Full-automatic production line of lead-acid battery

A lead-acid battery, fully automatic technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery assembly machine, etc., can solve the problems of saving processing space, occupying, large processing space, etc., to reduce occupied space and reasonable layout , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

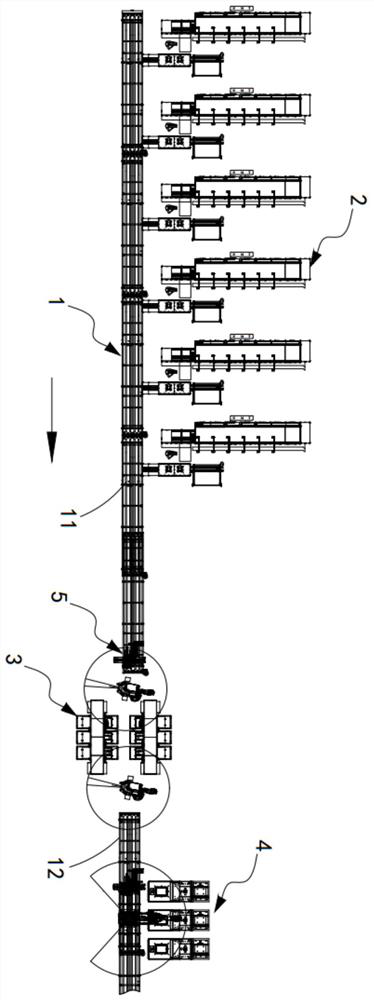

[0055] Such as Figure 1 to Figure 2 As shown, a fully automatic production line for lead-acid batteries includes a conveying line 1, which includes a first conveying line 11 and a second conveying line 12 connected end to end, and also includes:

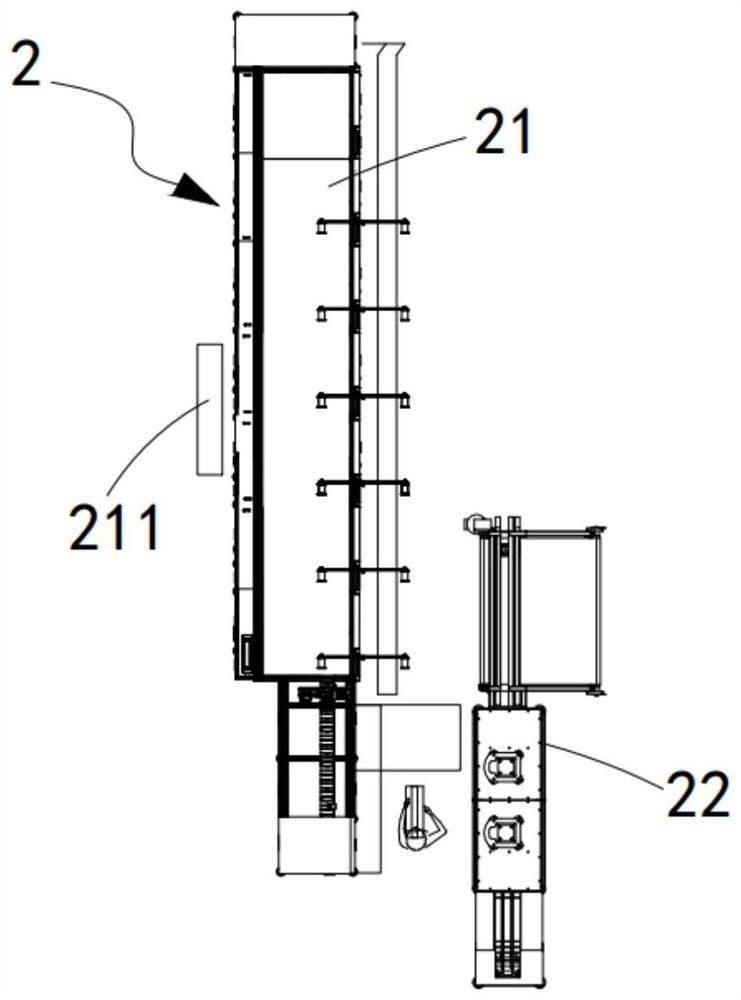

[0056] Clad plate assembly unit 2, at least one set of clad plate assembled unit 2 is arranged on one side of the first conveying line 11 along the conveying path of the first conveying line 11, which is used to assemble the pole plates into pole groups Then insert it into the plastic case of the battery;

[0057] The brush cutting unit 3, the brush cutting unit 3 is arranged at the connecting position of the first conveying line 11 and the second conveying line 12, and is used for cutting and brushing the pole group inserted into the battery plastic case ;

[0058] Casting and welding unit 4, at least one set of said casting and welding unit 4 is arranged on one side of the second conveying line 12 along the conveying path of sai...

Embodiment approach

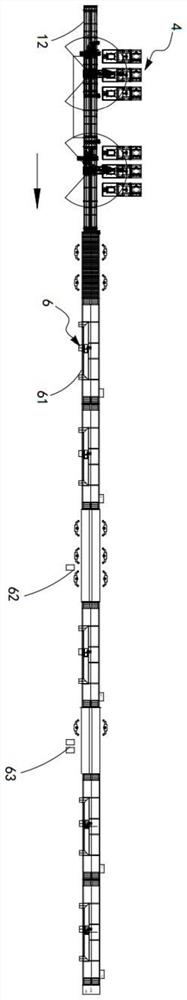

[0091] As a preferred embodiment, the sealing unit 6 includes:

[0092] A resin seal curing machine 61, the resin seal curing machine 61 is arranged along the conveying direction of the second conveying line 12;

[0093] An automatic bottom glue dispensing machine 62, the automatic bottom glue dispensing machine 62 is arranged on the rear side of the resin seal curing machine 61 along the conveying direction of the second conveying line 12; and

[0094] Red and blue automatic glue dispensing machine 63 , the red and blue automatic glue dispensing machine 63 is arranged on the rear side of the bottom glue automatic glue dispensing machine 62 along the conveying direction of the second conveying line 12 .

[0095] It should be noted that the resin sealing and curing machine 61 is used for curing the sealed TV battery. The bottom glue automatic glue dispenser 62 is used for automatic batching of bottom glue, and the red and blue automatic glue dispenser 63 is used for batching r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com