Seamless steel pipe and method of manufacturing the same

a technology of seamless steel pipe and manufacturing method, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of not having good ssc resistance in a reliable manner, not sufficiently considering reducing the hardness of the surface layer or thus improving ssc resistance, etc., to achieve good ssc resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0124]The present invention will be described using specific examples. The present invention is not limited to these examples.

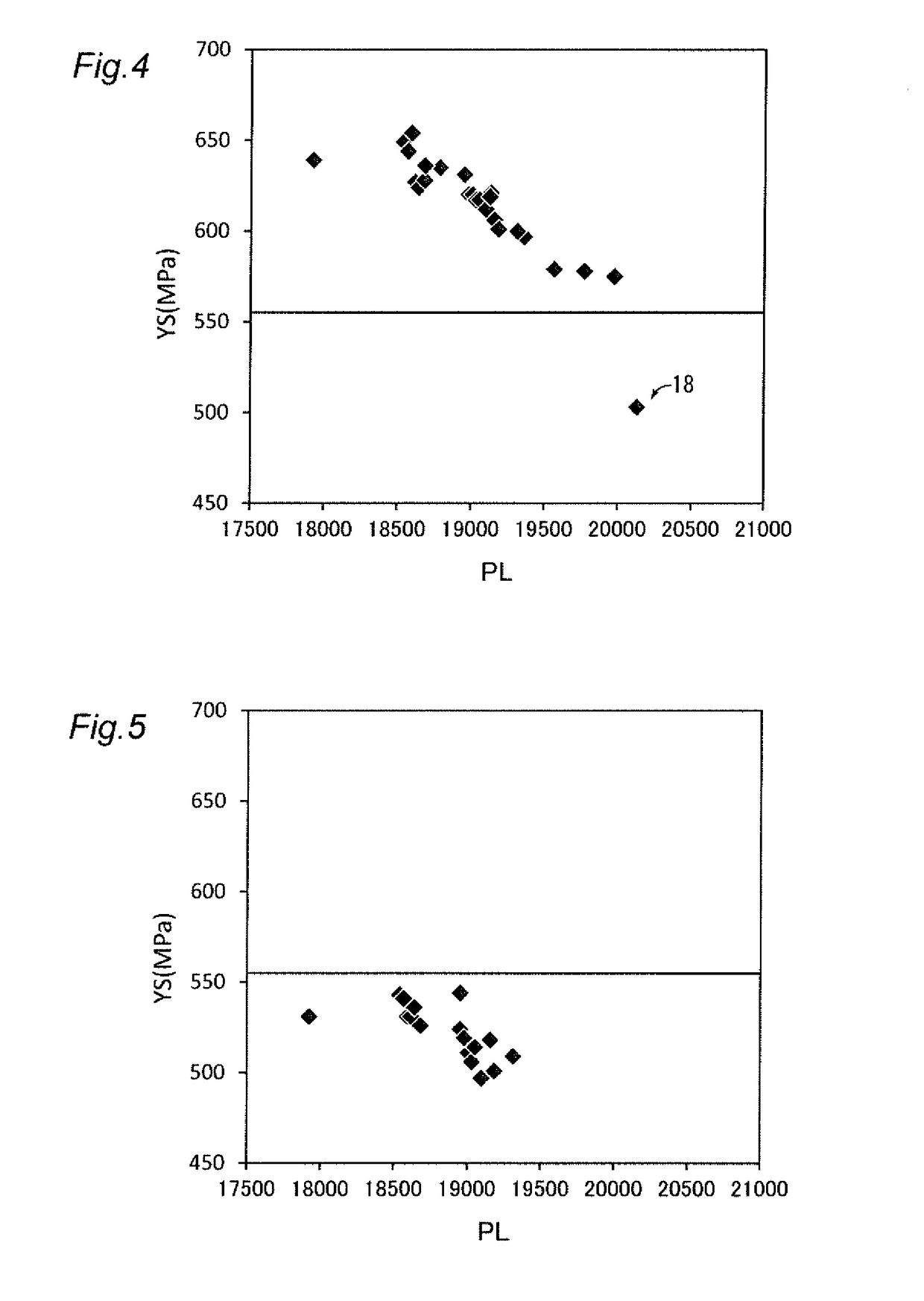

[0125]A plurality of seamless steel pipes with various chemical compositions were produced and their yield strength, tensile strength, surface hardness and sour resistance were investigated.

[0126][Investigation Methods]

[0127]A plurality of steels having the chemical compositions shown in Table 1 were melt and were subjected to continuous casting to produce round billets for pipe forming. Steels A, C, D1, D2 and J in Table 1 are steels in which the chemical composition or the value of Ceq does not meet the requirements of the present invention.

TABLE 1Chemical Composition (in mass %, balance being Fe and impurities)SteelCSiMnPSCuCrNiMoTiVNbAlCaONCeqA0.0590.121.530.0050.00070.200.280.230.100.0030.05—0.0310.00080.00150.00360.429B0.0610.111.510.0080.00090.200.310.310.250.0030.05—0.0320.00170.00180.00500.468C0.0700.091.420.0110.00050.410.310.390.350.0050.05—0.0300....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com