Rinsing device for electroplating machining of metal plates

A metal plate and rinsing technology, applied in the direction of drying gas arrangement, lighting and heating equipment, cleaning methods and utensils, etc., can solve the problems of separation of cleaning and drying processes, low work efficiency, and high toxicity of cleaning reagents, etc., to achieve effective Sequence connection, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

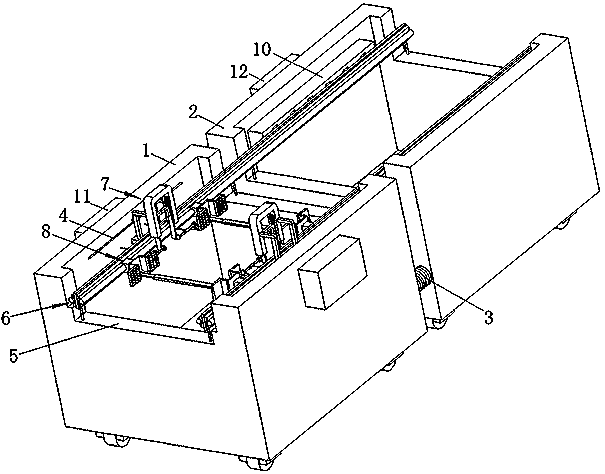

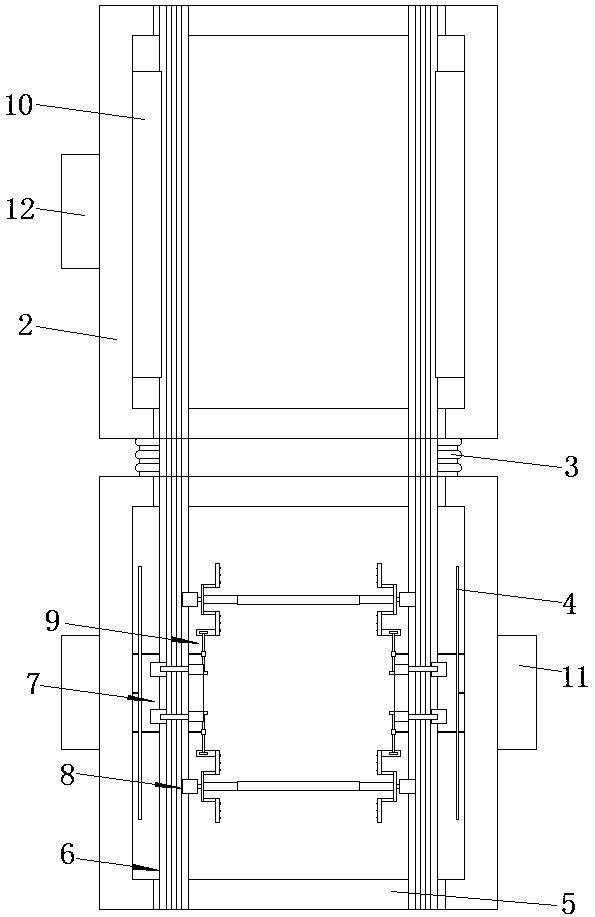

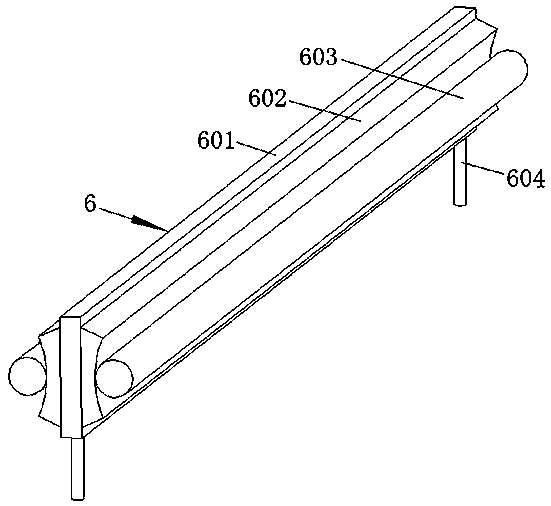

[0038] refer to figure 1 , figure 2 , a rinsing device for electroplating processing of metal plates, comprising a rinsing box 1 and a drying box 2, the rinsing box 1 and the drying box 2 are fixedly connected by a connecting hose 3, and the inner wall of the rinsing box 1 is connected There is a cleaning pipe 4, the side walls of the rinsing box 1 and the drying box 2 are provided with installation grooves 5, the inner wall of the installation groove 5 is connected with a sliding guide rail 6, and one side of the sliding guide rail 6 is connected with a push rod 7, the other side of the sliding guide rail 6 is connected with a clamping assembly 8, and the pushing rod 7 is connected with the clamping assembly 8 through a steering mechanism 9; the inner wall of the drying box 2 is connected with a symmetrical The drying air duct 10; through the rinsing box 1 and the drying box 2, the plated parts to be rinsed are placed in the clamping assembly 8, and the plated parts are cla...

Embodiment 2

[0040] refer to figure 1 , a rinsing device for electroplating processing of metal plates, which is basically the same as embodiment 1, and furthermore, the bottom walls of the rinsing box 1 and the drying box 2 are connected with universal wheels; the existence of the universal wheels is convenient for rinsing. Box 1 and drying box 2 are moved.

Embodiment 3

[0042] refer to figure 1 , figure 2 , image 3 A rinsing device for electroplating processing of metal plates, comprising a rinsing box 1 and a drying box 2, the rinsing box 1 and the drying box 2 are fixedly connected by a connecting hose 3, and the inner wall of the rinsing box 1 is connected with a cleaning pipe 4 , the side walls of the rinsing box 1 and the drying box 2 are provided with installation grooves 5, the inner wall of the installation groove 5 is connected with a sliding guide rail 6, one side of the sliding guide rail 6 is connected with a push and hold rod 7, and the other side of the sliding guide rail 6 A clamping assembly 8 is connected, and the push rod 7 and the clamping assembly 8 are connected through a steering mechanism 9; the inner wall of the drying box 2 is connected with a symmetrical drying air duct 10; Box 2, place the plated parts to be rinsed in the clamping assembly 8, and clamp the plated parts in the clamping assembly 8 with the push an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com