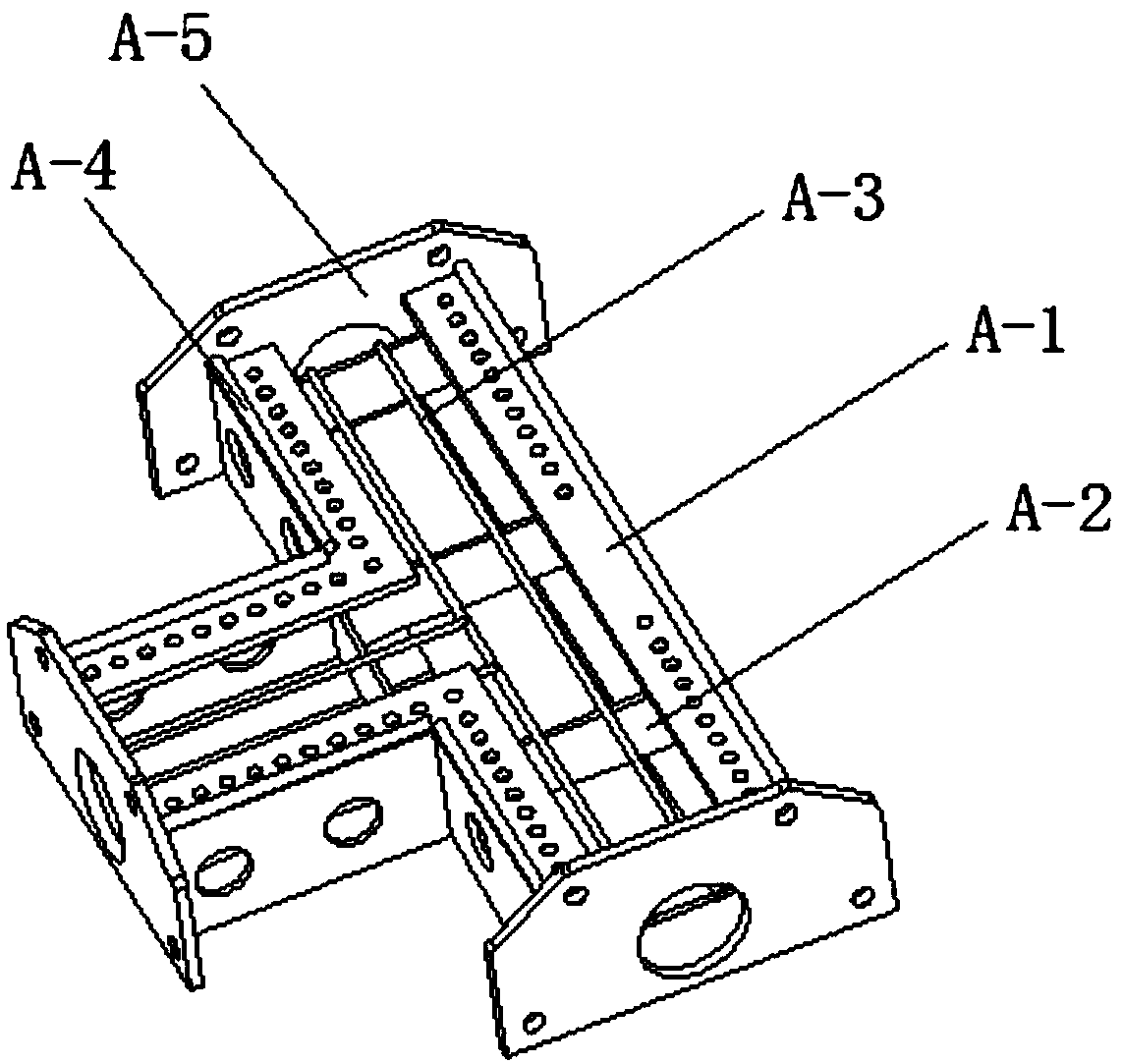

[0032] Specific implementation mode three: combination Figure 3 to Figure 7 To illustrate this embodiment, the standard section of this embodiment includes two channel steel A-1, two steel bars A-3, two round steel pipes A-4, multiple reinforcing ribs A-2 and at least one connecting plate A-5 , the open ends of the two channel steels A-1 are set opposite to each other, and the two channel steels A-1 are connected by a plurality of reinforcing ribs A-2 vertically installed in the grooves of the two channel steels A-1. Reinforcement A-3 is parallel to the length direction of two channel steels A-1 and is fixedly installed on multiple reinforcing ribs A-2 inside the two channel steels A-1, and two round steel pipes A-4 are fixedly installed in two channels The upper end of the steel A-1 is close to the corner, and the two ends of the two channel steel A-1 are at least connected with one connecting plate A-5. Such setting provides a basic standard joint, which is convenient for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com