Patents

Literature

30results about How to "Yield strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

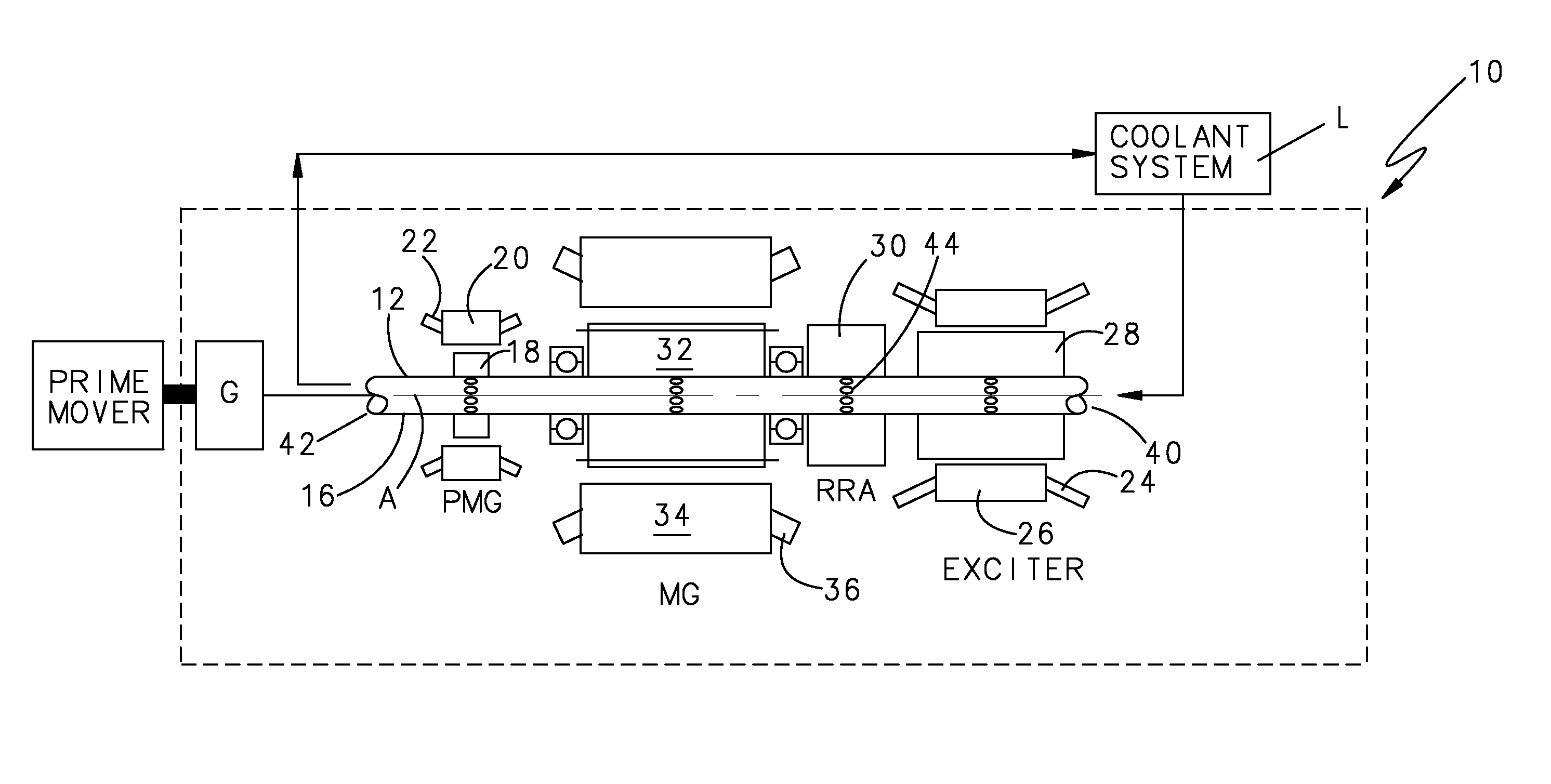

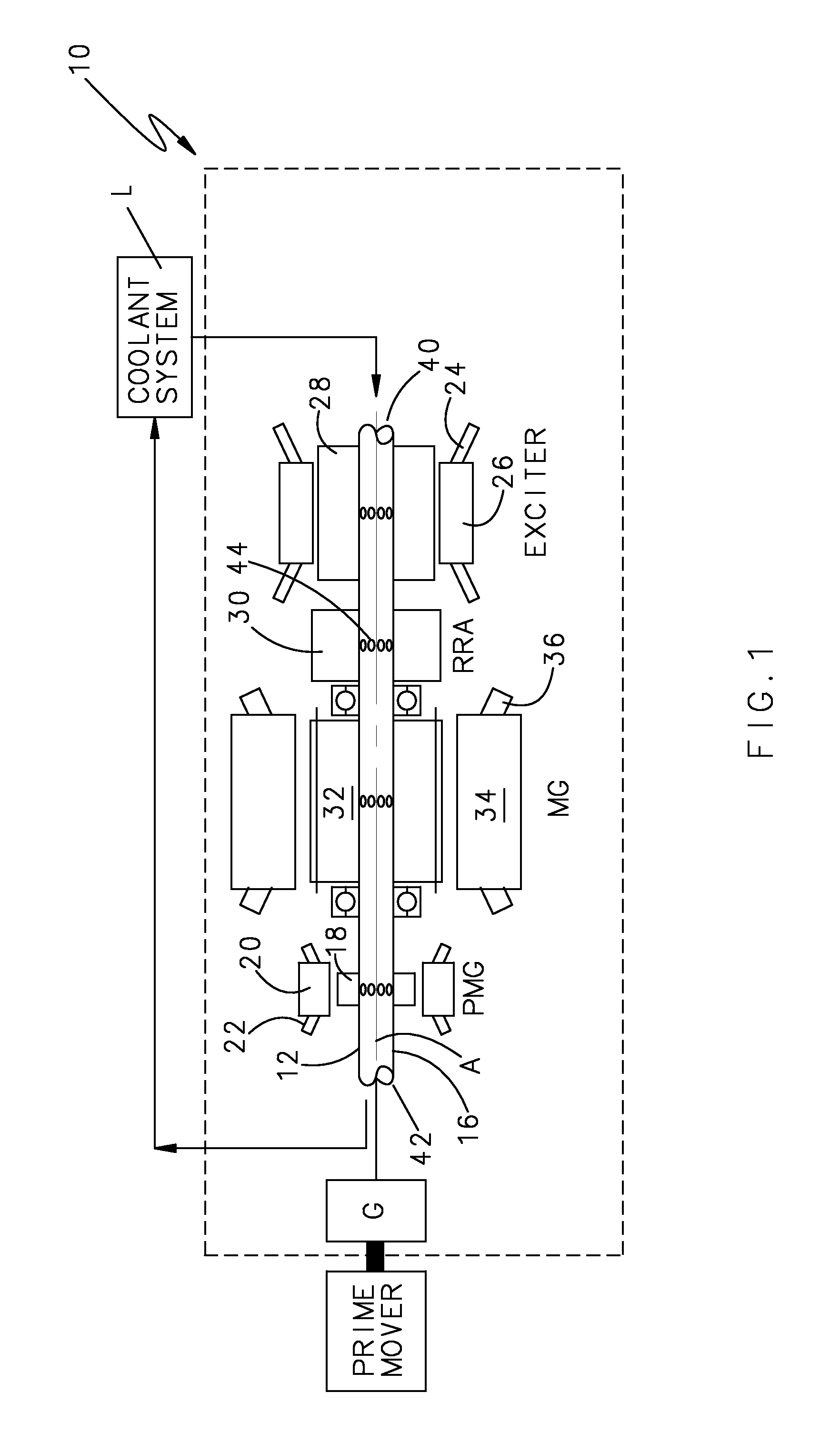

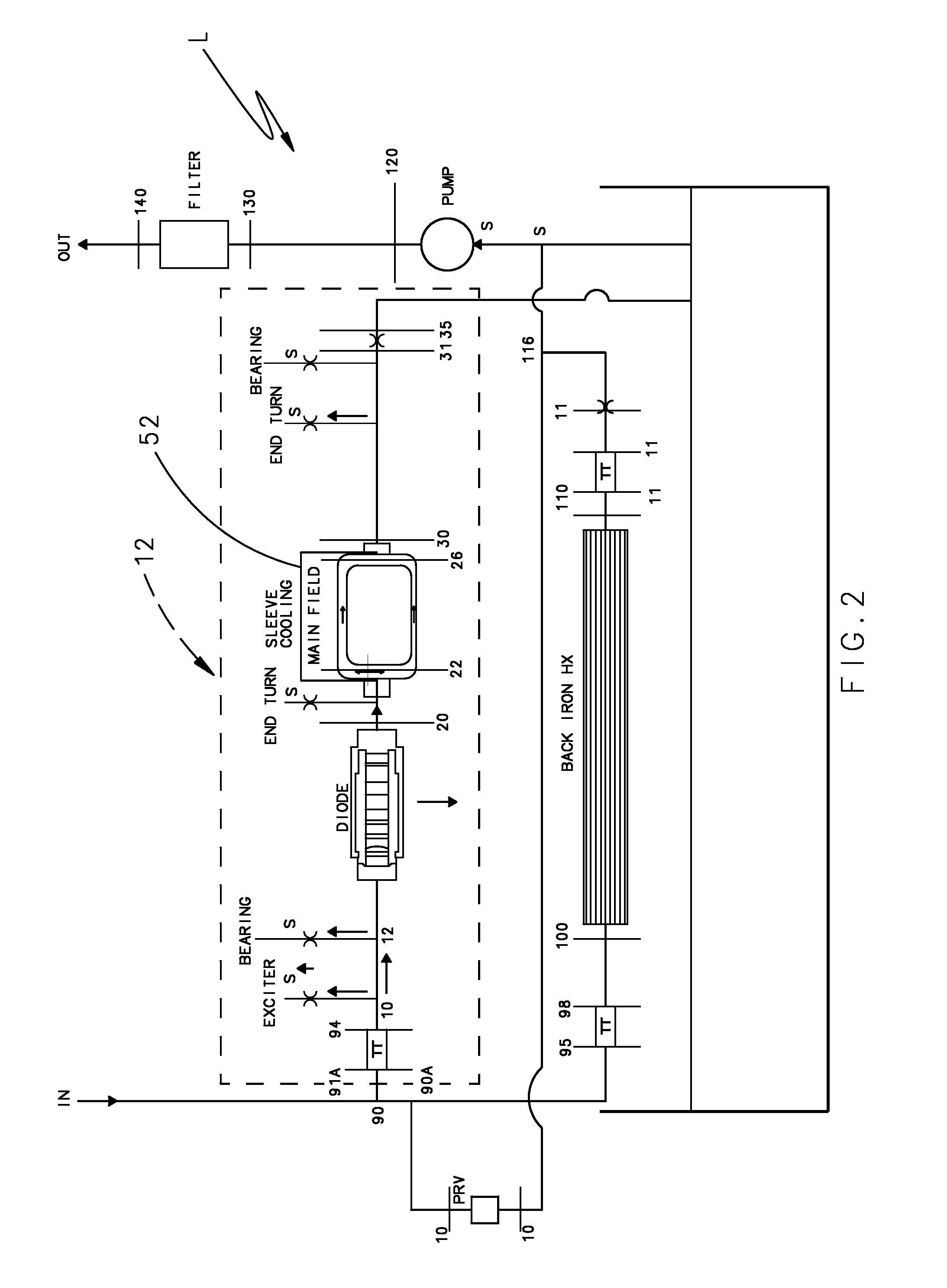

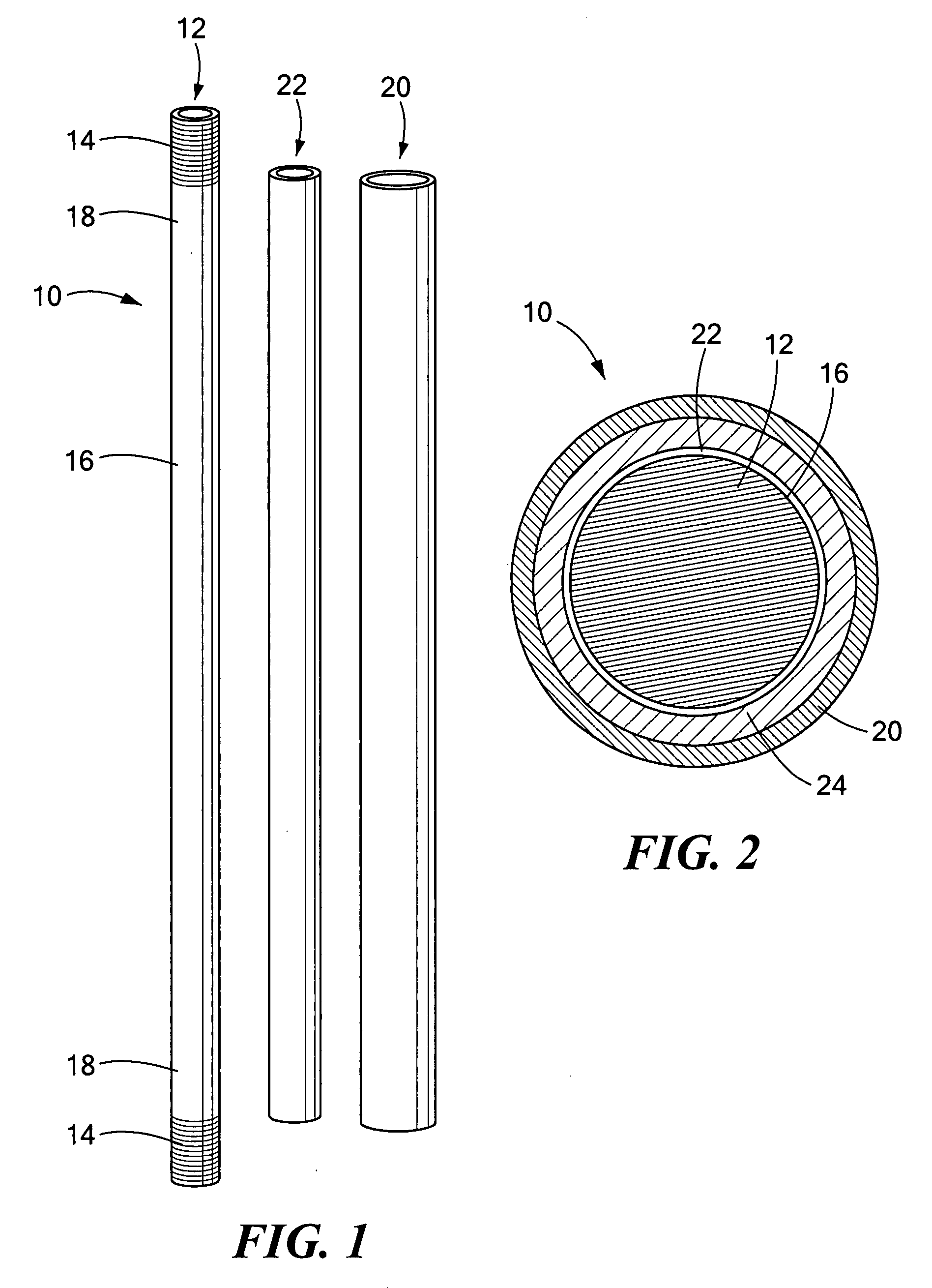

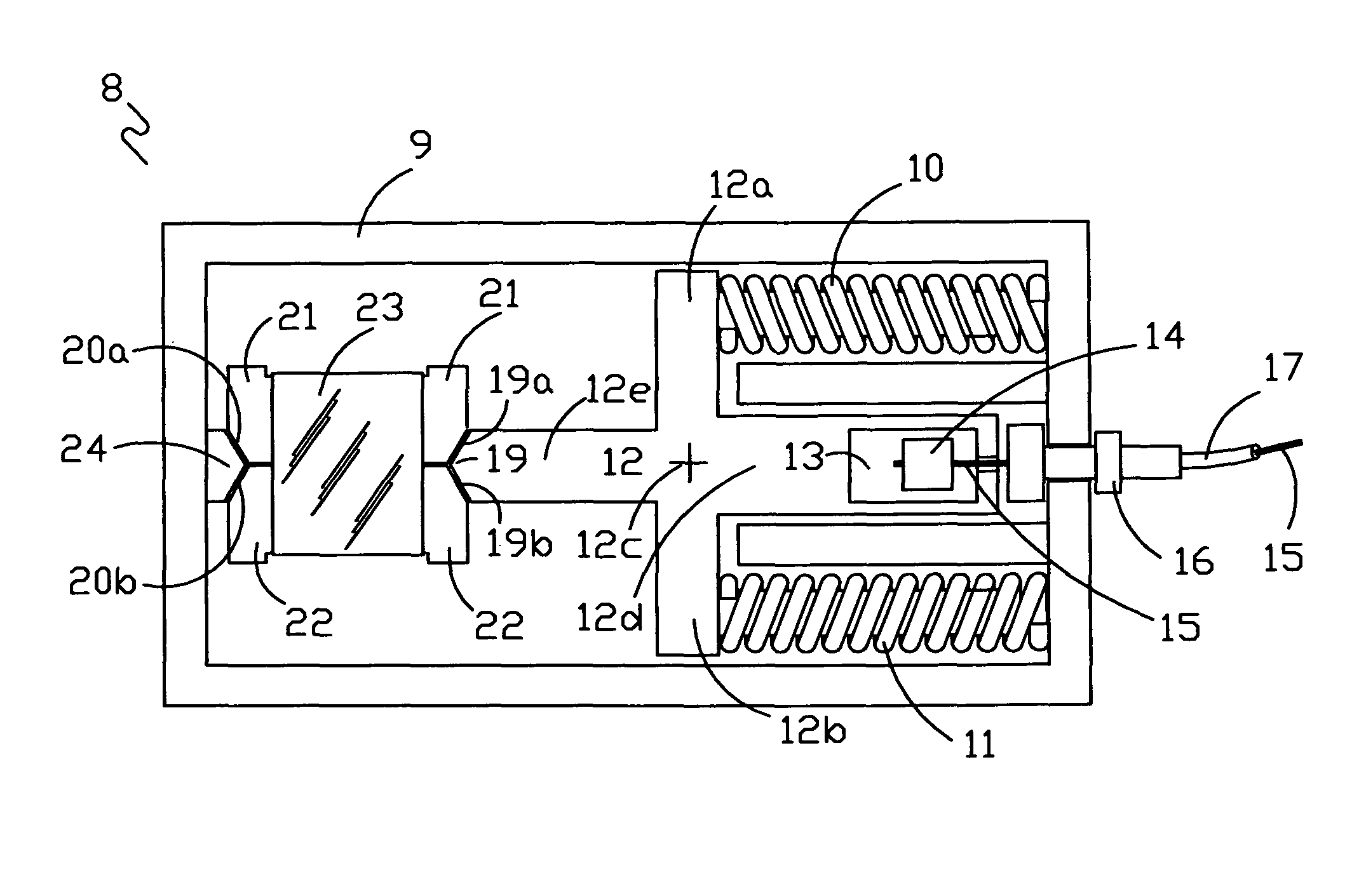

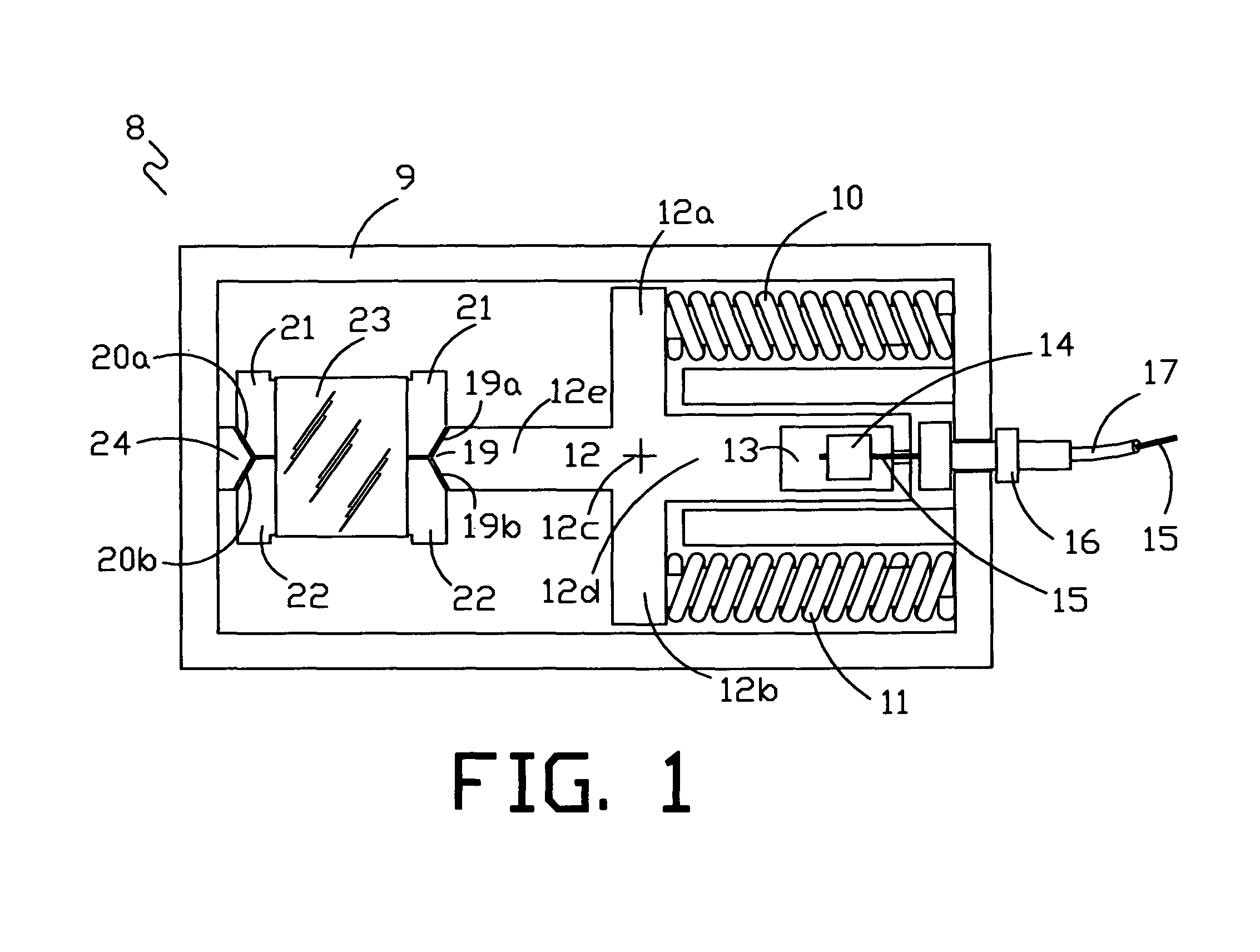

Rotor cooling system for synchronous machines with conductive sleeve

ActiveUS7208854B1Low operating temperatureThin constructionMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringElectrical and Electronics engineering

A wound field synchronous machine includes direct oil cooling along a conductive sleeve with elongated semi-arcuate shaped channels which alternate with damper bar channels containing tie-rod supports structures. With a reduction in sleeve thickness permitted by the direct cooling, the overall weight of the machine is reduced.

Owner:HAMILTON SUNDSTRAND CORP

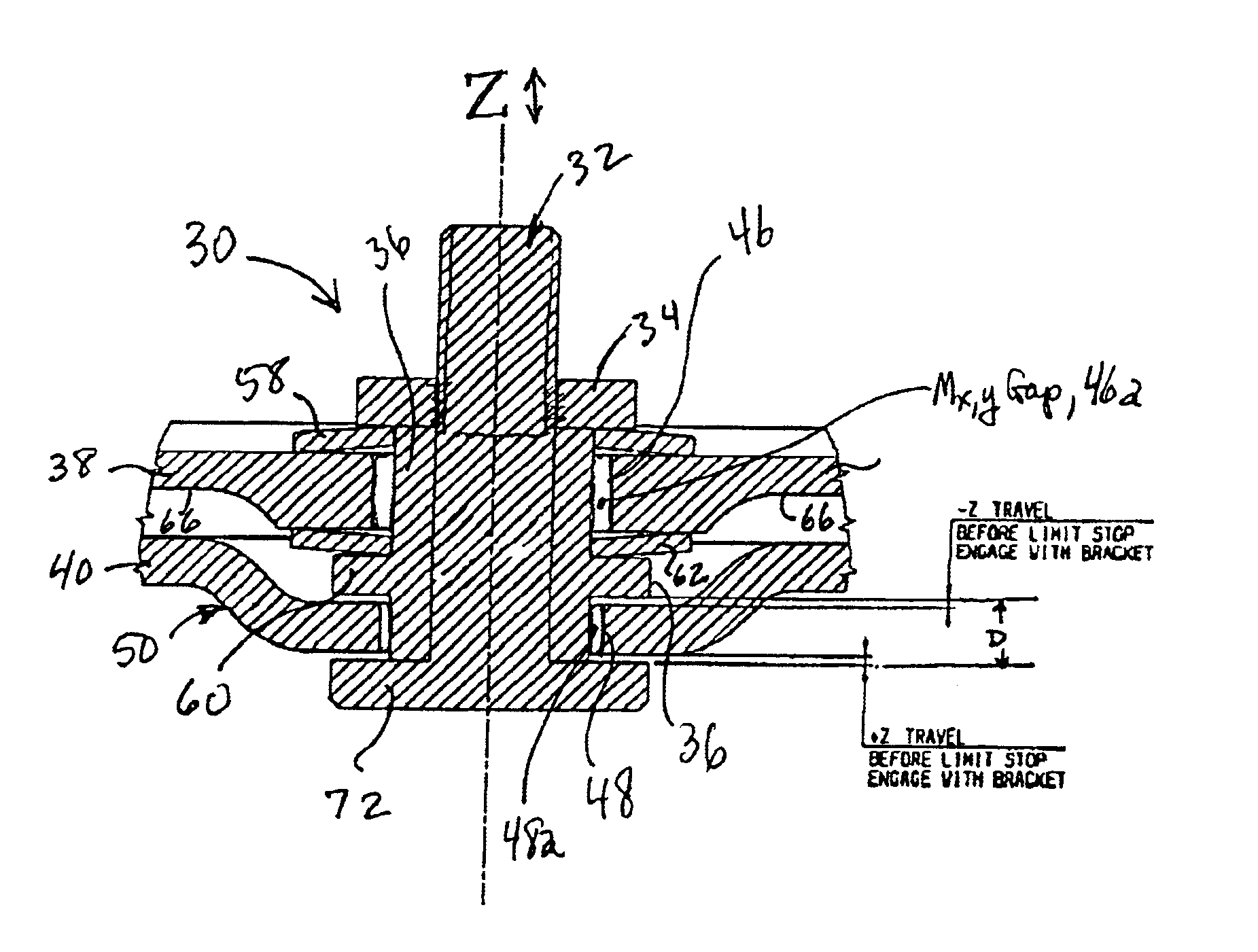

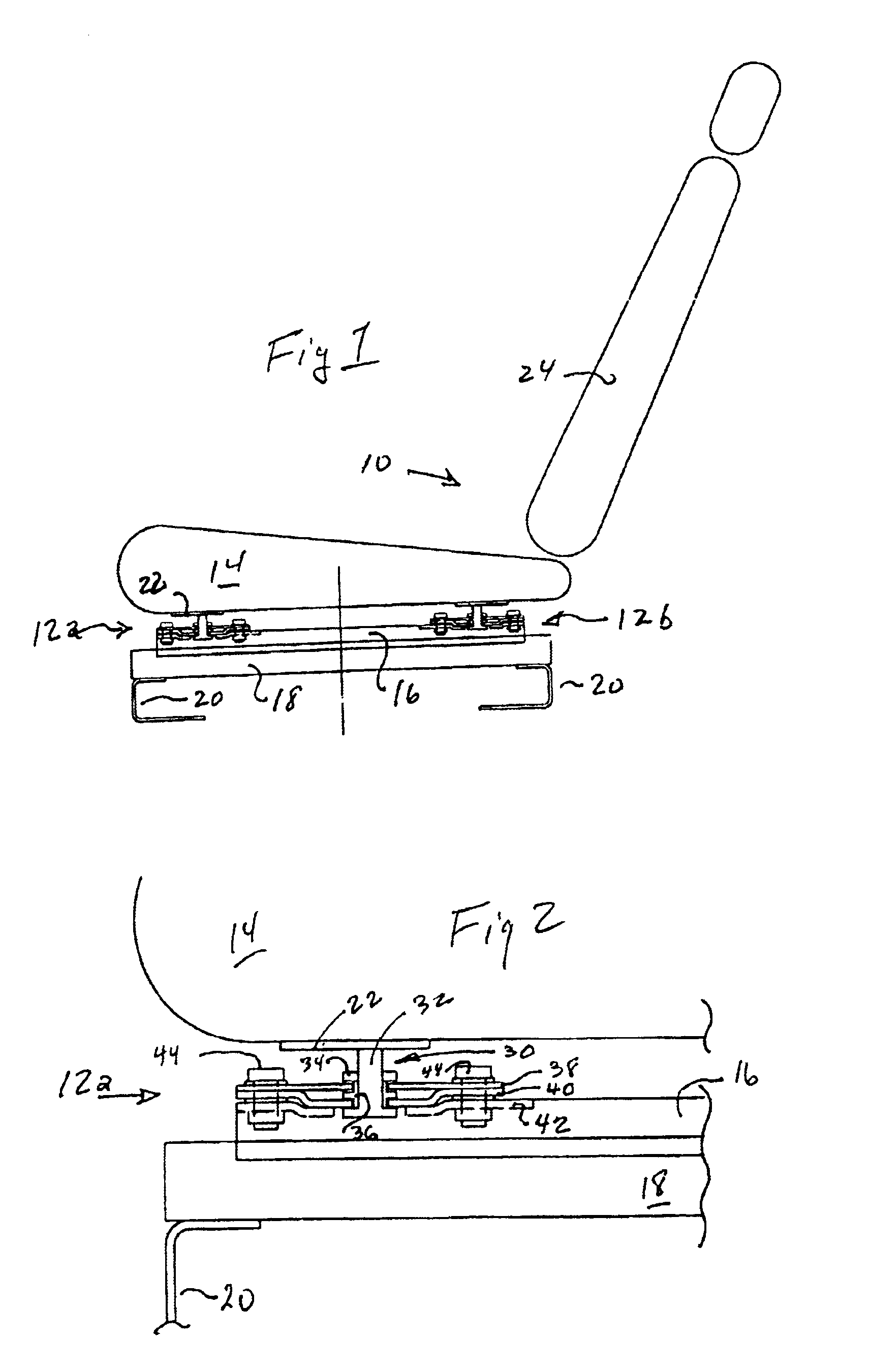

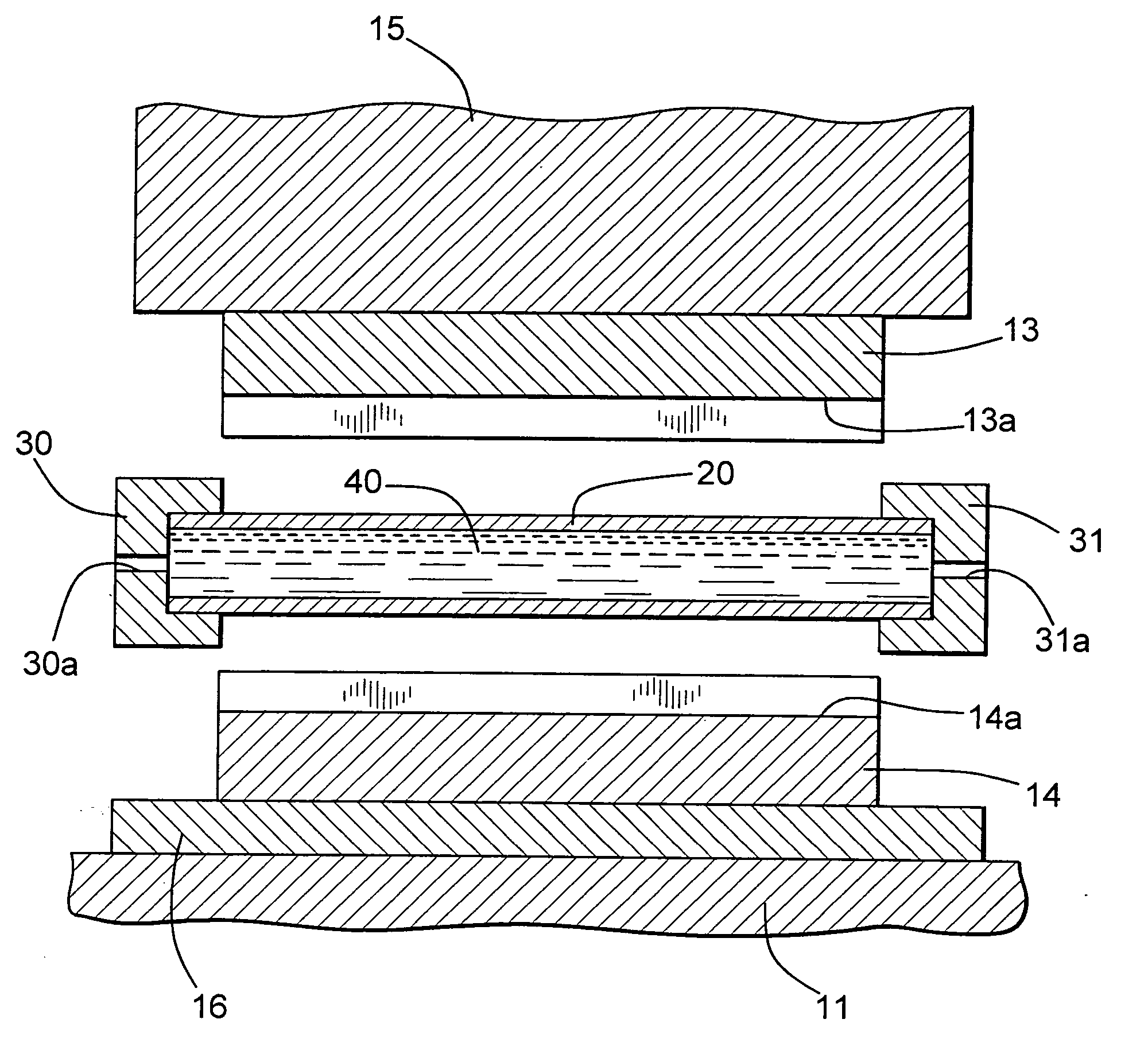

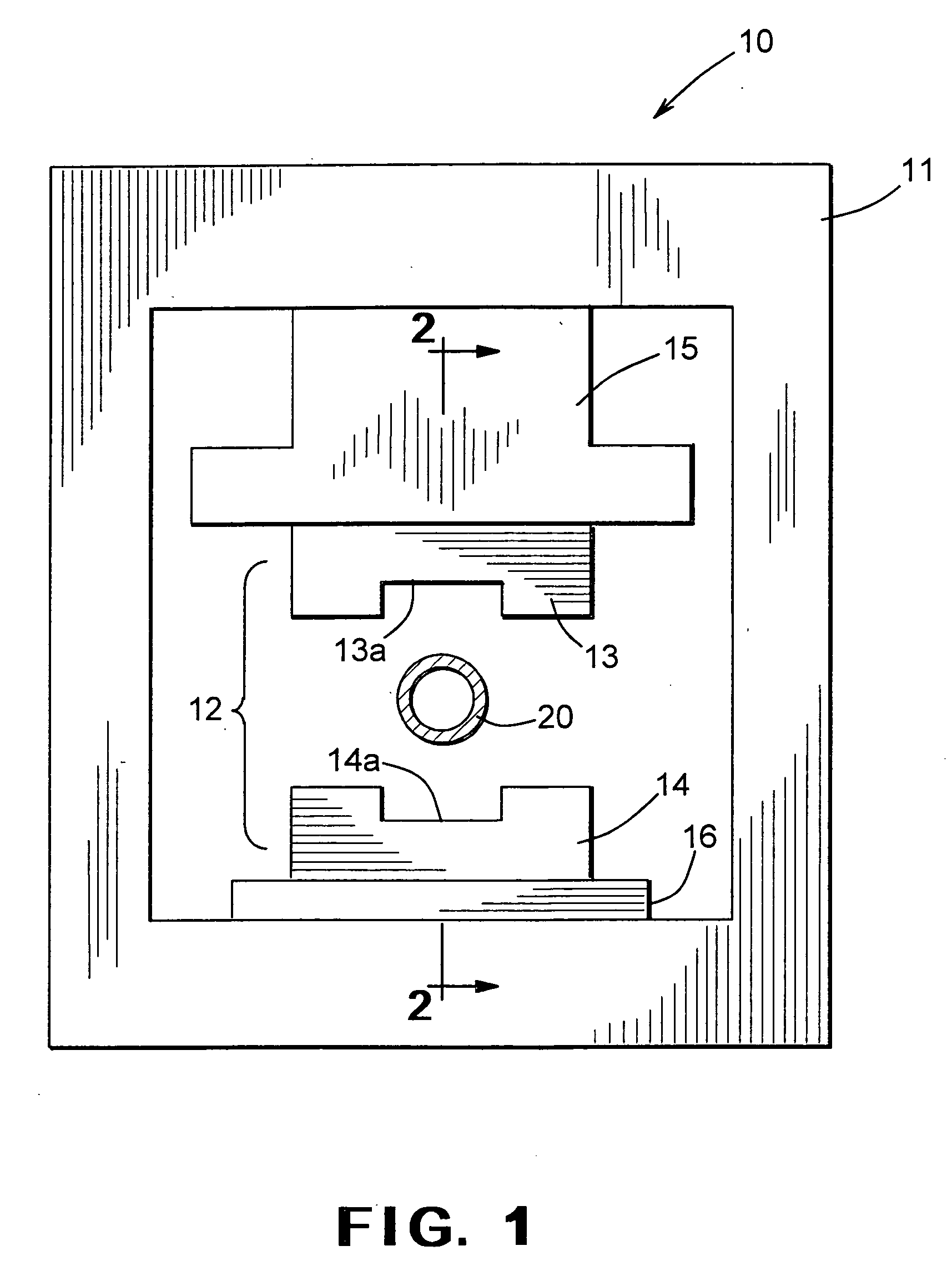

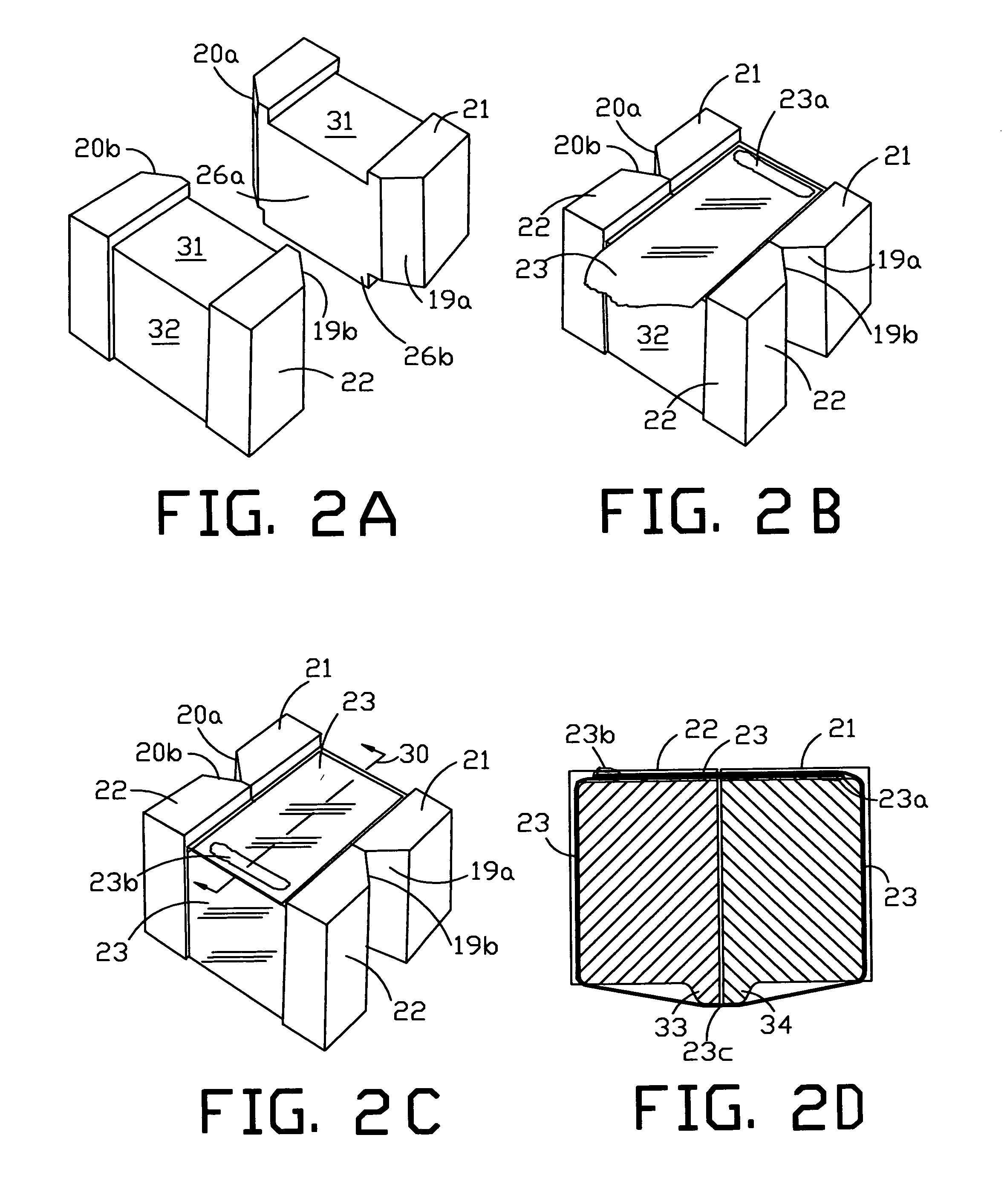

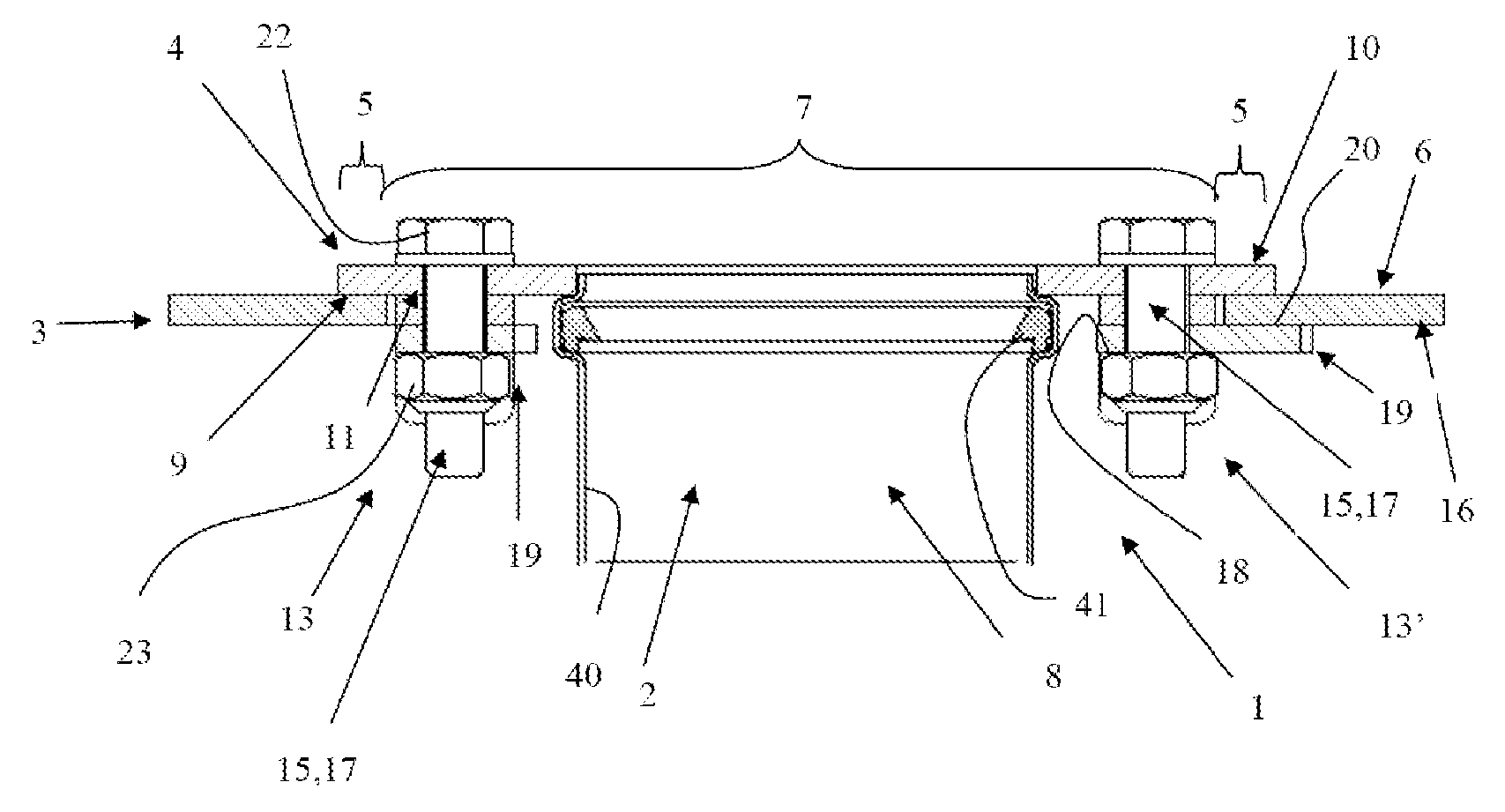

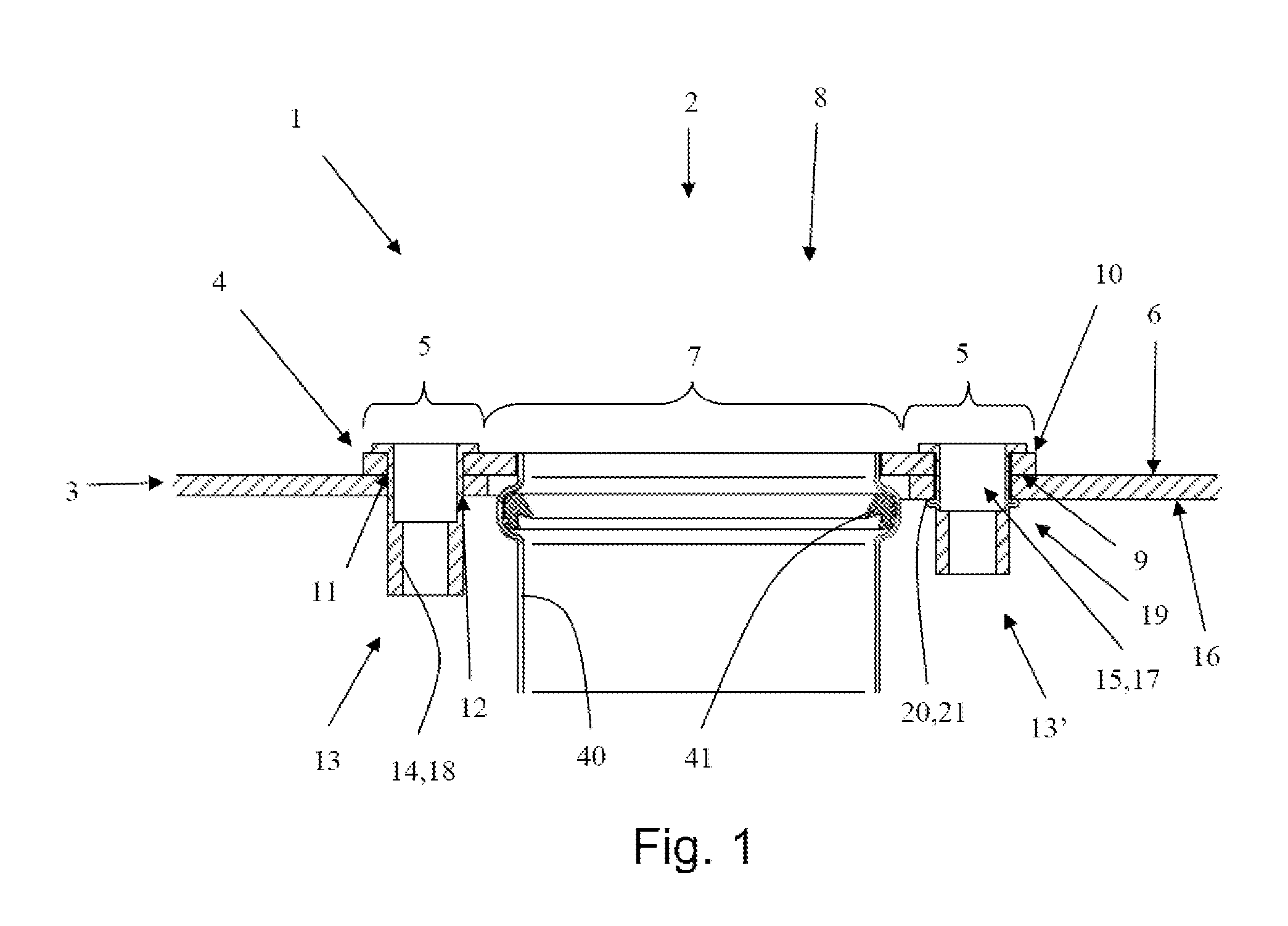

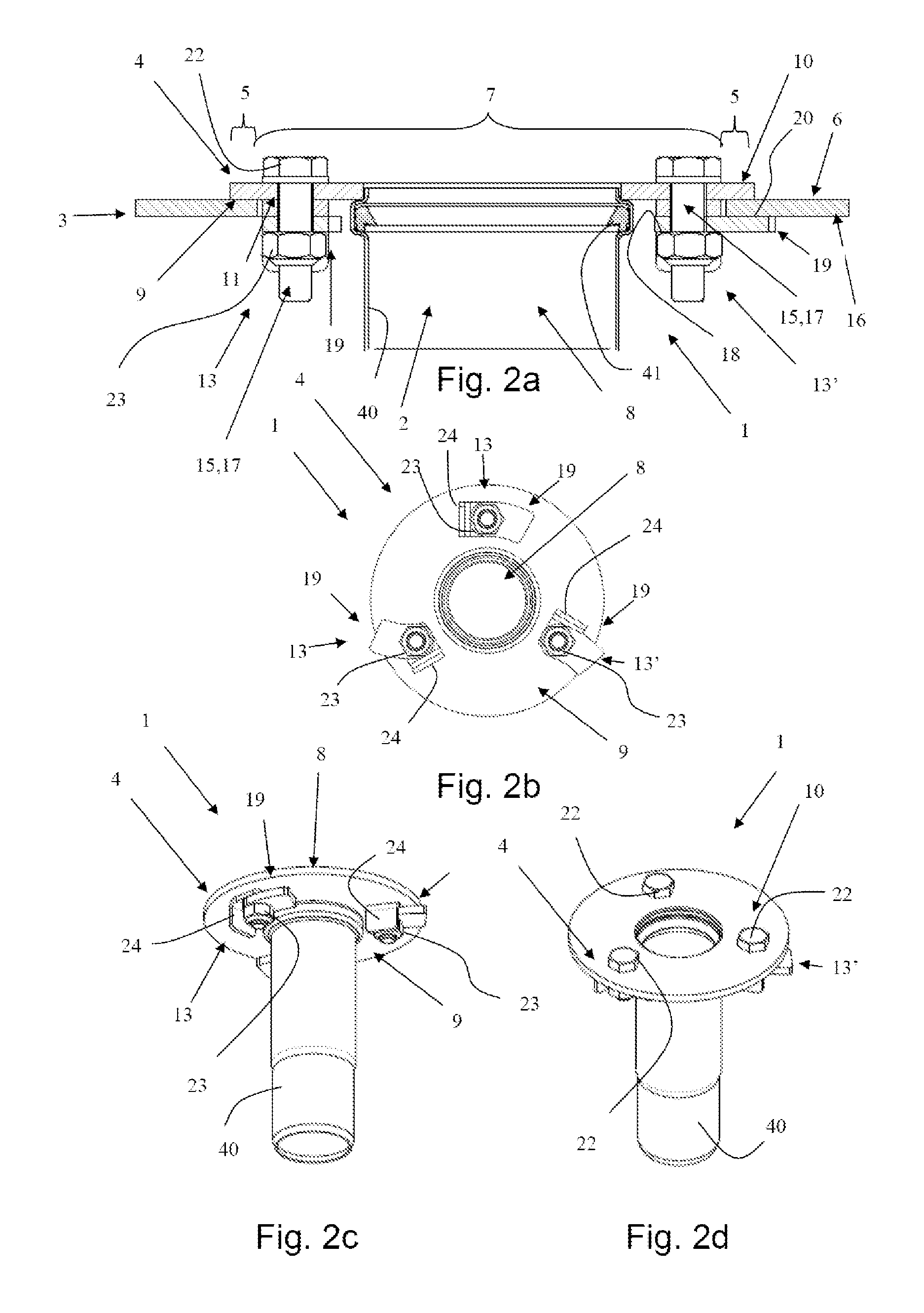

Weight sensors having centralized loose tolerance universal force and Mx/My moments overload stops

InactiveUS6916997B2Convenient travelReduce loadWeighing apparatus using elastically-deformable membersElectric devicesModularityAngular rotation

Automotive load cells having centralized, multi-axis, loose tolerance overload / limit stops provide improved strain gauge response. The modular, integrated stop assemblies magnify sensor substrate deflection by use of opposed concave (Belleville) springs are used in direct contact with the substrate to accommodate ±Z axis deflection and Mx / My moment angular rotation. A flanged guide member on the load stud permits a wide range of geometries. The substrate is thickened around the load stud hole and the outboard support bolt holes. Hollow rivets assist in design modularity. Strain gauges are placed at the yield zones symmetrically with respect to the X axis. The substrate hole Mx / My gap is larger than the stop bracket hole to insure a positive stop for Mx / My moments prior to yield. The inventive multi-axis stop assembly is used in any type load cell, including rectangular, thinned, notched, necked / dogbone, or cantilever substrates with any strain gauge layout configuration.

Owner:ROBERT BOSCH CORP

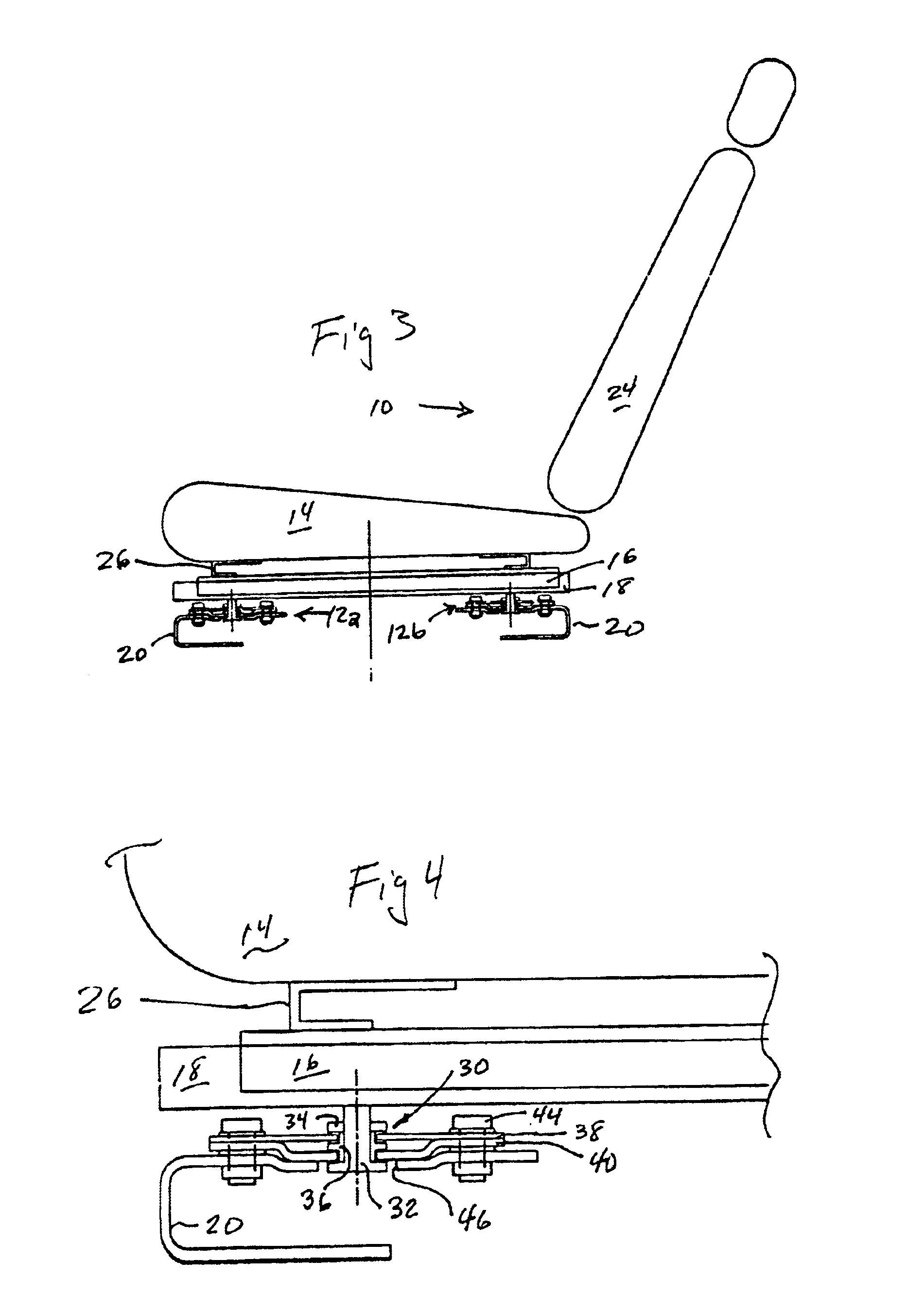

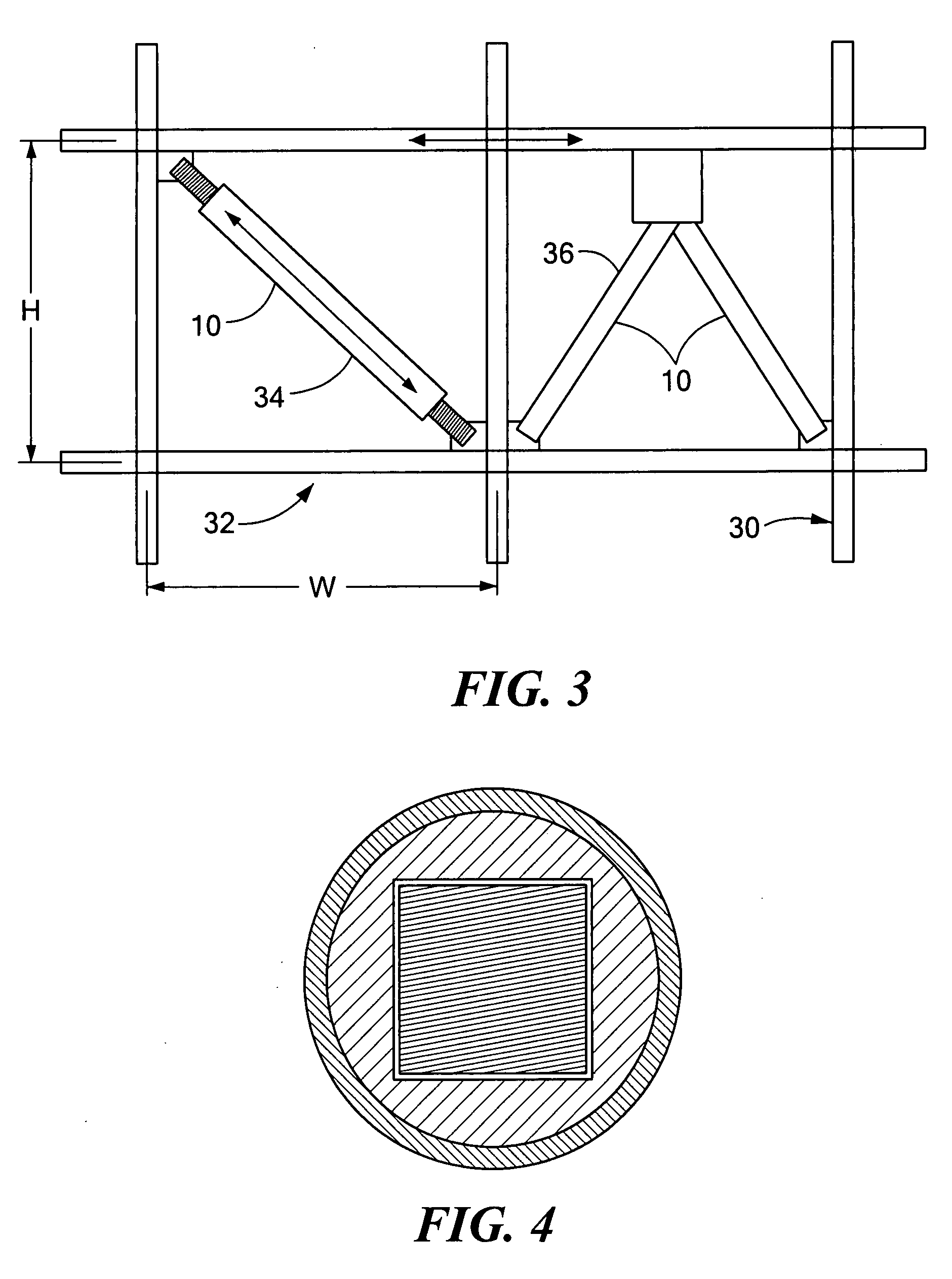

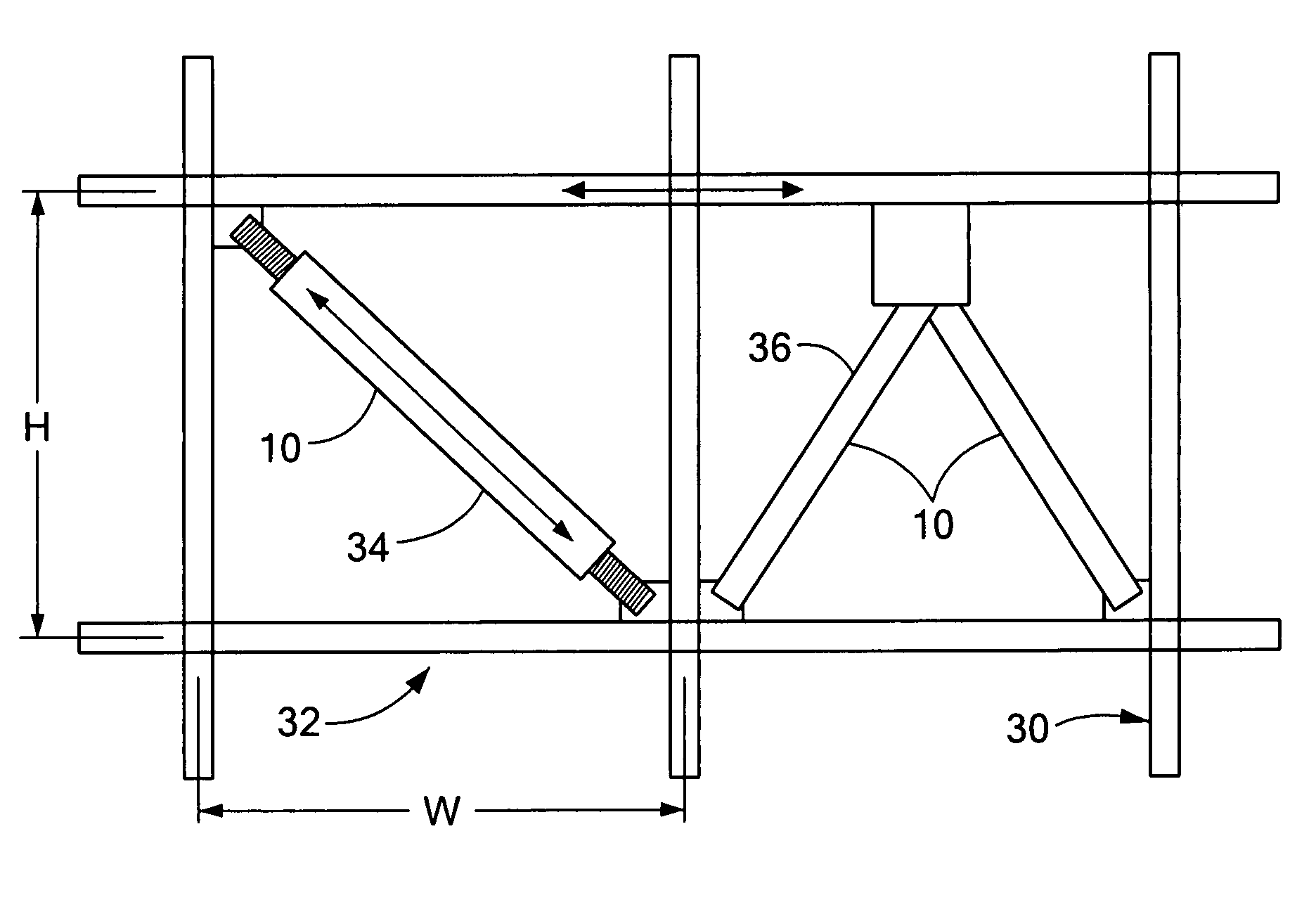

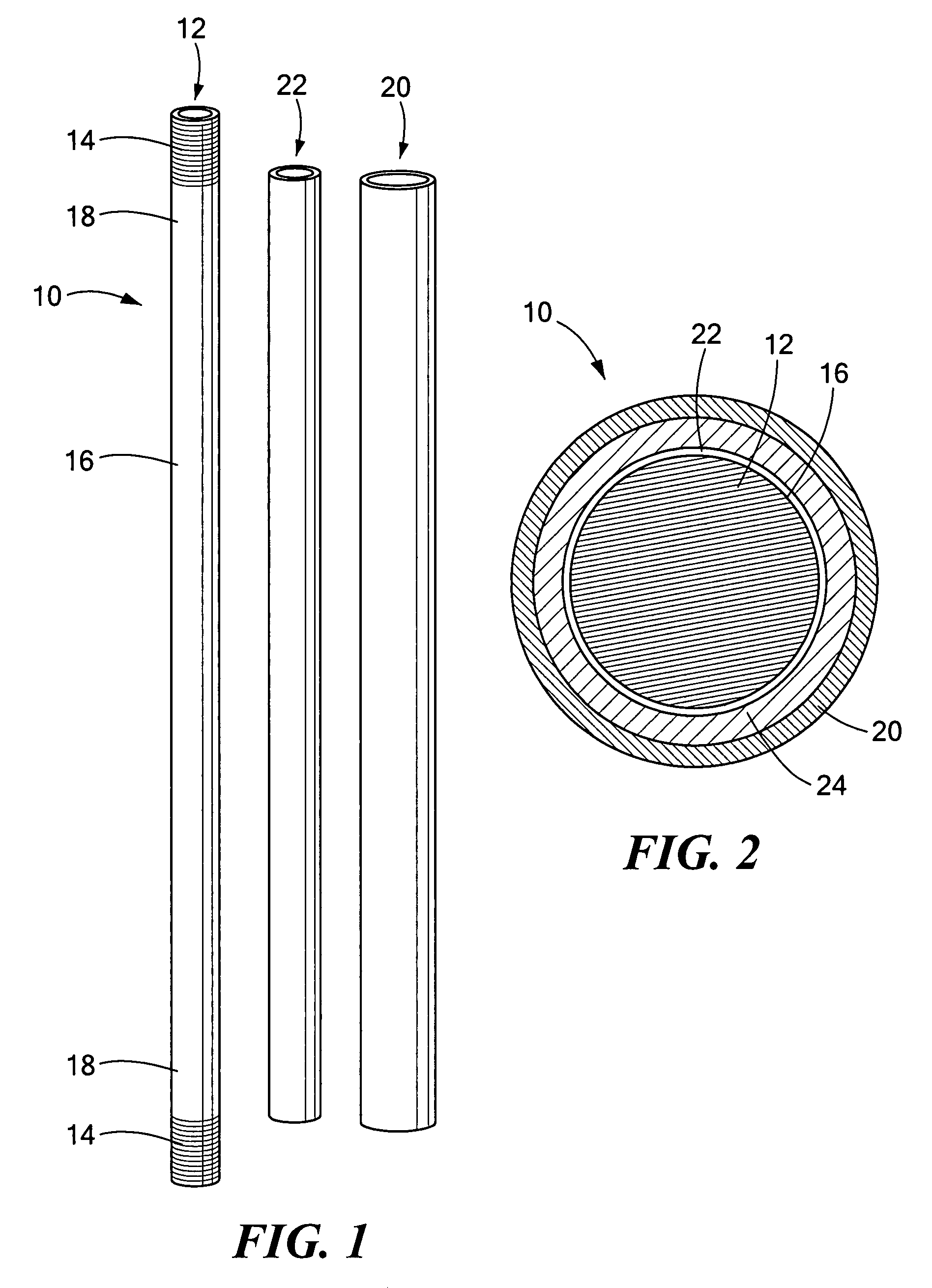

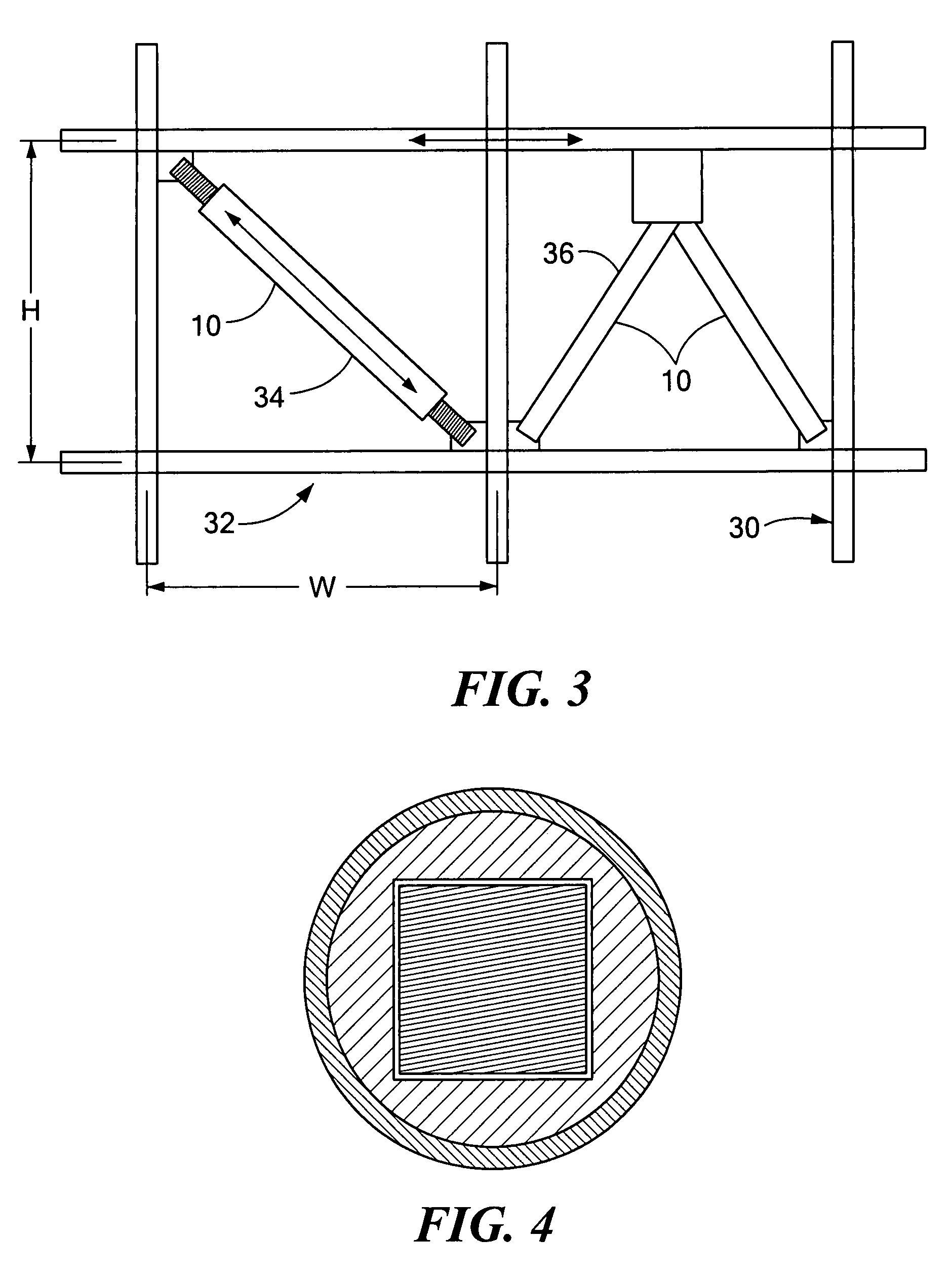

Buckling restrained brace for structural reinforcement and seismic energy dissipation and method of producing same

InactiveUS20080229683A1Improve performanceEnhance resilienceMetal-working apparatusProtective buildings/sheltersMetal foilBuckling-restrained brace

A buckling restrained brace includes a deformable core contained within an outer casing. Ends of the core protrude from the casing for connection to a frame or other structure. A length of the deformable core between its ends, referred to as the gauge or yielding section, is capable of deforming during an earthquake or blast loading. The gauge section is differentially heat treated from the ends so that the gauge section has a lower yield strength than the ends. The casing provides containment of the core to prevent buckling of the core. A metal foil interface or unbonding layer is provided between the deformable core and the casing so that the deformable core does not bind to the casing. The buckling restrained brace provides significant performance improvements over prior art BRBs coupled with simplified assembly.

Owner:KAZAK COMPOSITES

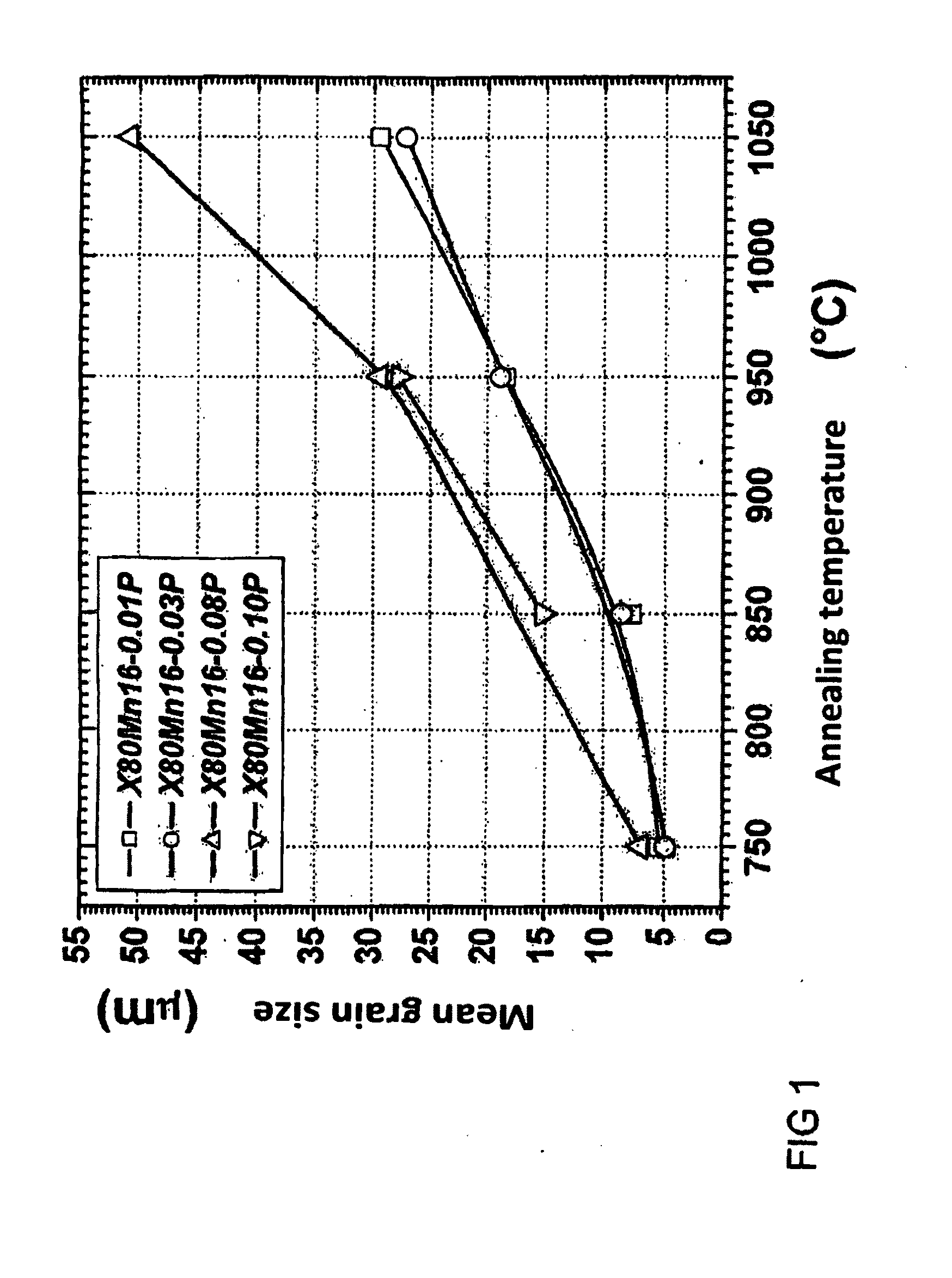

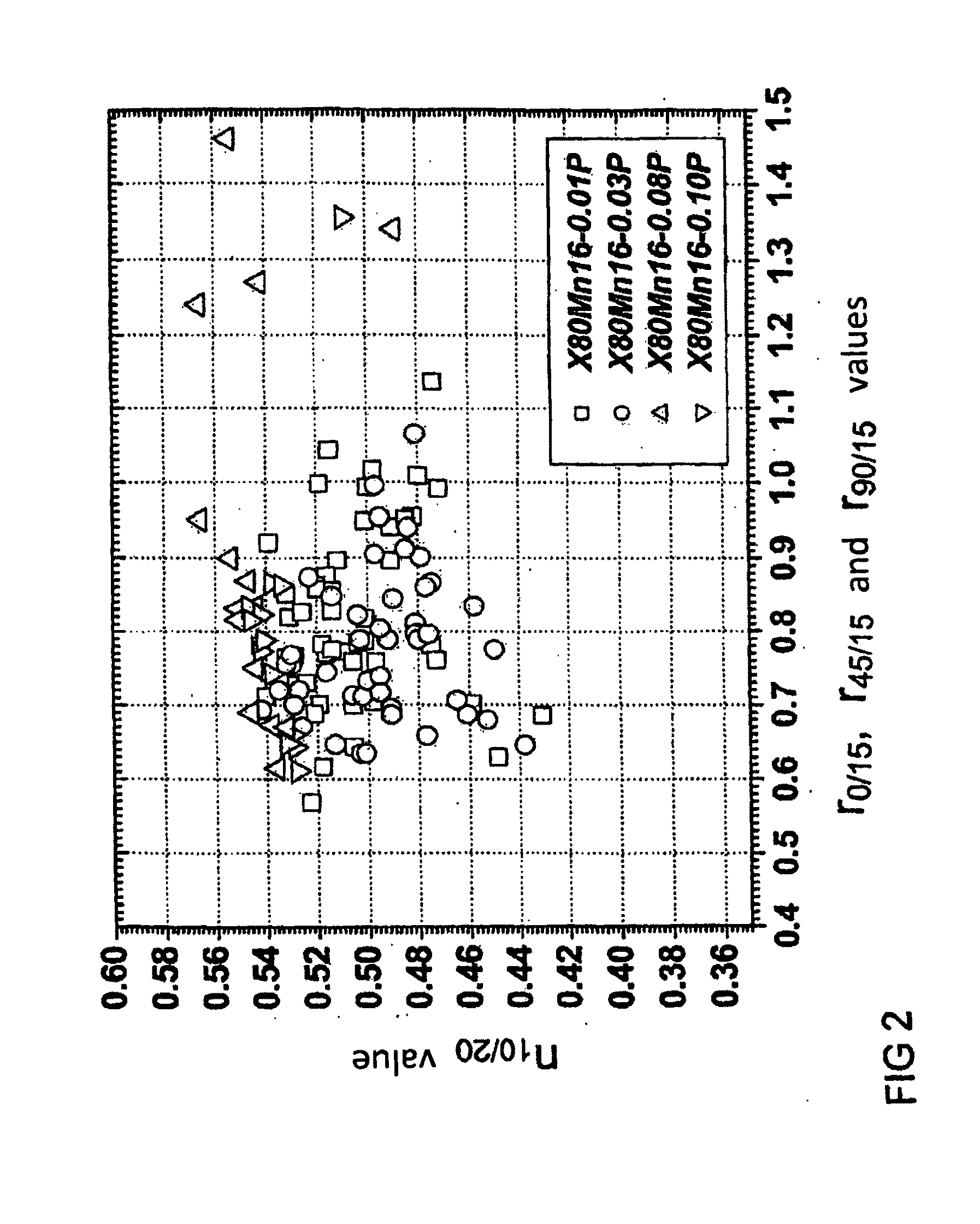

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

High-Strength Steel Material Having Outstanding Ultra-Low-Temperature Toughness and a Production Method Therefor

ActiveUS20130174941A1Good cryogenic temperature toughnessYield strengthHeat treatment process controlLiquefied natural gasReduction rate

The present invention provides steel containing manganese and nickel that is used as a structural material for a cryogenic storage container for liquefied natural gas (LNG) or the like, and a manufacturing method thereof; and more particularly, to steel having good cryogenic temperature toughness and also high strength by adding low-cost Mn instead of relatively expensive Ni at an optimized ratio, refining a microstructure through controlled rolling and cooling, and precipitating retained austenite through tempering, and a manufacturing method of the steel. To achieve the object, the technical feature of the present invention is a method of manufacturing high-strength steel with cryogenic temperature toughness. In the method, a steel slab is heated to a temperature within a range of 1,000 to 1,250° C., wherein the steel slab includes, by weight: 0.01-0.06% of carbon (C), 2.0-8.0% of manganese (Mn), 0.01-6.0% of nickel (Ni), 0.02-0.6% of molybdenum (Mo), 0.03-0.5% of silicon (Si), 0.003-0.05% of aluminum (Al), 0.0015-0.01% of nitrogen (N), 0.02% or less of phosphorous (P), 0.01% or less of sulfur (S), with a remainder of iron (Fe) and other unavoidable impurities. Then, the heated slab is finish-rolled at a temperature of 950° C. or less at a rolling reduction rate of 40% or more. The rolled steel is cooled to a temperature of 400° C. or less at a cooling rate of 2° C. / s or more. Thereafter, the steel is tempered for 0.5-4 hours to a temperature within a range of 550 to 650° C. after the cooling.

Owner:POHANG IRON & STEEL CO LTD

Nickel based alloys for internal combustion engine valve seat inserts, and the like

InactiveUS6482275B1Improving insert retention characteristicGood high-temperature compressive yield strengthMachines/enginesWelding/cutting media/materialsManganeseAlloy

A nickel based alloy is provided which includes, in weight percentage,carbon from about 2 to about 3;chromium from about 30 to about 40;tungsten from about 12 to about 18;iron from about 3.5 to about 8.5;molybdenum from about 1 to about 8;manganese up to about 0.5;silicon up to about 1.0; andthe balance nickel and incidental impurities. The alloy is useful for internal combustion engine valve seat inserts and the like.

Owner:L E JONES CO

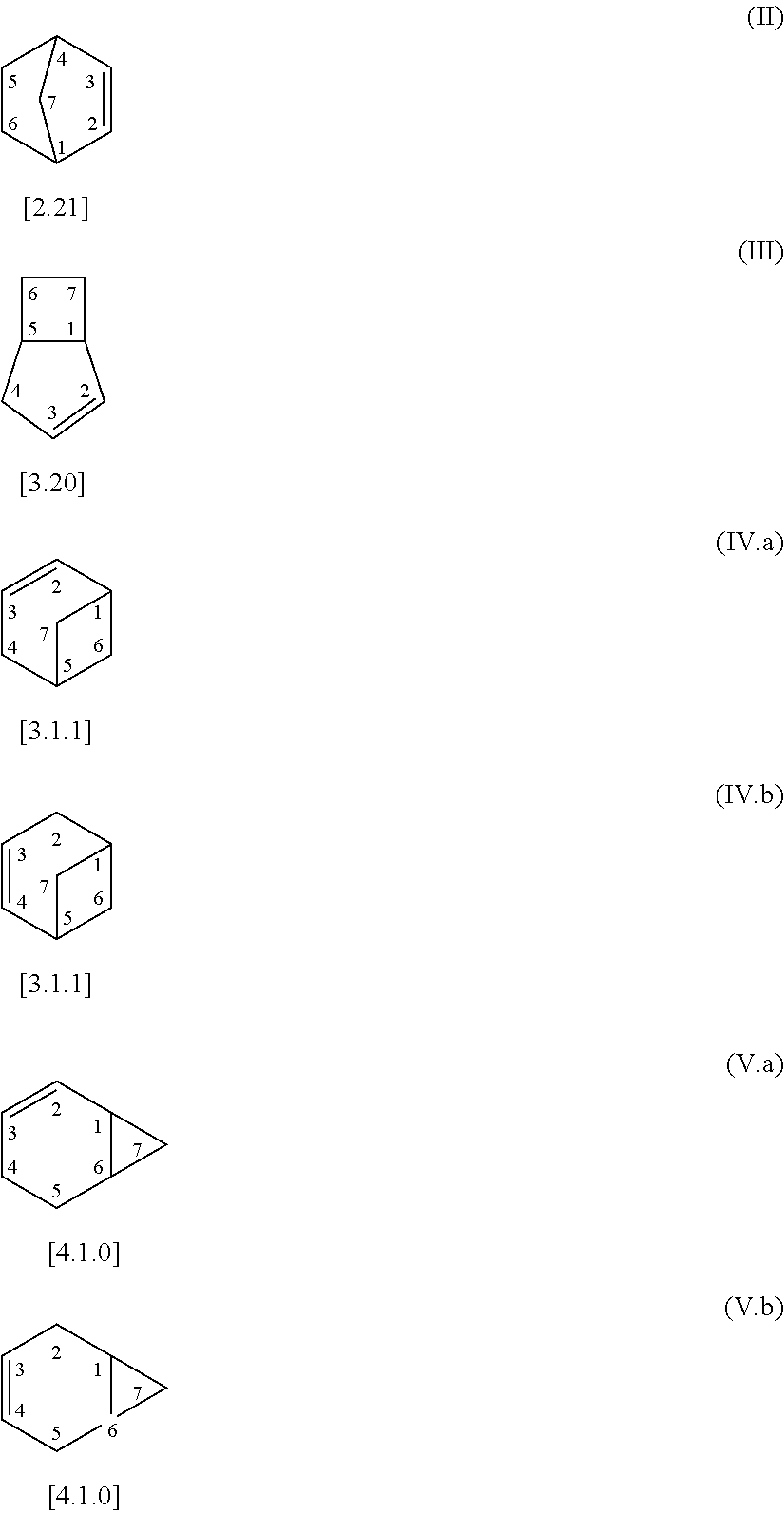

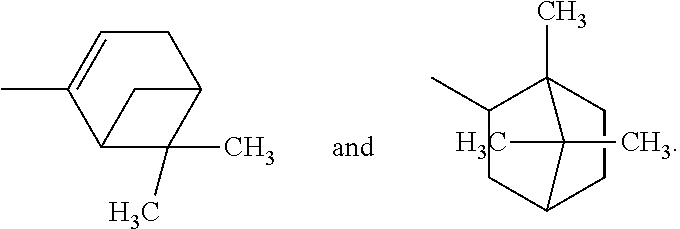

Rheology modifier polymer

ActiveUS20110243873A1Yield strengthImprove toleranceCosmetic preparationsBiocidePersonal carePolymer chemistry

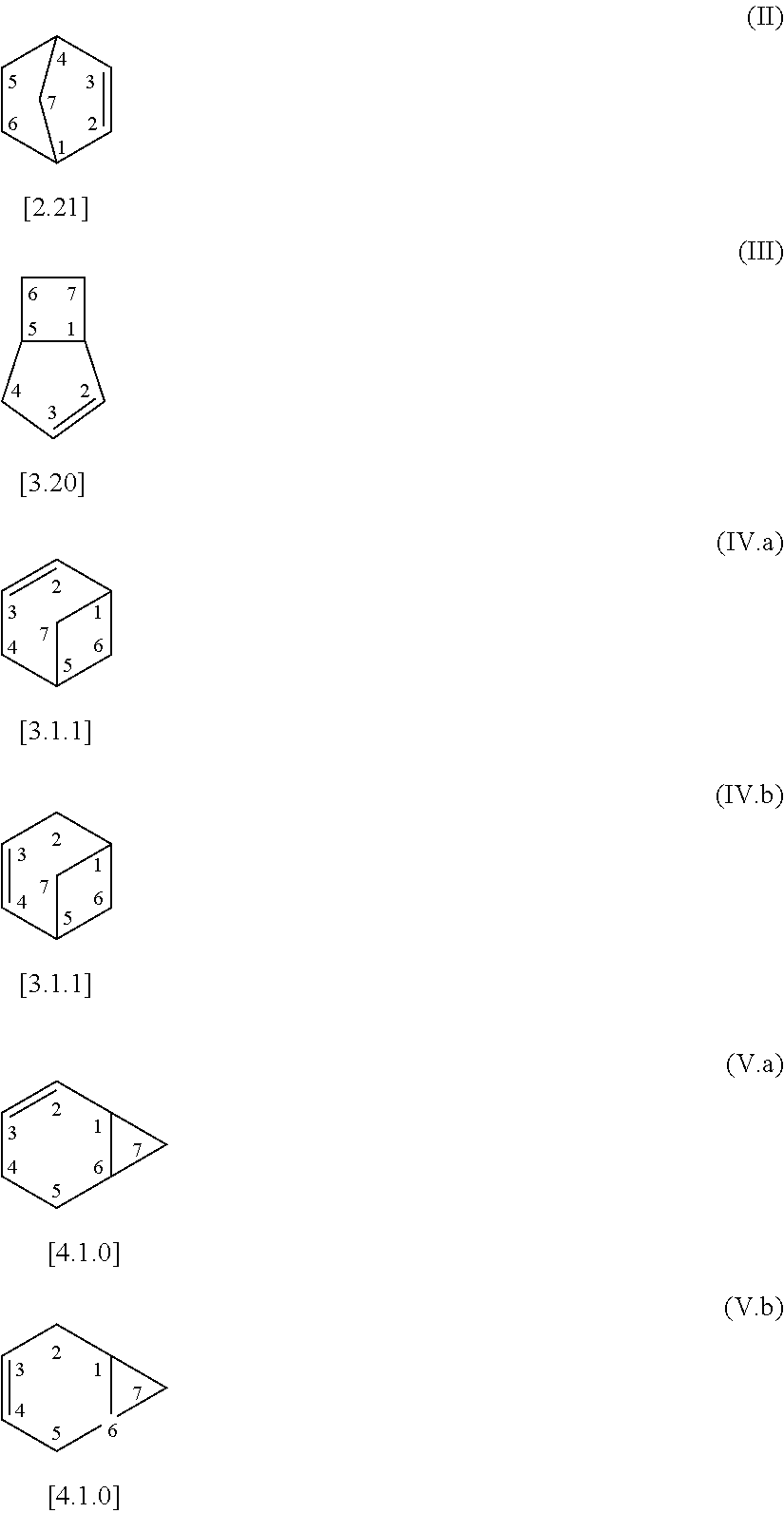

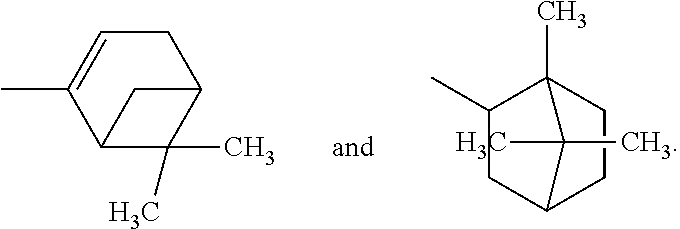

A polymer includes (a) one or more first monomeric units, each independently comprising at least one bicycloheptyl-polyether, bicycloheptenyl-polyether or branched (C5-C50)alkyl-polyether group per monomeric unit, wherein the bicycloheptyl-polyether or bicycloheptenyl-polyether group may optionally be substituted on one or more ring carbon atoms by one or two (C1-C6)alkyl groups per carbon atom, and (b) one or more second monomeric units, each independently comprising at least one pendant linear or branched (C5-C50)alkyl-polyether group per monomeric unit, provided that the first and second monomeric units cannot both comprise a branched (C5-C50)alkyl-polyether group and is useful as a component in liquid compositions, such as aqueous latex coating compositions, personal care compositions, home care compositions, and institutional or industrial care compositions.

Owner:RHODIA OPERATIONS SAS

Buckling restrained brace for structural reinforcement and seismic energy dissipation and method of producing same

InactiveUS7707788B2Improve performanceEnhance resilienceMetal-working apparatusProtective buildings/sheltersBuckling-restrained braceMetal foil

A buckling restrained brace includes a deformable core contained within an outer casing. Ends of the core protrude from the casing for connection to a frame or other structure. A length of the deformable core between its ends, referred to as the gauge or yielding section, is capable of deforming during an earthquake or blast loading. The gauge section is differentially heat treated from the ends so that the gauge section has a lower yield strength than the ends. The casing provides containment of the core to prevent buckling of the core. A metal foil interface or unbonding layer is provided between the deformable core and the casing so that the deformable core does not bind to the casing. The buckling restrained brace provides significant performance improvements over prior art BRBs coupled with simplified assembly.

Owner:KAZAK COMPOSITES

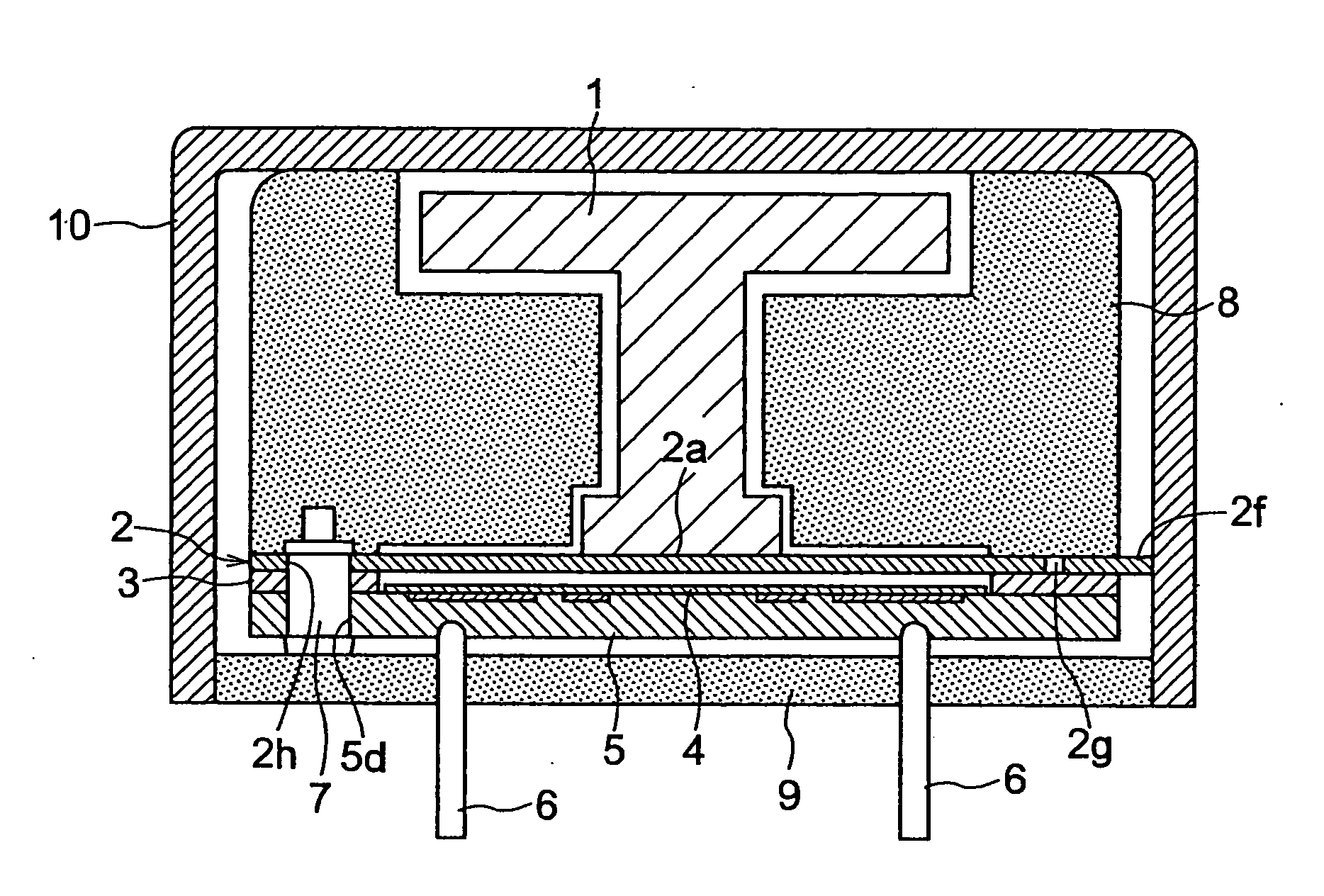

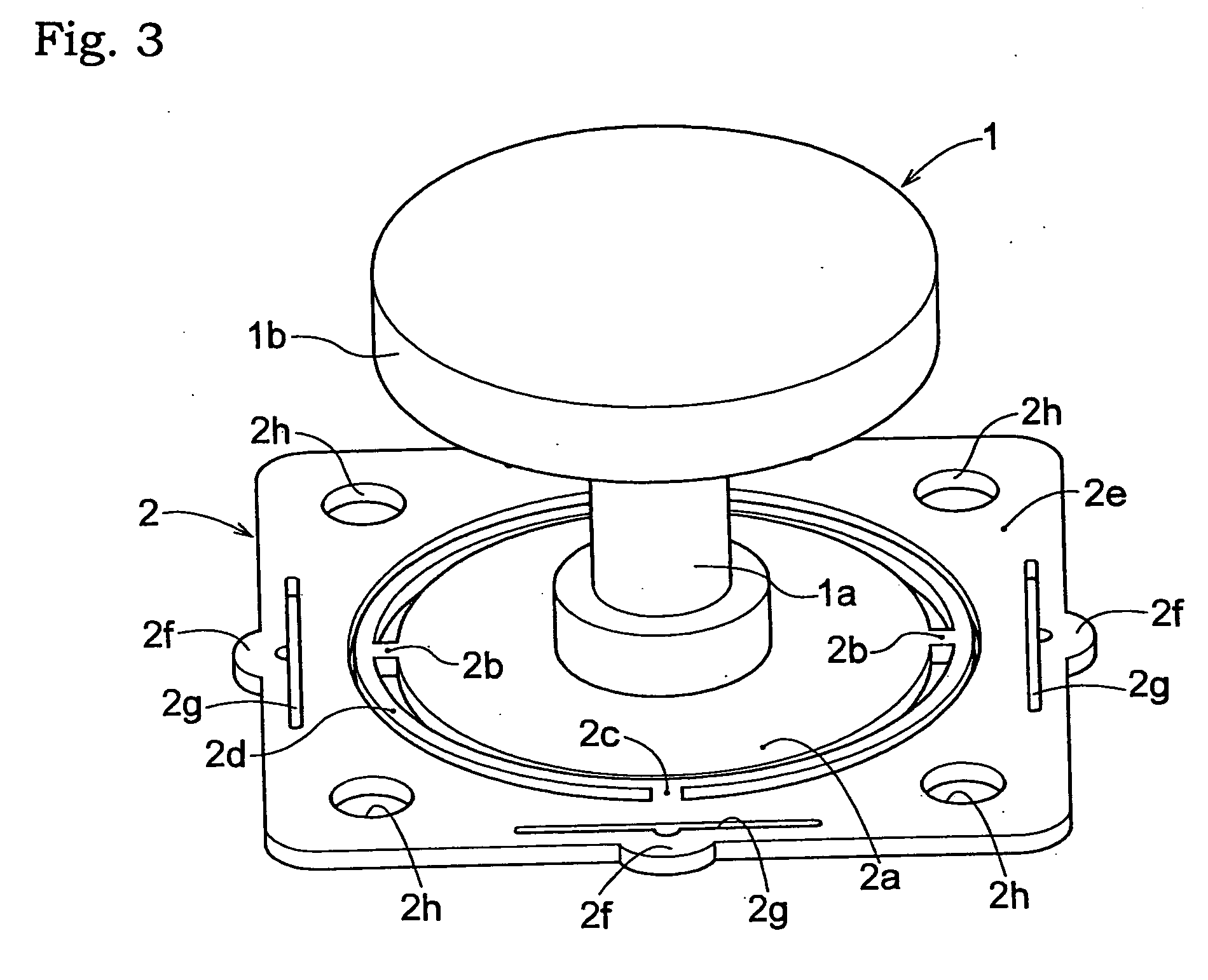

Acceleration sensor

InactiveUS20060053888A1Easy to assembleAccurate detectionAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementCapacitanceEngineering

A three-axis acceleration sensor having a simple construction is provided for improving shock resistance without lowering sensor sensitivity. An acceleration sensor for detecting acceleration in three orthogonal directions includes an electrode substrate (5) having fixed electrodes corresponding to three axes, respectively, a diaphragm (2) having one surface thereof opposed to the fixed electrodes acting as a movable electrode, and a weight (1) mounted centrally of the other surface of the diaphragm. Acceleration is detected based on variations in capacitance between the fixed electrodes and diaphragm (2). The electrode substrate (5) has an electret layer (4) formed to cover surfaces of the fixed electrodes.

Owner:HOSIDEN CORP

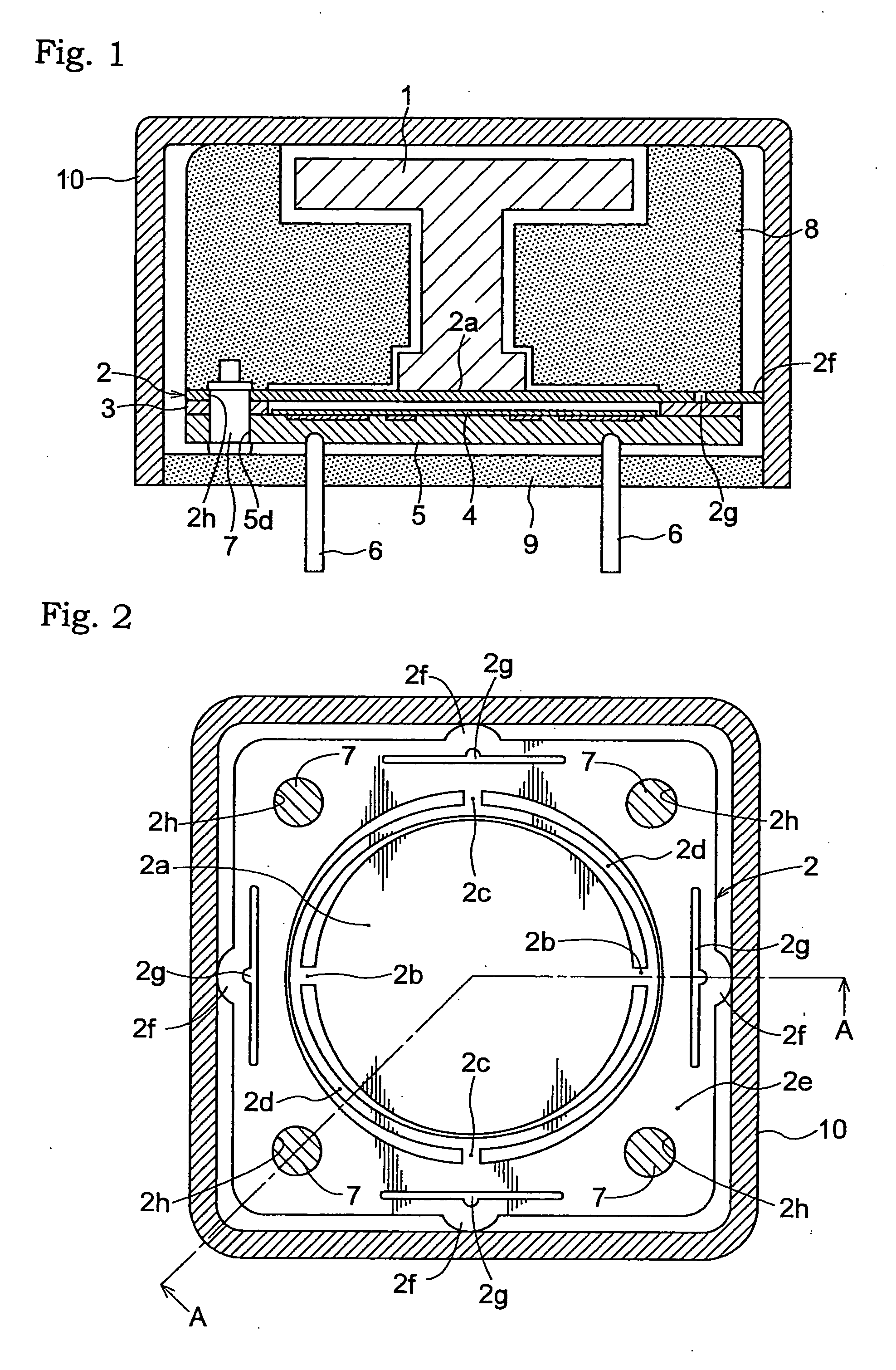

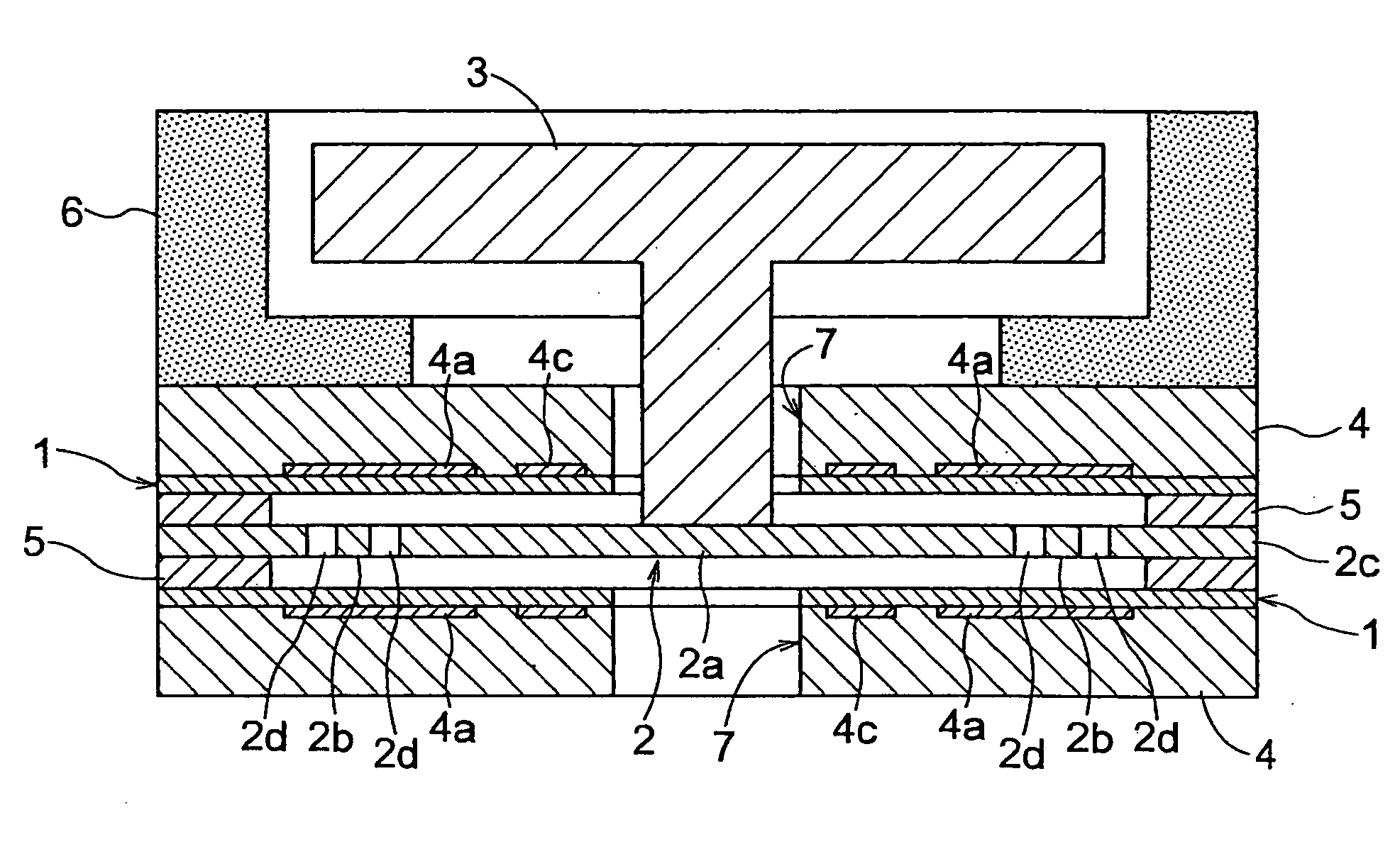

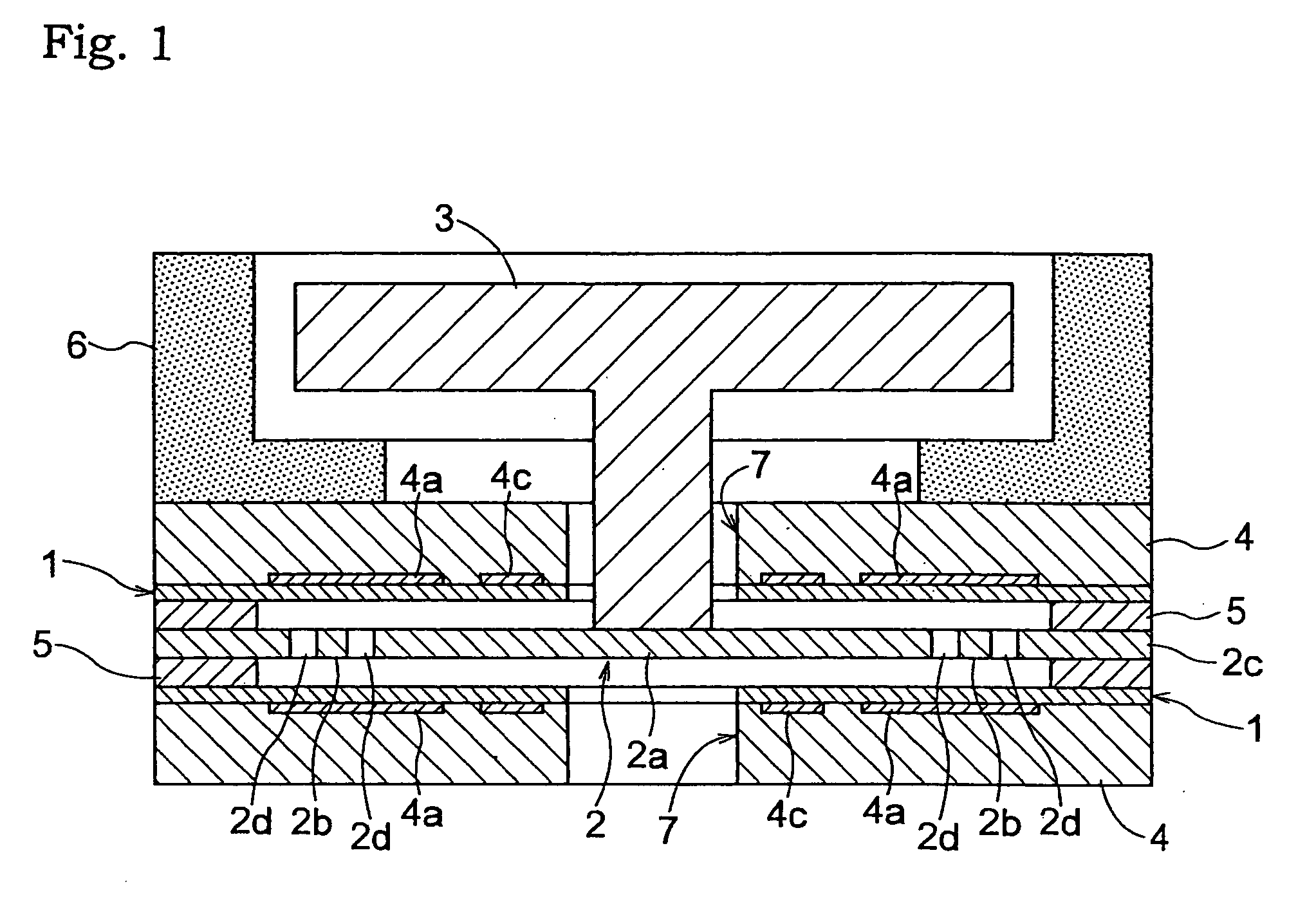

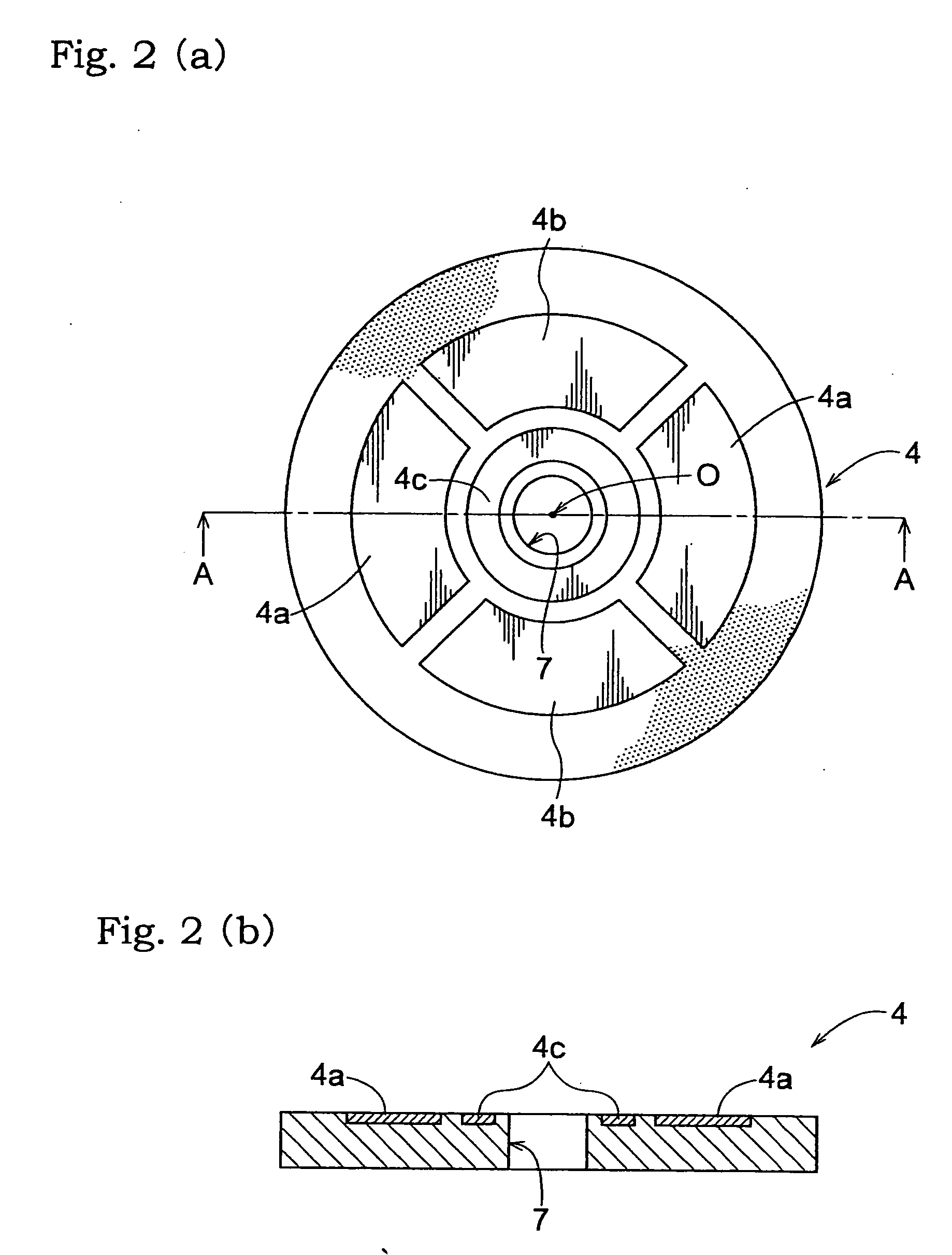

Acceleration sensor

InactiveUS20060053889A1Improve seismic performanceAvoid concentrationAcceleration measurement using interia forcesAnalysing solids using sonic/ultrasonic/infrasonic wavesCapacitanceClassical mechanics

A three-axis acceleration sensor having a simple construction is provided for improving shock resistance without lowering sensor sensitivity. An acceleration sensor for detecting acceleration in three orthogonal directions comprises an electrode substrate pair including electrode substrates (4) opposed to each other, and each having fixed electrodes (4c, 4b, 4a) corresponding to three axes, respectively, a diaphragm (2) acting as a movable electrode, and an umbrella-like weight (3) mounted centrally of the diaphragm (2). Acceleration is detected based on variations in capacitance between the fixed electrodes (4c, 4b, 4a) and diaphragm (2). Each electrode substrate (4) has an electret layer (1) formed to cover surfaces of the fixed electrodes (4c, 4b, 4a). At least one of the electrode substrates defines, centrally thereof, a through hole (7). A shaft portion of the umbrella-like weight (3) extends through the through hole (7) from outside, and is connected to the diaphragm (2).

Owner:HOSIDEN CORP

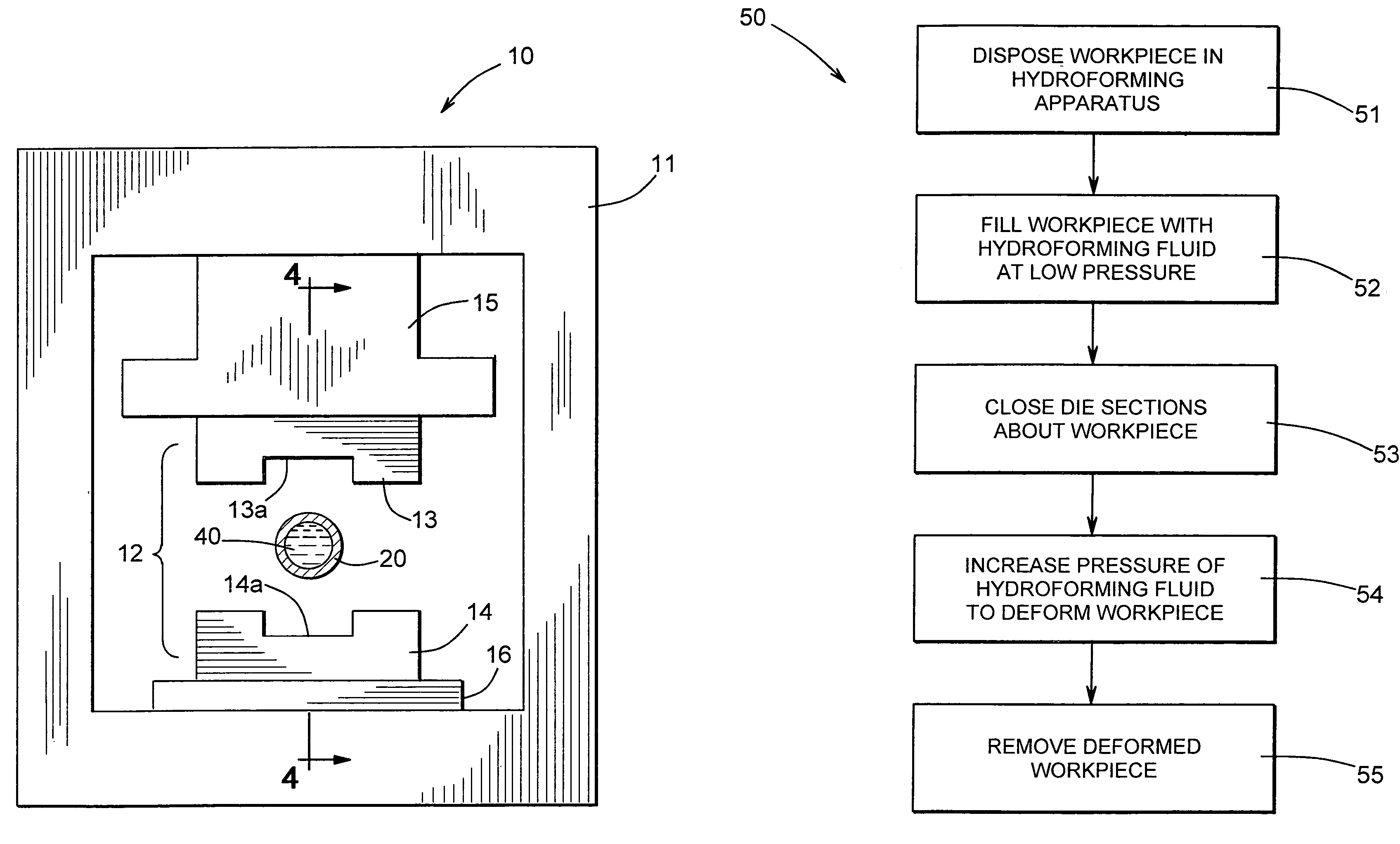

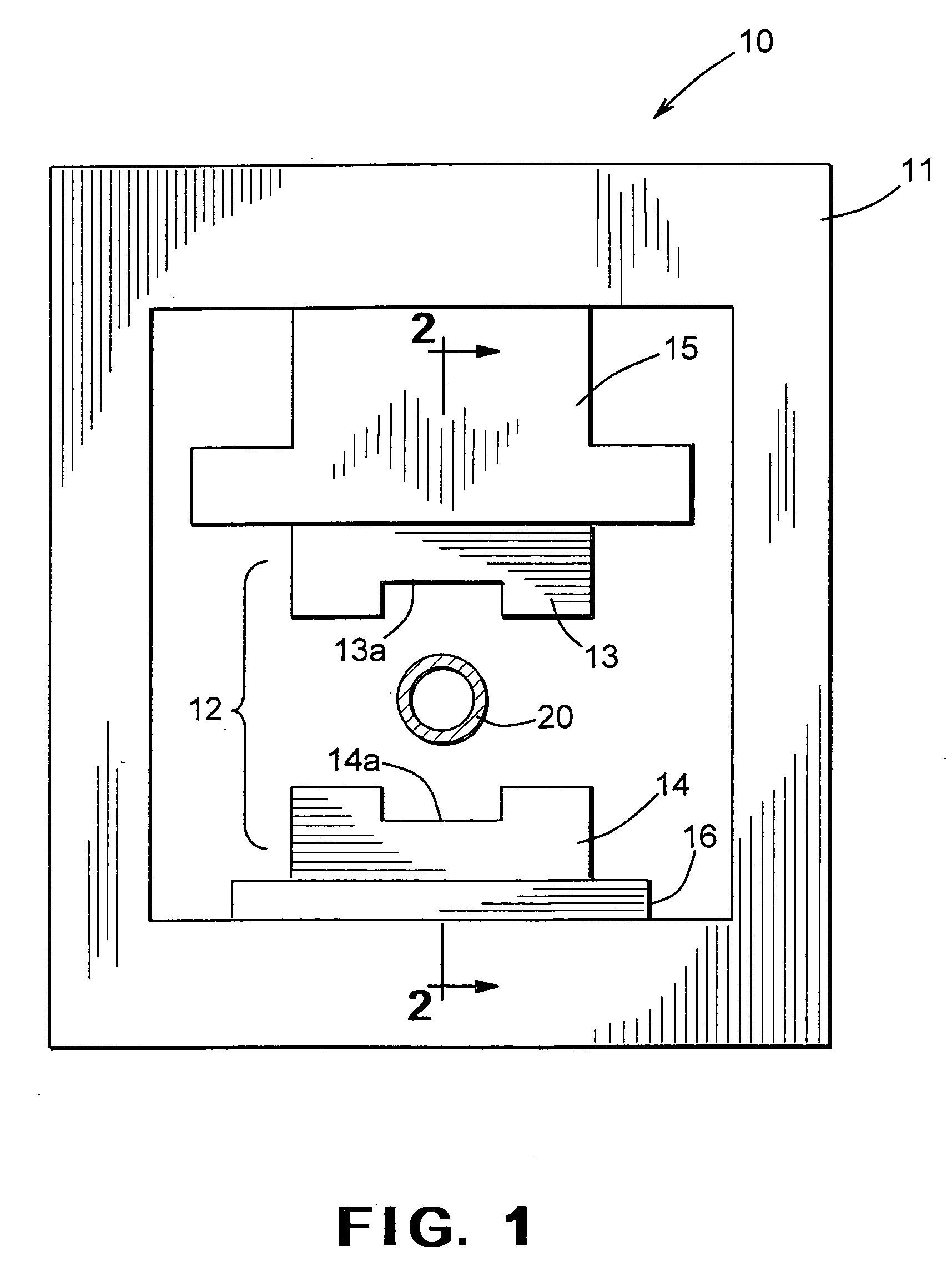

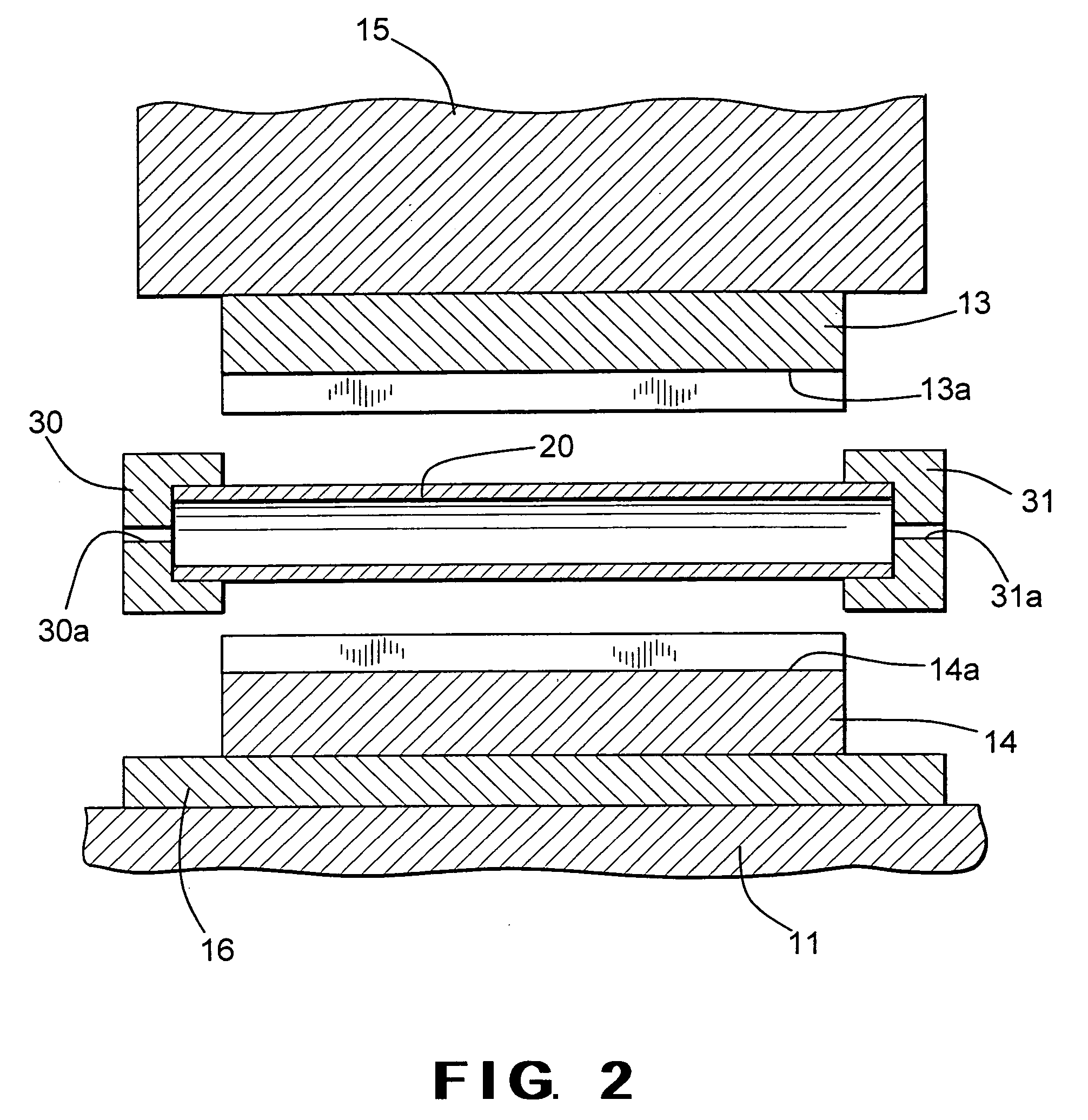

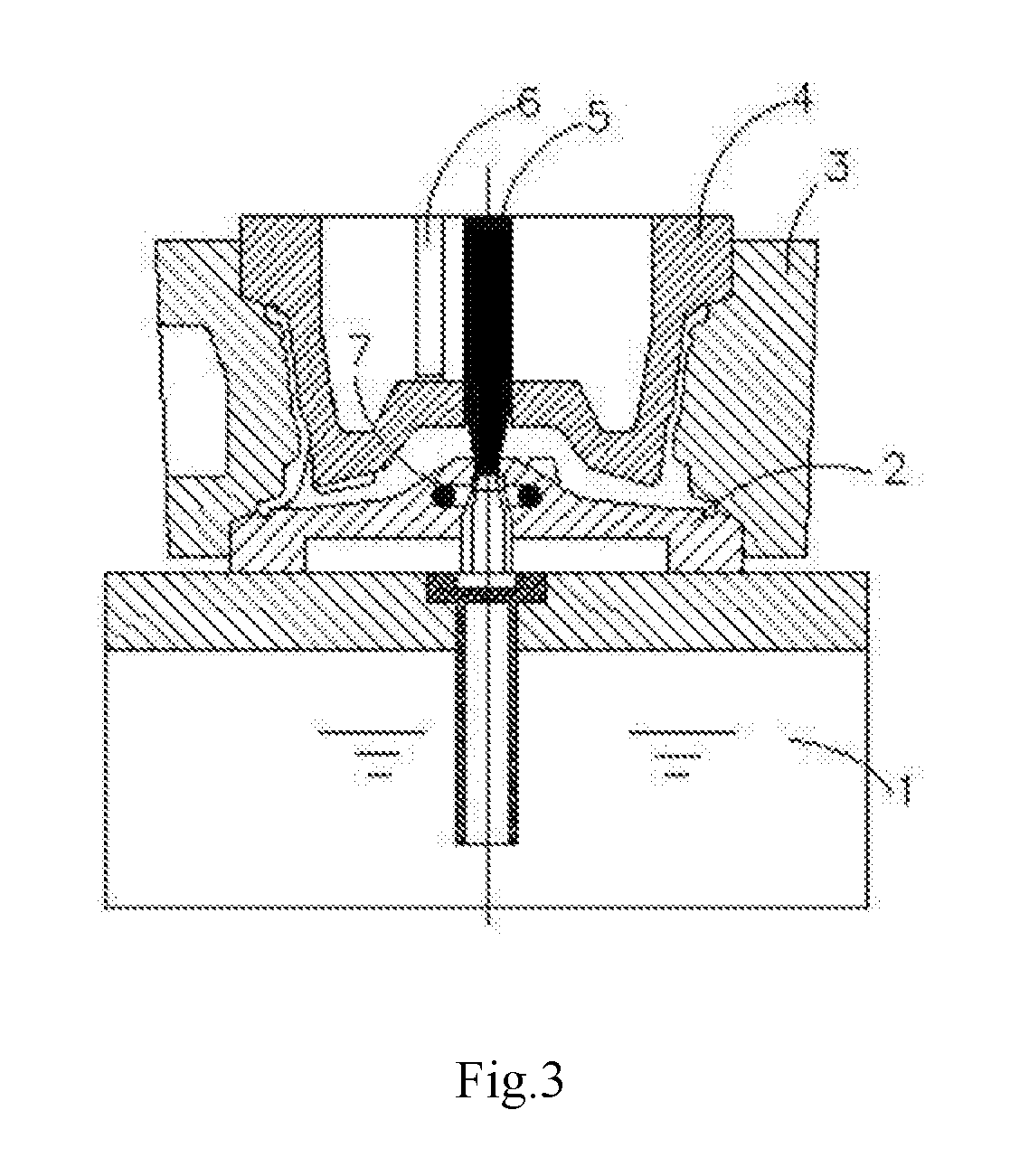

Method for performing a hydroforming operation

A method for performing a hydroforming operation on a hollow workpiece includes the initial step of filling the interior of the workpiece with a hydroforming fluid. The pressure exerted by the hydroforming fluid against the interior of the workpiece is below the yield strength of the workpiece so as to not change the shape of the workpiece. Then, first and second die sections of the hydroforming apparatus are closed about the workpiece. The movement of the two die sections causes some mechanical deformation of the workpiece, but the presence of the hydroforming fluid within the workpiece prevents the amount of this mechanical deformation of the hollow workpiece from being undesirably large. Thereafter, the pressure exerted by the hydroforming fluid against the interior of the workpiece is increased to above the yield strength of the workpiece. As a result, the workpiece is deformed into engagement with the first and second die sections of the hydroforming die.

Owner:METALSA SA DE CV

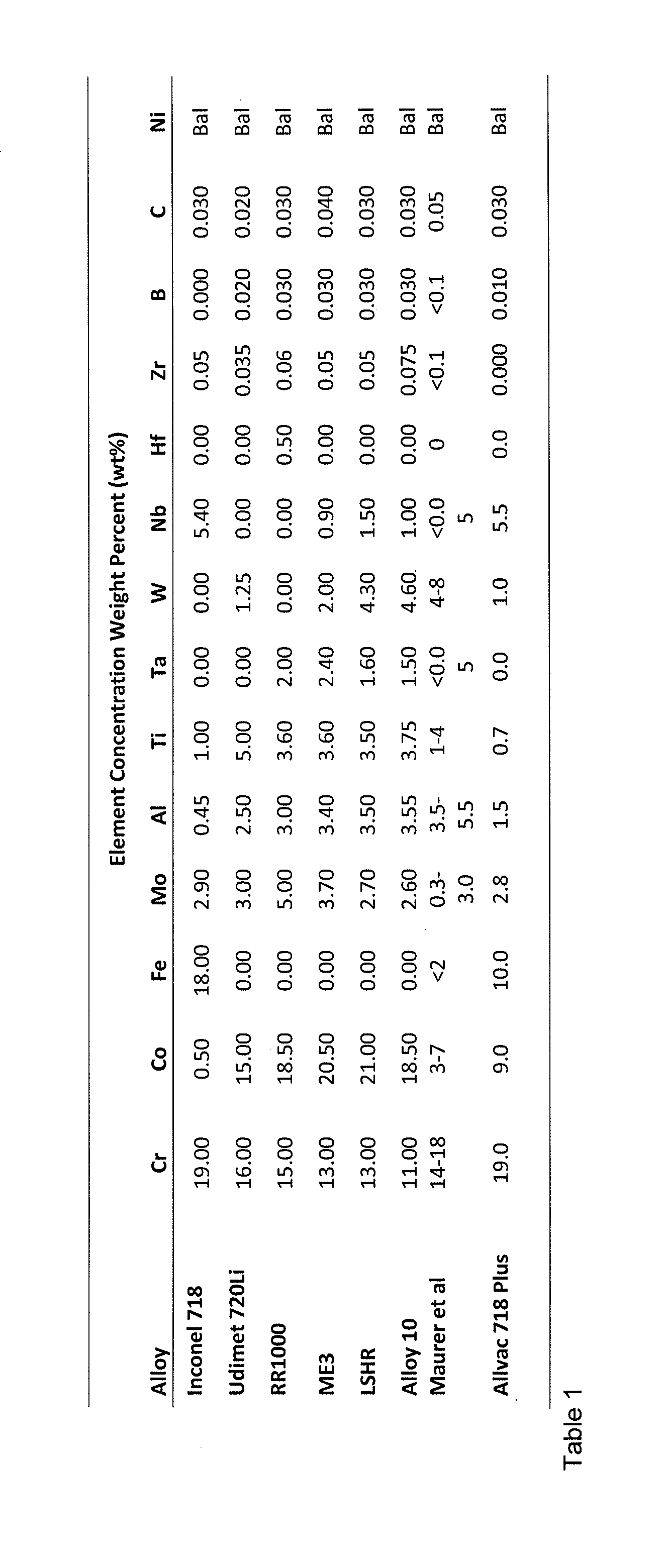

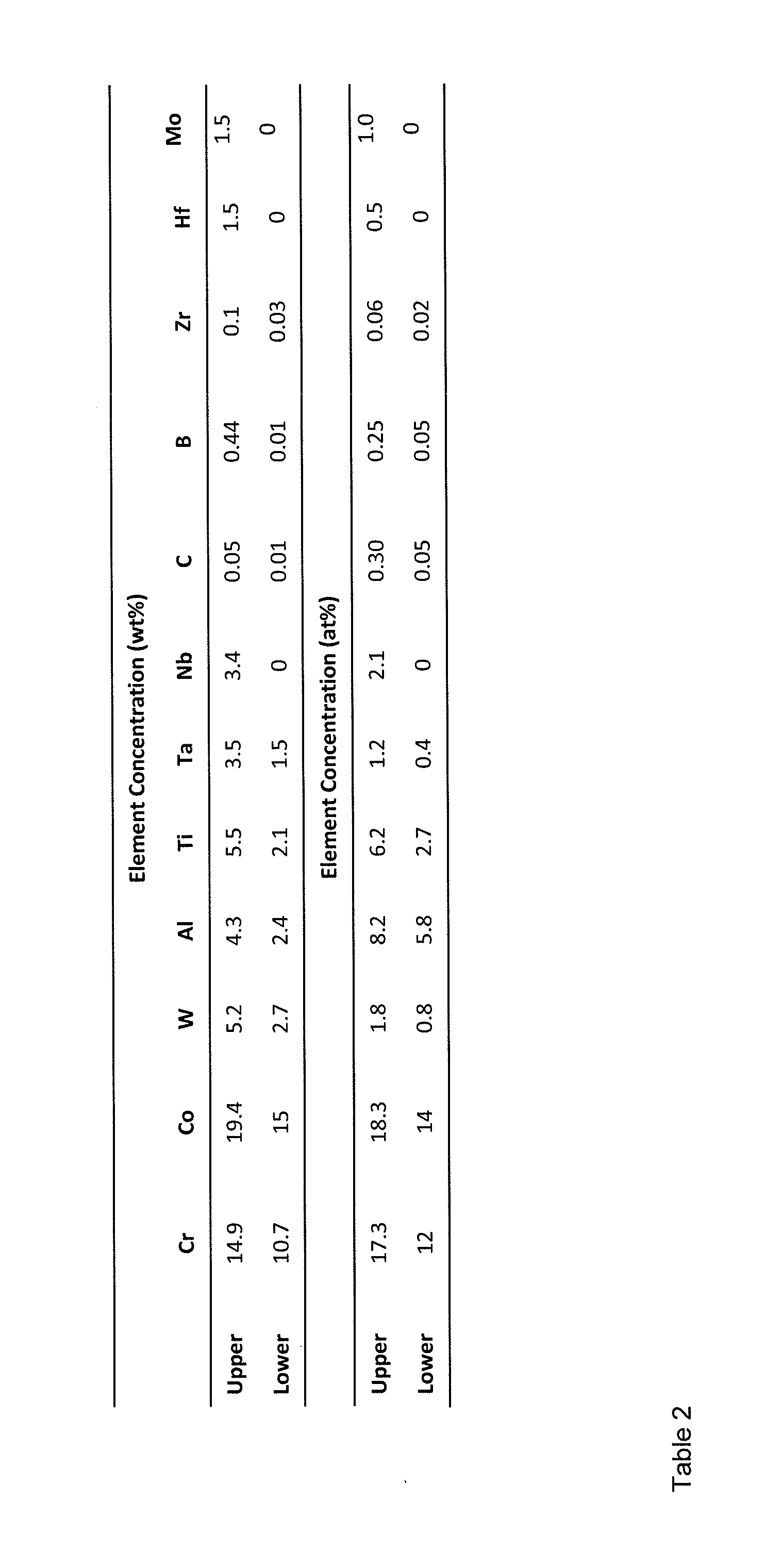

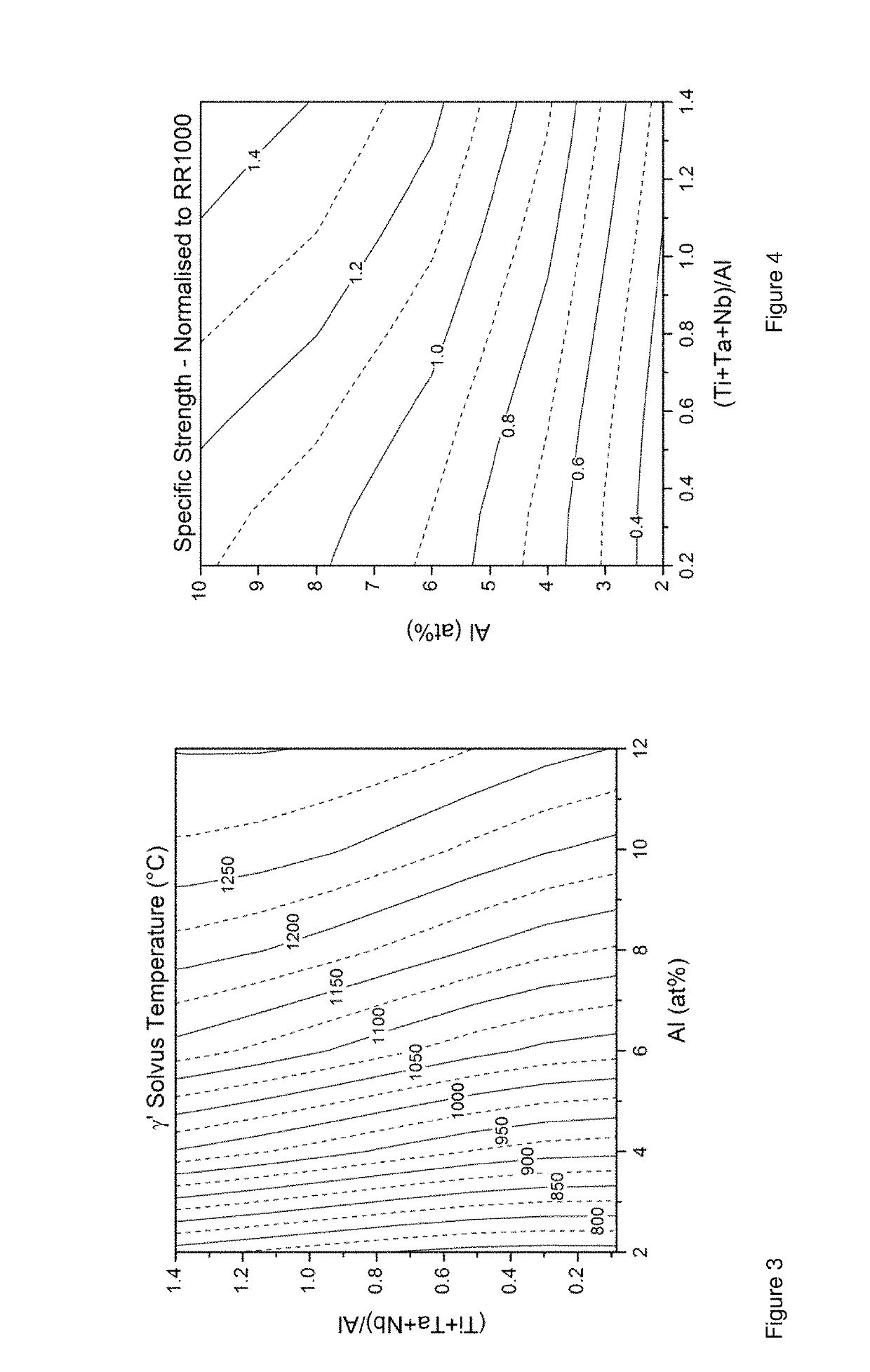

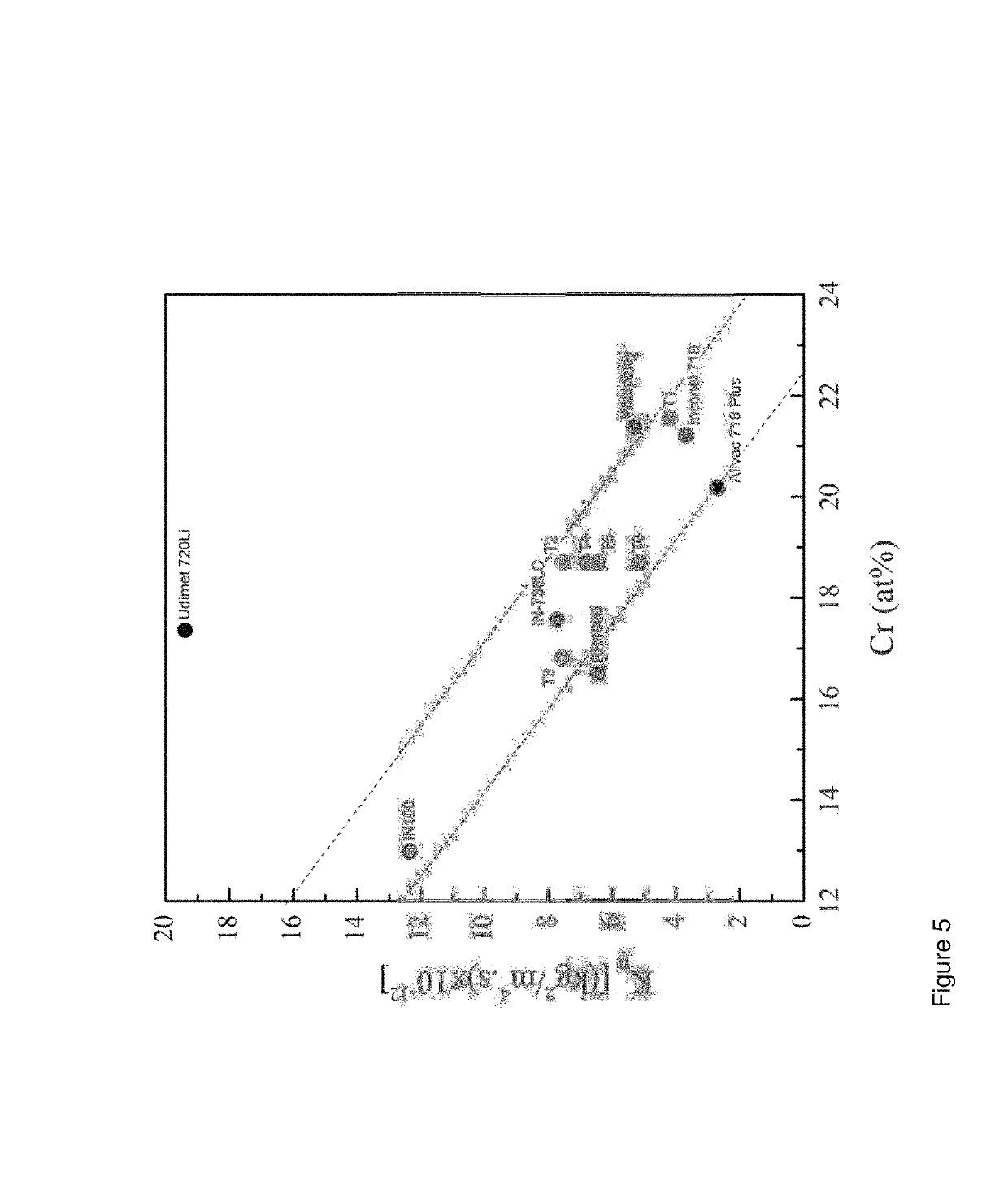

Nickel based alloy composition

A nickel based alloy composition including, by atomic per cent, between 12 and 15% of elements from the group of aluminium, titanium, tantalum and niobium, between 0.8 and 1.8% tungsten, between 5 and 8% aluminium, at least 28% of elements from the group of molybdenum, tungsten, chromium and cobalt, wherein the atomic ratio of the sum of titanium, tantalum and niobium to aluminium is between 0.6 and 1.1, and wherein the composition includes less than 1.5% molybdenum, the balance being nickel save for incidental impurities.

Owner:ROLLS ROYCE PLC

Cu-Ni-Co-Si based copper alloy sheet material and method for producing the same

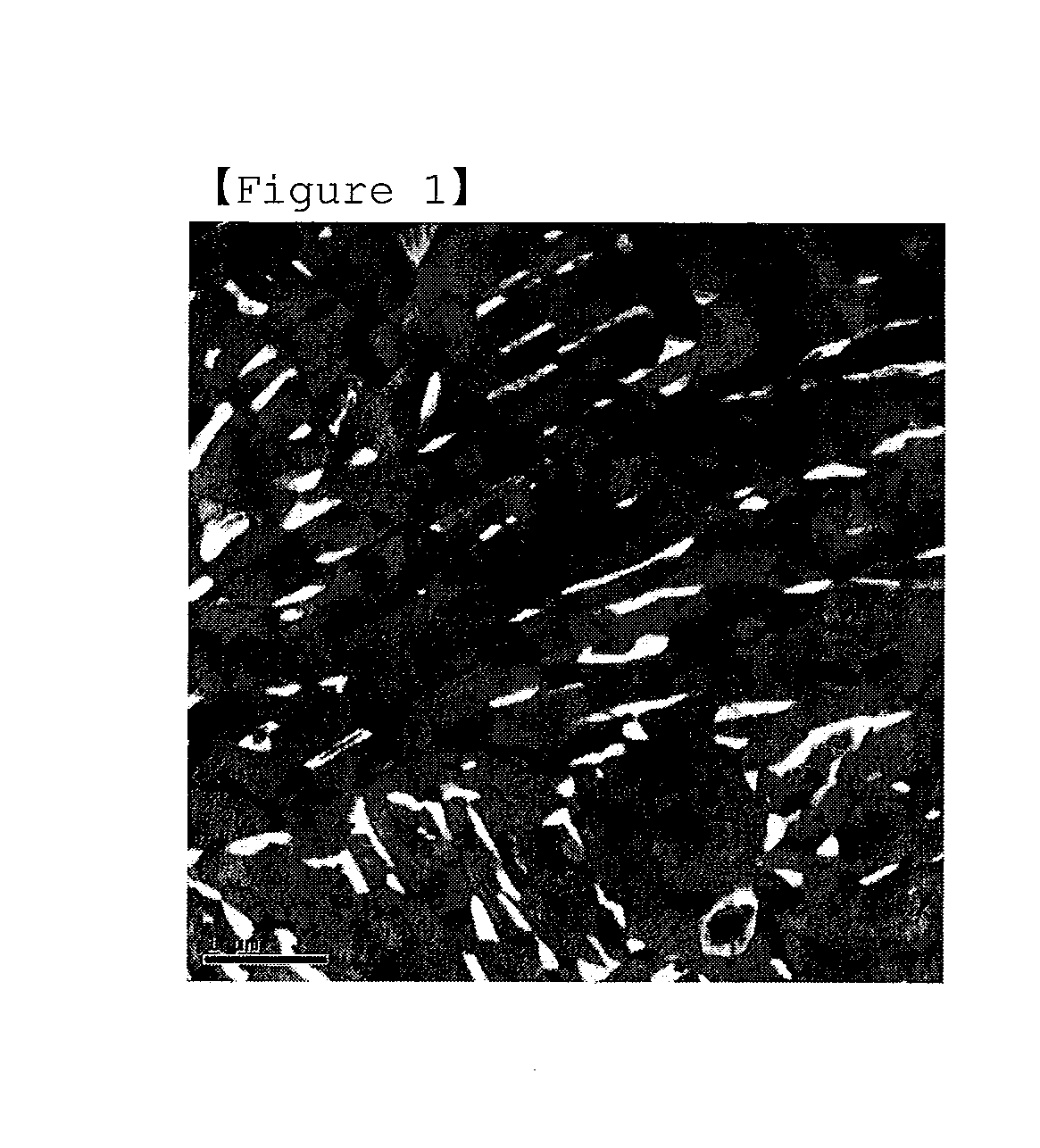

ActiveUS9412482B2Satisfactory bending workabilityBending deflectionConductive materialMetal/alloy conductorsNumber densityCrystal orientation

A Cu—Ni—Co—Si based copper alloy sheet material has second phase particles existing in a matrix, with a number density of ultrafine second phase particles is 1.0×109 number / mm2 or more. A number density of fine second phase particles is not more than 5.0×107 number / mm2. A number density of coarse second phase particles is 1.0×105 number / mm2 or more and not more than 1.0×106 number / mm2. The material has crystal orientation satisfying the following equation (1):I{200} / I0{200}≧3.0 (1)wherein I{200} represents an integrated intensity of an X-ray diffraction peak of the {200} crystal plane on the sheet material sheet surface; and I0{200} represents an integrated intensity of an X-ray diffraction peak of the {200} crystal plane in a pure copper standard powder sample.

Owner:DOWA METALTECH CO LTD

Cu-Ni-Co-Si BASED COPPER ALLOY SHEET MATERIAL AND METHOD FOR PRODUCING THE SAME

ActiveUS20140116583A1High strengthImprove conductivityConductive materialMetal/alloy conductorsNumber densityX-ray

A Cu—Ni—Co—Si based copper alloy sheet material has second phase particles existing in a matrix, with a number density of ultrafine second phase particles is 1.0×109 number / mm2 or more. A number density of fine second phase particles is not more than 5.0×107 number / mm2. A number density of coarse second phase particles is 1.0×105 number / mm2 or more and not more than 1.0×106 number / mm2. The material has crystal orientation satisfying the following equation (1):I{200} / I0{200}≧3.0 (1)wherein I{200} represents an integrated intensity of an X-ray diffraction peak of the {200} crystal plane on the sheet material sheet surface; and I0{200} represents an integrated intensity of an X-ray diffraction peak of the {200} crystal plane in a pure copper standard powder sample.

Owner:DOWA METALTECH CO LTD

Method for performing a hydroforming operation

A method for performing a hydroforming operation on a hollow workpiece includes the initial step of filling the interior of the workpiece with a hydroforming fluid. The pressure exerted by the hydroforming fluid against the interior of the workpiece is below the yield strength of the workpiece so as to not change the shape of the workpiece. Then, first and second die sections of the hydroforming apparatus are closed about the workpiece. The movement of the two die sections causes some mechanical deformation of the workpiece, but the presence of the hydroforming fluid within the workpiece prevents the amount of this mechanical deformation of the hollow workpiece from being undesirably large. Thereafter, the pressure exerted by the hydroforming fluid against the interior of the workpiece is increased to above the yield strength of the workpiece. As a result, the workpiece is deformed into engagement with the first and second die sections of the hydroforming die.

Owner:METALSA SA DE CV

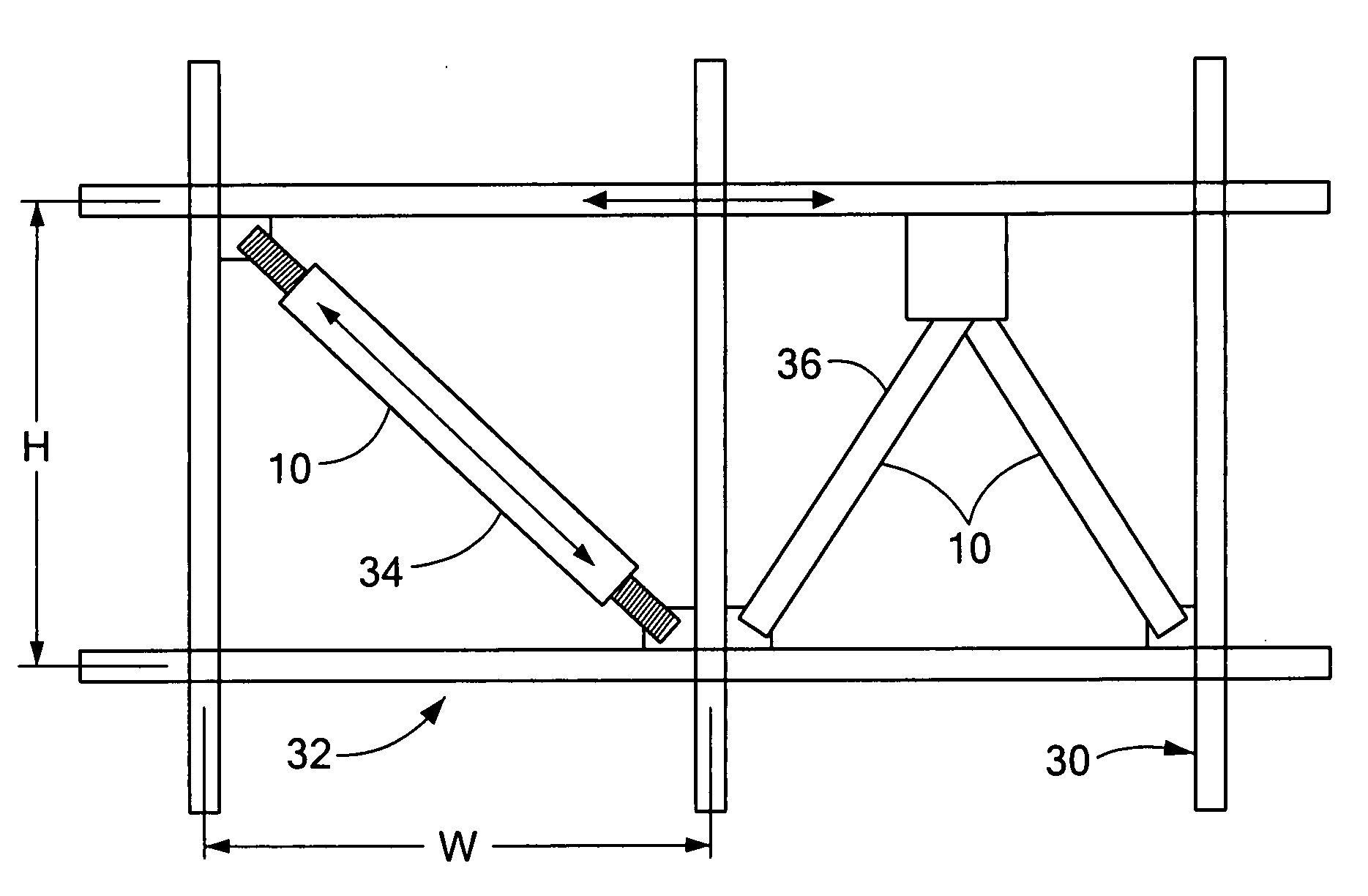

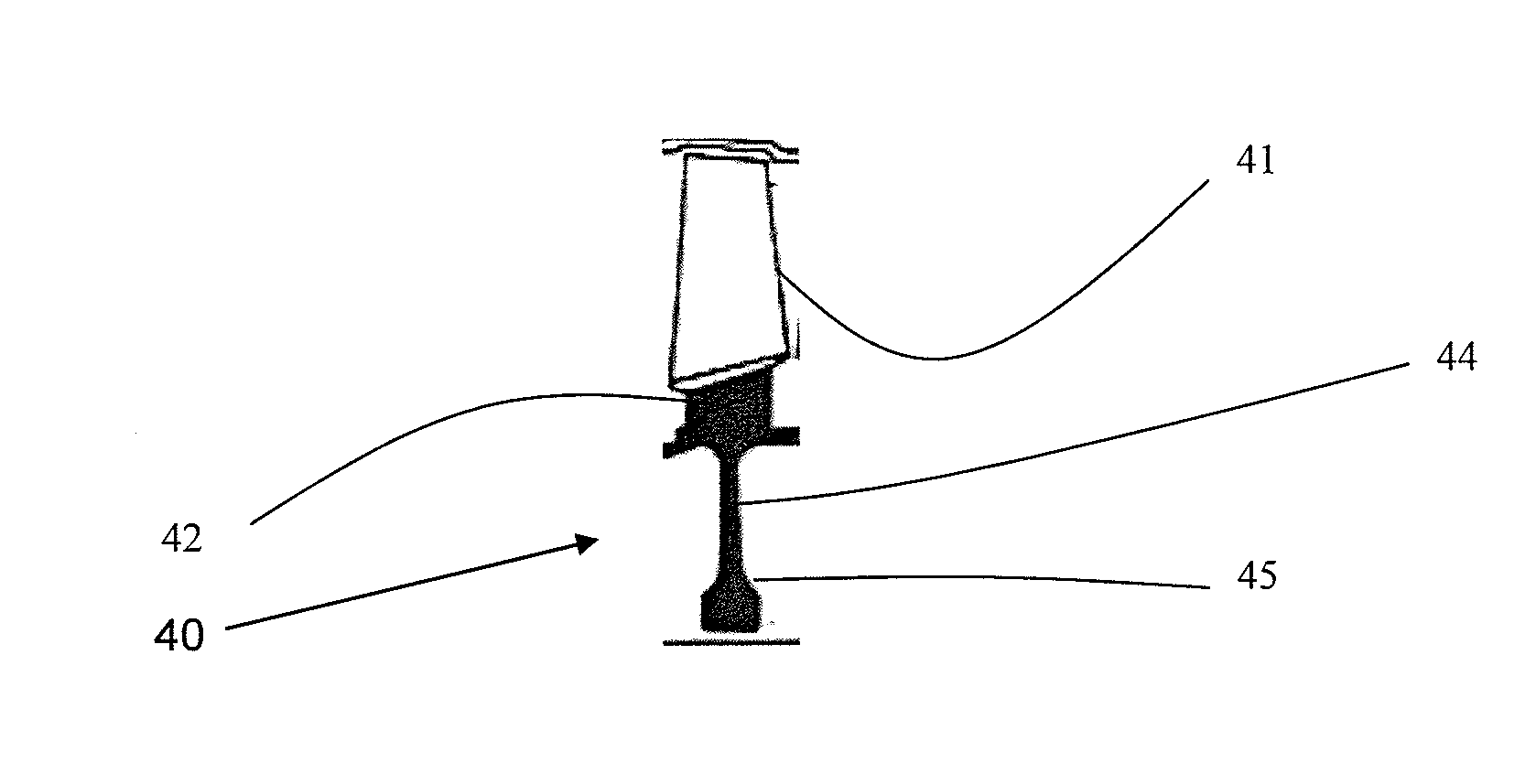

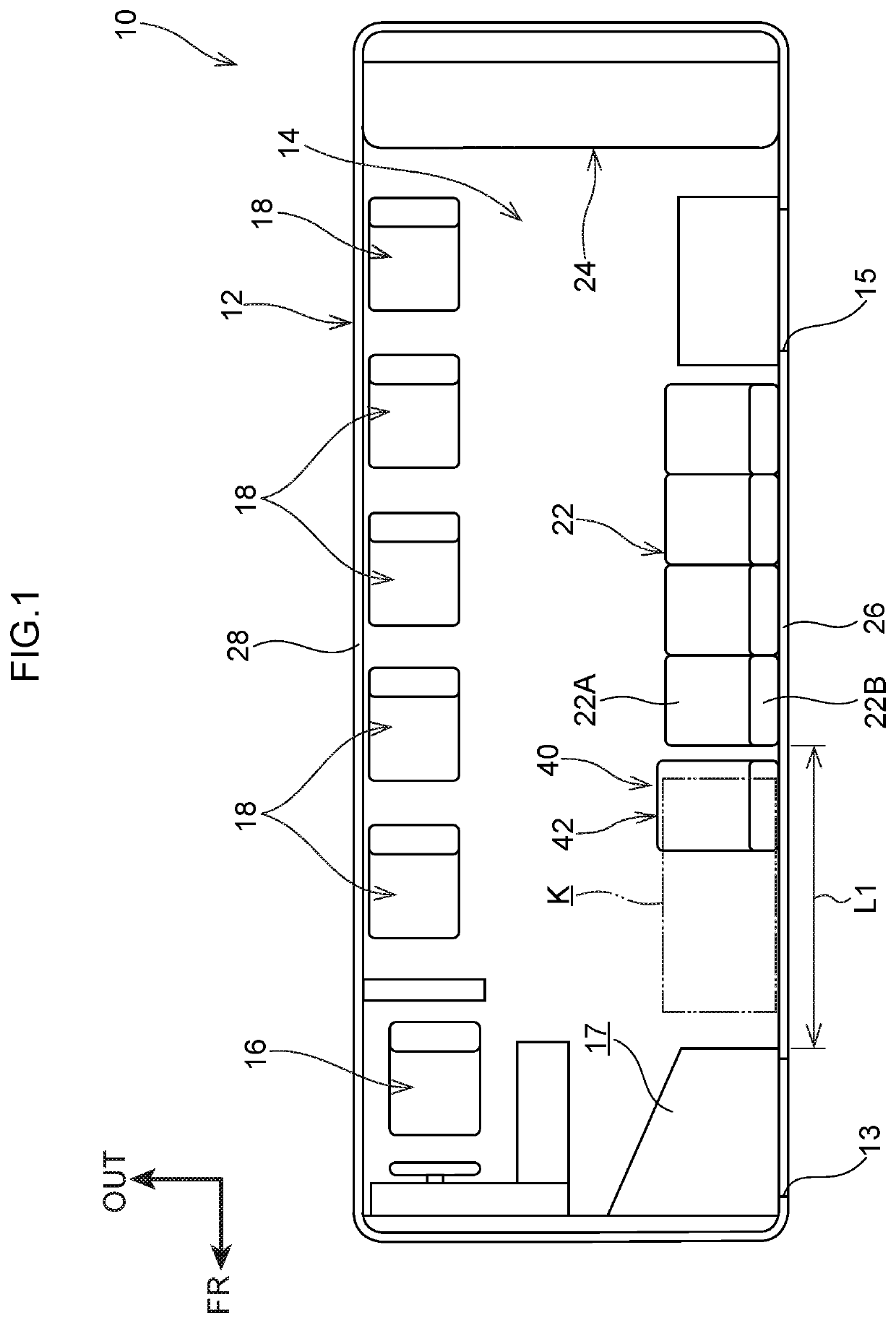

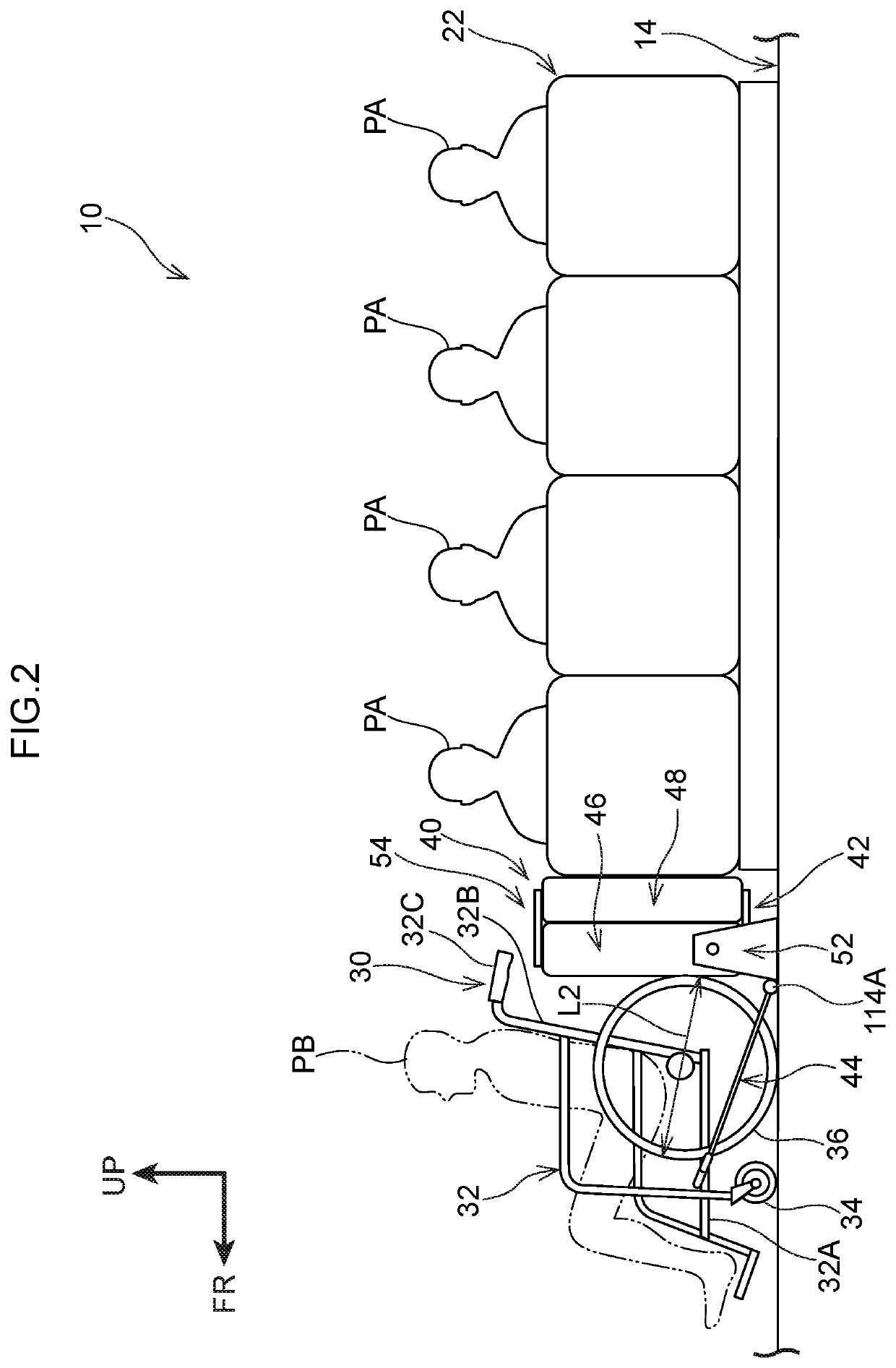

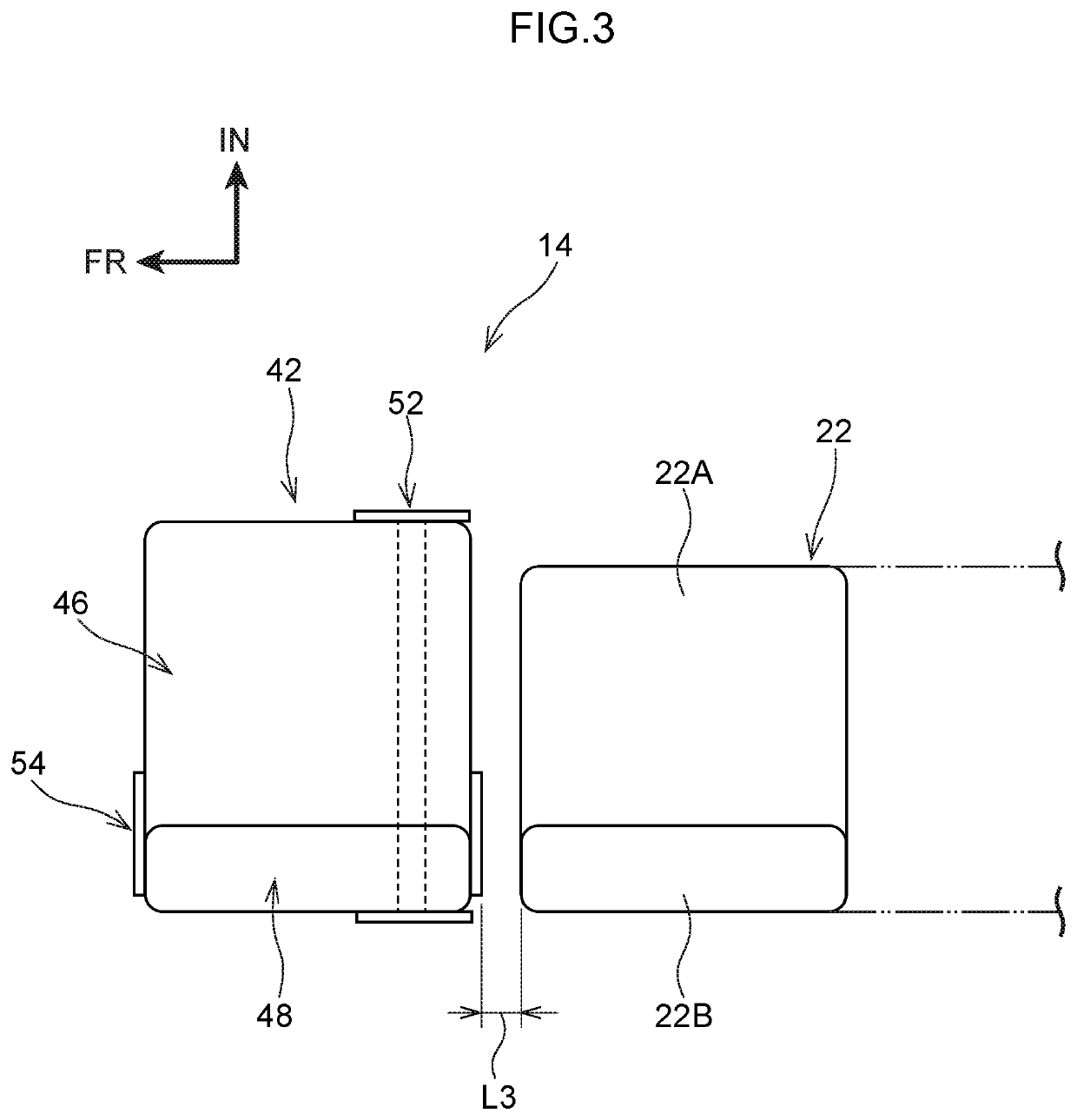

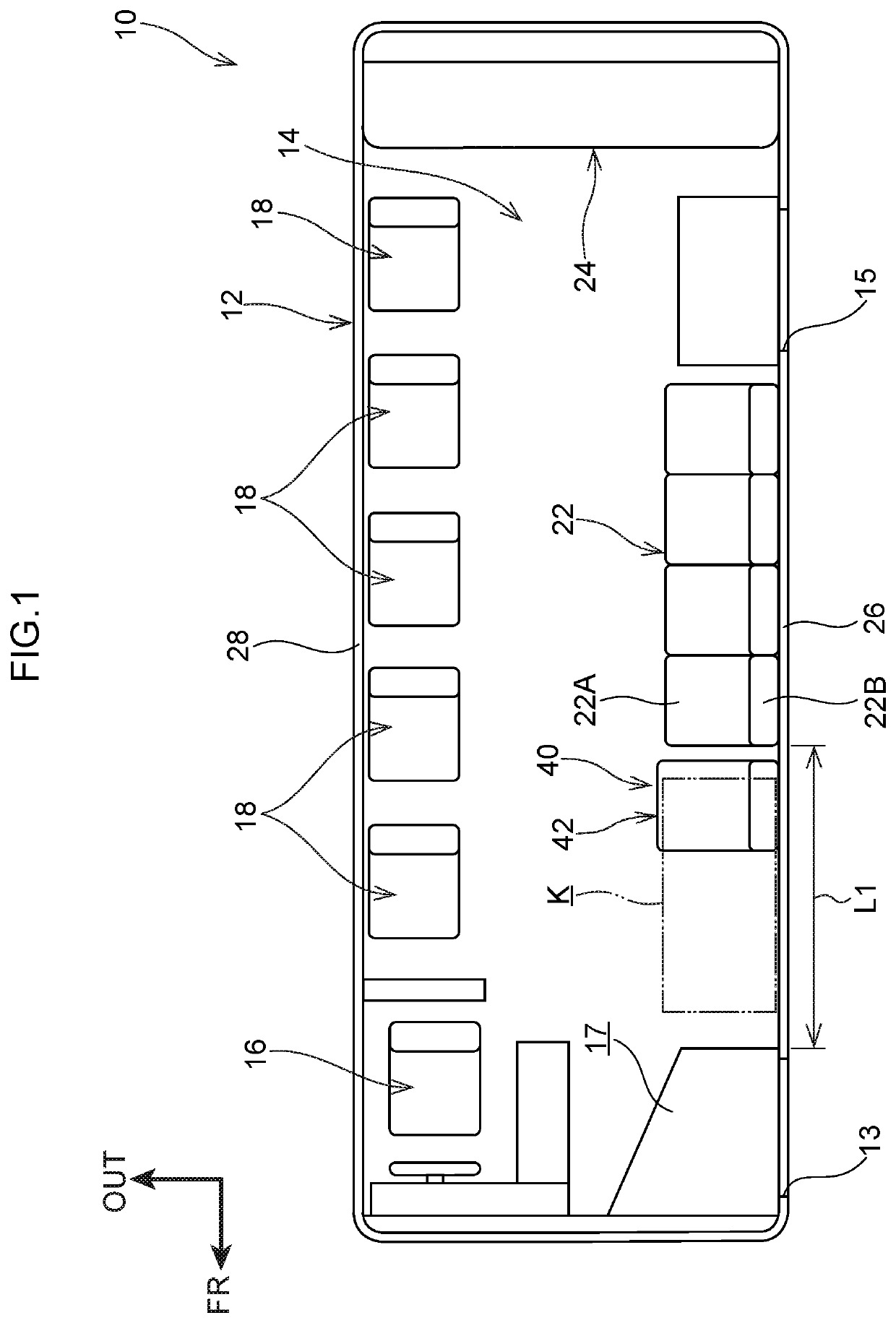

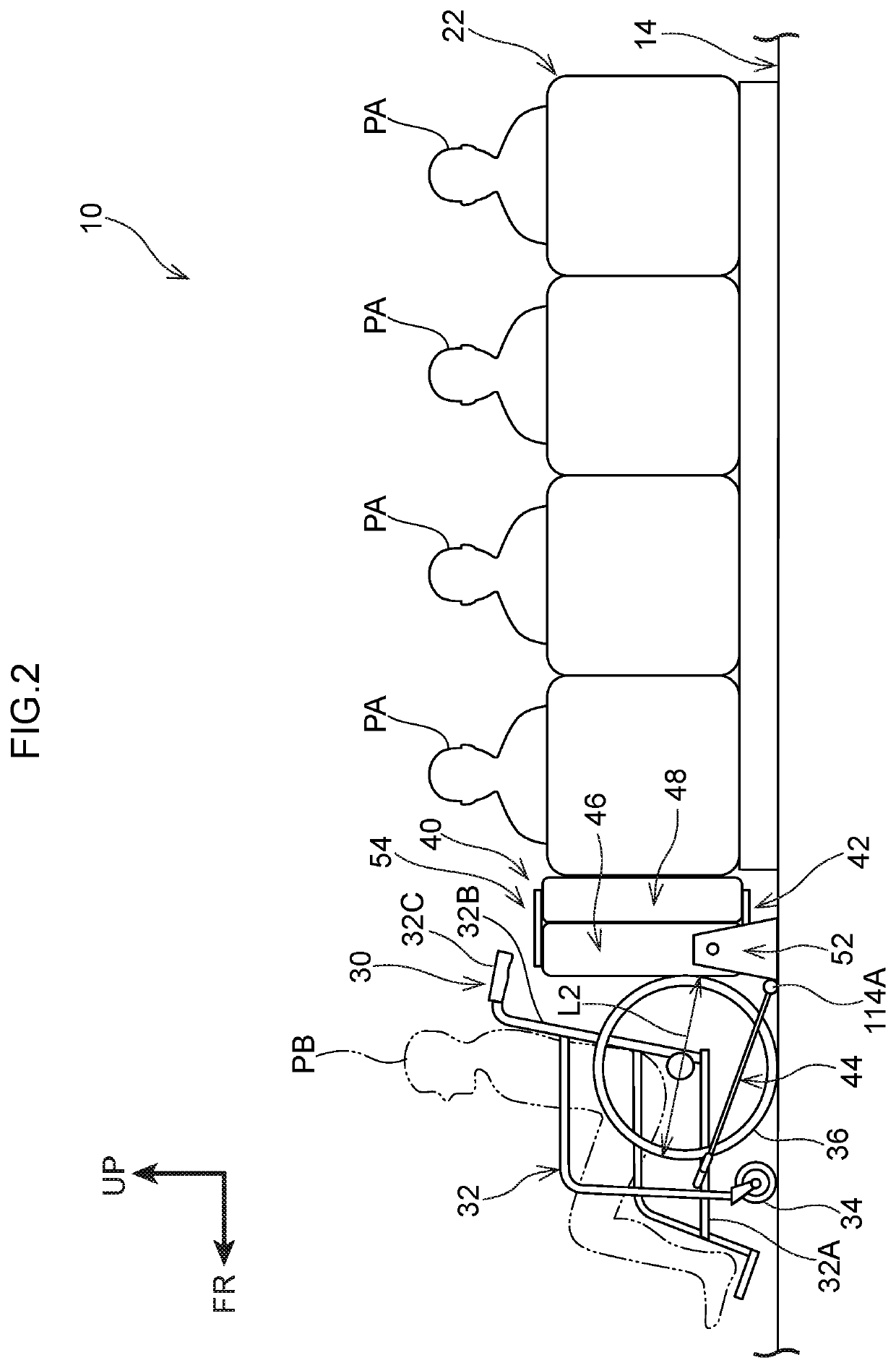

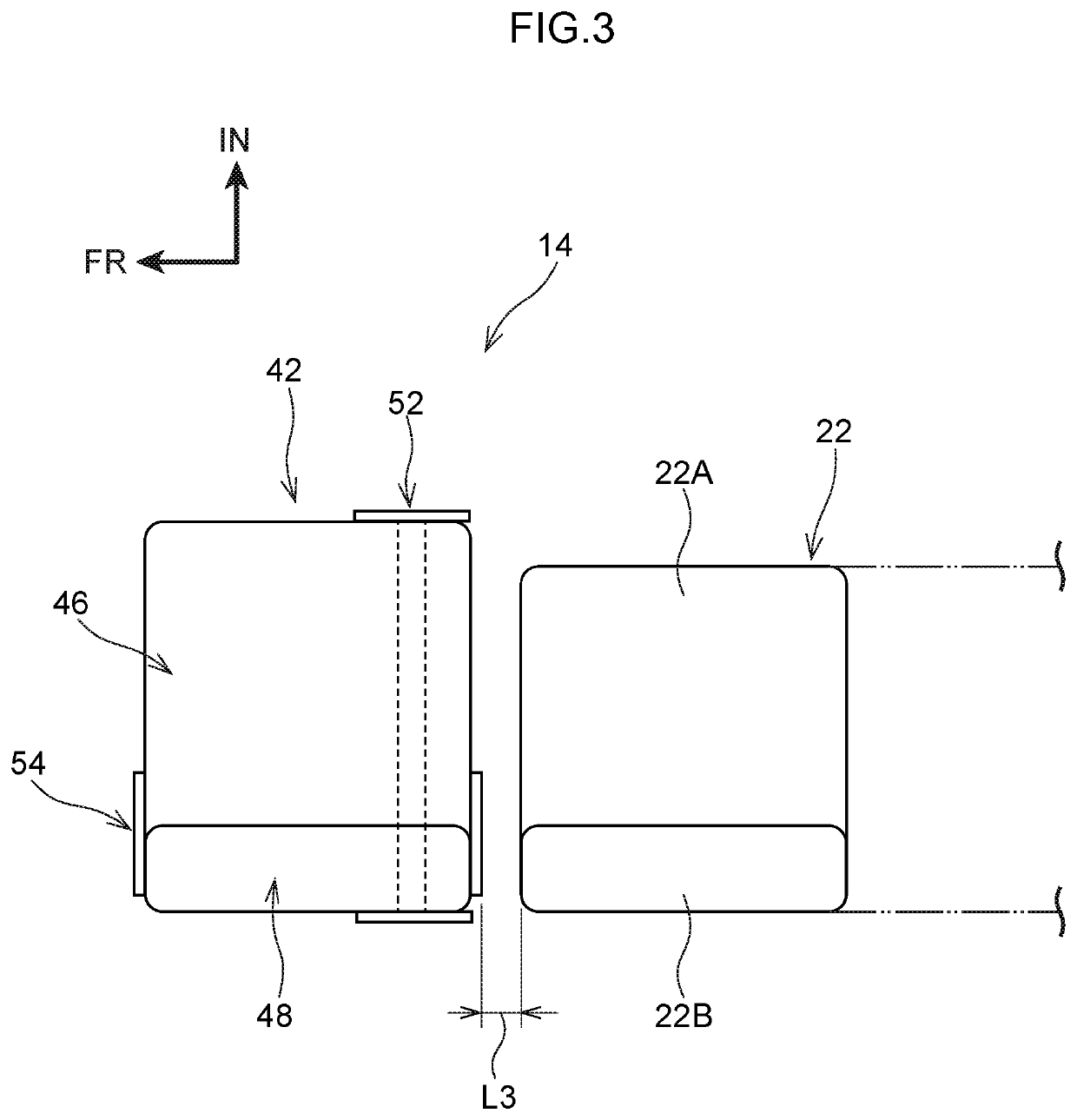

Vehicle

A fixing structure 40 has an inwardly-facing seat 22, a front side seat 42, and fixing members 44. The inwardly-facing seat 22 is fixed to a floor portion 14 such that passengers PA face in a vehicle transverse direction. The front side seat 42 has a seat cushion 46 on which the passenger PA sits, and a supporting member 52, and is disposed at the floor portion 14 at a vehicle longitudinal direction front side of the inwardly-facing seat 22, and rear wheels 36 can contact the seat cushion 46 in a vehicle longitudinal direction. The supporting member 52 supports the seat cushion 46 such that the seat cushion 46 can rotate toward the inwardly-facing seat 22. The fixing members 44 fix a wheelchair 30 to the floor portion 14 in a state in which the rear wheels 36 are made to contact the front side seat 42.

Owner:TOYOTA JIDOSHA KK

Rheology modifier polymer

ActiveUS8784786B2Yield strengthImprove toleranceCosmetic preparationsBiocidePersonal carePolymer chemistry

Owner:SPECIALTY OPERATIONS FRANCE

Water sensor with activation mechanism

ActiveUS8464744B1Sufficient strengthYield strengthOperating means/releasing devices for valvesOther washing machinesRefrigerator carRefrigerated temperature

A water sensor and activation assembly including a paper element to sense the presence of water leaks from appliances such as clothes washing machines, refrigerator ice makers and the like, and to cause an associated water shutoff valve to turn off the source of water leakage. The water sensor, in conjunction with the shutoff valve, operates without any electrical power requirement. The design allows the water sensor to operate in a high humidity environment.

Owner:FRLIN ROBERT C

Tempered martensitic steel having low yield ratio and excelllent uniform elongation, and manufacturing method therefor

PendingUS20190382864A1Low yield ratioReduce weightFurnace typesHeat treatment furnacesYield ratioFerric

Provided is a tempered martensitic steel having a low yield ratio and an excellent uniform elongation, the tempered martensitic steel: comprising, by wt %, 0.2-0.6% of C, 0.01-2.2% of Si, 0.5-3.0% of Mn, 0.015% or less of P, 0.005% or less of S, 0.01-0.1% of Al, 0.01-0.1% of Ti, 0.05-0.5% of Cr, 0.0005-0.005% of B, 0.05-0.5% of Mo, 0.01% or less of N, and the balance of Fe and inevitable impurities; having a yield ratio of 0.4-0.6; having a product (TS*U-El), of a tensile strength and a uniform elongation, of 10,000 MPa % or more; and having a microstructure containing, by an area fraction, 90% or more of tempered martensite, 5% or less of ferrite and the balance of bainite.

Owner:POHANG IRON & STEEL CO LTD

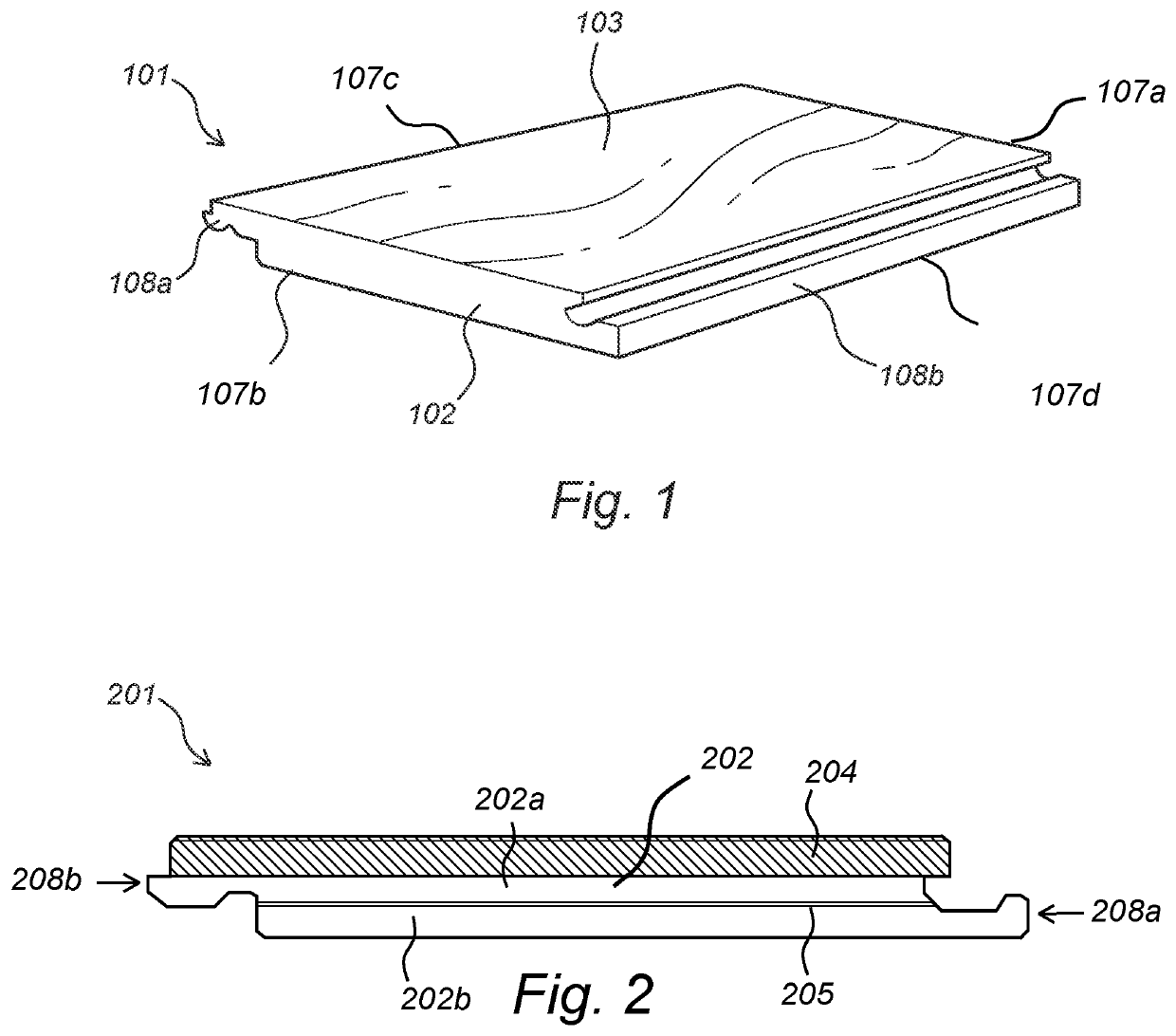

Splicing device for closing a looped material band and material band provided with such splicing device

ActiveUS20150345588A1Easy to manufactureYield strengthConveyorsV-beltsEngineeringMechanical engineering

Owner:TANALS S

Floor panel and method of manufacturing a floor panel

ActiveUS11097512B1Increase flexibilityHigh strengthCovering/liningsWallsPanellingUltimate tensile strength

Owner:CHAMPION LINK INT

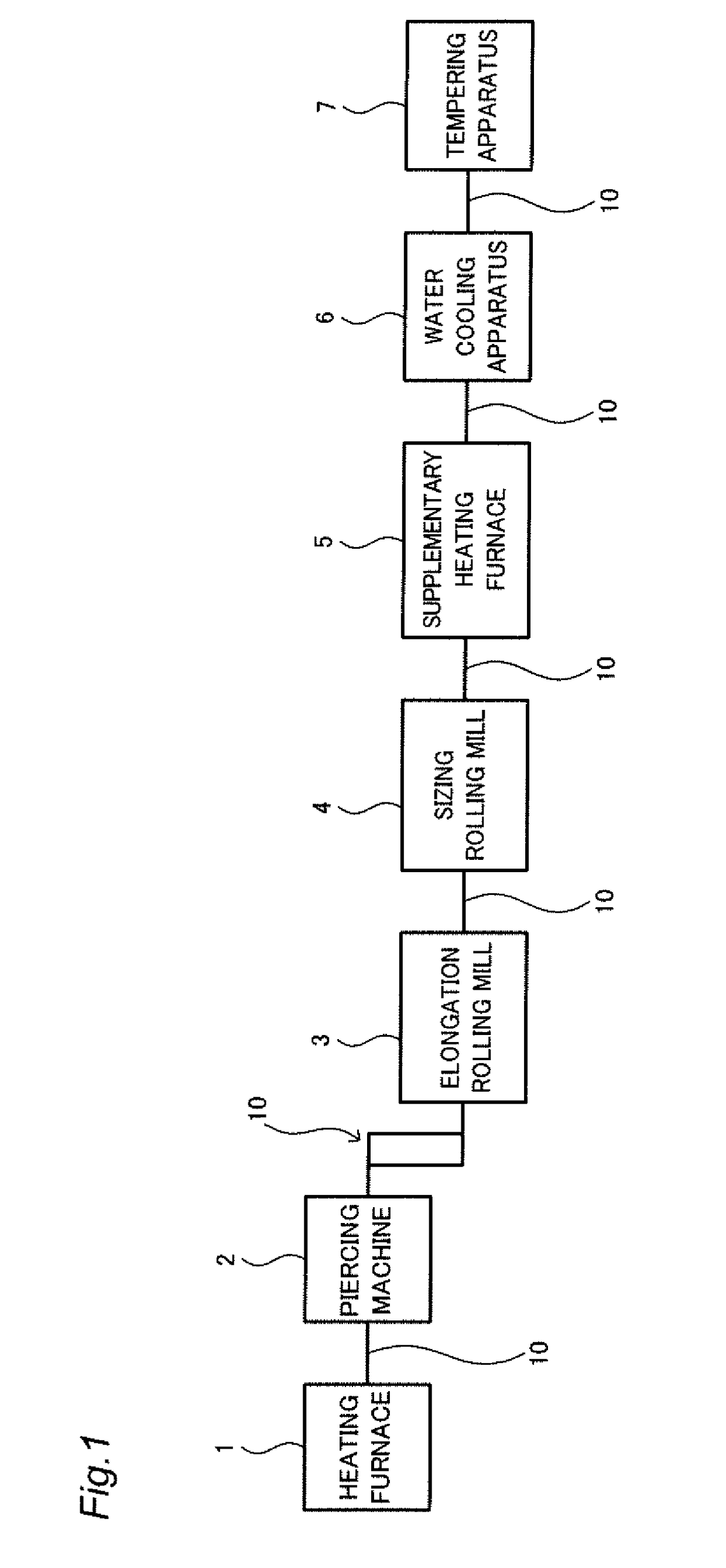

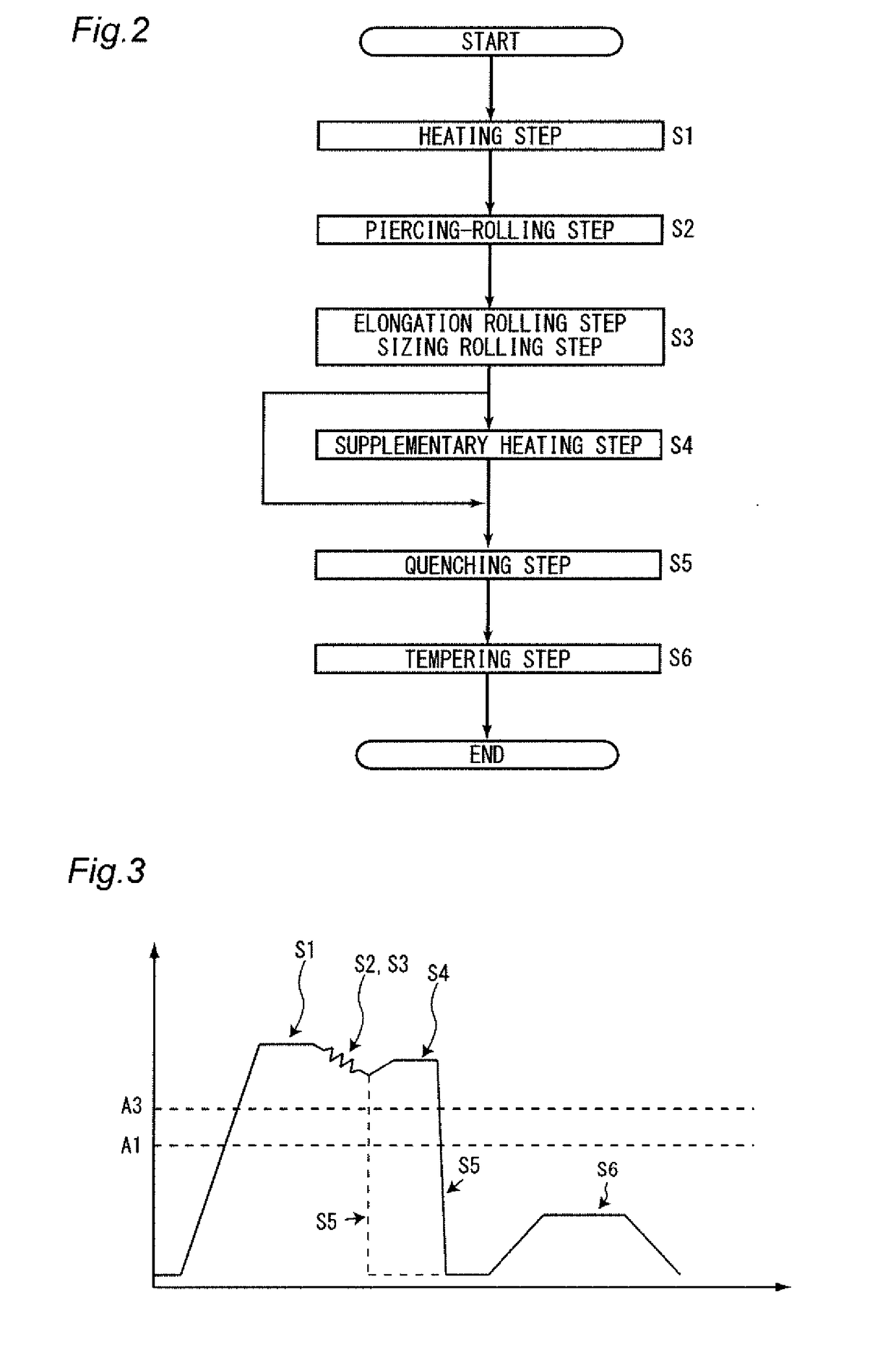

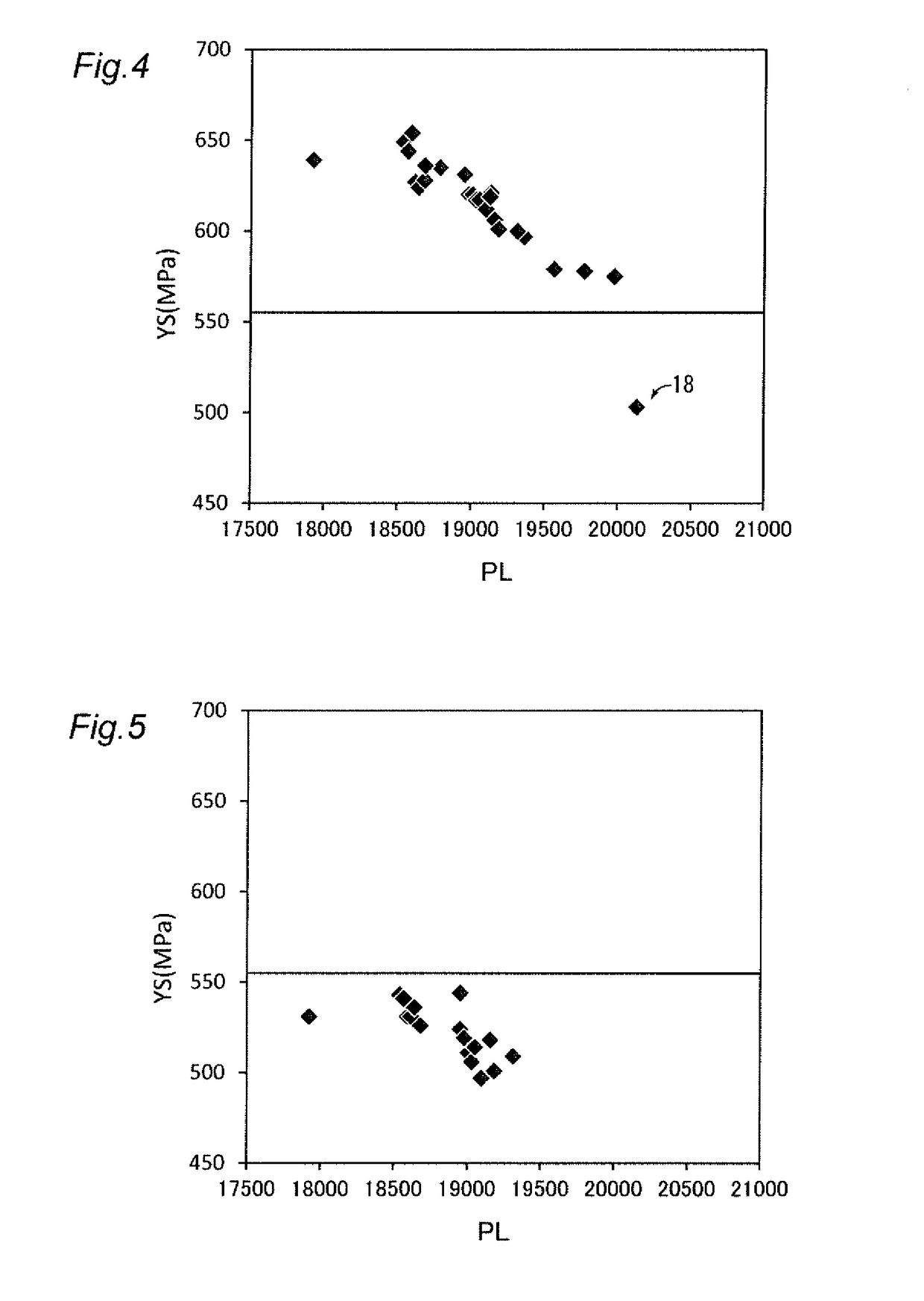

Seamless steel pipe and method of manufacturing the same

InactiveUS20180355451A1High strengthImprove toughnessFurnace typesHeat treatment furnacesAustenite grainBainite

A seamless steel pipe contains, (mass %), C: 0.02 to 0.15%; Si: 0.05 to 0.5%; Mn: 0.30 to 2.5%; Al: 0.01 to 0.10%; Ti: 0.001 to 0.010%; N: up to 0.007%; Cr: 0.05 to 1.0%; Mo: not less than 0.02% and less than 0.5%; Ni: 0.03 to 1.0%; Cu: 0.02 to 1.0%; V: 0.020 to 0.20%; Ca: 0.0005 to 0.005%; and Nb: 0 to 0.05%, where carbon equivalent is not less than 0.430% and less than 0.500%, the microstructure main phase from the surface to an in-the-wall portion is tempered martensite or tempered bainite, prior austenite grain size is lower than 6.0, a portion between 1 mm from the inner surface and 1 mm from the outer surface has Vickers hardness of 250 Hv or lower, and yield strength is 555 MPa or higher.

Owner:NIPPON STEEL CORP

High-strength steel material having outstanding ultra-low-temperature toughness and a production method therefor

ActiveUS9394579B2Improve low temperature toughnessYield strengthHeat treatment process controlManganeseImpurity

The present invention provides steel containing manganese and nickel that is used as a structural material for a cryogenic storage container for liquefied natural gas (LNG) or the like, and a manufacturing method thereof; and more particularly, to steel having good cryogenic temperature toughness and also high strength by adding low-cost Mn instead of relatively expensive Ni at an optimized ratio, refining a microstructure through controlled rolling and cooling, and precipitating retained austenite through tempering, and a manufacturing method of the steel. To achieve the object, the technical feature of the present invention is a method of manufacturing high-strength steel with cryogenic temperature toughness. In the method, a steel slab is heated to a temperature within a range of 1,000 to 1,250° C., wherein the steel slab includes, by weight: 0.01-0.06% of carbon (C), 2.0-8.0% of manganese (Mn), 0.01-6.0% of nickel (Ni), 0.02-0.6% of molybdenum (Mo), 0.03-0.5% of silicon (Si), 0.003-0.05% of aluminum (Al), 0.0015-0.01% of nitrogen (N), 0.02% or less of phosphorous (P), 0.01% or less of sulfur (S), with a remainder of iron (Fe) and other unavoidable impurities. Then, the heated slab is finish-rolled at a temperature of 950° C. or less at a rolling reduction rate of 40% or more. The rolled steel is cooled to a temperature of 400° C. or less at a cooling rate of 2° C. / s or more. Thereafter, the steel is tempered for 0.5-4 hours to a temperature within a range of 550 to 650° C. after the cooling.

Owner:POHANG IRON & STEEL CO LTD

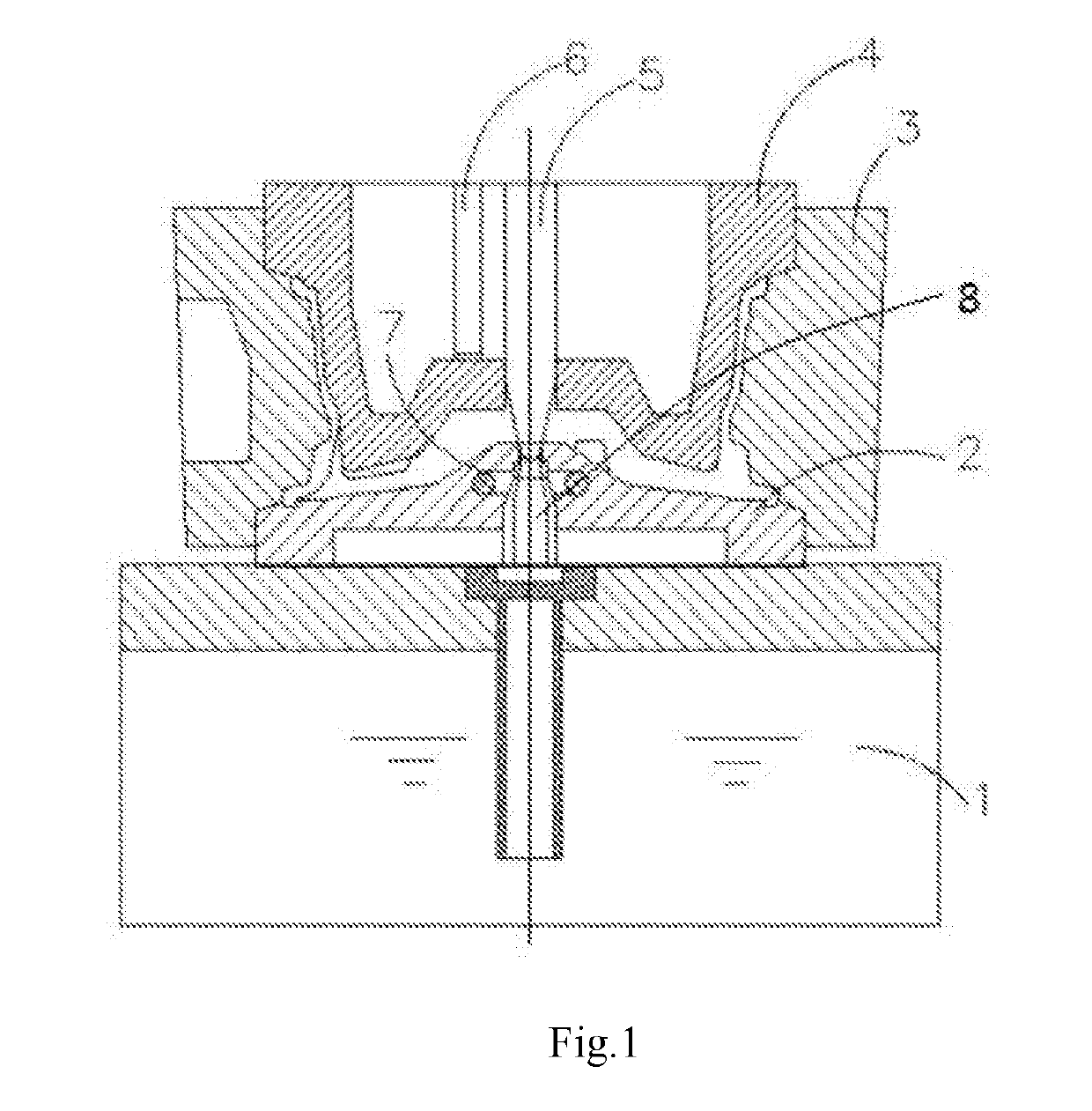

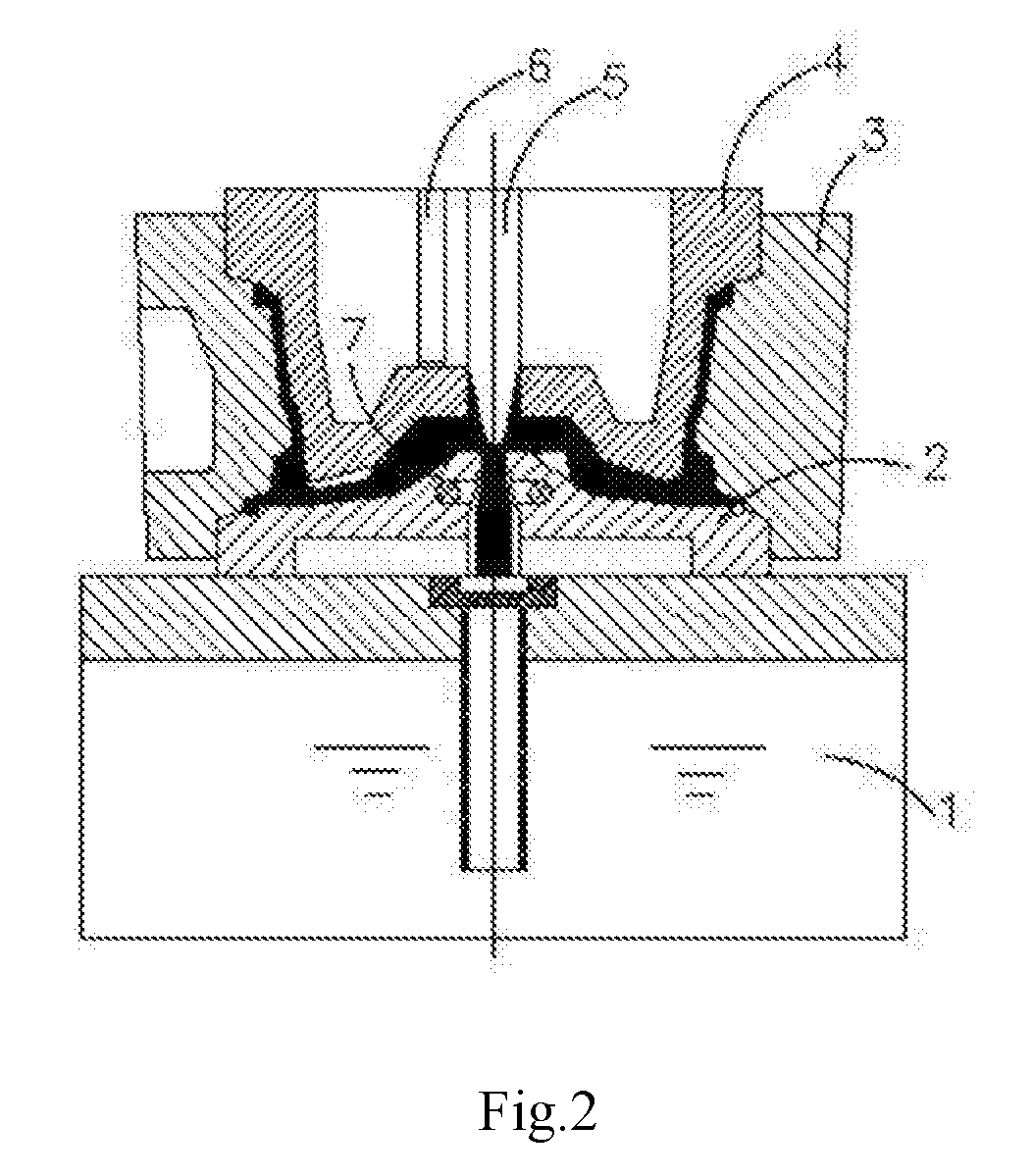

Low-pressure casting secondary pressure process for aluminum wheel

ActiveUS20190283124A1High strengthShorten holding timeFoundry mouldsFoundry coresWater coolingMechanical property

The present application discloses a low-pressure casting secondary pressure process for an aluminum wheel. The characteristics of smooth low-pressure filling of molten aluminum alloy and rapid solidification of a rim are preserved, the aluminum alloy at a center sprue is frozen by using a center sprue spreader and a forced water coolling to close a mold cavity, and secondary pressure is implemented to the aluminum wheel by means of down-movement of center extrusion rods, so that the material mechanical properties of an aluminum wheel casting and the production efficiency of the casting process are improved.

Owner:CITIC DICASTAL

Nickel based alloy composition

ActiveUS10309229B2High strengthResistant to environmentalBlade accessoriesMachines/enginesNiobiumTitanium

A nickel based alloy composition including, by atomic per cent, between 12 and 15% of elements from the group of aluminium, titanium, tantalum and niobium, between 0.8 and 1.8% tungsten, between 5 and 8% aluminium, at least 28% of elements from the group of molybdenum, tungsten, chromium and cobalt, wherein the atomic ratio of the sum of titanium, tantalum and niobium to aluminium is between 0.6 and 1.1, and wherein the composition includes less than 1.5% molybdenum, the balance being nickel save for incidental impurities.

Owner:ROLLS ROYCE PLC

Vehicle

A fixing structure 40 has an inwardly-facing seat 22, a front side seat 42, and fixing members 44. The inwardly-facing seat 22 is fixed to a floor portion 14 such that passengers PA face in a vehicle transverse direction. The front side seat 42 has a seat cushion 46 on which the passenger PA sits, and a supporting member 52, and is disposed at the floor portion 14 at a vehicle longitudinal direction front side of the inwardly-facing seat 22, and rear wheels 36 can contact the seat cushion 46 in a vehicle longitudinal direction. The supporting member 52 supports the seat cushion 46 such that the seat cushion 46 can rotate toward the inwardly-facing seat 22. The fixing members 44 fix a wheelchair 30 to the floor portion 14 in a state in which the rear wheels 36 are made to contact the front side seat 42.

Owner:TOYOTA JIDOSHA KK

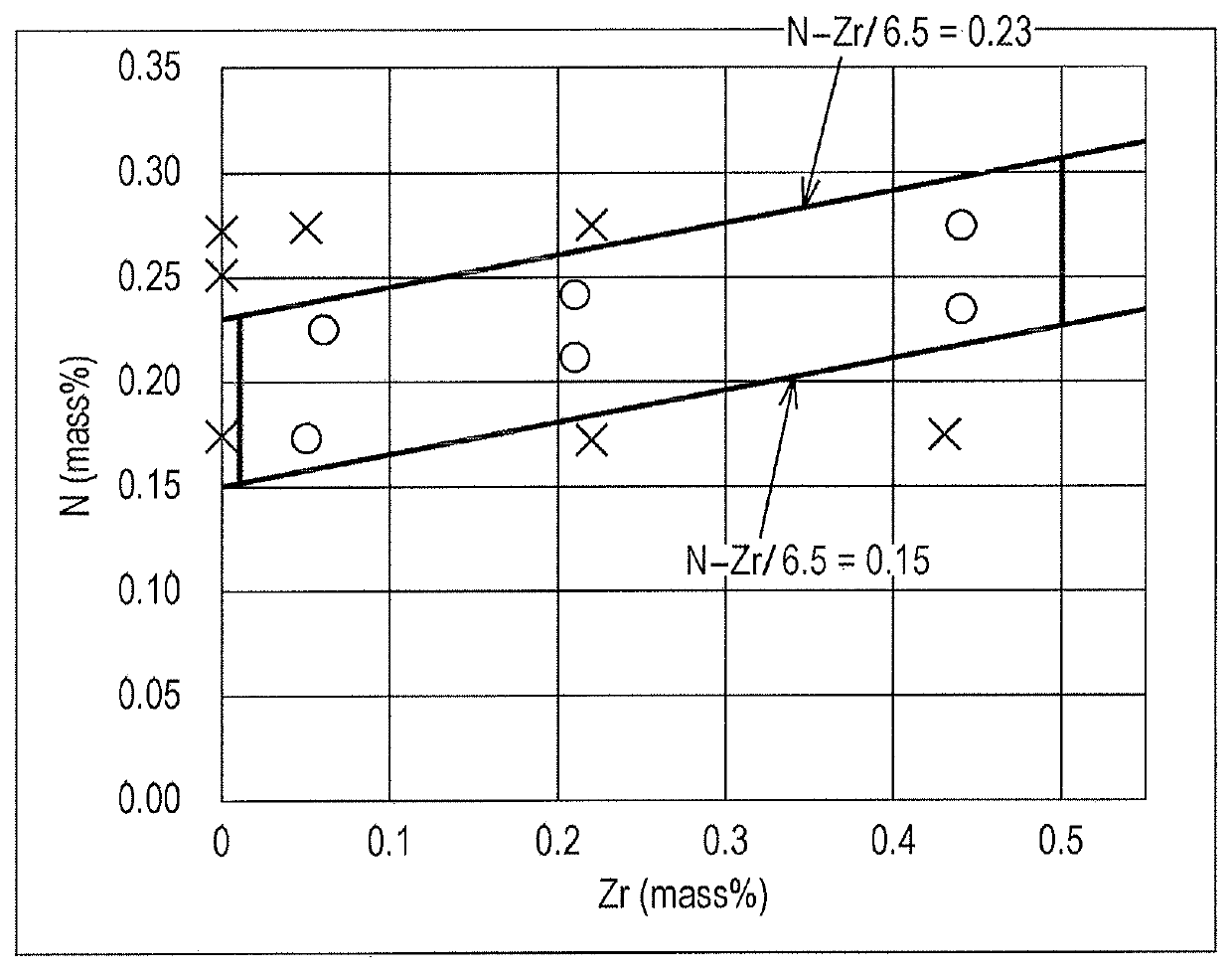

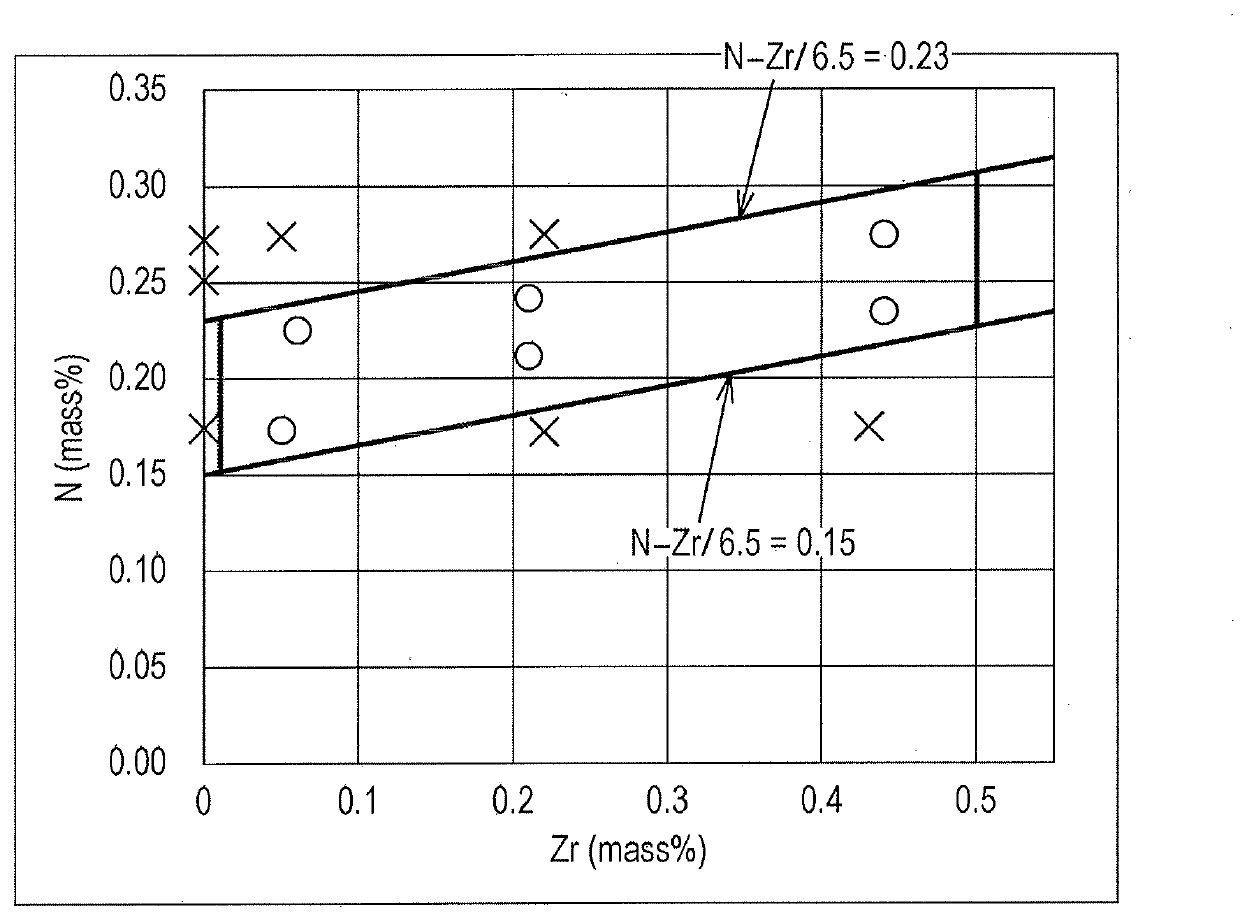

Ferritic-austenitic duplex stainless steel sheet

ActiveUS11142814B2High strengthIncrease the amount of dissolutionFurnace typesHeat treatment furnacesChemical compositionChemical element

Provided is a ferritic-austenitic duplex stainless steel sheet in which no blowholes are formed during welding and which has excellent strength.A chemical composition includes, in mass %, C: 0.10% or less, Si: 1.0% or less, Mn: 2.0 to 7.0%, P: 0.07% or less, S: 0.030% or less, Cr: 18.0 to 24.0%, Ni: 0.1 to 3.0%, Mo: 0.01 to 1.0%, Cu: 0.1 to 3.0%, Al: 0.003 to 0.10%, Zr: 0.01 to 0.50%, and N: 0.15 to 0.30%, with the balance being Fe and incidental impurities, the chemical composition satisfying formula (1) below and formula (2) below.N—Zr / 6.5≥0.15% (1)N—Zr / 6.5≤0.23% (2)Here, in formula (1) and formula (2), N represents a content (mass %) of the corresponding chemical element N and Zr represents a content (mass %) of the corresponding chemical element Zr.

Owner:JFE STEEL CORP

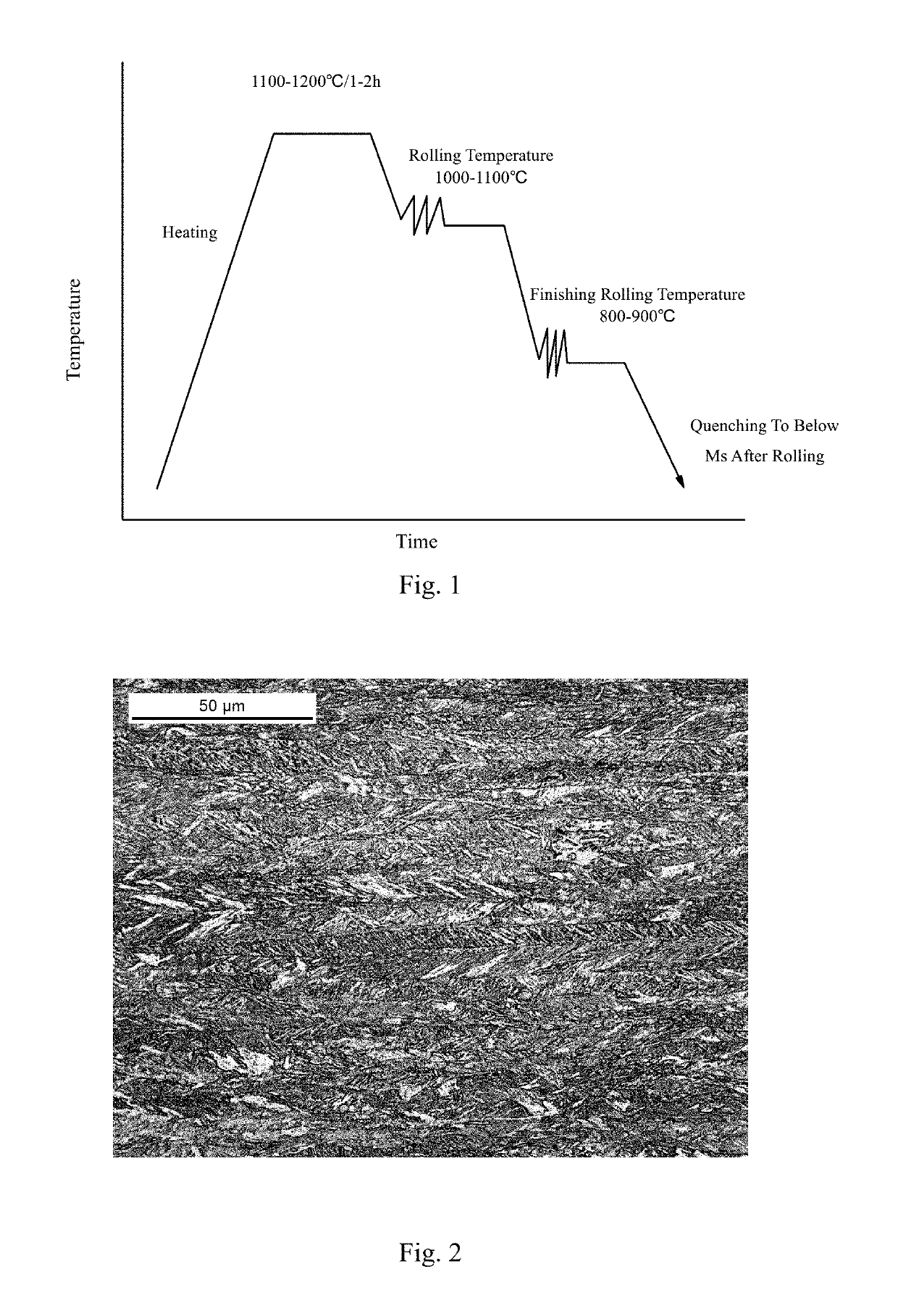

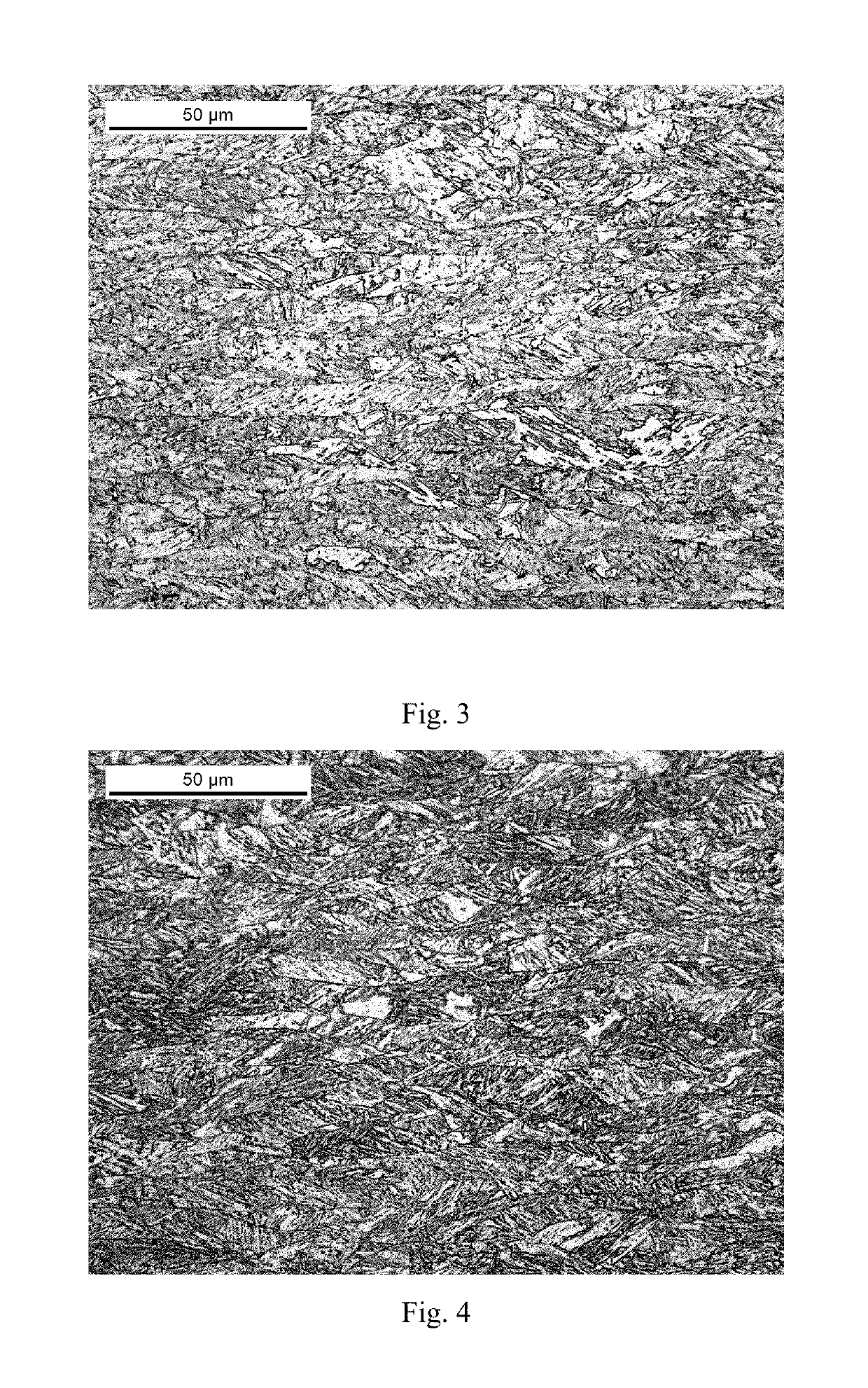

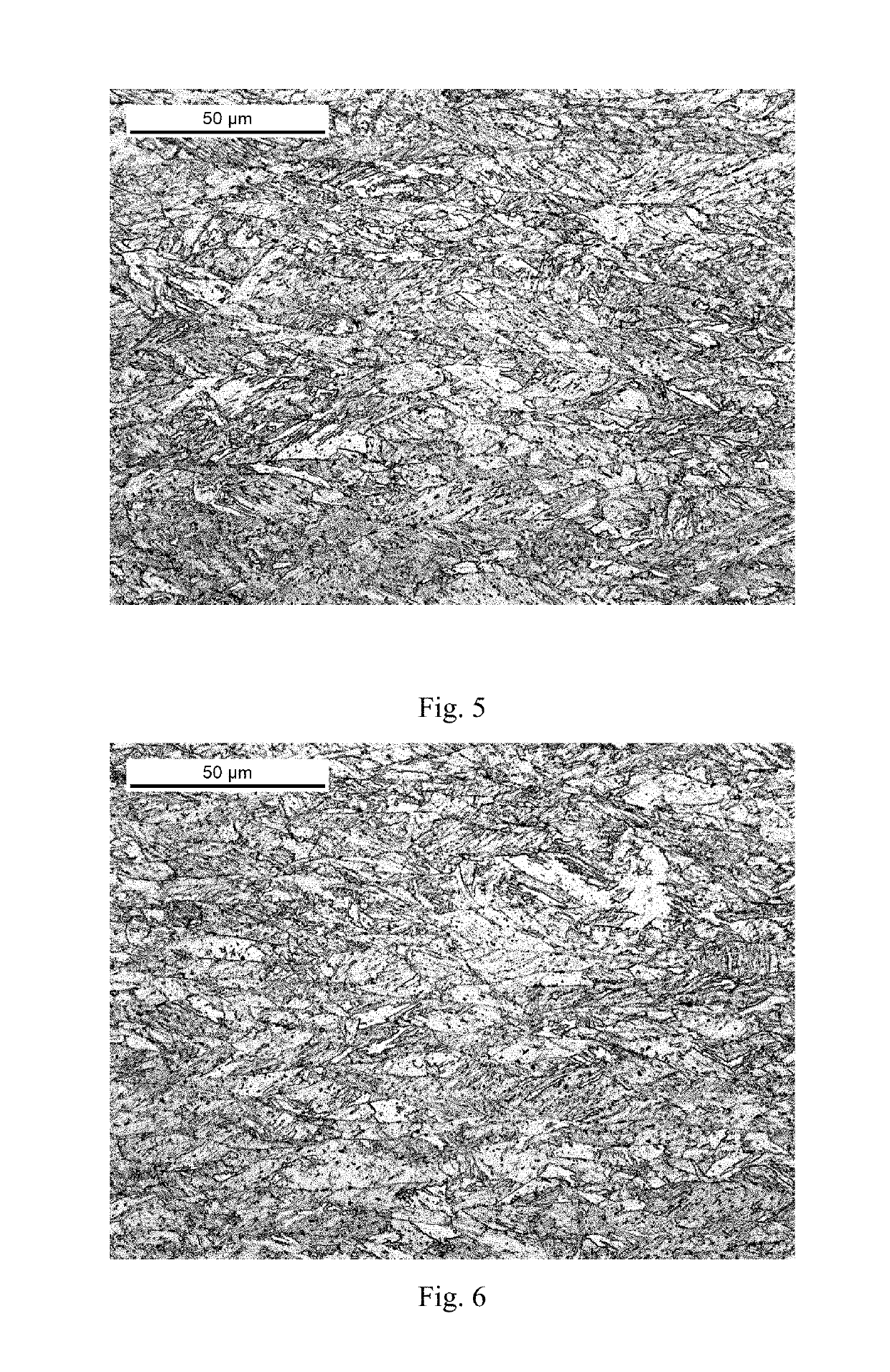

High-toughness hot-rolling high-strength steel with yield strength of 800 MPa, and preparation method thereof

ActiveUS10378073B2Small sizeImprove hardenability and temper softening resistanceMartensiteQuenching

A high-toughness hot-rolled high-strength steel with a yield strength of Grade 800 MPa with its chemical components, in weight percentages, being C 0.02-0.05%, Si≤0.5%, Mn 1.5-2.5%, P≤0.015%, S≤0.005%, Al 0.02-0.10%, N≤0.006%, Nb 0.01-0.05%, Ti 0.01-0.03%, 0.03%≤Nb+Ti≤0.06%, Cr 0.1%-0.5%, Mo 0.1-0.5%, B 0.0005-0.0025%, and the balance of Fe and unavoidable impurities, and a preparation method thereof. The present invention acquires, via direct quenching, an ultra-low carbon martensite structure with a yield strength of 800 Mpa and an impact energy of more than 100J under a temperature of −80° C.

Owner:BAOSHAN IRON & STEEL CO LTD

Ferritic-austenitic duplex stainless steel sheet

ActiveUS20190390310A1High strengthReduce thicknessFurnace typesHeat treatment furnacesChemical compositionChemical element

Provided is a ferritic-austenitic duplex stainless steel sheet in which no blowholes are formed during welding and which has excellent strength.A chemical composition includes, in mass %, C: 0.10% or less, Si: 1.0% or less, Mn: 2.0 to 7.0%, P: 0.07% or less, S: 0.030% or less, Cr: 18.0 to 24.0%, Ni: 0.1 to 3.0%, Mo: 0.01 to 1.0%, Cu: 0.1 to 3.0%, Al: 0.003 to 0.10%, Zr: 0.01 to 0.50%, and N: 0.15 to 0.30%, with the balance being Fe and incidental impurities, the chemical composition satisfying formula (1) below and formula (2) below.N—Zr / 6.5≥0.15% (1)N—Zr / 6.5≤0.23% (2)Here, in formula (1) and formula (2), N represents a content (mass %) of the corresponding chemical element N and Zr represents a content (mass %) of the corresponding chemical element Zr.

Owner:JFE STEEL CORP

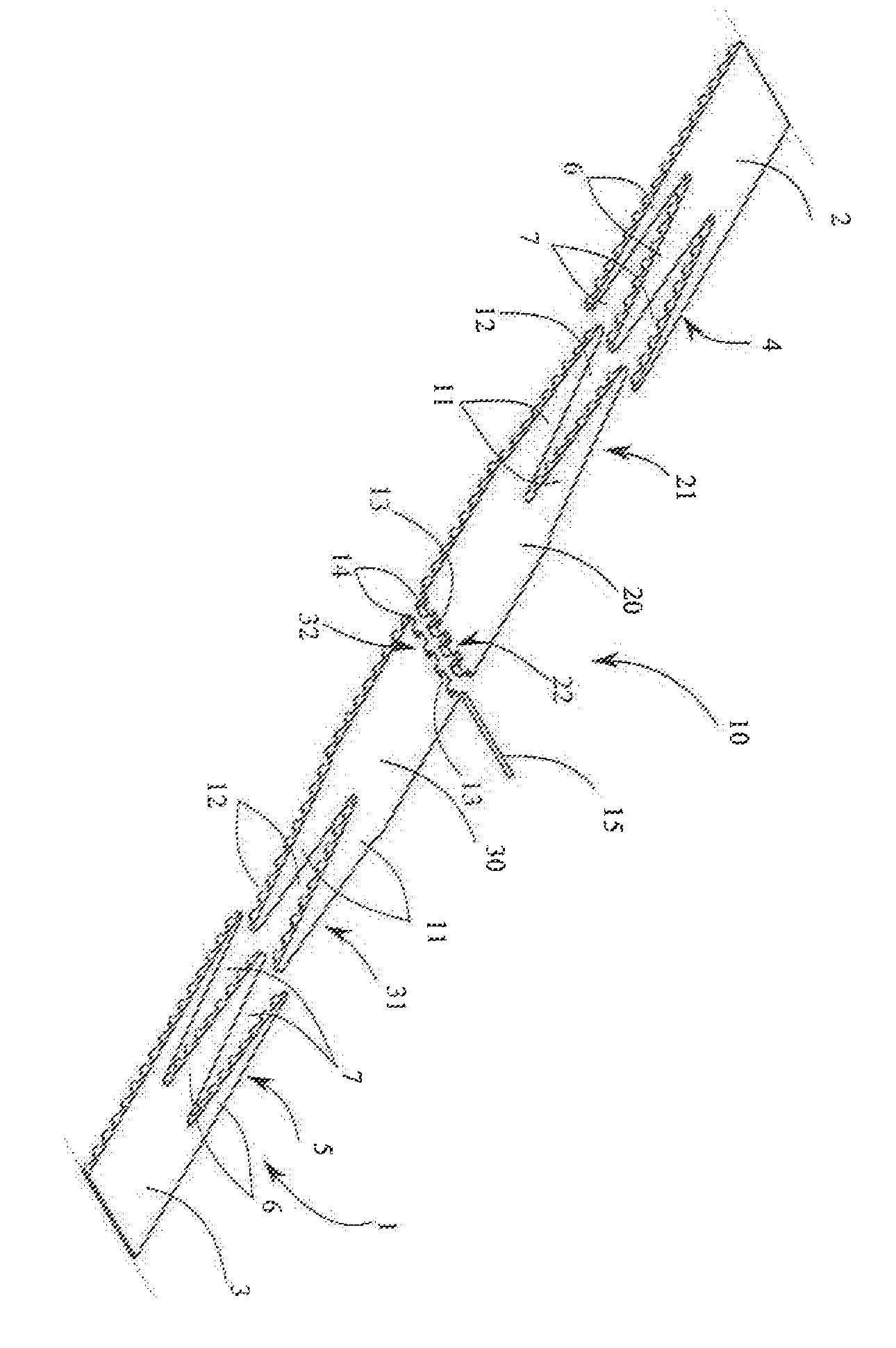

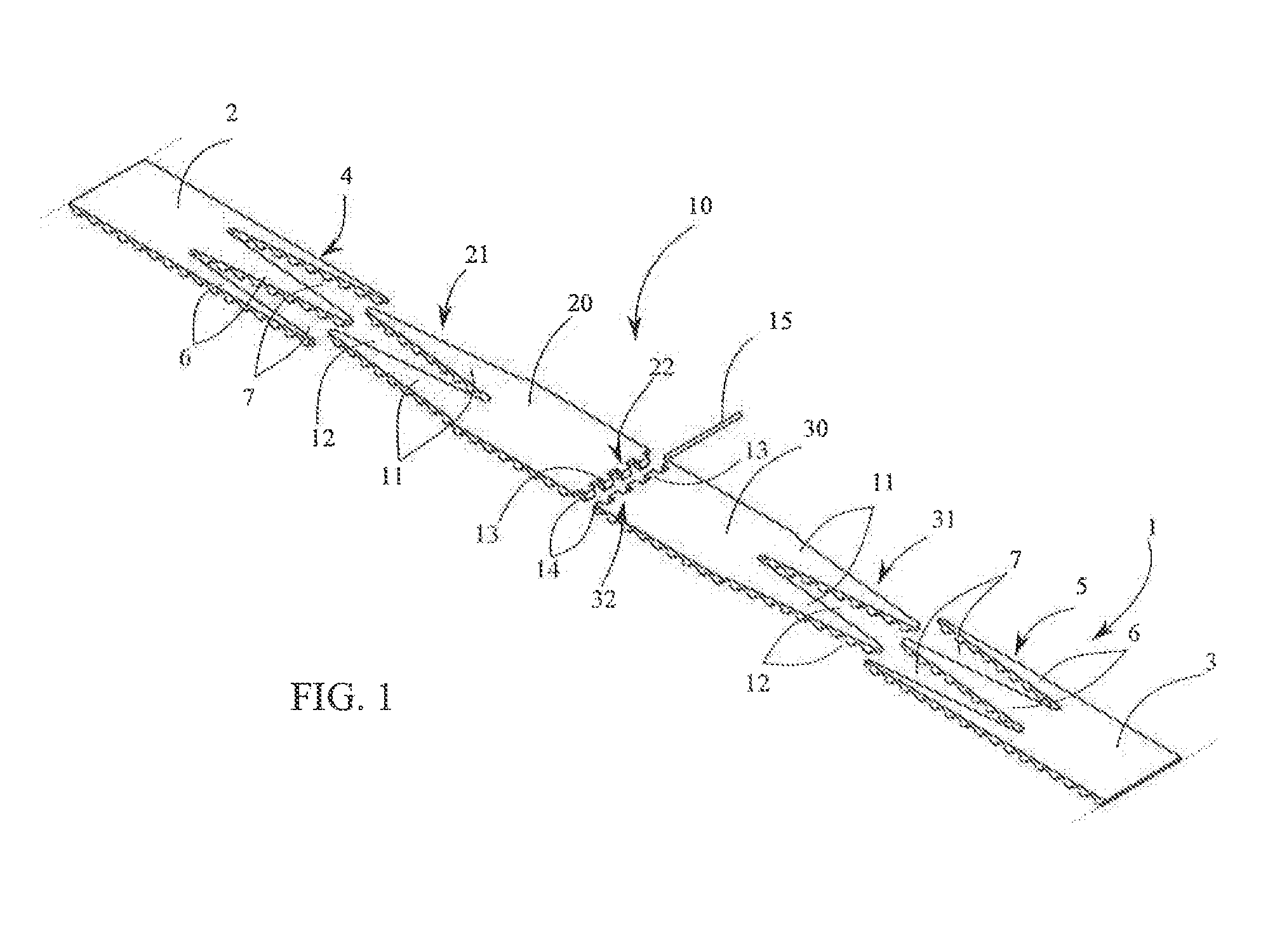

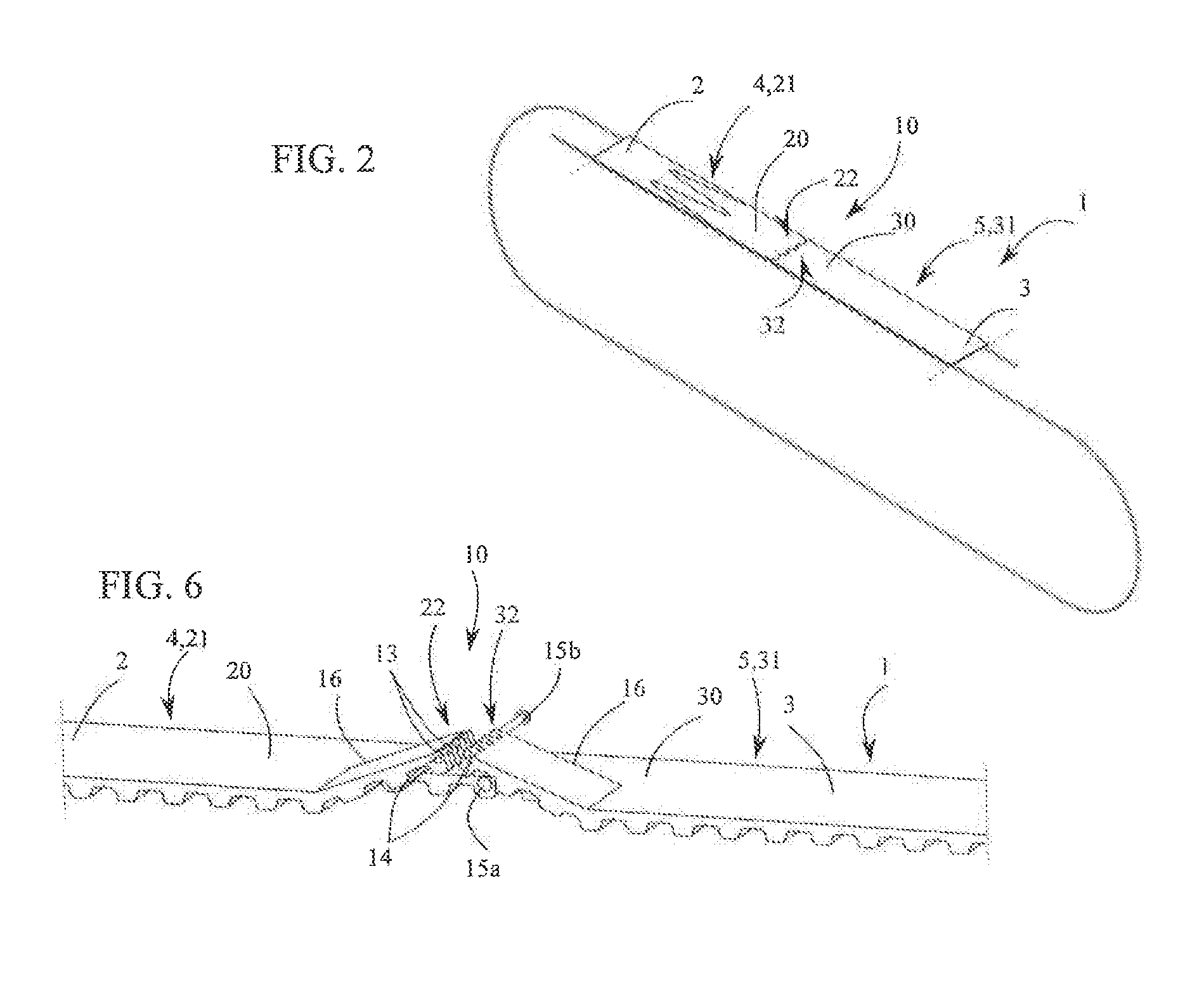

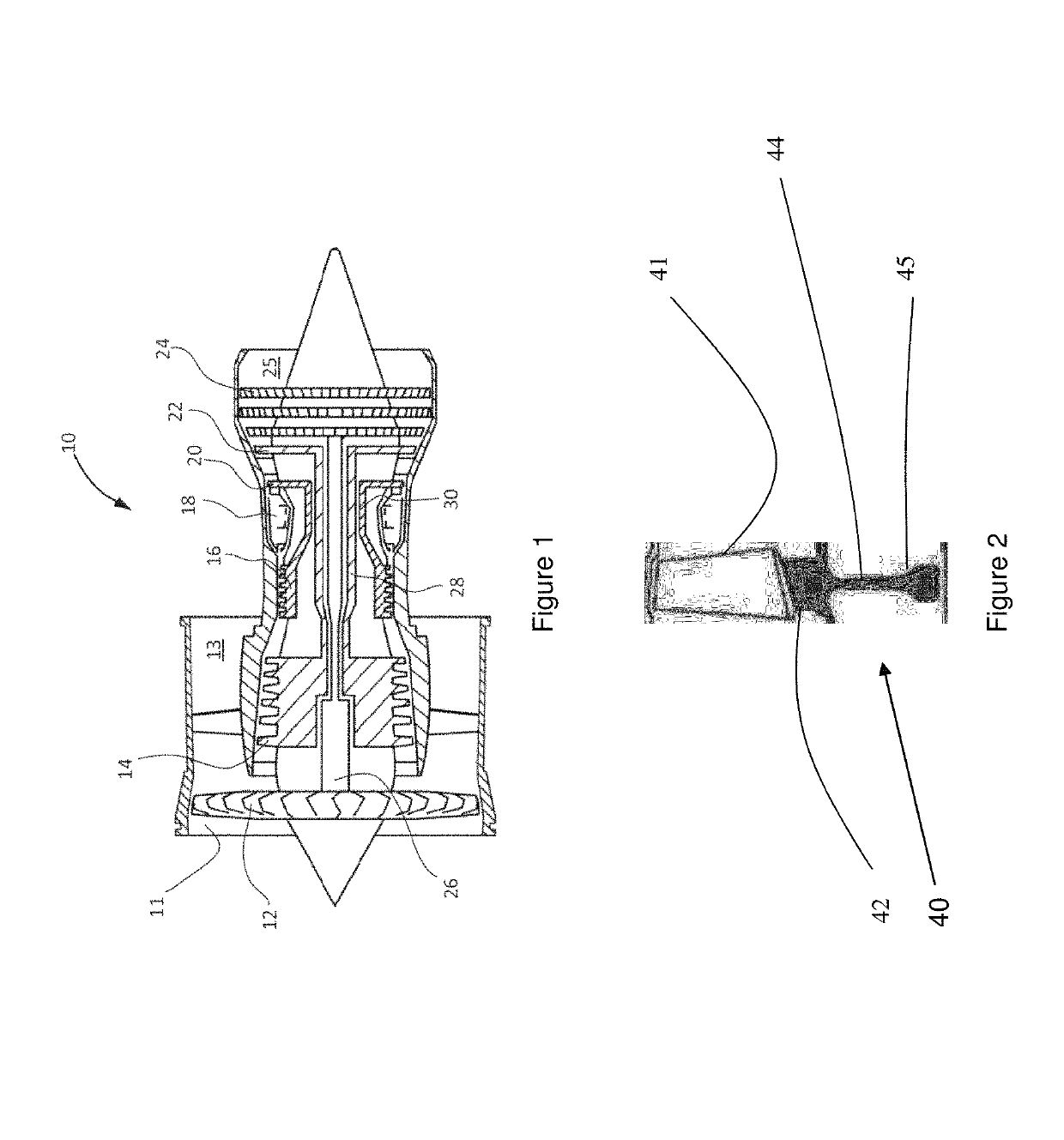

Ductwork

ActiveUS20130212833A1Easy to installYield strengthElectrical apparatusSelf-bailing equipments/scuppersEngineeringFlange

Ductwork (1) for arranging at least one pipe through an opening (2) in a partitioning (3), including a flange (4) having an outer periphery area (5) and a central area (7) which is formed with a guide opening (8) for every pipe, the flange (4) being provided with a number of mounting apertures (11), the flange (4) having an inner side (9) and an outer side (10) opposite the inner side (9), where the inner side (9) is adapted for bearing against one side (6) of the partitioning, wherein the ductwork (1) further includes a connecting arrangement mounted in each mounting aperture (13), the connecting arrangement including force transmission means (15) with an operating member (22) disposed over the outer side (10) of the flange, and with a shank (17) extending through the mounting aperture (11), a clamping means (23) disposed on the shank (17) of the force transmission means and which is displaceable around and / or along the shank (17) by actuating the operating member (22), and an engagement arrangement (19) disposed between the inner side (9) of the flange and the clamping means (23), and which is adapted with contact surfaces (23) interacting with contact surfaces (18) on the clamping means (23), and engaging faces (20) that may be displaced radially relative to the orientation of the shank by actuating the operating member (22).

Owner:BLUCHER METAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com