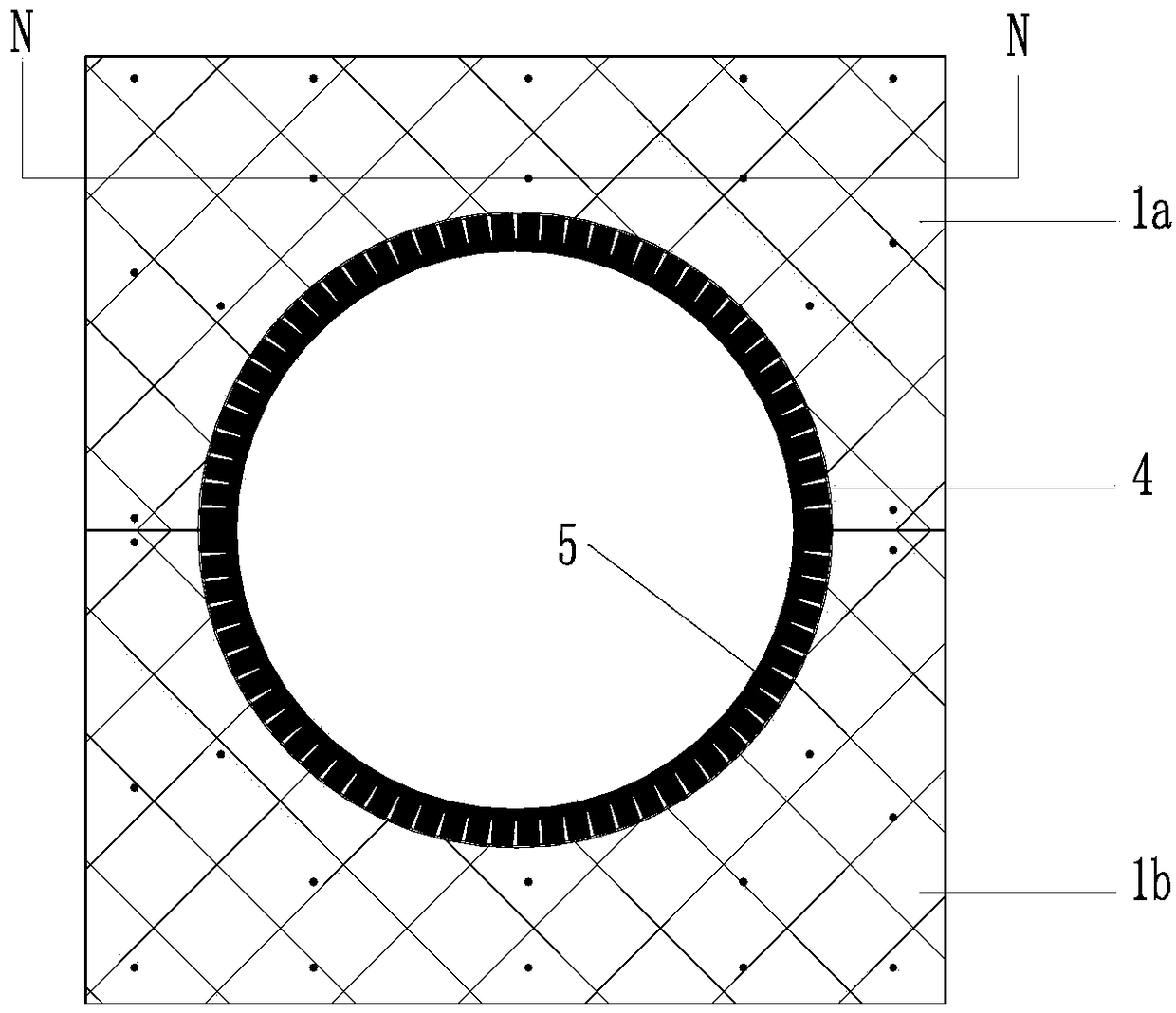

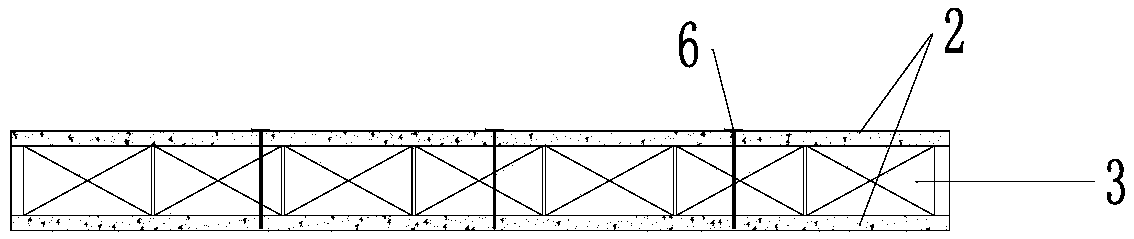

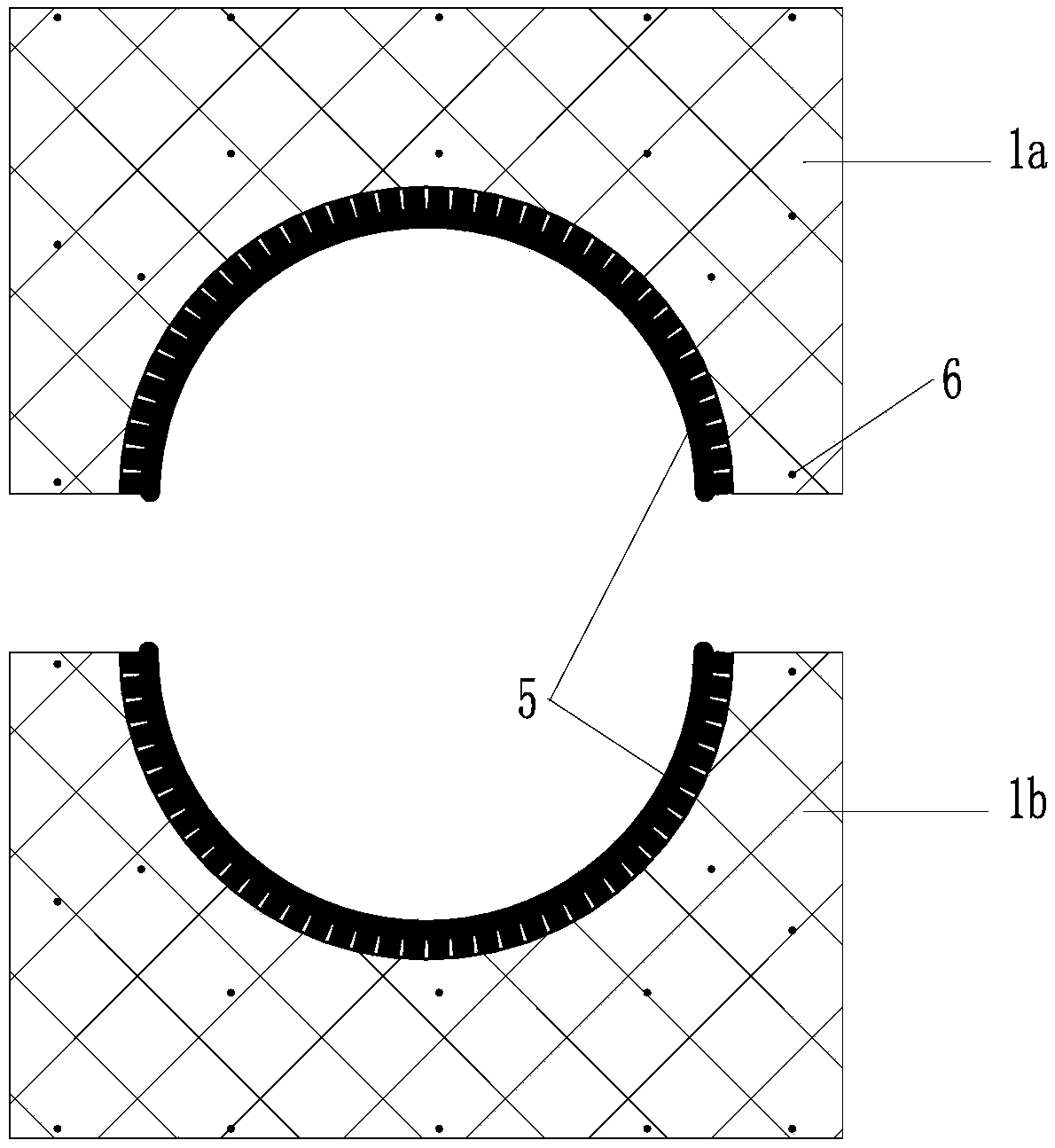

Mold for manufacturing reinforced concrete circular column and construction method thereof

A reinforced concrete and concrete technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of long mechanical occupation period, low turnover rate, poor demoulding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the prior art, the volume and load of the reinforced concrete cylinder are very large, and the concrete pouring and hardening process will generate a large impact force and lateral pressure on the support mold. When constructing the reinforced concrete cylinder, the support mold mostly adopts steel formwork or stereotypes. Multi-layer boards, including steel cylindrical molds, are heavy and inconvenient to transport, requiring a long-term use of the crane; the turnover rate of multi-layer boards is low, and the cost is high; the strength and rigidity are low, and the process of setting up the molds is numerous and complicated. In order to facilitate the construction, the present invention provides a mold for making reinforced concrete cylinders, which can greatly reduce the weight of the mold and increase the turnover rate under the premise of ensuring sufficient strength, rigidity and stability when resisting concrete impact force and lateral pressure. to offer comfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com