Installing method for bridge crane in enclosed environment workshop

A technology for bridge cranes and installation methods, which is applied to cranes, trolley cranes, transportation and packaging, etc., can solve the problems of progress, precision, safety and quality of large bridge cranes, and achieve convenient and quick ground assembly and reduce total costs , The effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

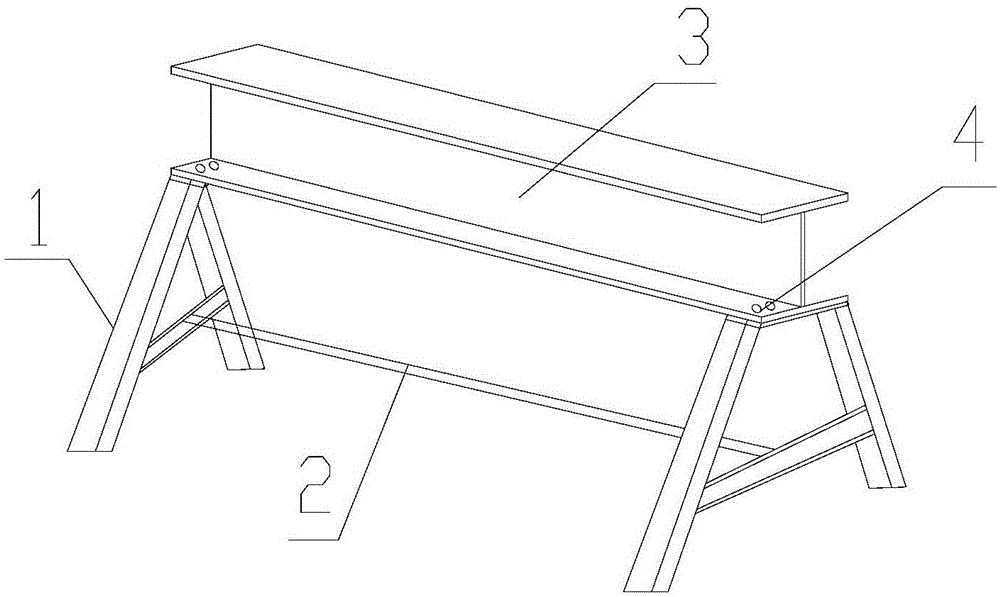

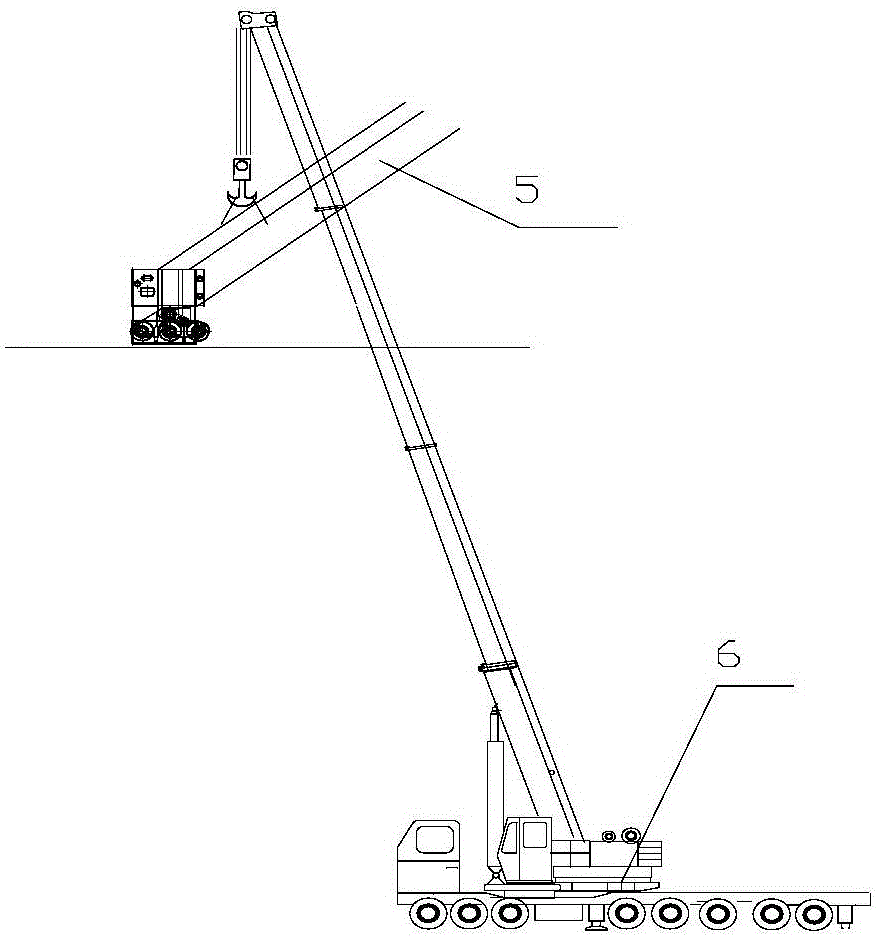

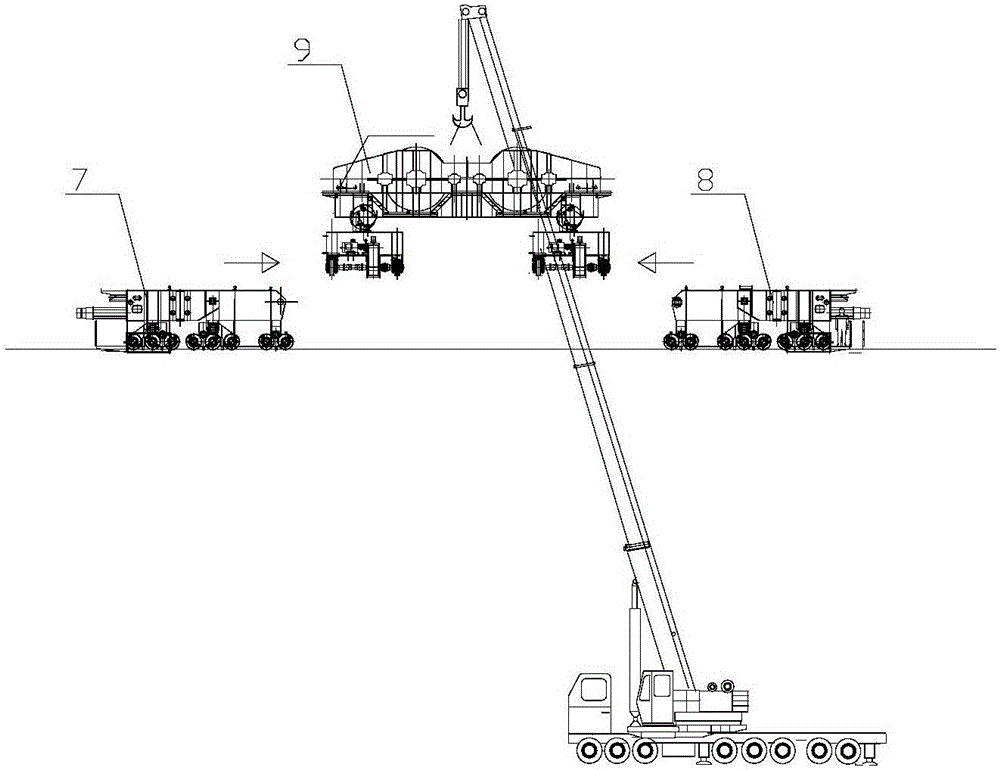

[0026] The installation method of the bridge crane in the factory building under the closed environment provided by the present invention is to utilize a single machine (one truck crane) to hoist all the main and auxiliary beams, and the main trolley utilizes two truck cranes to lift and lift the installation method, and the beam crane method is used to install the bridge crane Methods. Specifically, follow the steps below:

[0027] Step 1: Construction preparation:

[0028] ① Carry out a second retest of the driving beam track of the original factory building. After long-term operation and foundation settlement, the driving beam track of the technically transformed factory building must be retested before installation to meet the driving installation requirements. Re-test requirements are gauge deviation ±2mm, height difference 1mm;

[0029] ② Clean up the hoisting ground site to ensure the storage of equipment after entering the site and the station and hoisting of large-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com