Patents

Literature

60results about How to "Lower temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

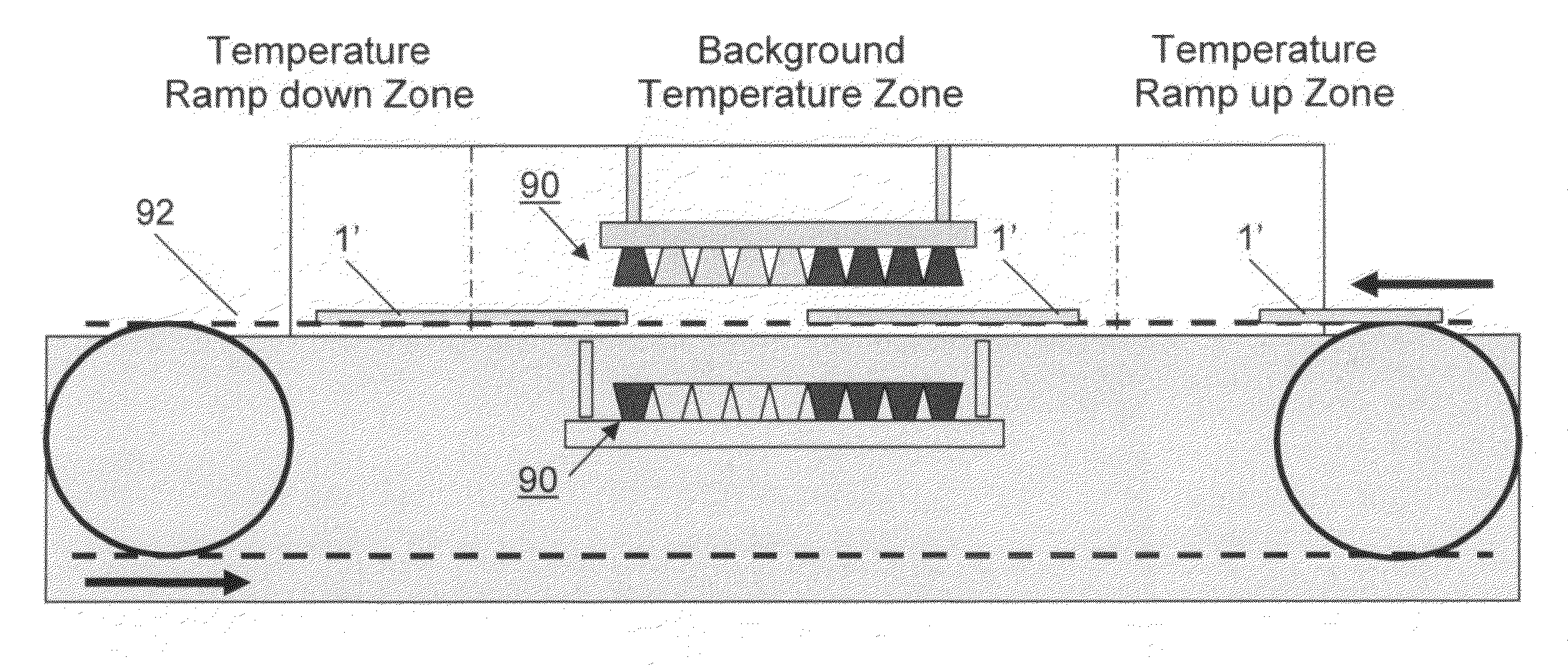

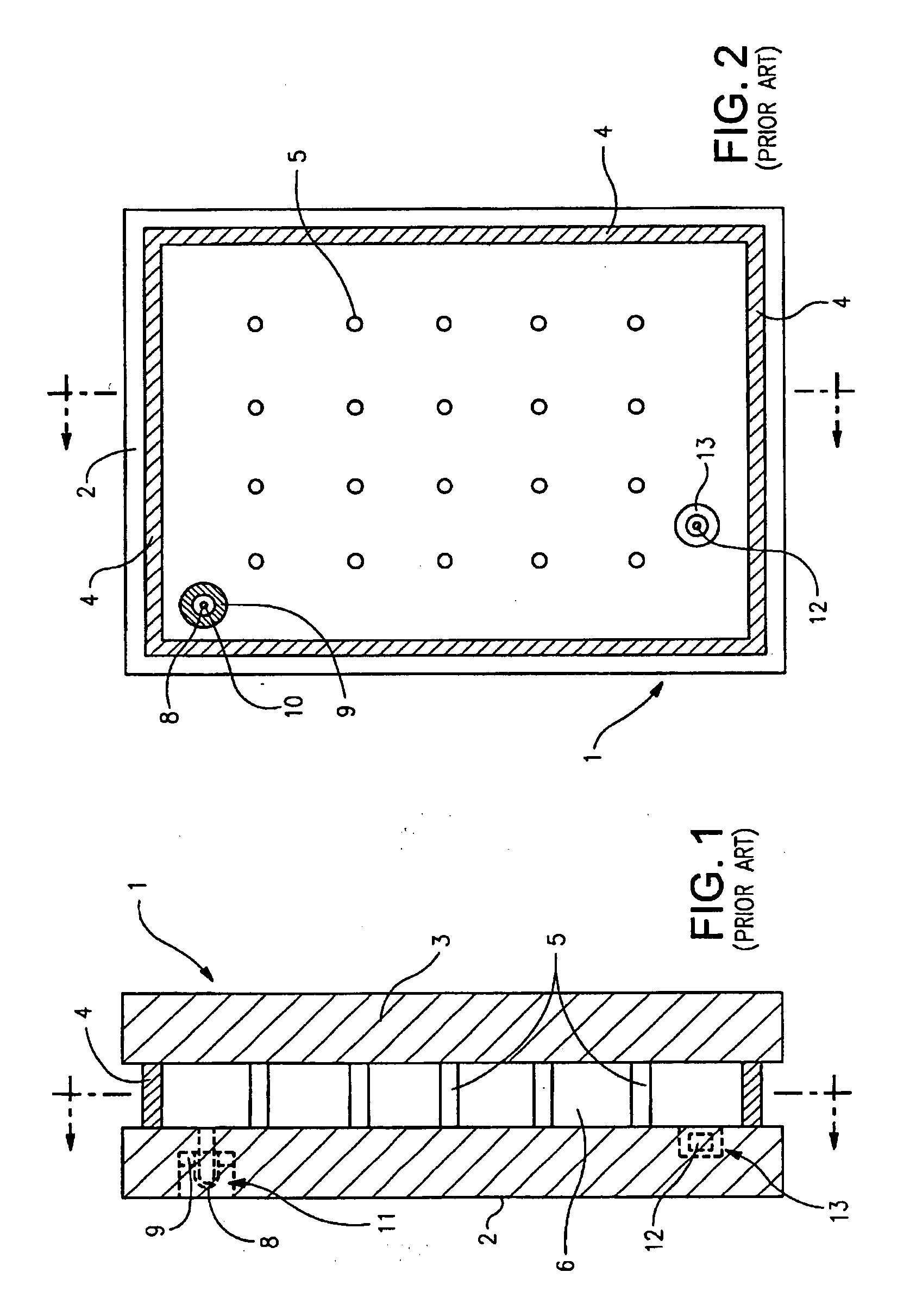

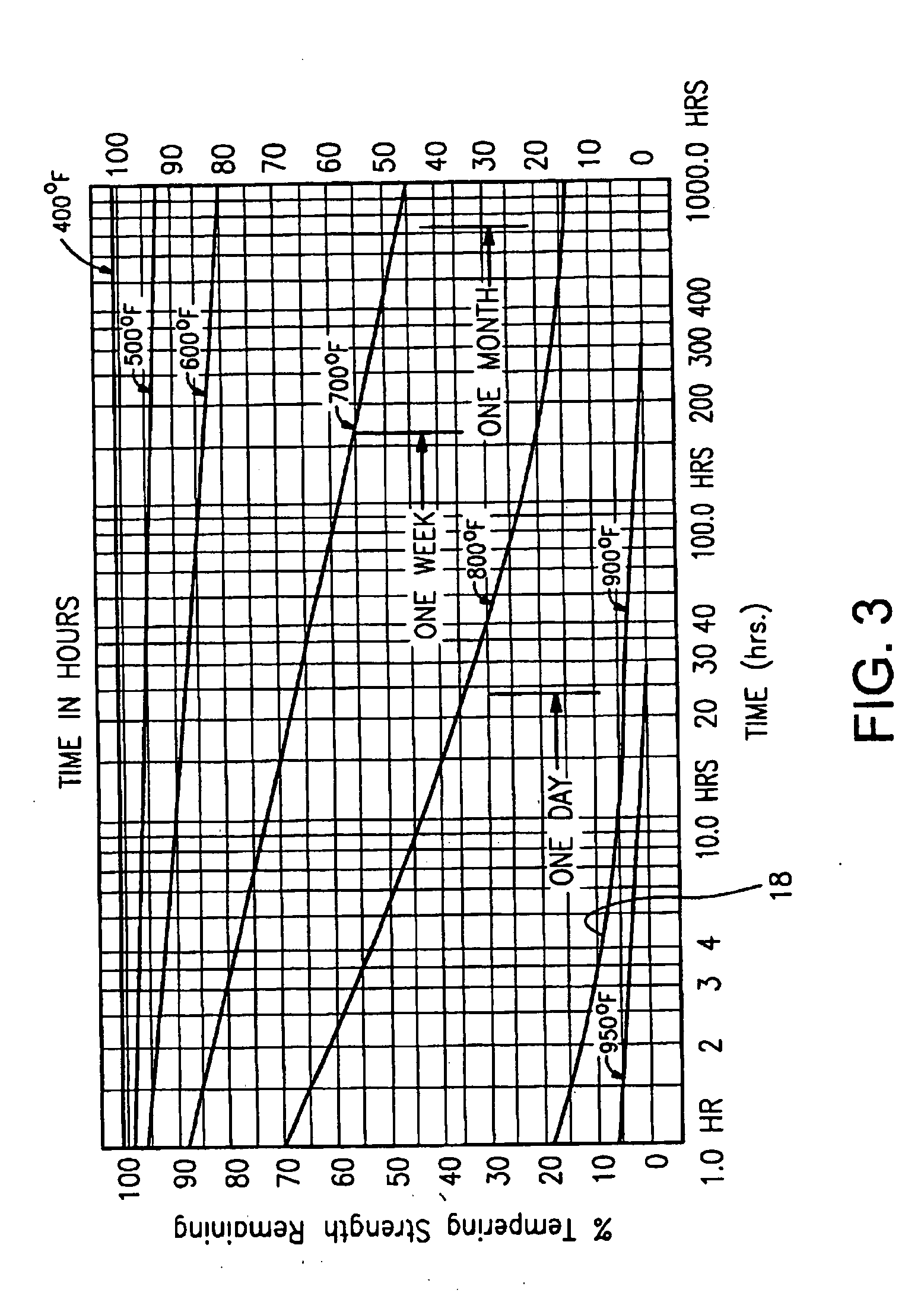

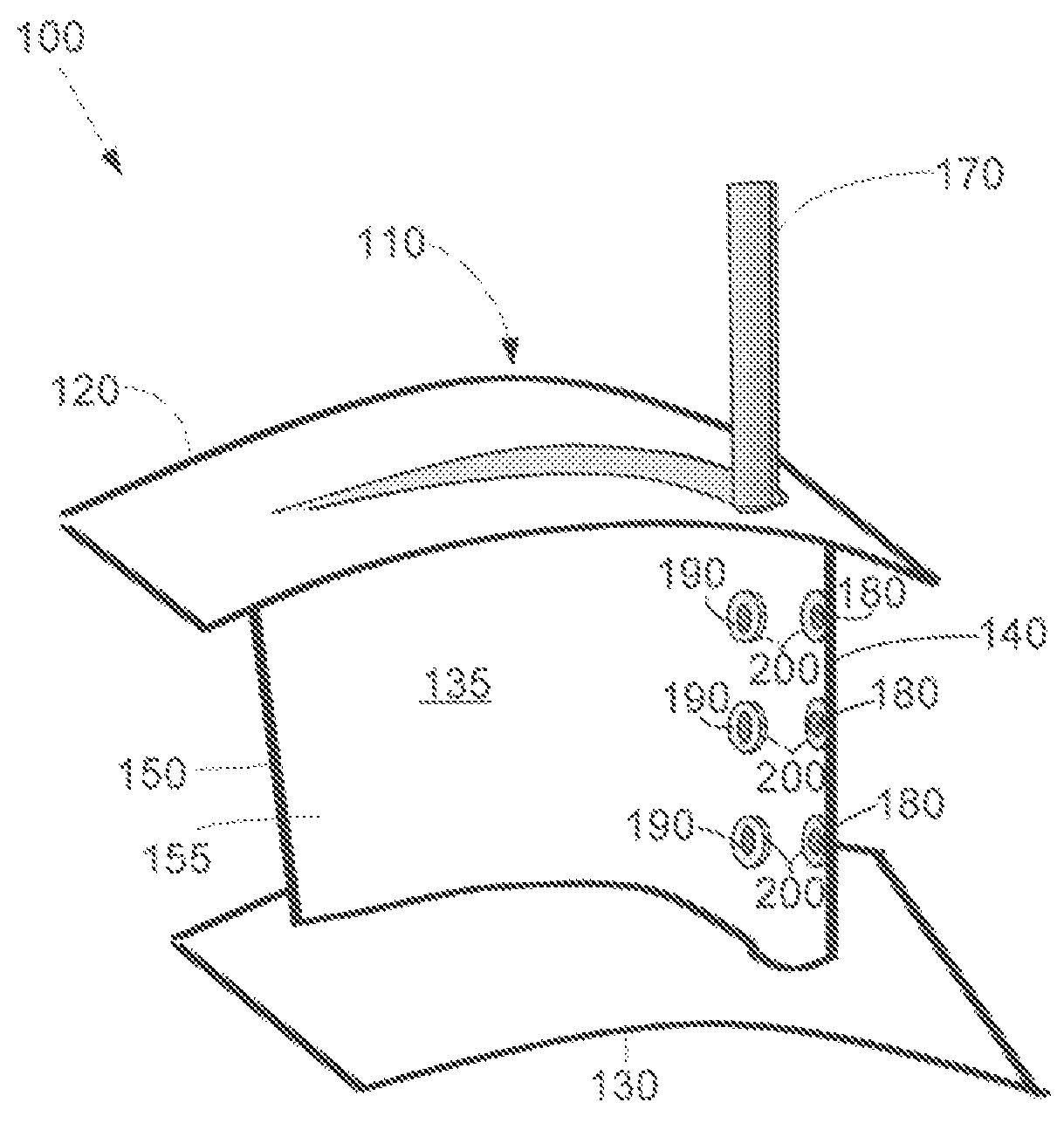

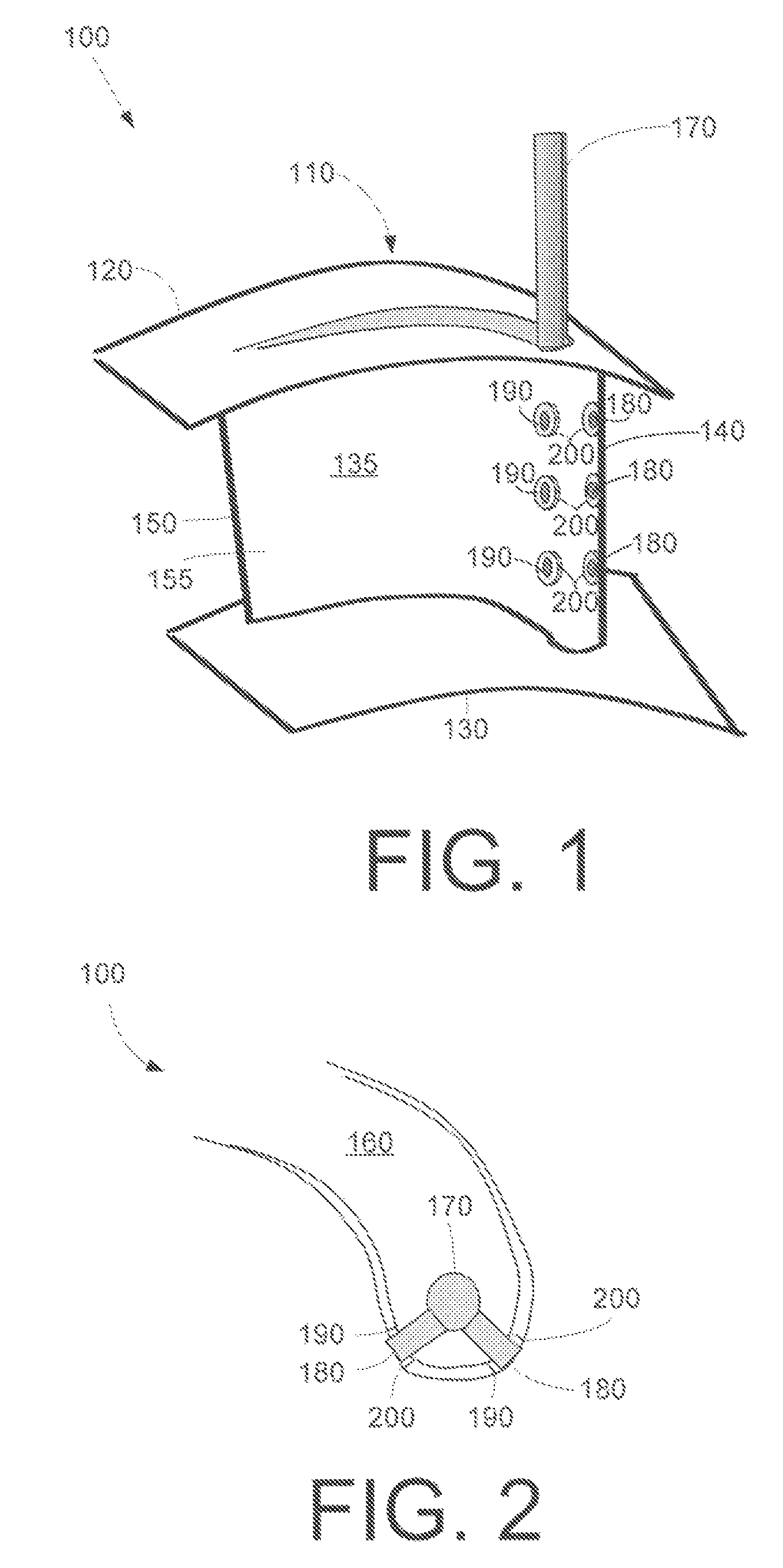

Localized heating via an infrared heat source array of edge seals for a vacuum insulating glass unit, and/or unitized oven with infrared heat source array for accomplishing the same

ActiveUS20090151855A1Lower temperatureIncrease likelihood of deformationClimate change adaptationLaminationEngineeringThermal source

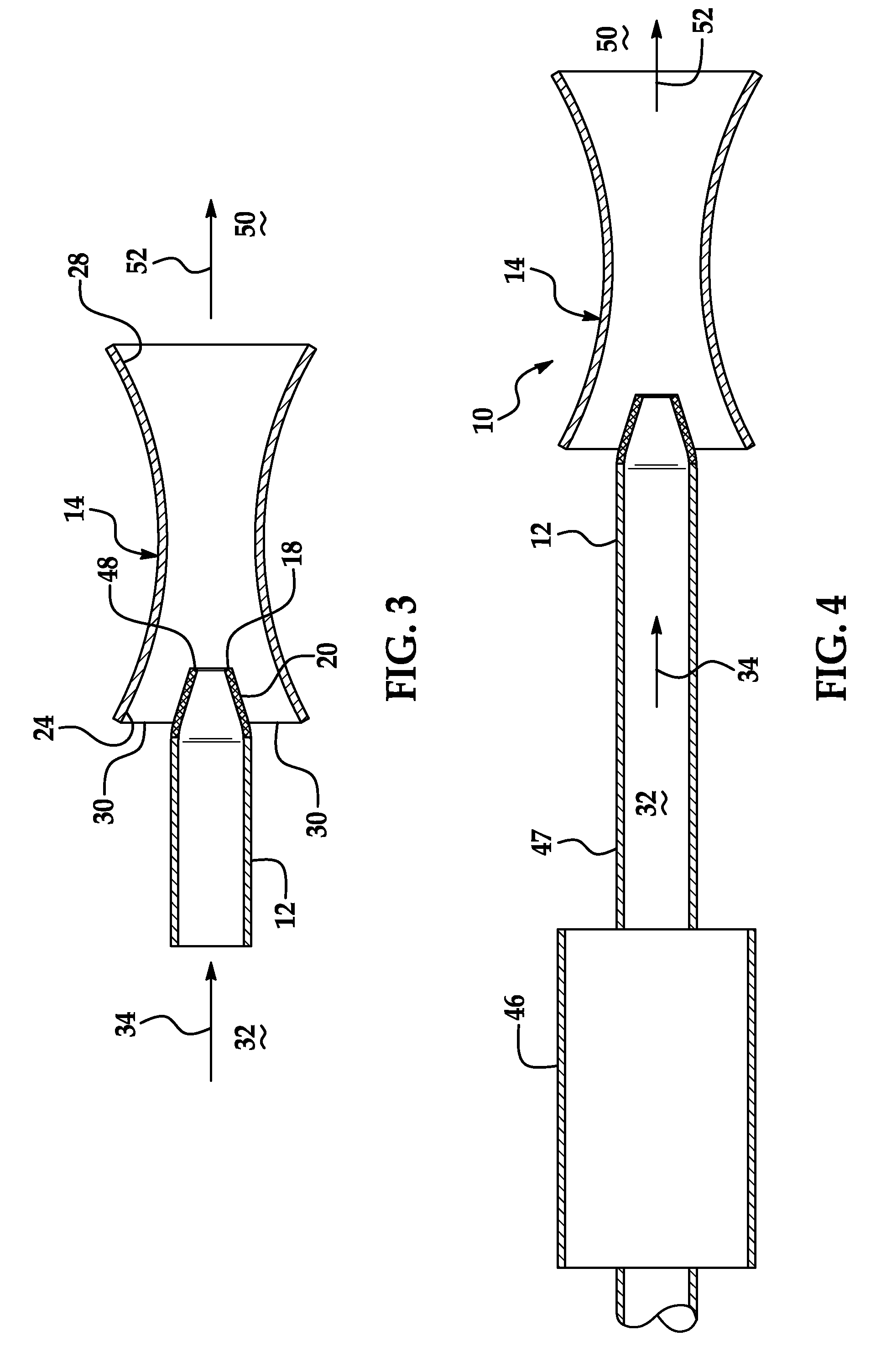

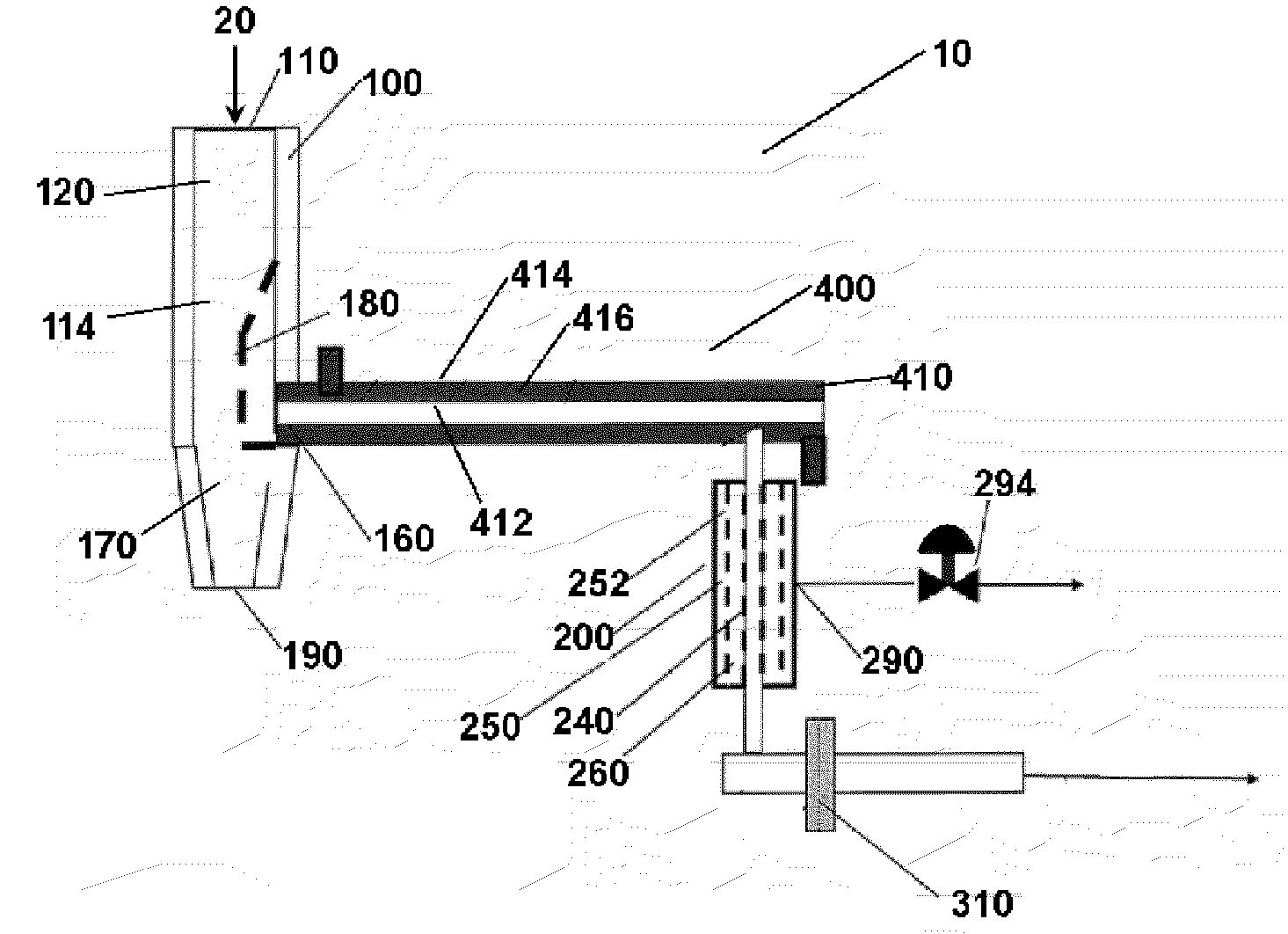

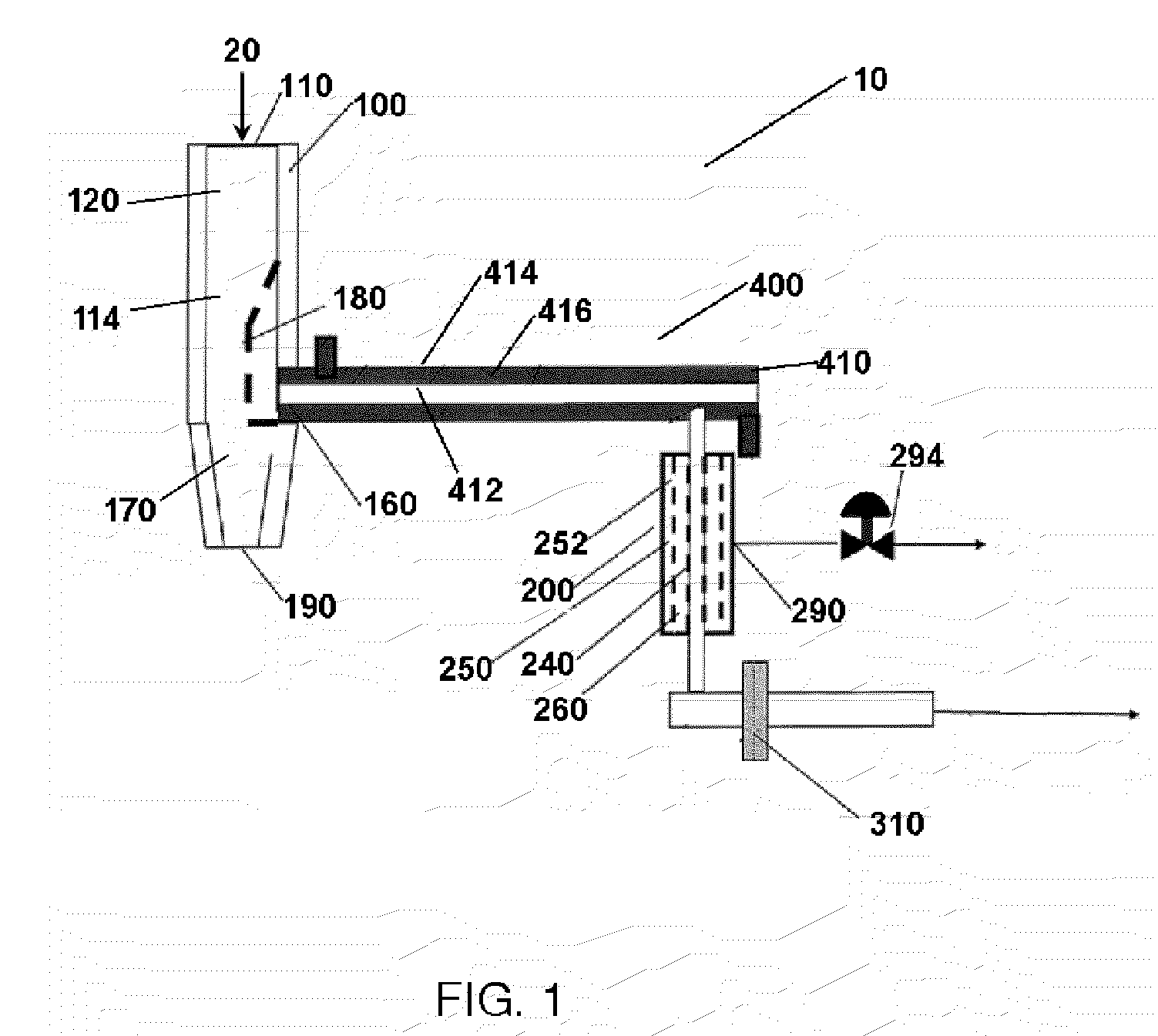

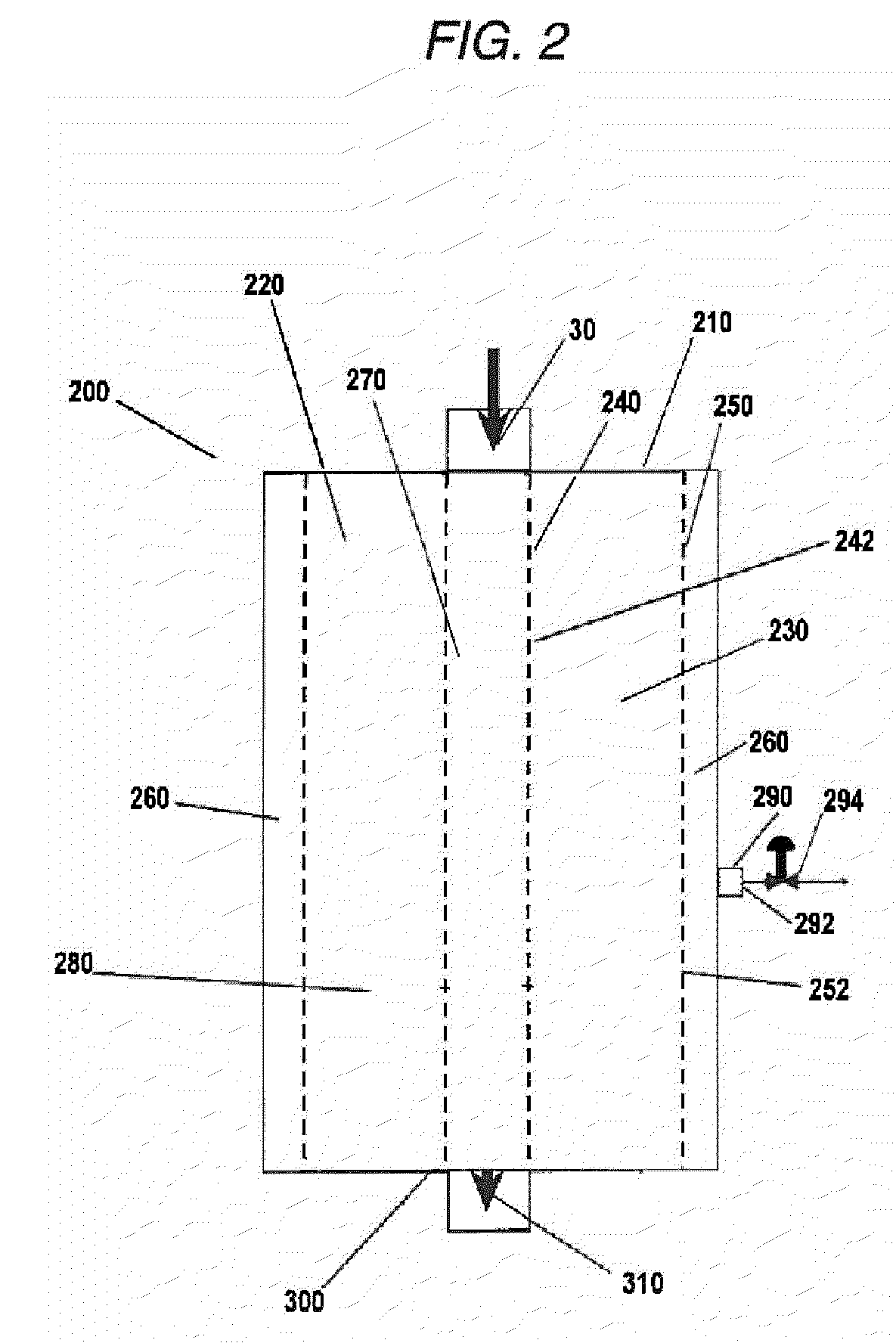

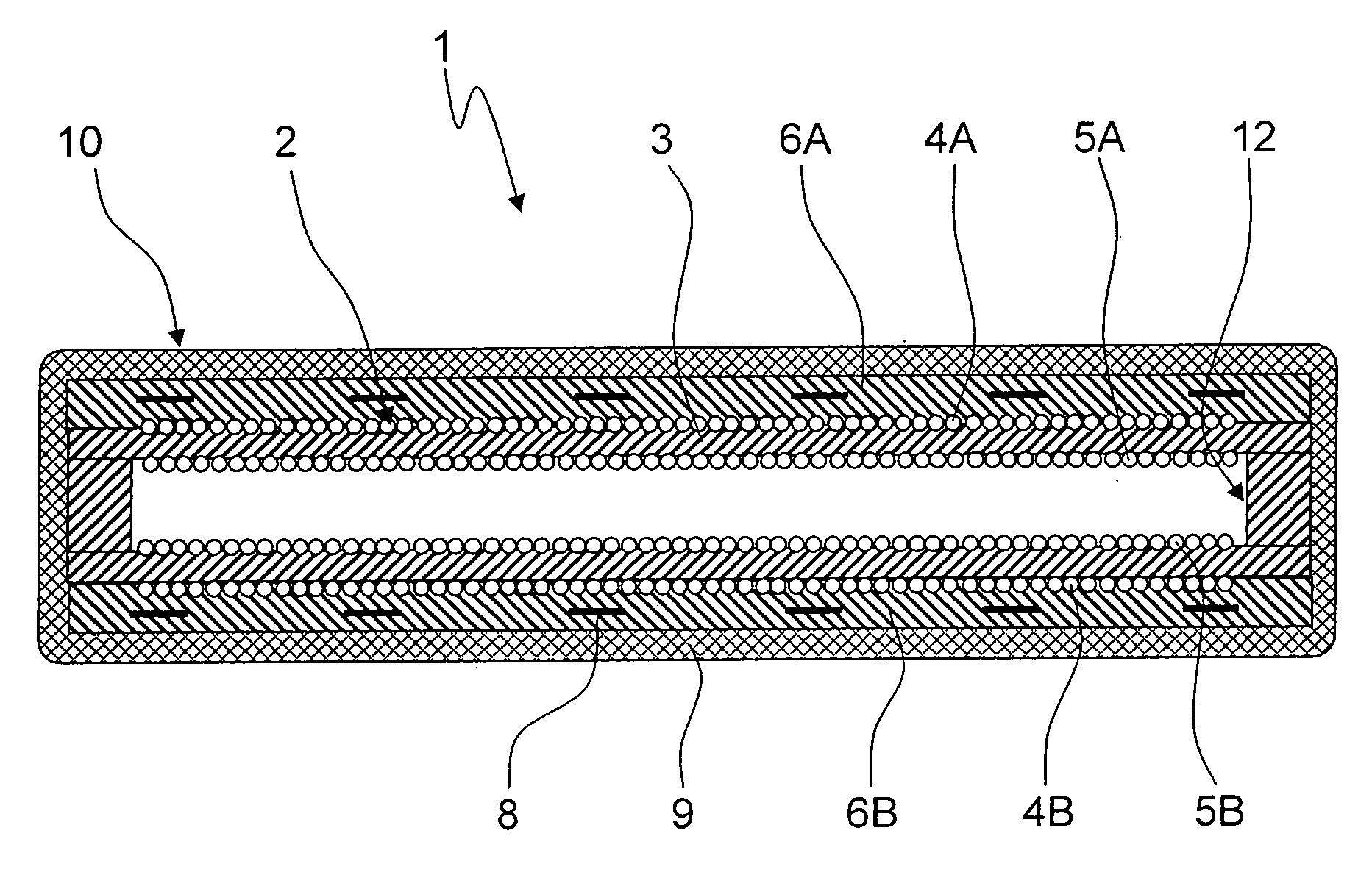

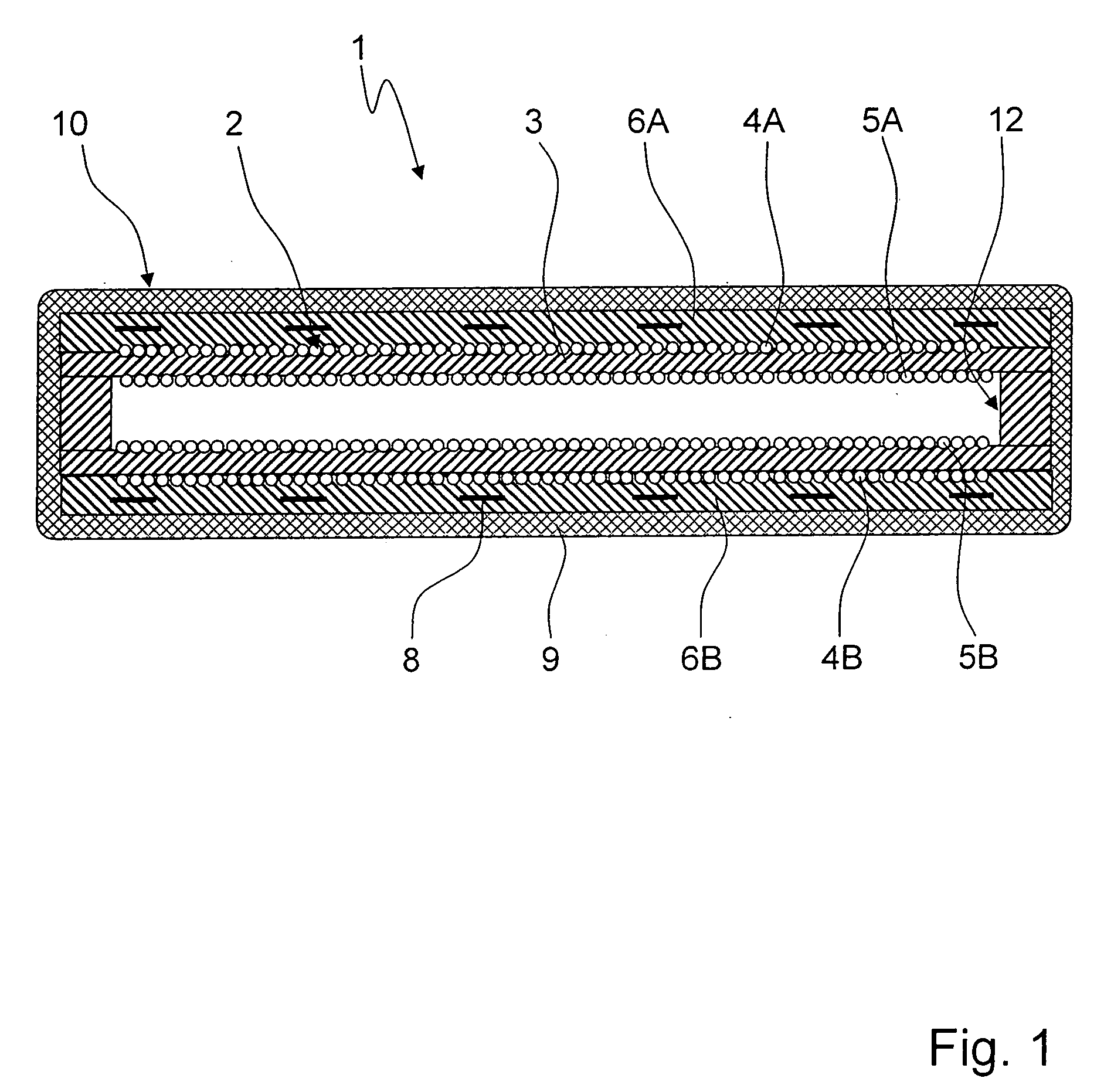

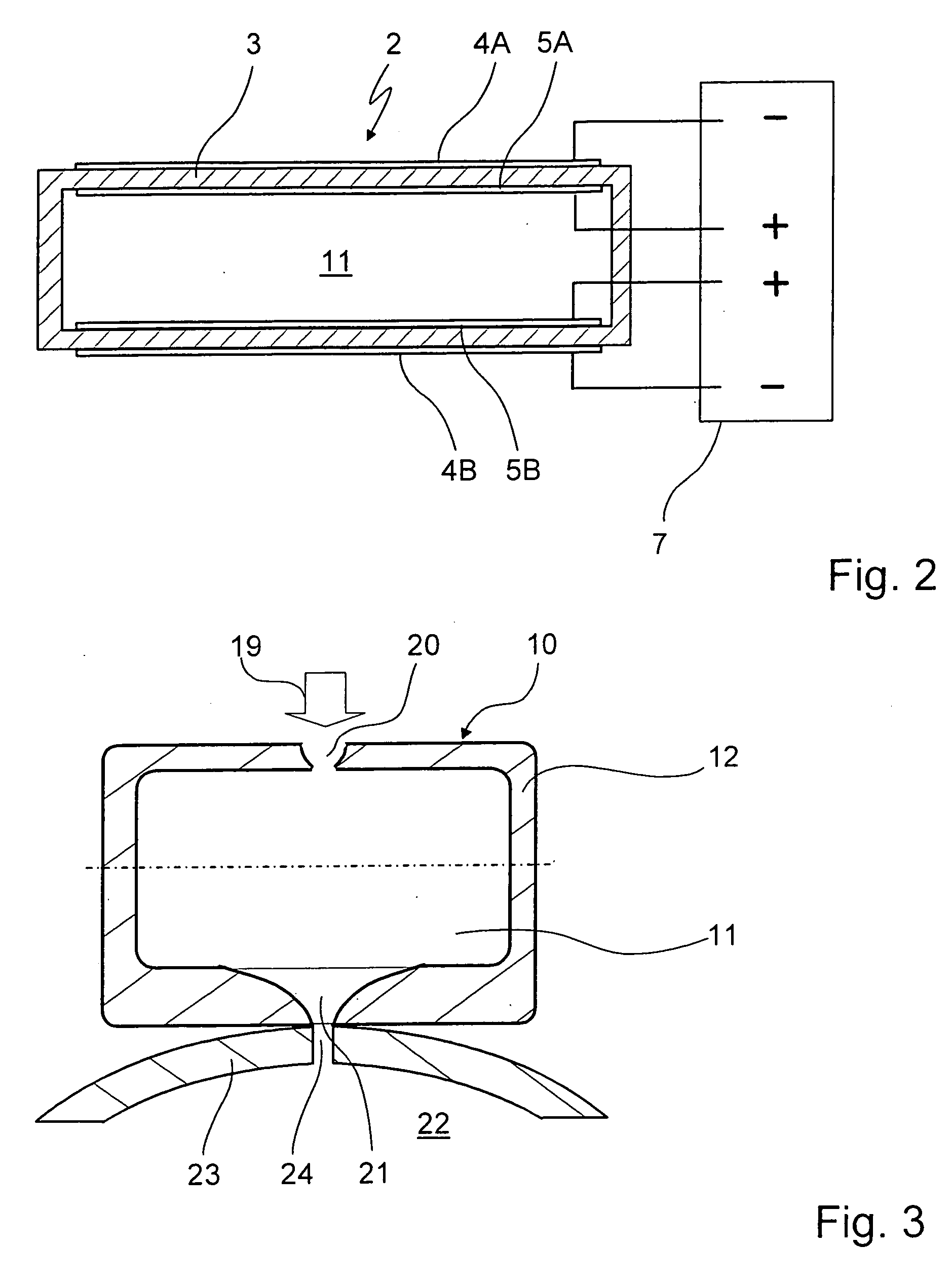

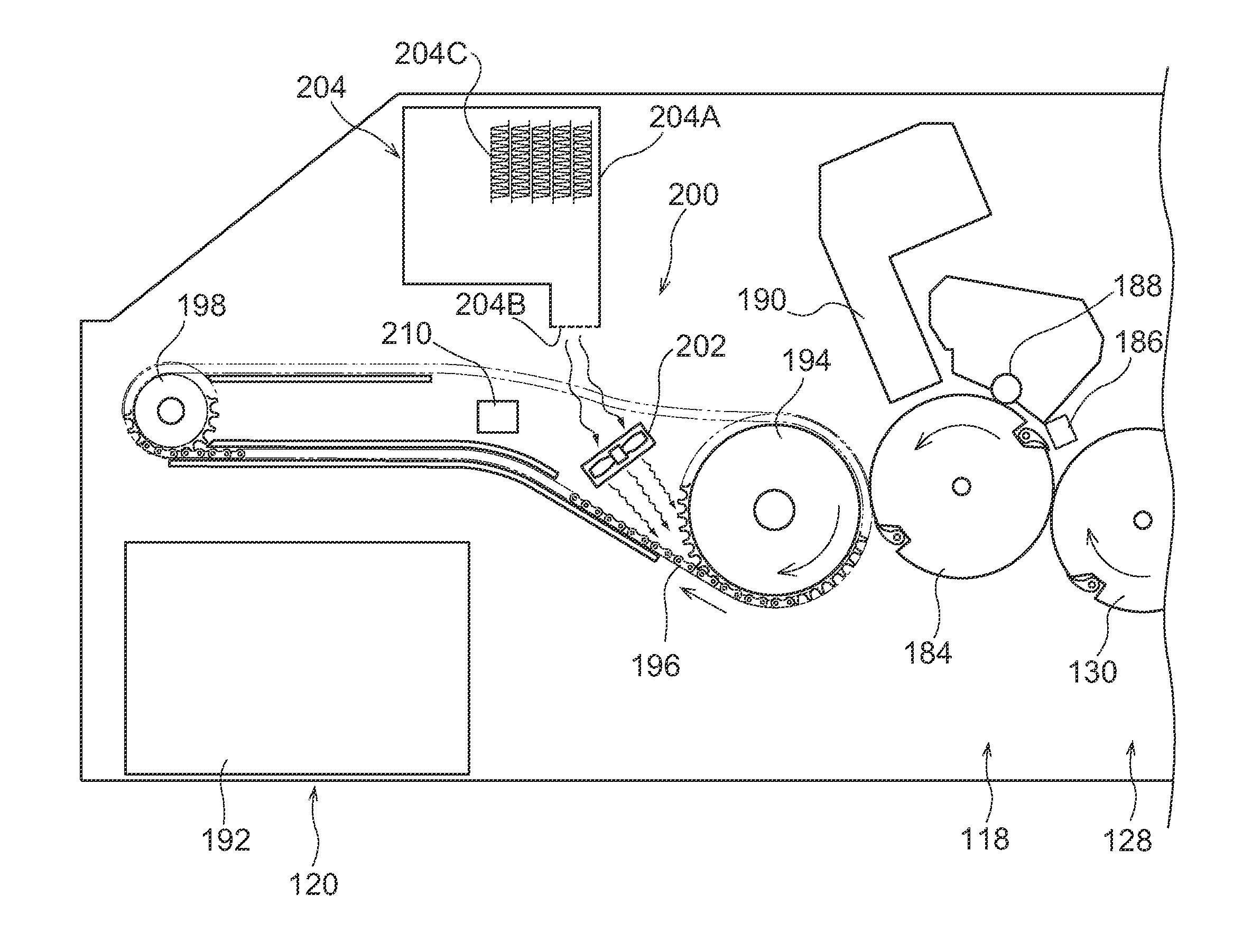

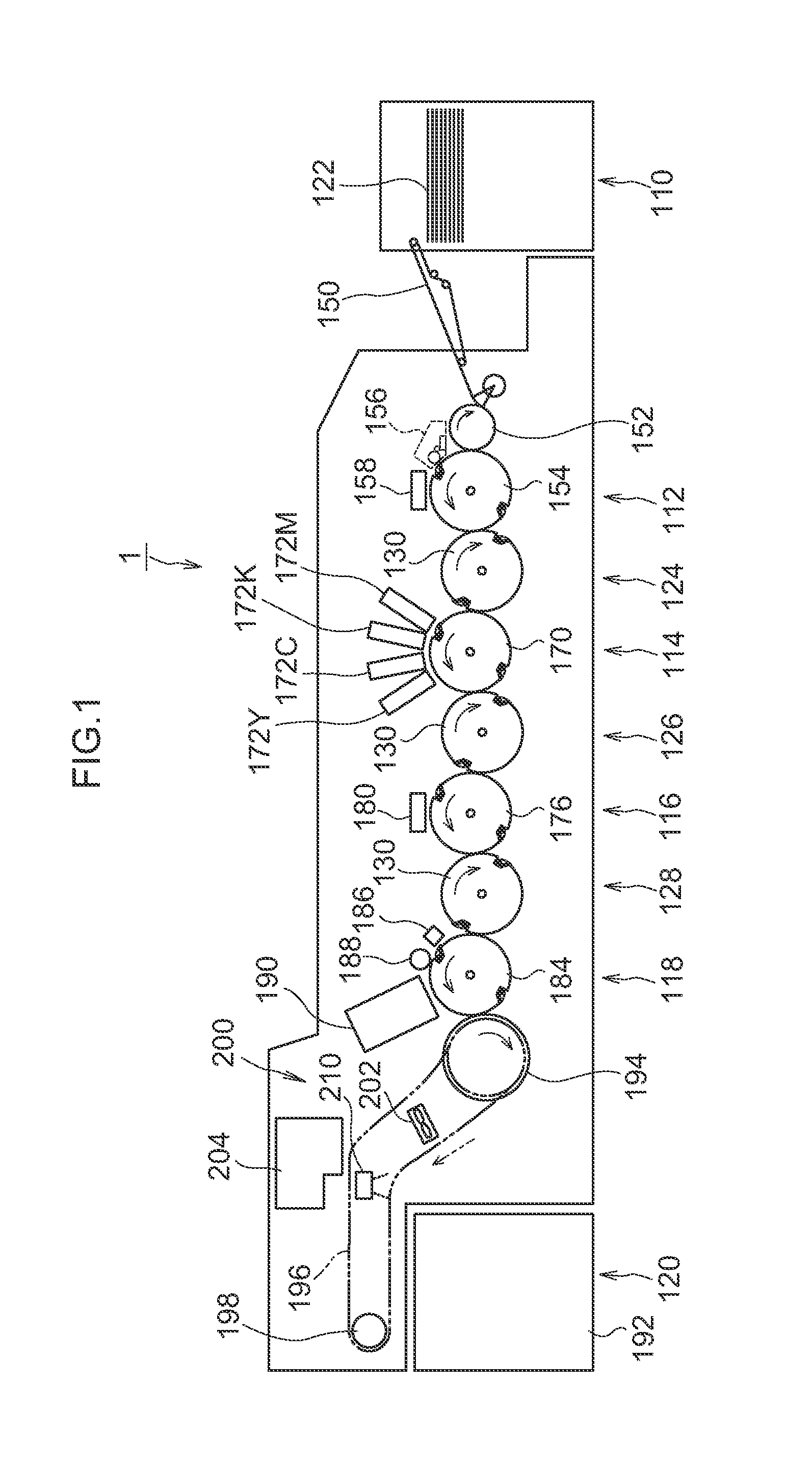

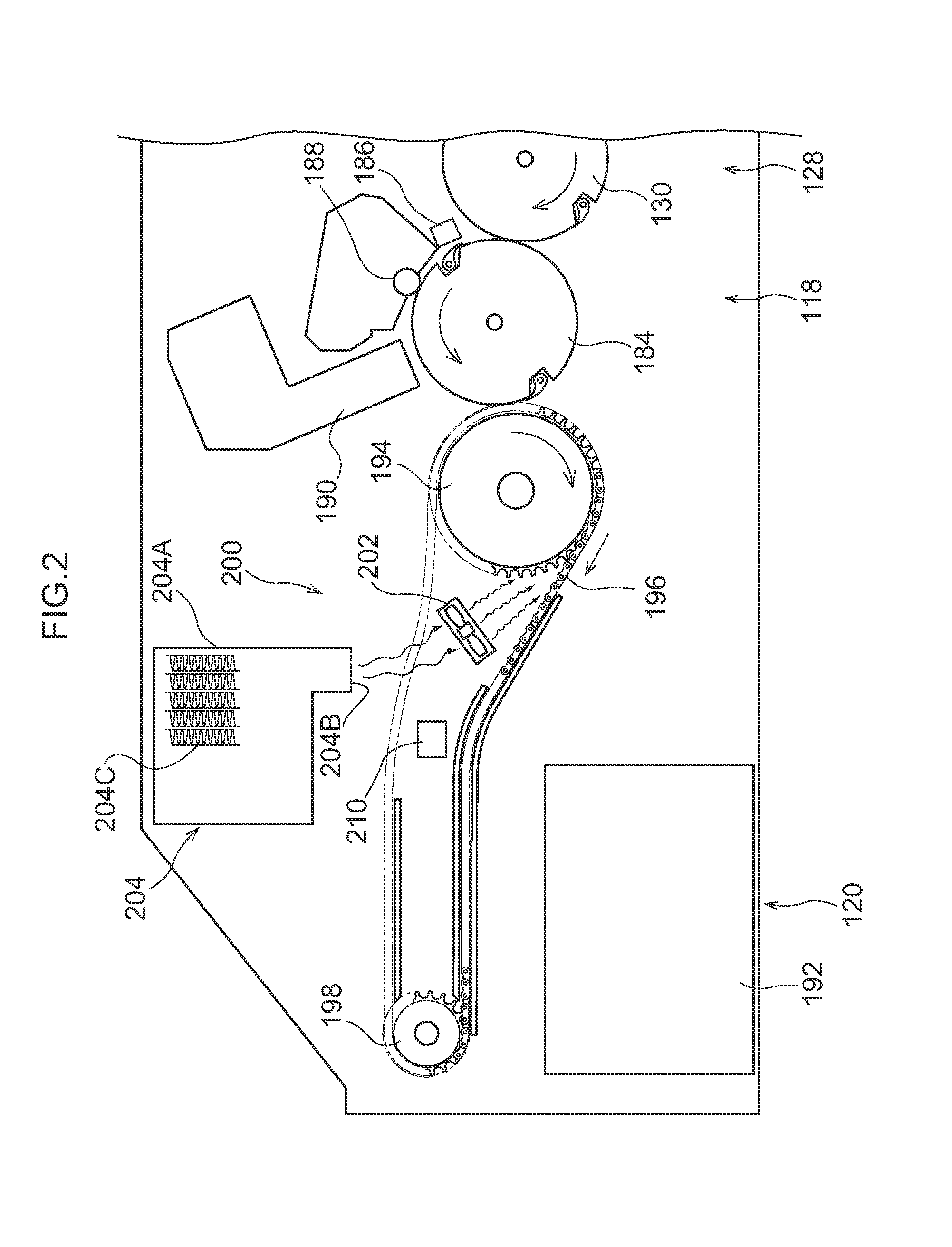

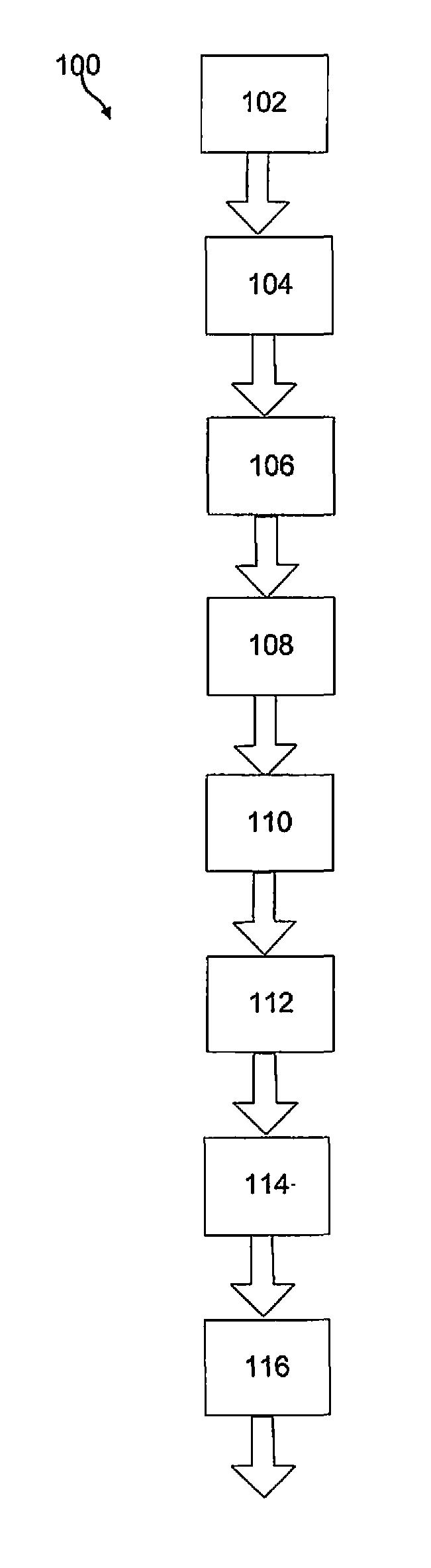

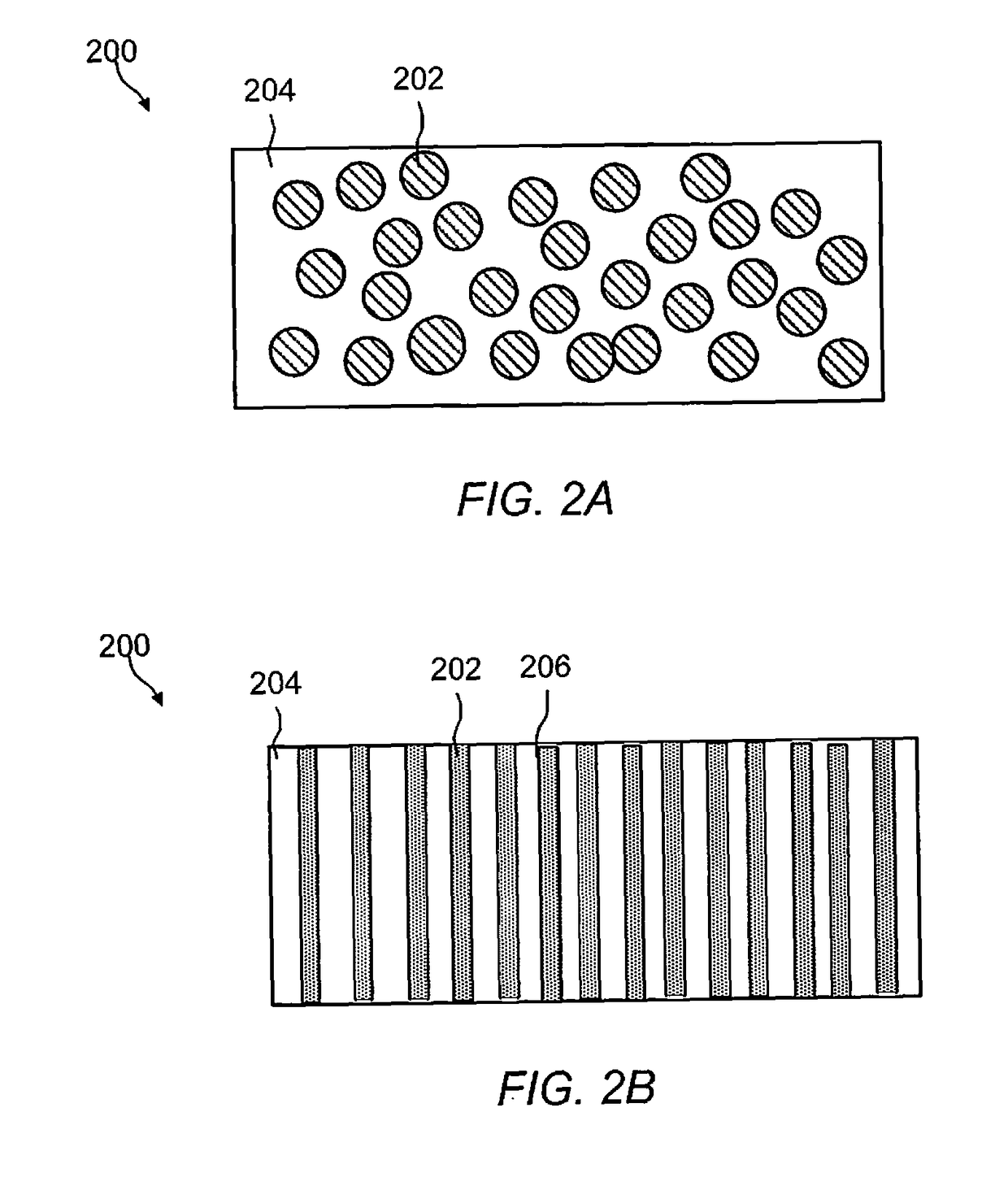

Certain example embodiments of this invention relate to edge sealing techniques for vacuum insulating glass (VIG) units. More particularly, certain example embodiments relate to techniques for providing localized heating to edge seals of units, and / or unitized ovens for accomplishing the same. In certain example embodiments, a unit is pre-heated to one or more intermediate temperatures, localized heating via at least one substantially two-dimensional array of heat sources is provided proximate to the peripheral edges of the unit so as to melt frits placed thereon, and cooled. In certain non-limiting implementations, the pre-heating and / or cooling may be provided in one or more steps. An oven for accomplishing the same may include multiple zones for performing the above-noted steps, each zone optionally including one or more chambers. Accordingly, in certain example embodiments, a temperature gradient proximate to the edges of the unit is created, thereby reducing the chances of breakage and / or at least some de-tempering of the substrates.

Owner:GUARDIAN GLASS LLC

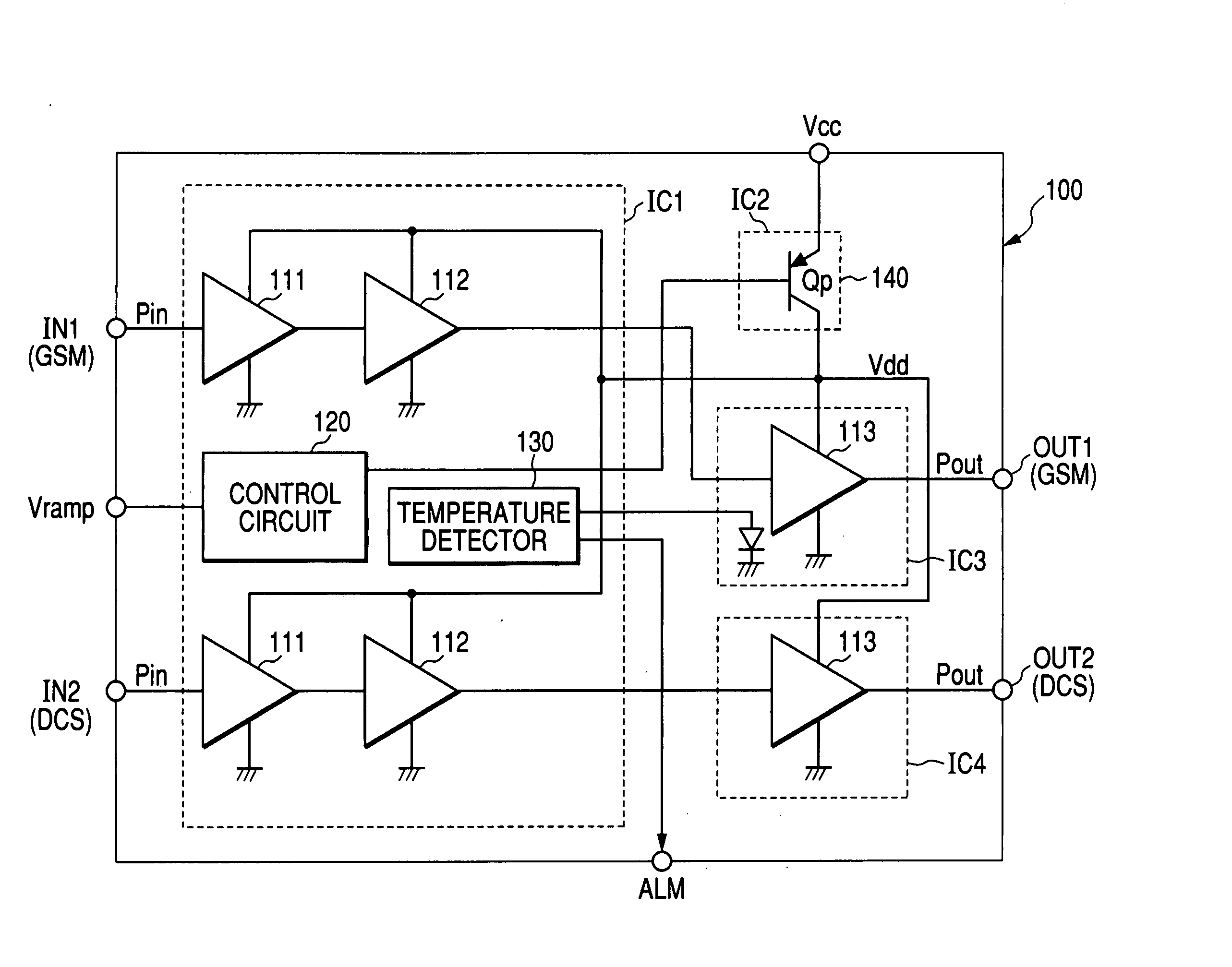

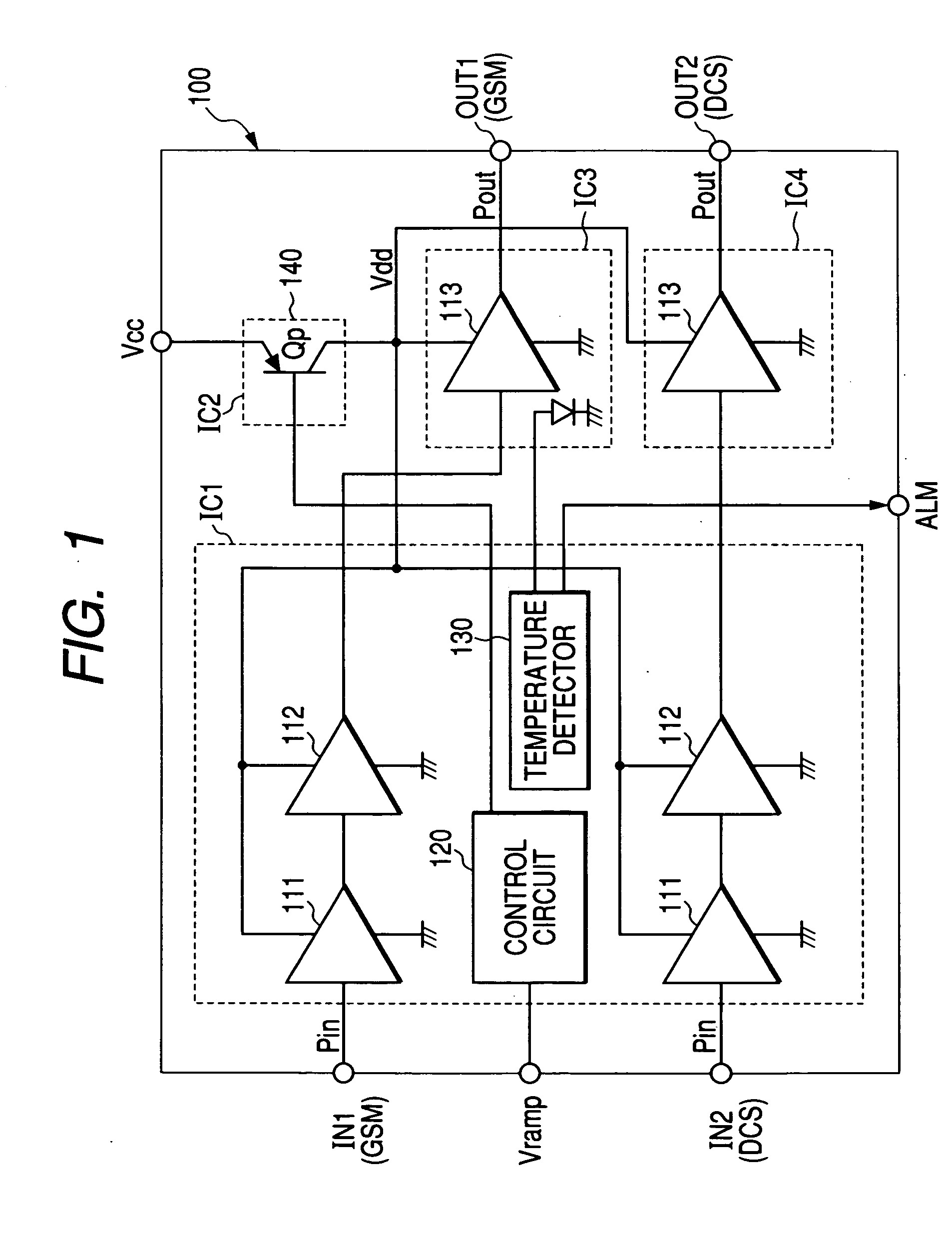

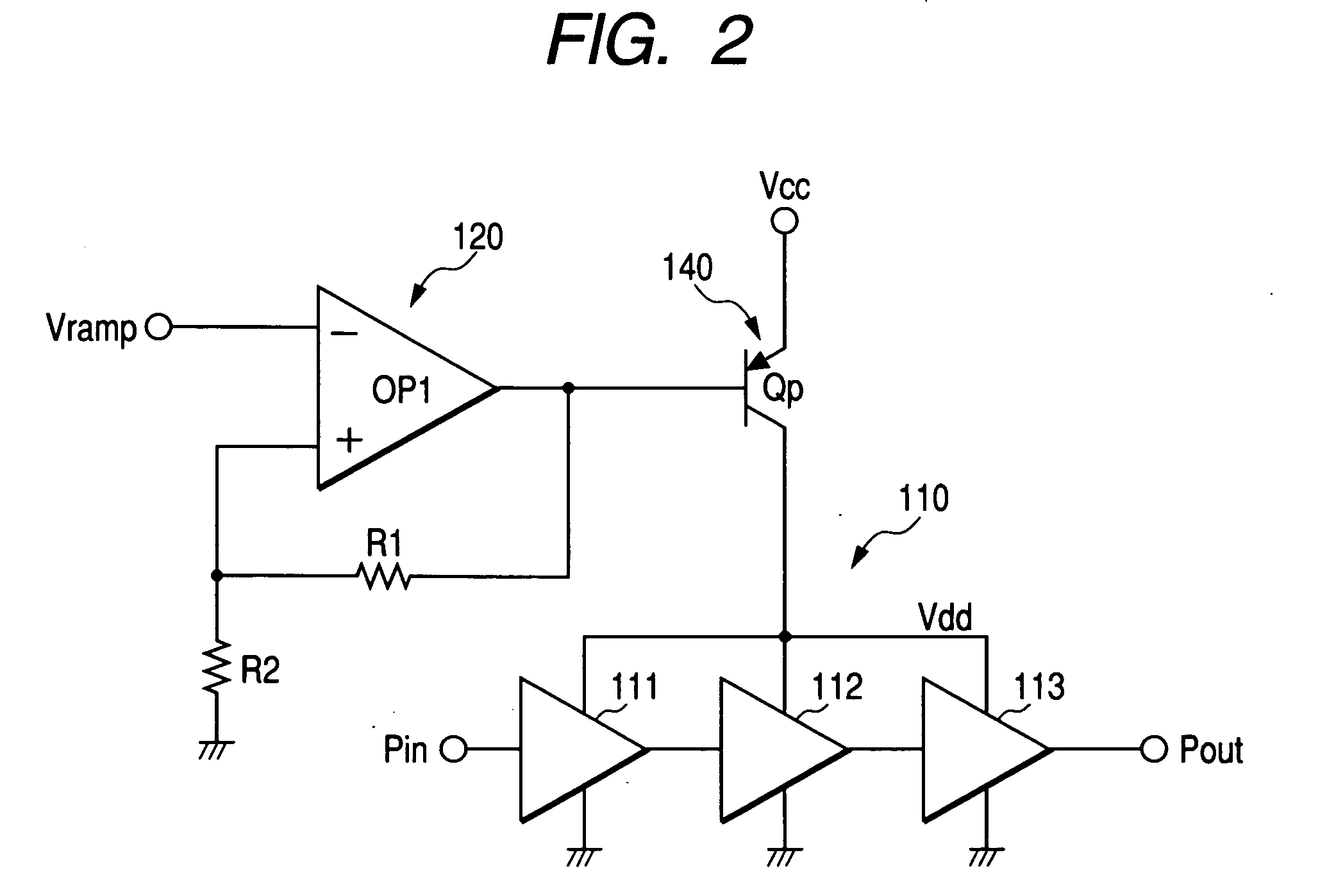

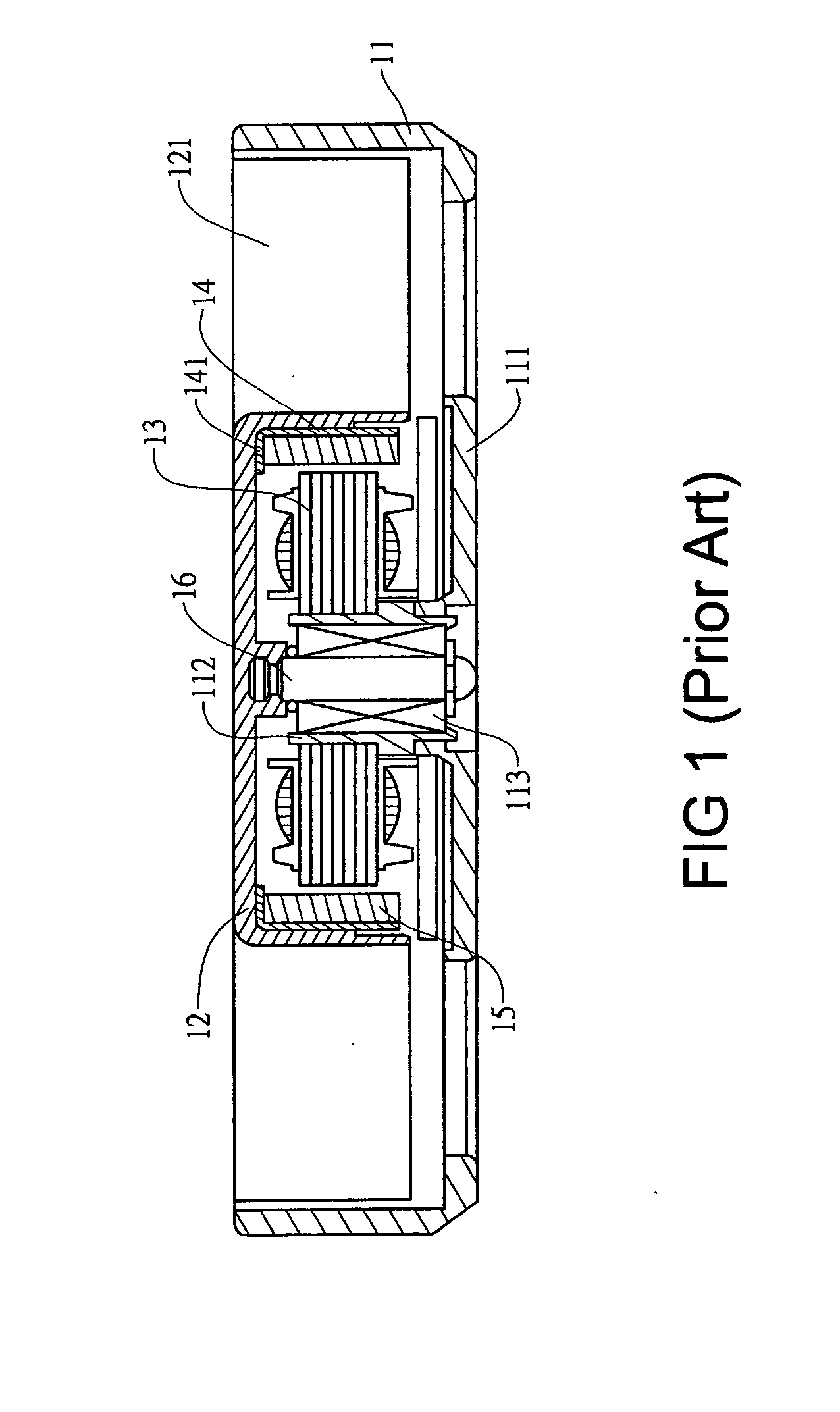

Electric component for high frequency power amplifier

InactiveUS20050280471A1Lower temperatureSmall sizeGain controlAmplifier modifications to reduce temperature/voltage variationHysteresisReference level

An RF power module in which operating voltage is controlled by a control signal based on amplitude information includes a temperature detecting device which is provided over a semiconductor chip formed with an amplifying transistor or a semiconductor chip formed with a power source circuit; and a detector having a hysteresis characteristic which is provided over the semiconductor chip formed with the device or a different semiconductor chip, applies a bias to the temperature detecting device to compare the state of the device at two reference levels, outputs a signal indicating abnormality when judging that the temperature of the semiconductor chip formed with the temperature detecting device is above a predetermined temperature, and outputs a signal indicating normality when judging that the temperature of the semiconductor chip is below a second predetermined temperature lower than the predetermined temperature.

Owner:RENESAS ELECTRONICS CORP +1

Secondary fuel injection from stage one nozzle

InactiveUS7603863B2Reduce NOx emissionLower temperatureTurbine/propulsion fuel supply systemsContinuous combustion chamberInjectorEngineering

A secondary combustion system for a stage one turbine nozzle. The secondary combustion system may include a supply tube extending into the stage one nozzle, a number of injectors extending from the supply tube to an outer surface of the stage one nozzle, and an air gap surrounding each of the number of injectors.

Owner:GENERAL ELECTRIC CO

Albumin-free factor VIII formulations

InactiveUS7087723B2Lower temperatureFactor VIIPowder deliveryPharmaceutical preservativesBuffering agent

A Factor VIII composition formulated without albumin, comprising the following formulation excipients in addition to Factor VIII: 4% to 10% of a bulking agent selected from the group consisting of mannitol, glycine and alanine; 1% to 4% of a stabilizing agent selected from the group consisting of sucrose, trehalose, raffinose, and arginine; 1 mM to 5 mM calcium salt; 100 mM to 300 mM NaCl; and a buffering agent for maintaining a pH of approximately between 6 and 8. Alternatively, the formulation can comprise 2% to 6% hydroxyethyl starch; 1% to 4% of a stabilizing agent selected from the group consisting of sucrose, trehalose, raffinose, and arginine; 1 mM to 5 mM calcium salt; 100 mM to 300 mM NaCl; and a buffering agent for maintaining a pH of approximately between 6 and 8. In a further embodiment, the formulation can comprise: 300 mM to 500 mM NaCl; 1% to 4% of a stabilizing agent selected from the group consisting of sucrose, trehalose, raffinose, and arginine; 1 mM to 5 mM calcium salt; and a buffering agent.

Owner:UNIV OF CONNECTICUT +1

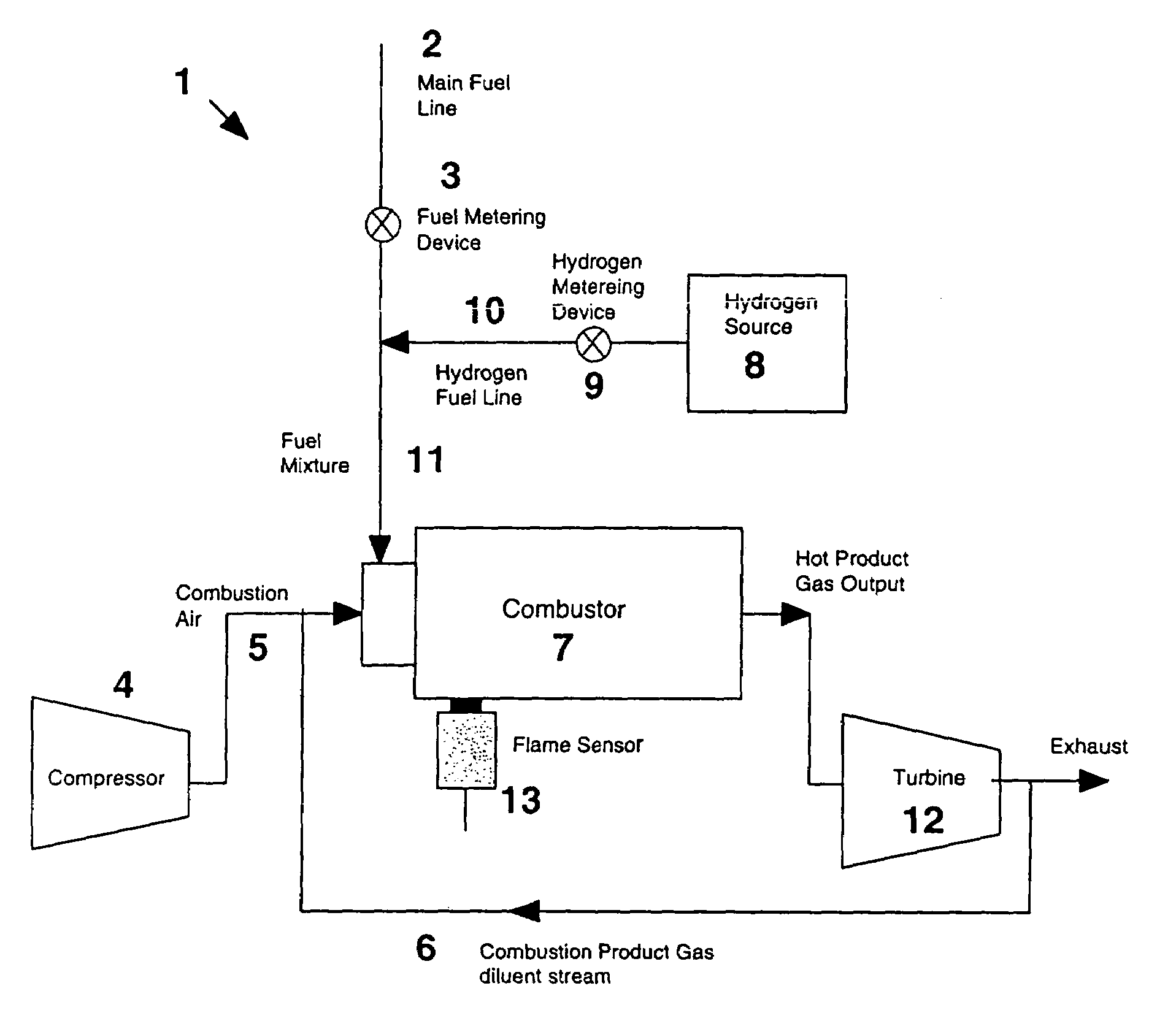

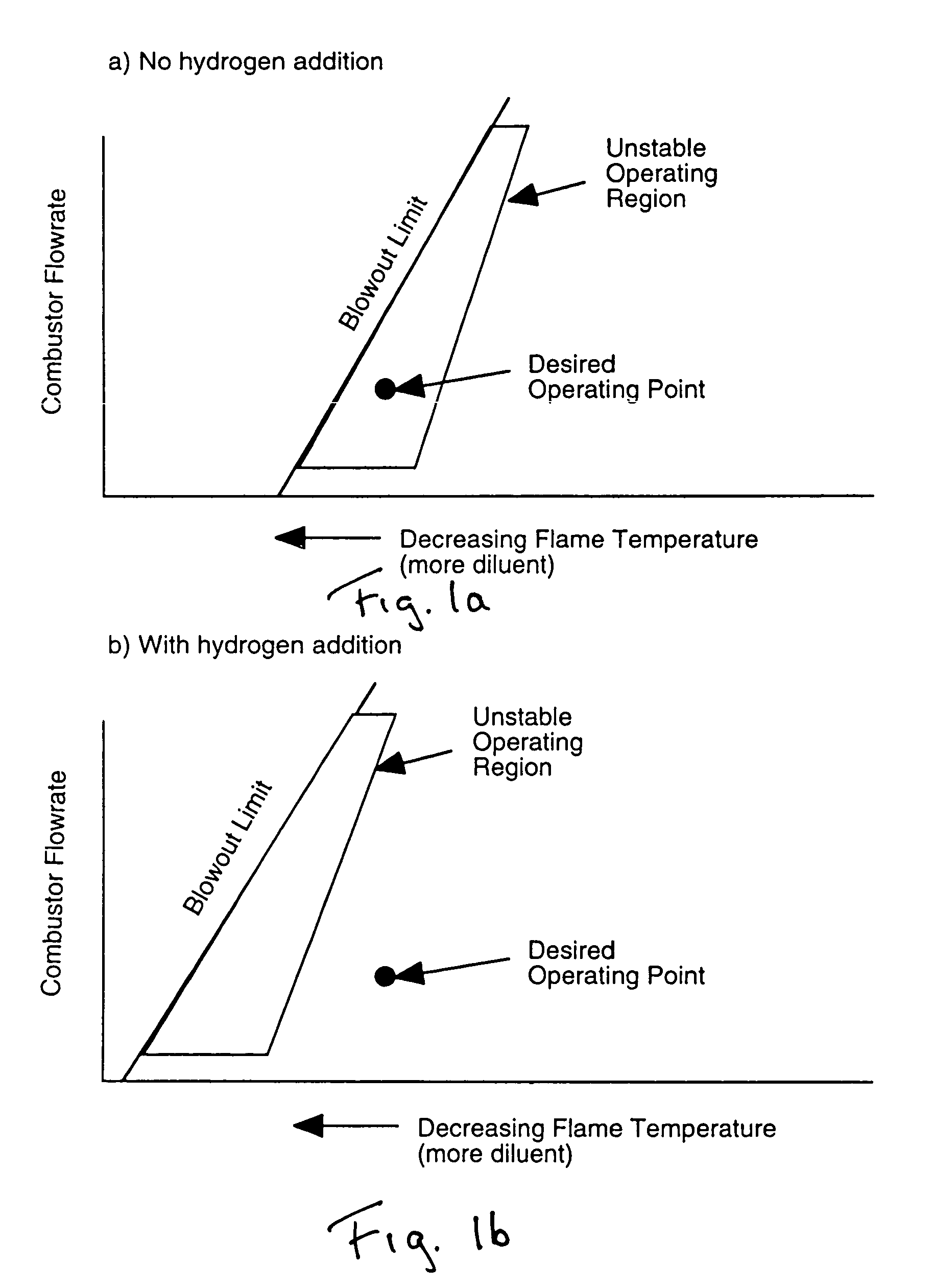

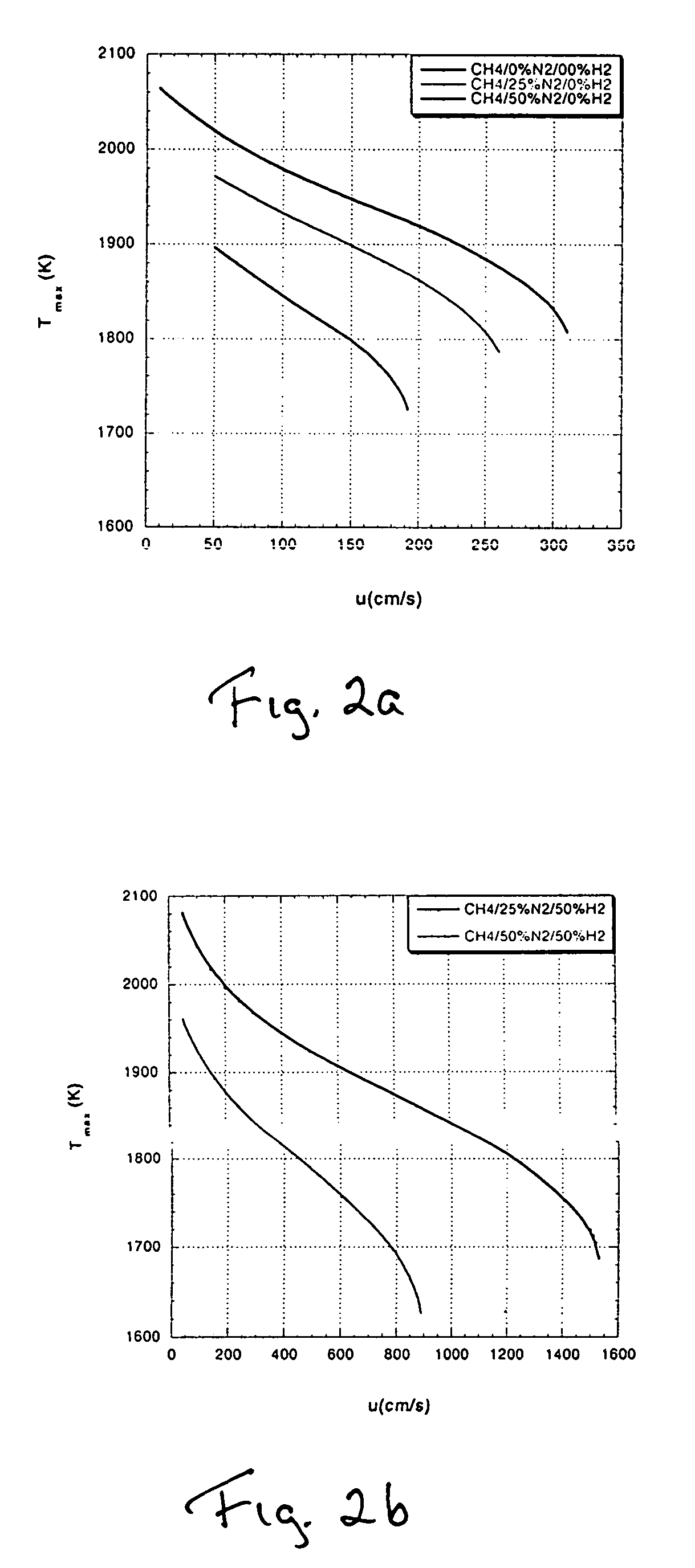

Method for control of NOx emission from combustors using fuel dilution

ActiveUS7162864B1Fast reaction timeLower temperatureInternal combustion piston enginesExhaust apparatusBiomassGas turbines

A method of controlling NOx emission from combustors. The method involves the controlled addition of a diluent such as nitrogen or water vapor, to a base fuel to reduce the flame temperature, thereby reducing NOx production. At the same time, a gas capable of enhancing flame stability and improving low temperature combustion characteristics, such as hydrogen, is added to the fuel mixture. The base fuel can be natural gas for use in industrial and power generation gas turbines and other burners. However, the method described herein is equally applicable to other common fuels such as coal gas, biomass-derived fuels and other common hydrocarbon fuels. The unique combustion characteristics associated with the use of hydrogen, particularly faster flame speed, higher reaction rates, and increased resistance to fluid-mechanical strain, alter the burner combustion characteristics sufficiently to allow operation at the desired lower temperature conditions resulting from diluent addition, without the onset of unstable combustion that can arise at lower combustor operating temperatures.

Owner:SANDIA NATIOANL LAB

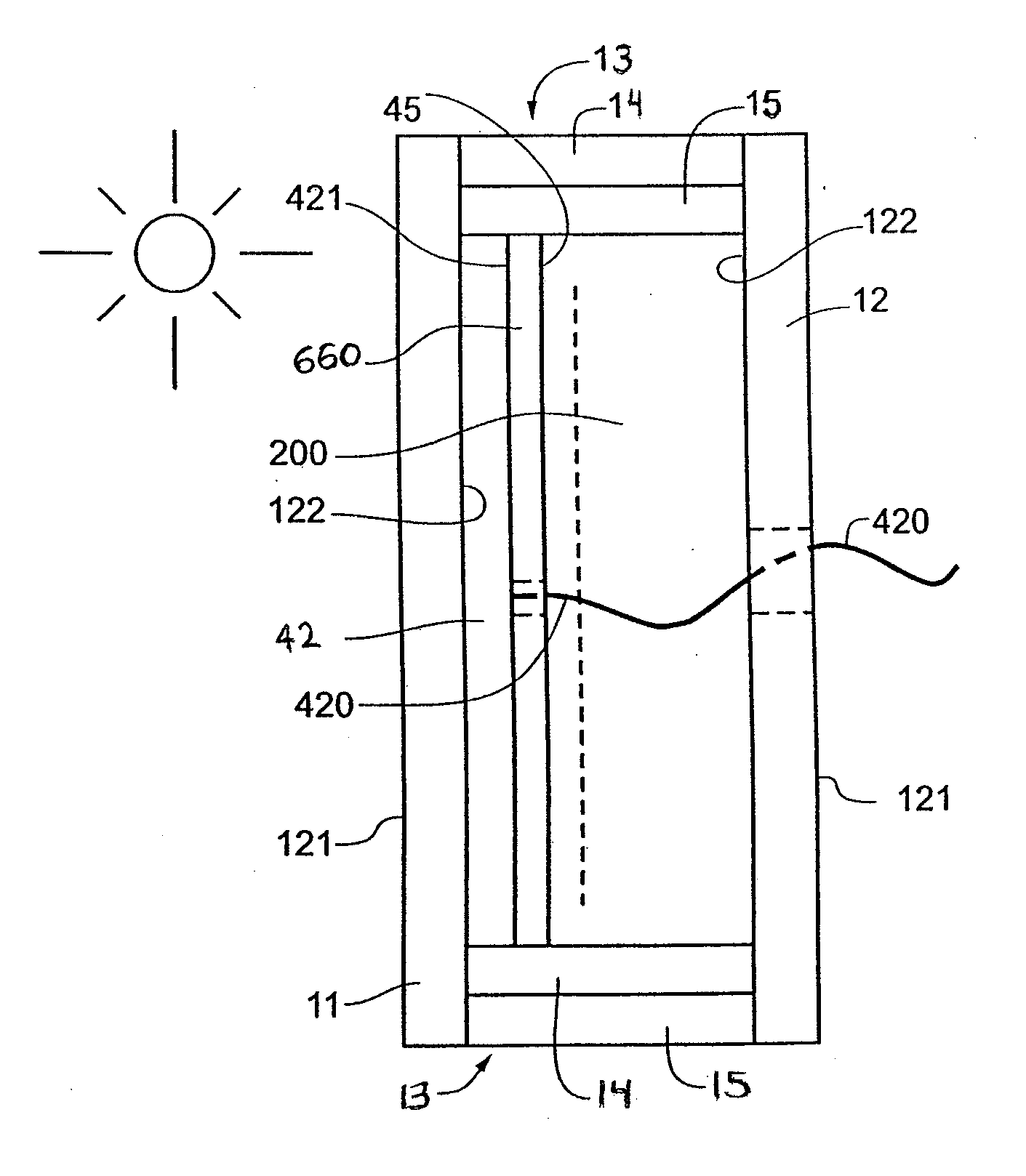

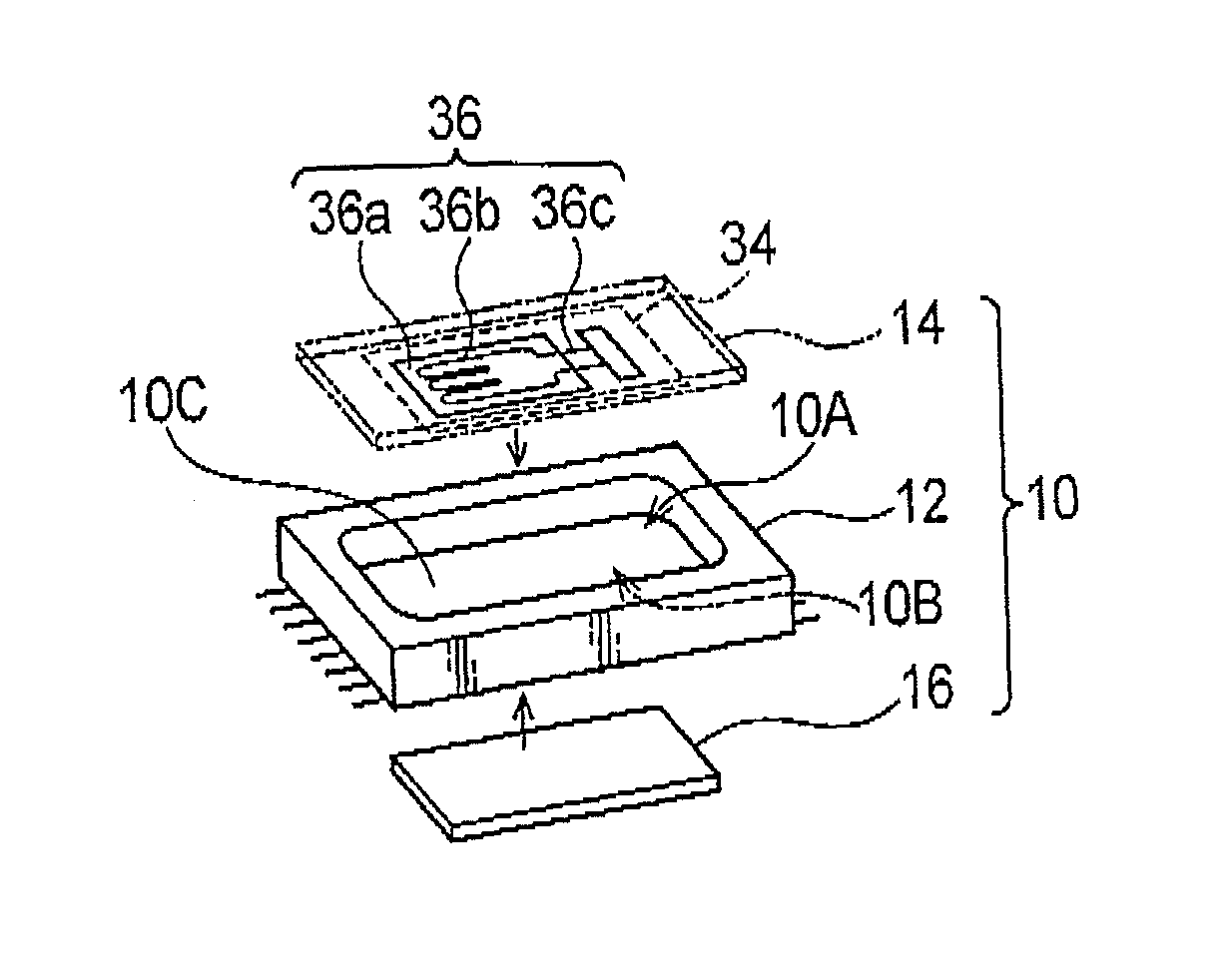

Photovoltaic Glazing Assembly and Method

InactiveUS20090320921A1Prevent efficiency lossLower temperatureDoors/windowsFinal product manufactureElectrical and Electronics engineeringCentral region

A photovoltaic glazing assembly including first and second substrates, at least one being formed of a light transmitting material. The assembly includes a photovoltaic coating over at least the central region of a surface of the first substrate or the second substrate. In some embodiments, a seal system encloses a gas space between the substrates and optionally has a thickness of between approximately 0.01 inch and approximately 0.1 inch. Certain embodiments provide a flexible and electrically non-conductive retention film over the photovoltaic coating. Additionally or alternatively, the assembly can have a peripheral seal system with relative dimensions in certain ranges. Advantageous manufacturing methods are also provided.

Owner:CARDINAL CG

Fire retardant and fire extinguishing material

A novel composition for the control of fire is disclosed. The novel composition can be used as a fire extinguisher or as a fire retardant. The composition is prepared by the admixture of a preferred amount of a selected emollient, a preferred amount of a selected emulsifier, and a preferred amount of a selected dispersant in a water carrier. To the minimal mixture may be added a preferred amount of a selected oxygen competitor, a preferred amount of a selected coolant, a preferred amount of a selected radical scavenger, or a preferred amount of a selected oxygen depleting compound. In the most preferred embodiment all of the foregoing are admixed together in a water carrier.The resulting composition functions well as a fire extinguisher by extinguishing flame. It also acts as an effective fire retardant when applied to a flammable material as a prophylactic procedure. In these instances, it is best to apply the composition to the surface of the flammable material between the surface of the flammable material and any available oxygen source.

Owner:SUMMIT ENVIRONMENTAL CORP INC

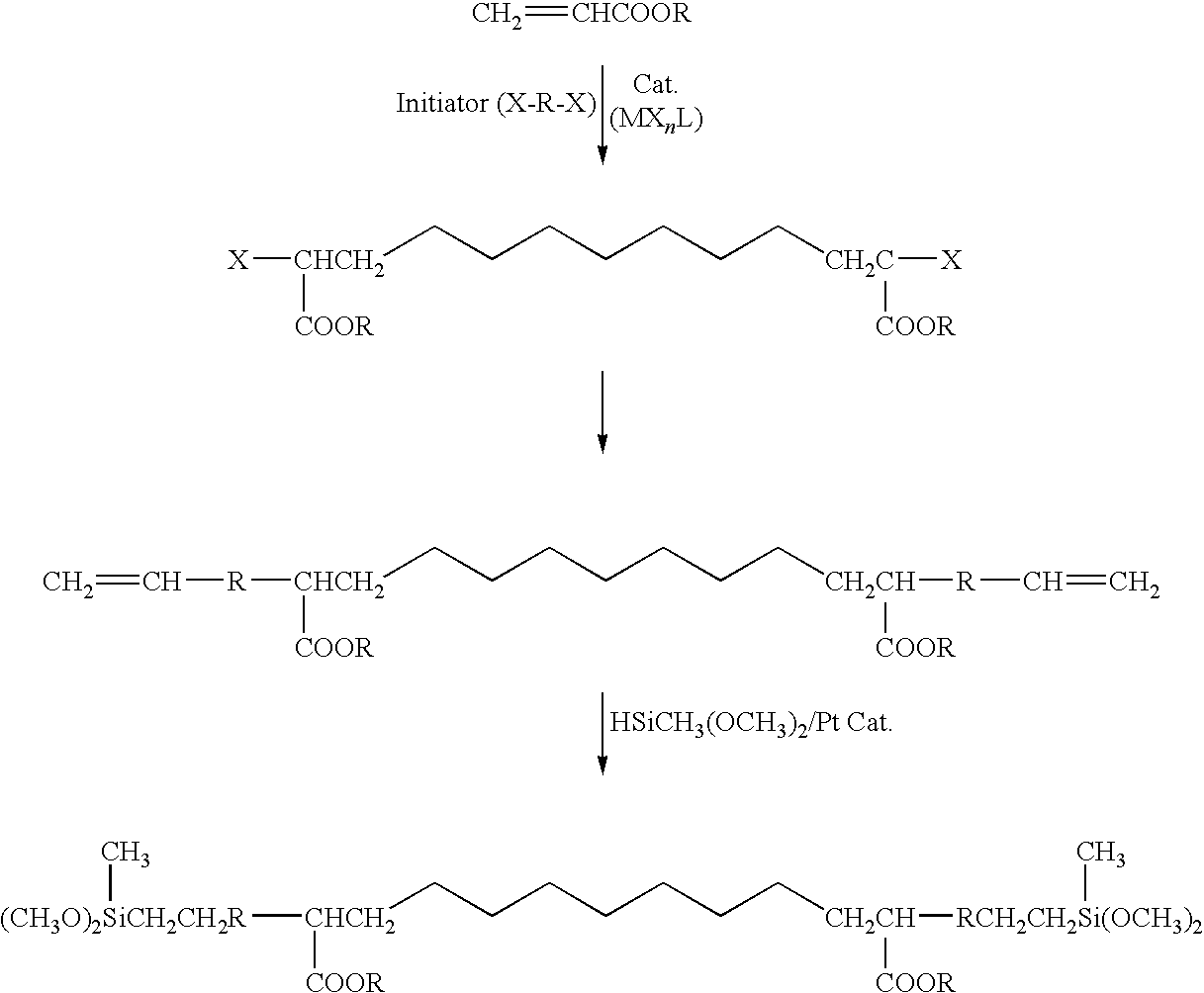

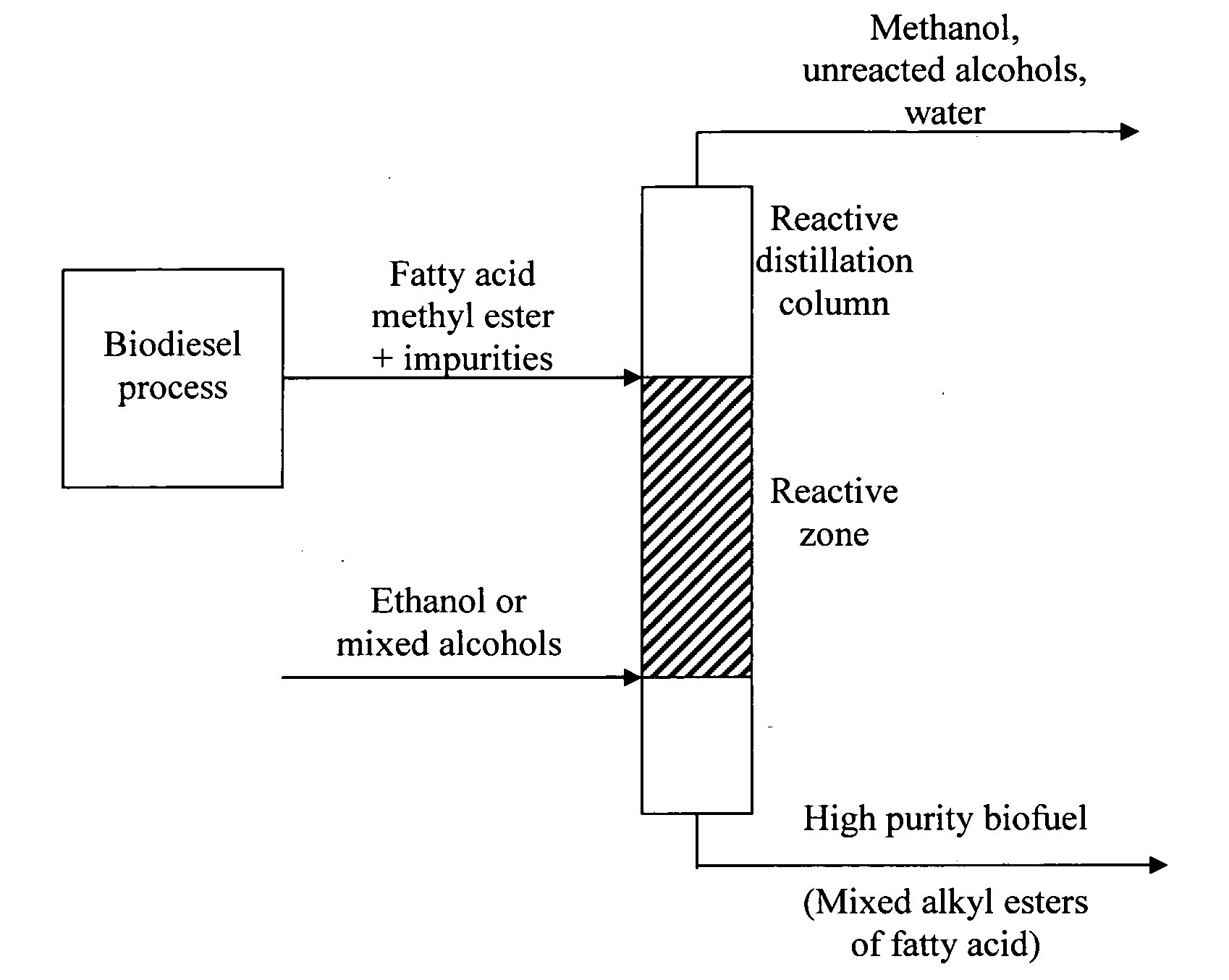

Process for producing mixed esters of fatty acids as biofuels

InactiveUS20090126262A1Lower temperatureExcellent propertyBiofuelsLiquid carbonaceous fuelsChemistryFatty acid ester

A process for producing mixed esters of fatty acids as biofuel or additive to a petroleum fuel for use in a compression ignition (CI) engine. The process preferably provides a partial transesterification of a mixture of fatty acid methyl esters with at least one alkyl alcohol containing 2 to 8 carbon atoms in the presence of a heterogeneous solid acid catalyst to produce a mixture of the fatty acid methyl esters and alkyl alcohol esters of the fatty acids.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

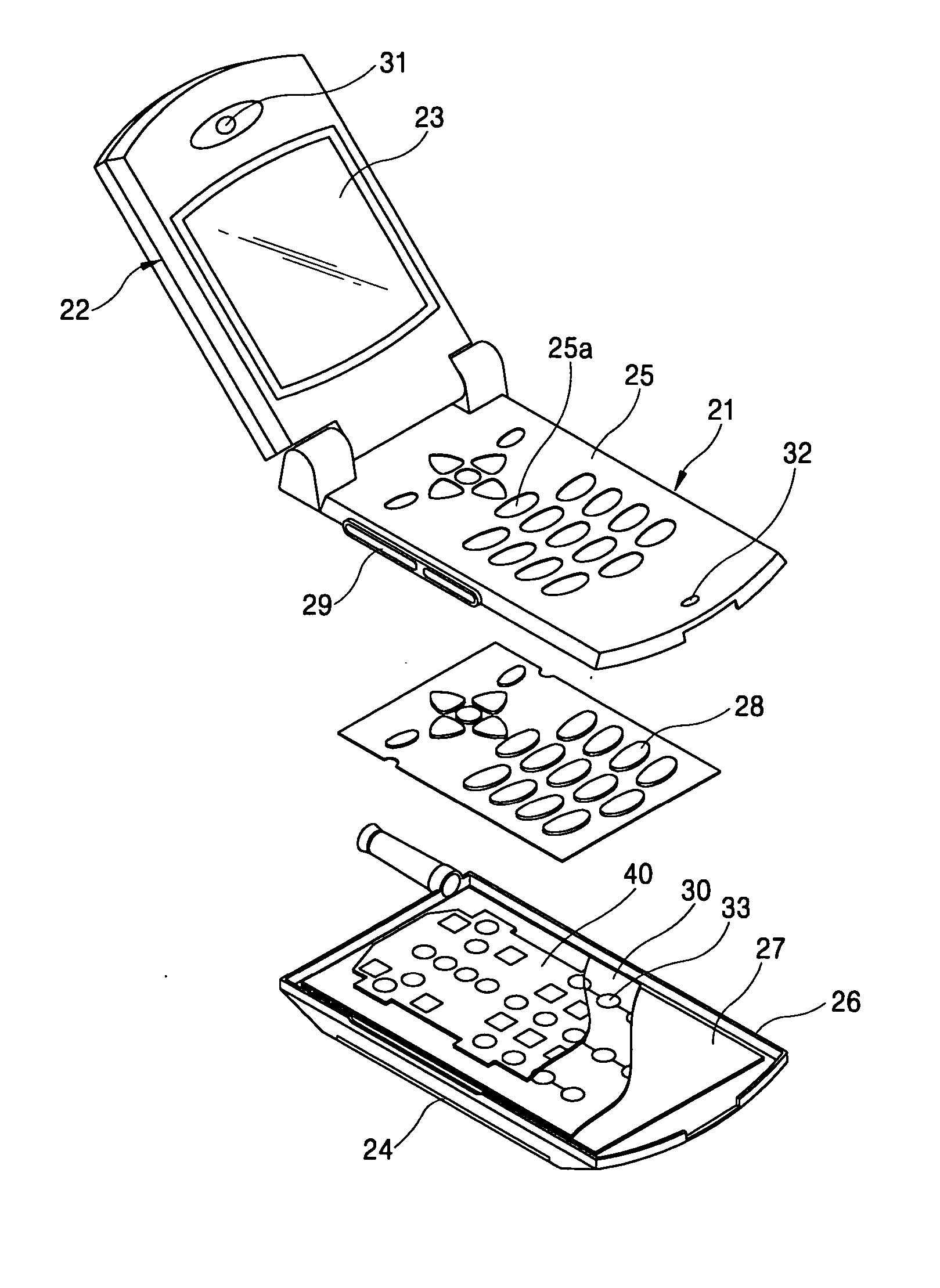

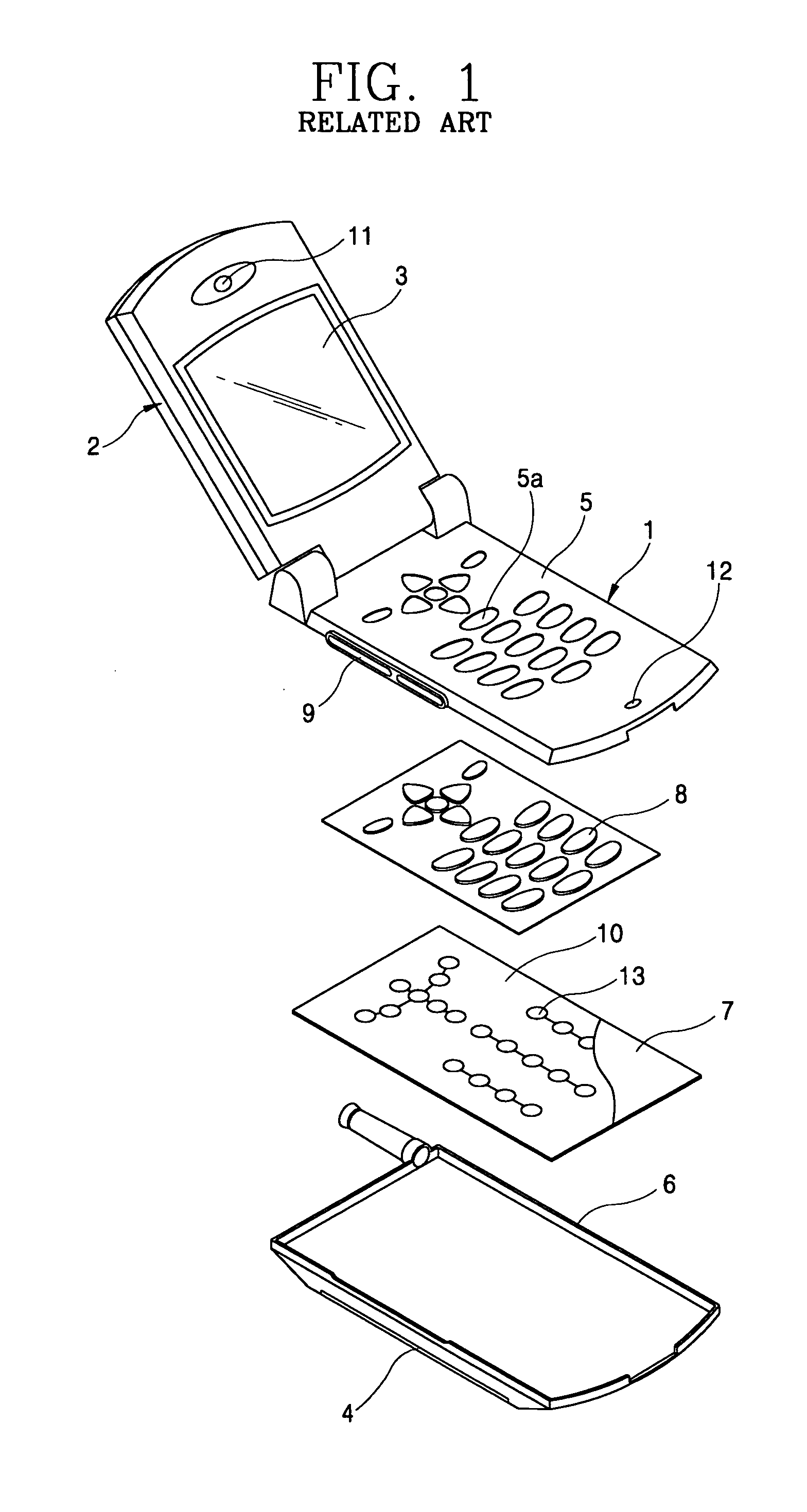

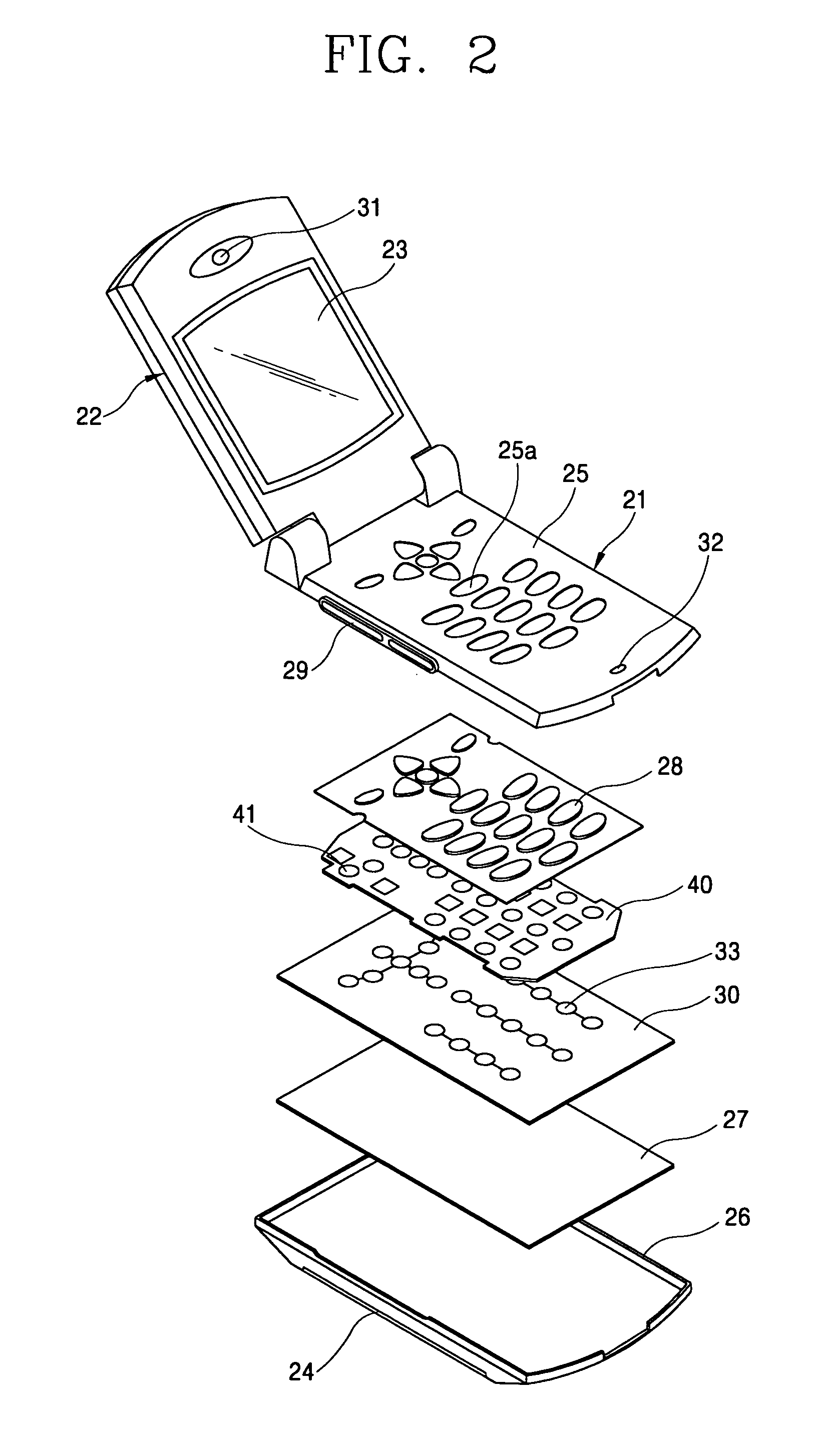

Mobile terminal

InactiveUS20050136967A1Excellent conductivityLower temperatureElectrolytic capacitorsDigital data processing detailsElectrical batteryLoudspeaker

A mobile terminal is provided that may conduct heat generated from a print circuit board when a mobile terminal is in operation to a wider area by use of a heat releasing member having excellent conductivity. This may release unpleasantness that a user feels when using the terminal by lowering a temperature of a key pad. The mobile terminal may include a main body including a plurality of key pads for receiving information from a user; a print circuit board mounted in the main body; a battery provided at the main body; a folder coupled to the main body; a display provided at the folder for displaying a text and other image information; a speaker unit provided at the folder; a microphone unit provided at the main body; and a heat releasing member for releasing heat generated from the print circuit board.

Owner:LG ELECTRONICS INC

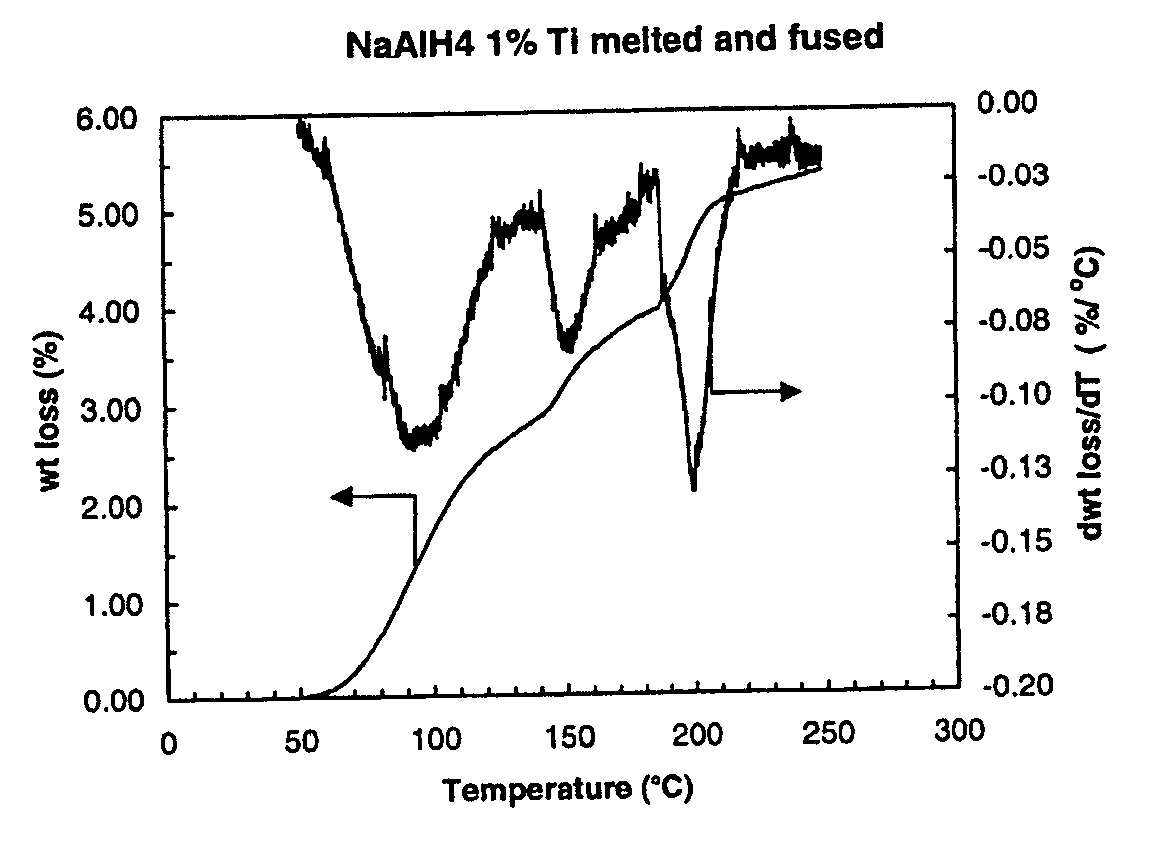

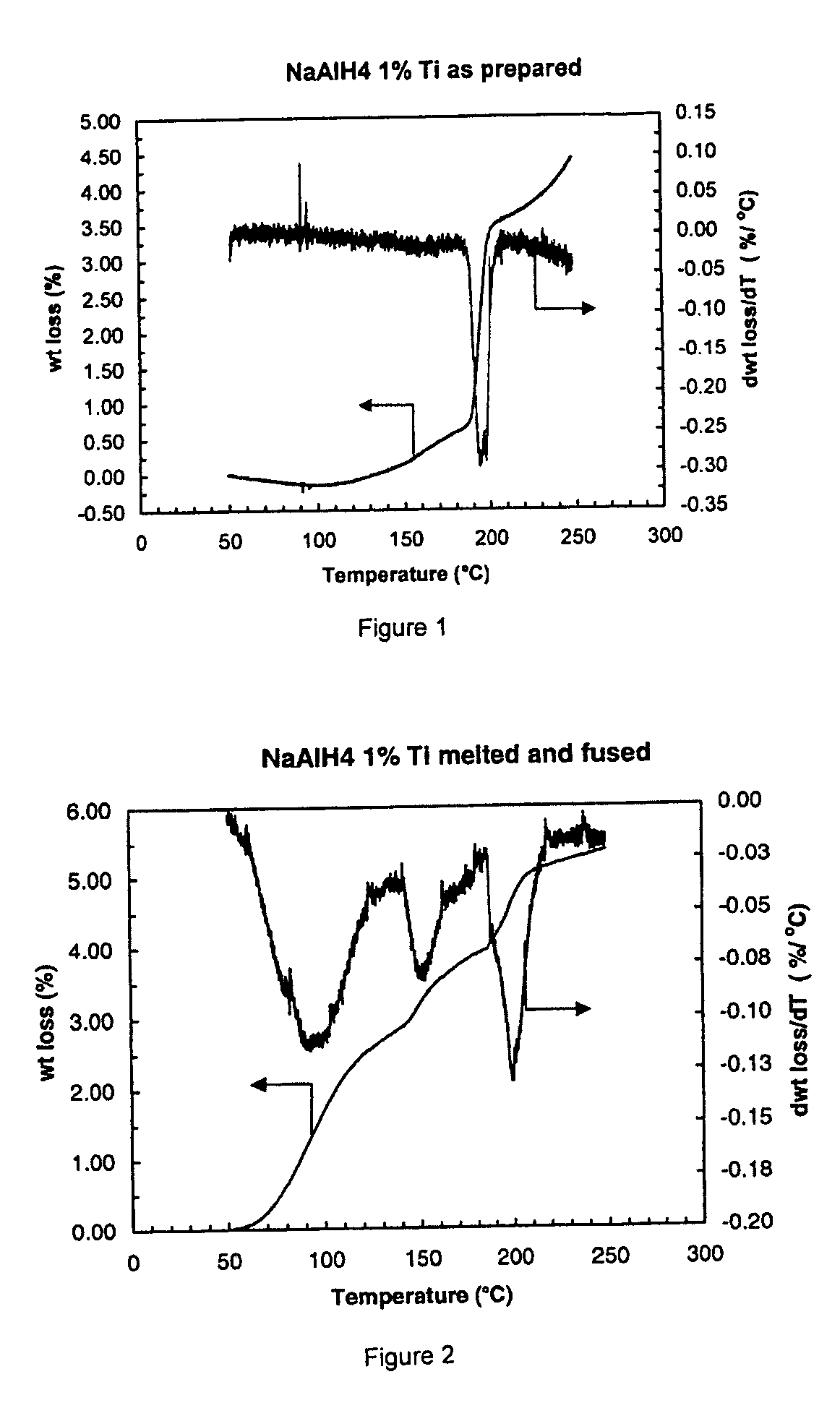

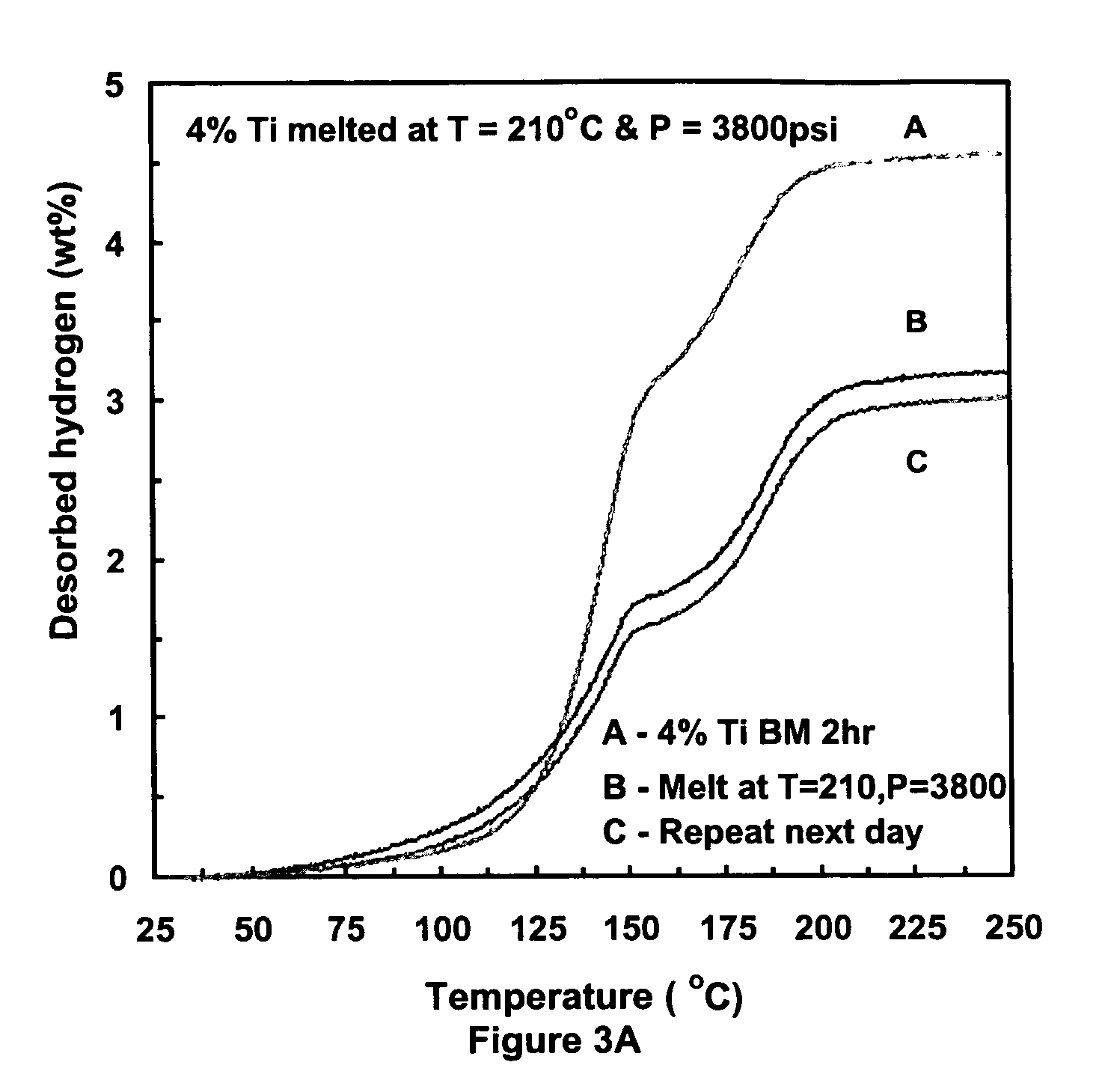

Complex hydrides for hydrogen storage

InactiveUS7094387B2Lower temperatureLow temperature hydrogen desorption kineticsAlkali/alkaline-earth/beryllium/magnesium hydridesMultiple metal hydridesChemistryTitanium butoxide

A hydrogen storage material and process of forming the material is provided in which complex hydrides are combined under conditions of elevated temperatures and / or elevated temperature and pressure with a titanium metal such as titanium butoxide. The resulting fused product exhibits hydrogen desorption kinetics having a first hydrogen release point which occurs at normal atmospheres and at a temperature between 50° C. and 90° C.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS +1

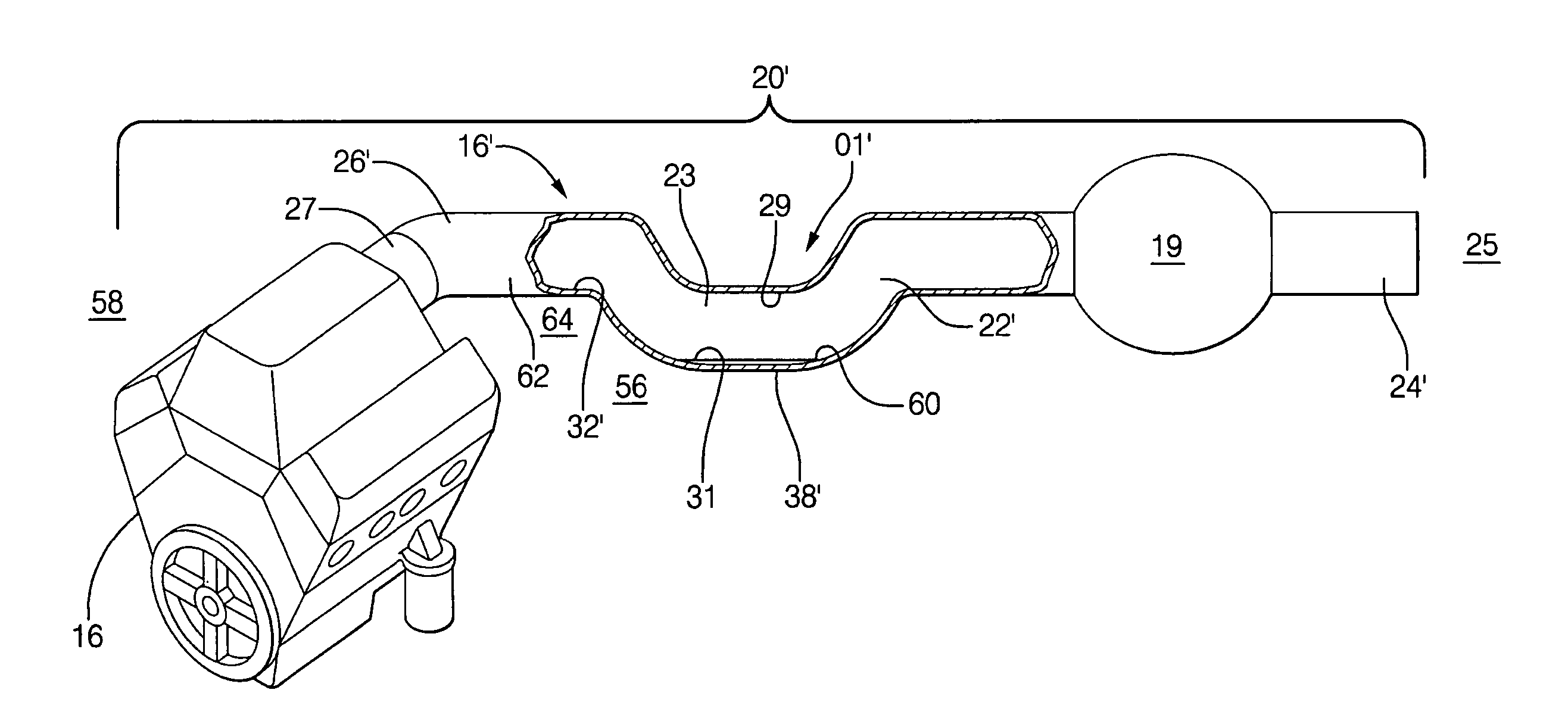

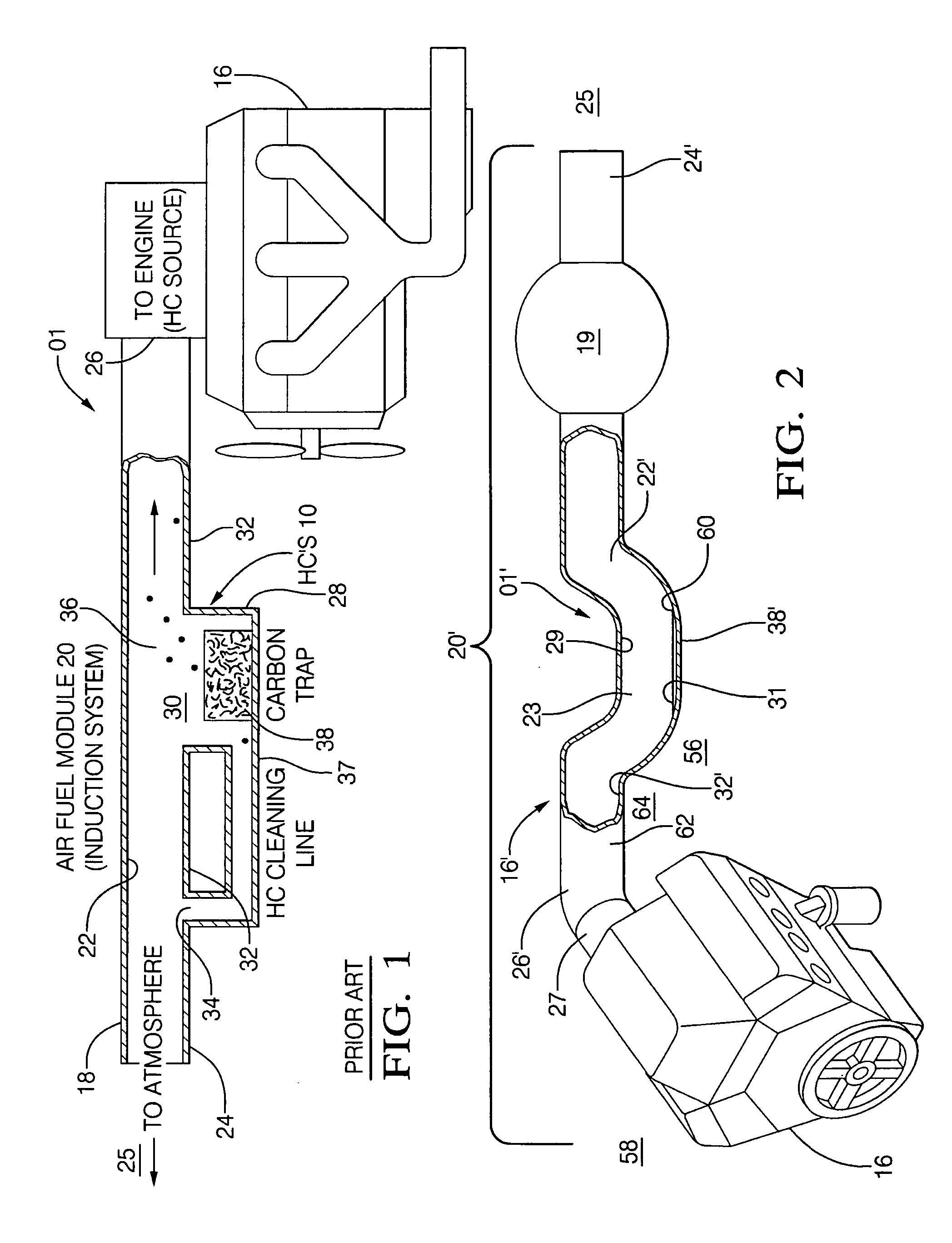

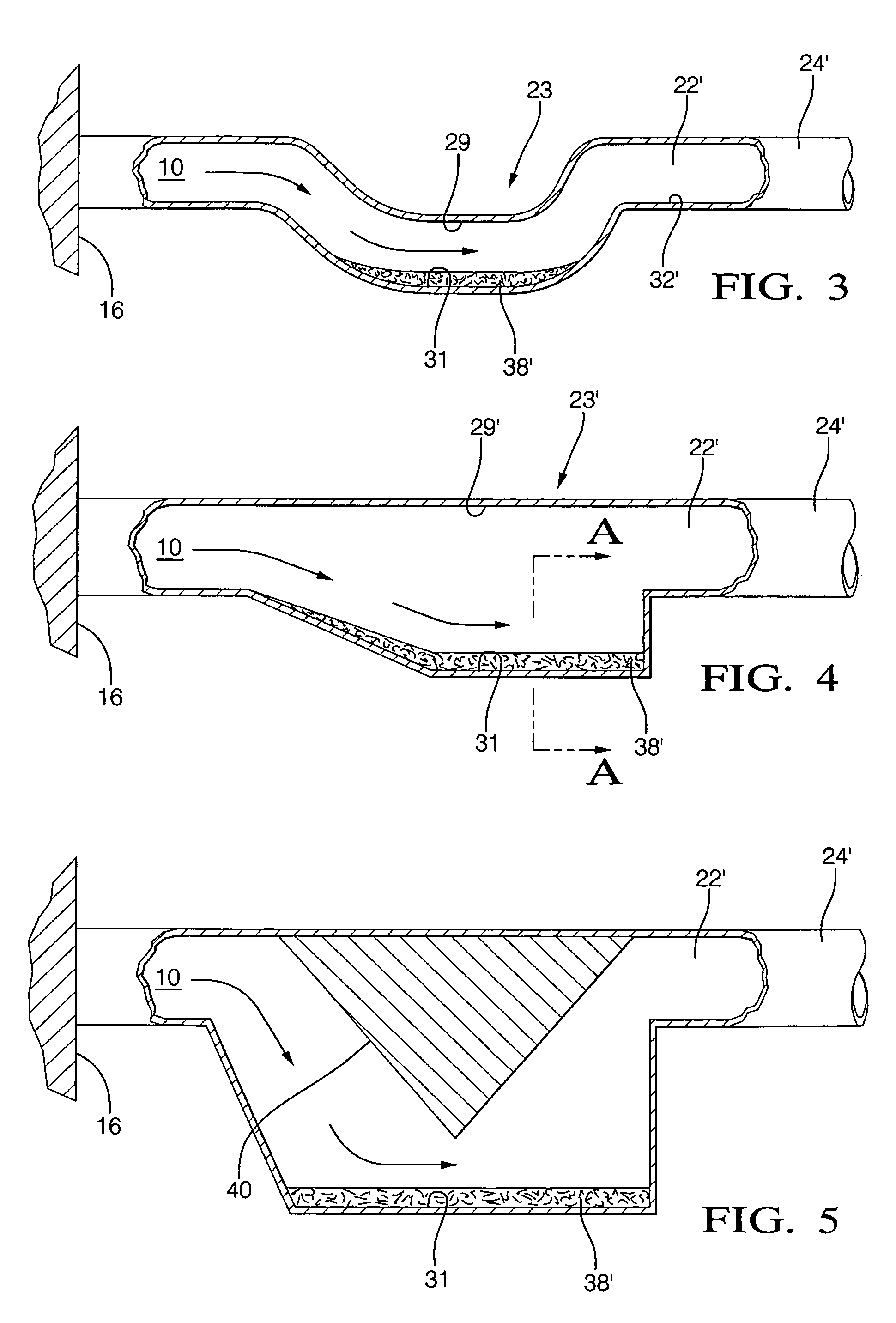

Engine intake hydrocarbon trap system

InactiveUS20060054142A1Increase adsorptionLower temperatureNon-fuel substance addition to fuelMachines/enginesActivated carbonEngineering

An air intake hydrocarbon vapor trap system for an internal combustion engine comprising a hydrocarbon-adsorptive medium, such as activated carbon, disposed in a gravitationally low point in the intake air flow passageway between the entrance to the system and the engine. The intake duct itself is configured to provide the low region for disposition of the medium. The medium is thereby fully exposed to the flow of gases through the duct and is not confined to a separate walled pit as in the prior art. The medium, for example, activated carbon, may be provided in any of several forms, such as in a pelletized bed, a rigid formed structure, or as a “sheet” or “paper.” Preferably, the medium is disposed in the engine compartment to optimally transfer heat away from it during engine shut-down.

Owner:DELPHI TECH INC

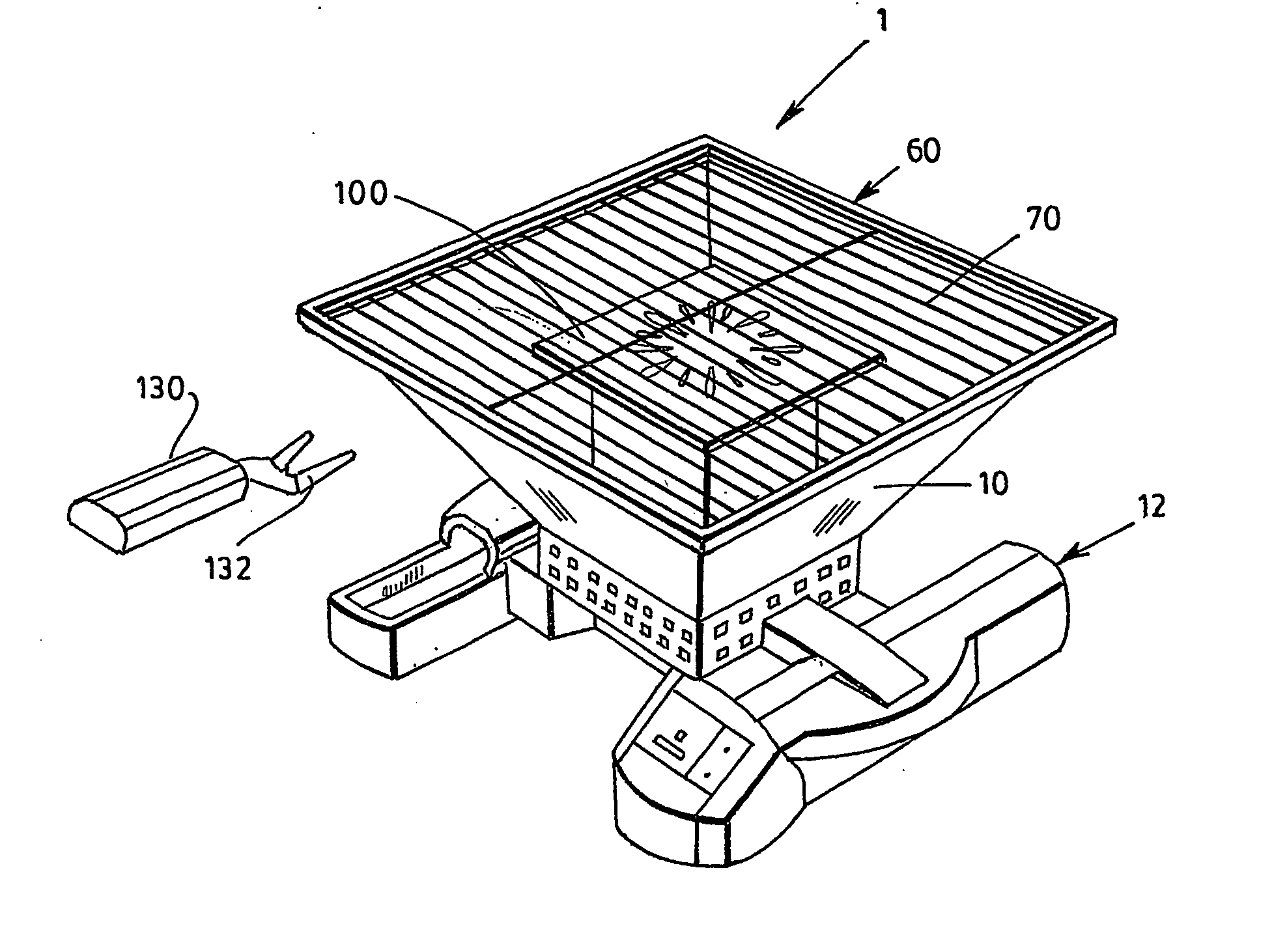

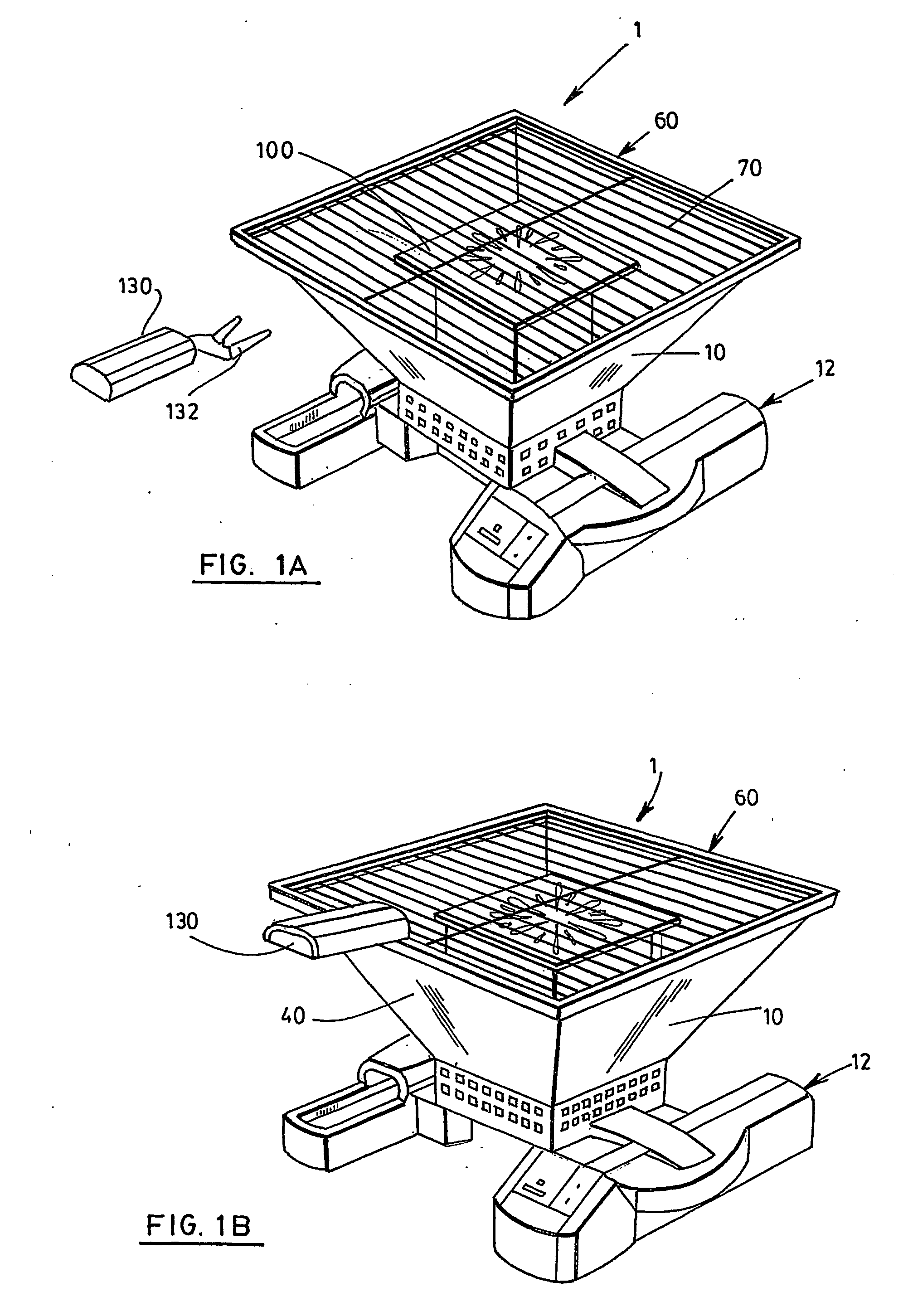

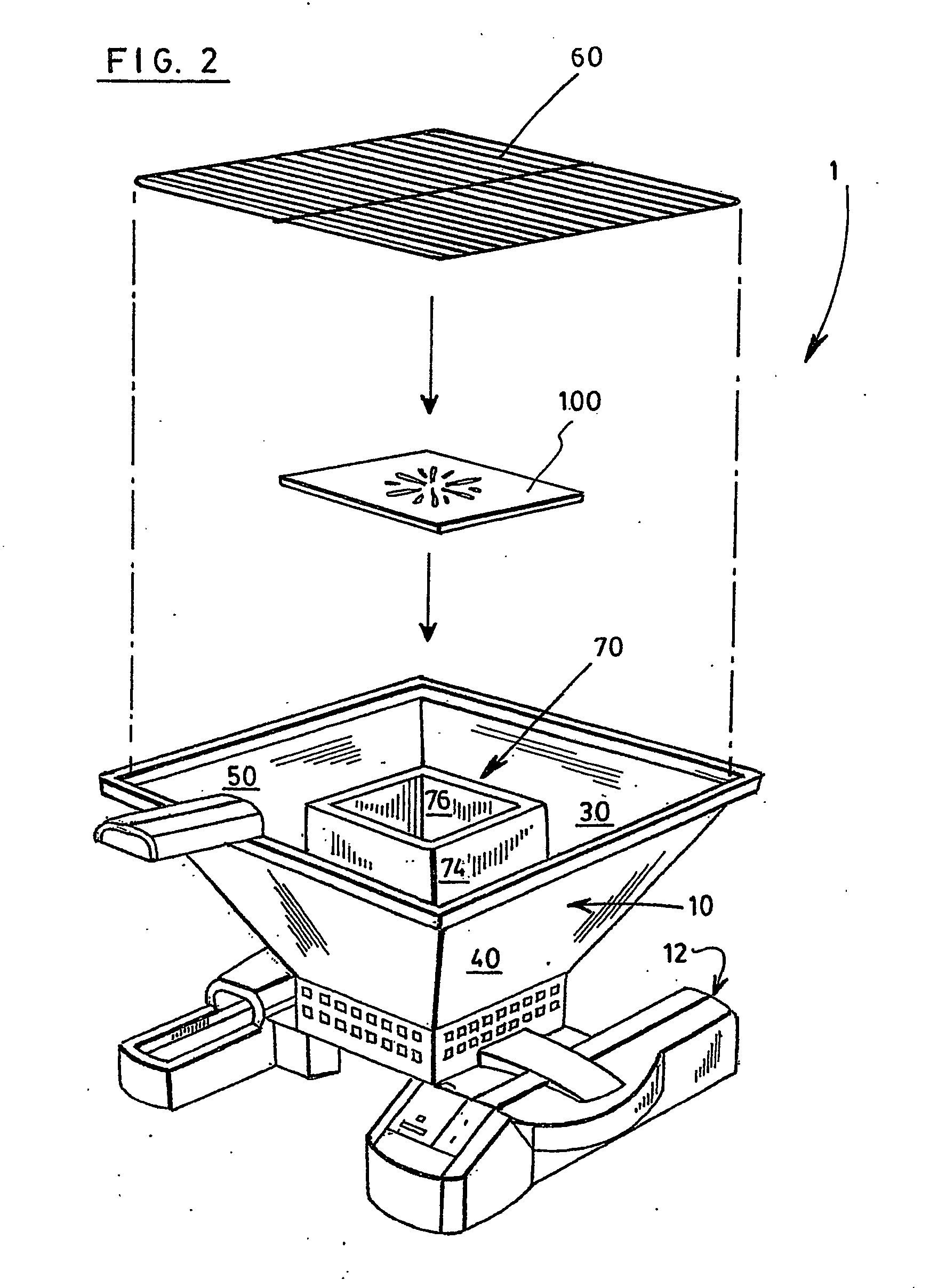

Wood fed barbecue apparatus

InactiveUS20050205076A1Less radiant energy/heat lossLower temperatureDomestic stoves or rangesLighting and heating apparatusRadiant energyForced-air

A barbecue cooking device (1) is disclosed. The barbecue cooking device comprises an inverted frustum casing (10) having a base wall (20), an open top (30) and a slanted side wall section (40) extending from the base wall (20) to the top (30), the slanted side wall section having an inner surface made of a material capable of reflecting radiant energy. A grill (60) mountable on the open top (30) is provided. The barbecue device further comprises a cup-shaped burner (70), with a bottom wall (72) and a side wall section (74), comprising a combustion chamber (76) in an upper portion thereof for burning a combustible material, thereby emitting thermal energy; an air chamber (78) located beneath the combustion chamber (76), the air chamber (78) having an air intake (82) for receiving air; and a diffuser plate (79) separating the combustion chamber (76) and the air chamber (78). The barbecue further comprises a blower (90) operatively connected to the air intake (82) of the air chamber (78) to provide forced-air to the air chamber. The burner (80) is located inside the casing (10) with the side wall section (74) of the burner spanning the height of the casing (10) such that most of the thermal energy emitted by the combustion chamber (76) radiate radially towards the slanted side wall section (40) of the casing (10) where it is reflected towards the grill mounted on top (30) of the casing (10).

Owner:WOODFLAME

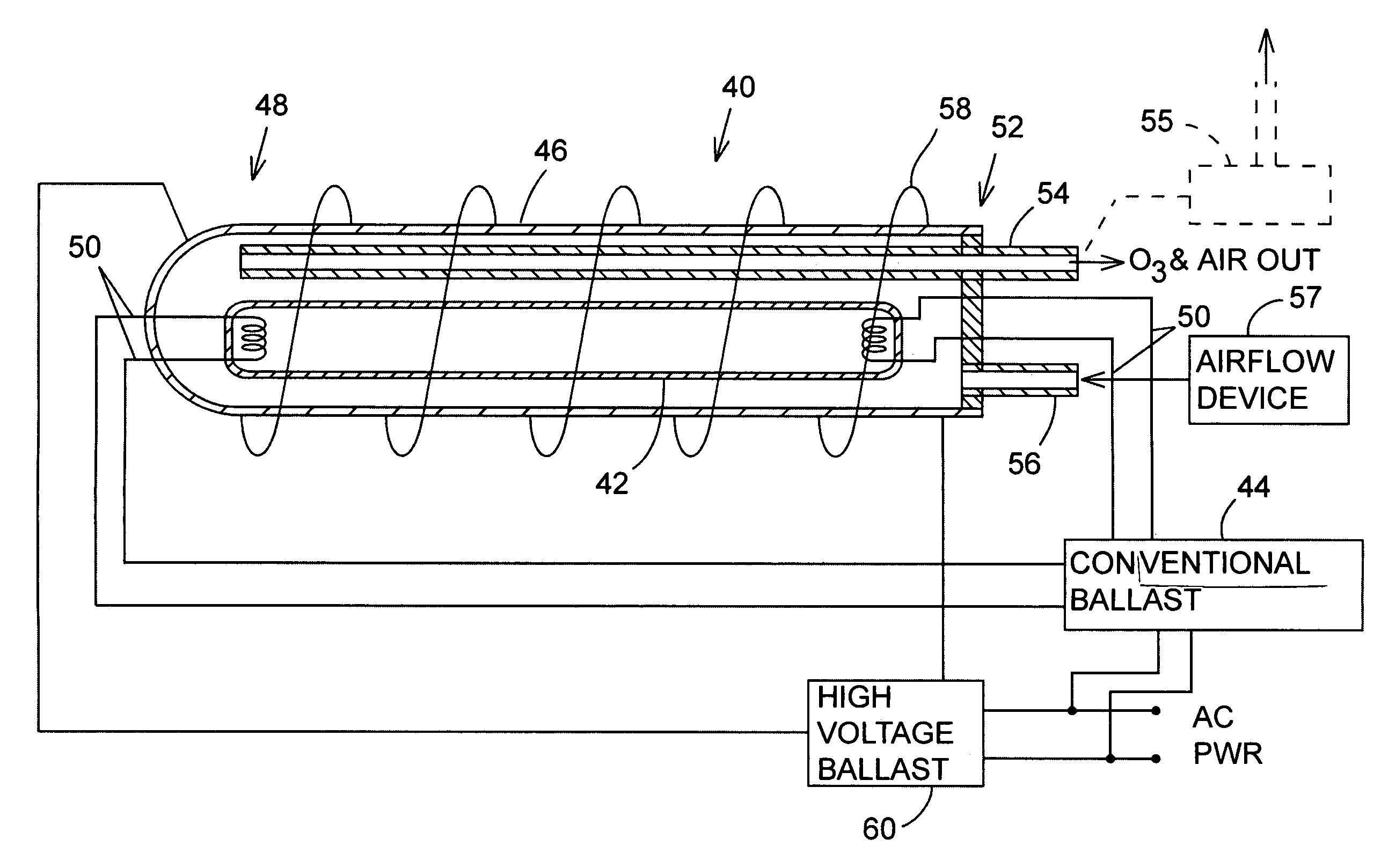

Hybrid ozone generator

InactiveUS6951633B1Increase efficiencyLower temperatureElectrical discharge ozone preparationEnergy based chemical/physical/physico-chemical processesPhysicsElectric field

Owner:BARNES RONALD L

Method for brazing ceramic-containing bodies, and articles made thereby

InactiveUS6884511B1Lower temperatureGlass/slag layered productsNatural mineral layered productsThermal conductivityLithography process

Ceramic-containing bodies can be bonded to other ceramic-containing bodies, or to metals or metal-containing bodies, by way of an aluminum-silicon brazing alloy. Such alloys feature high thermal conductivity and a melting range intermediate to Cu—Sil and Au—Si. By depositing a layer of silicon or aluminum, e.g., by vapor deposition, onto a surface of the ceramic-containing body, the formation of deleterious intermetallic phases at the brazing interface is avoided. This technique is particularly useful for joining reaction-bonded silicon carbide (RBSC) composite bodies, and particularly such composite bodies that contain appreciable amounts of aluminum as a metallurgical modification of the residual silicon phase. When the RBSC body contains minor amounts of the aluminum alloying constituent, or none, the metallization layer is not required. The resulting bonded structures have utility as mirrors, as packaging for electronics, and in semiconductor lithography equipment, e.g., as electrostatic chucks for supporting a silicon wafer during the lithography process.

Owner:BUSINESS ALLIANCE CAPITAL

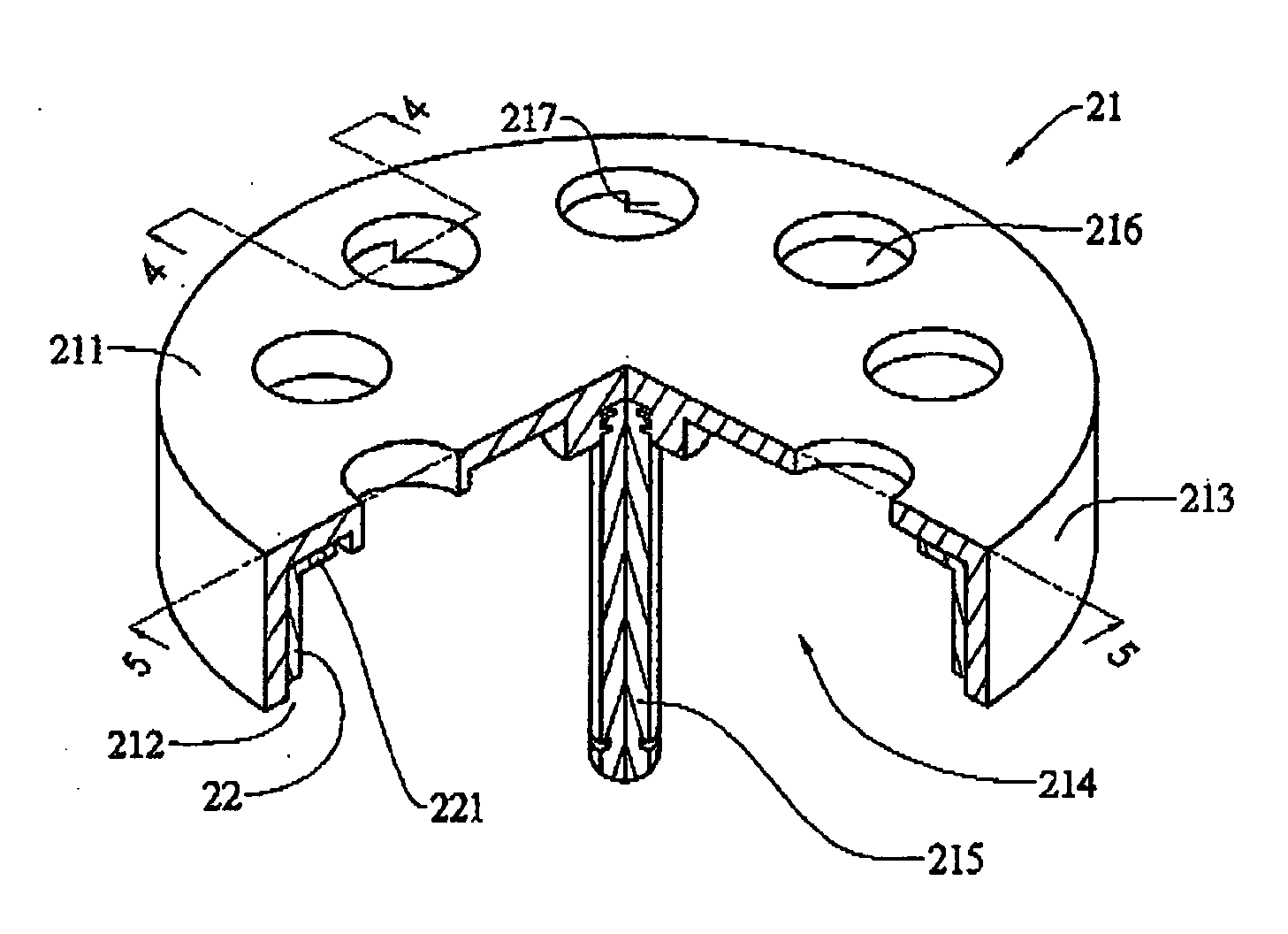

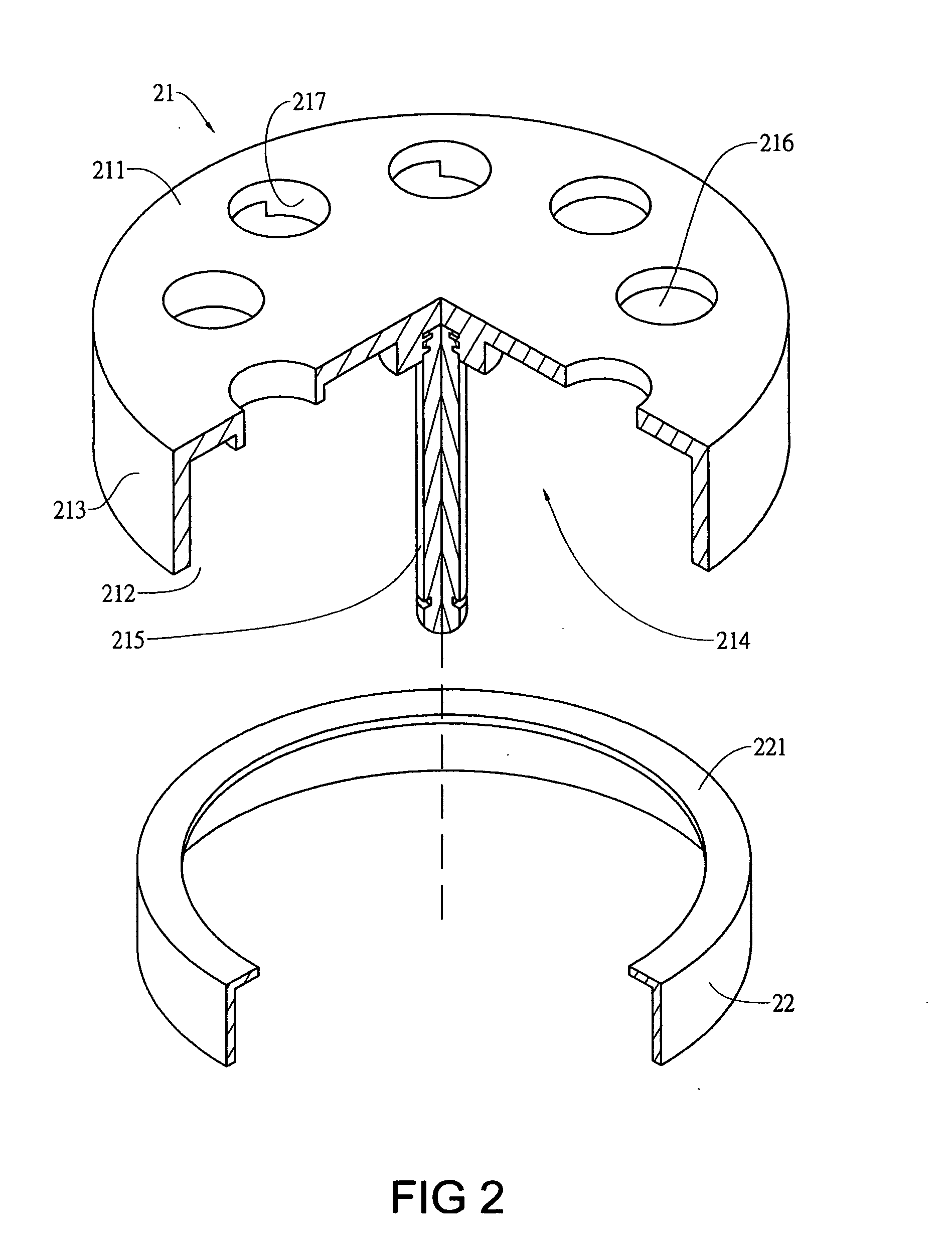

Rotor device capable of forcing heat dissipation

ActiveUS20060181163A1Reduce temperatureLower temperatureMagnetic circuit rotating partsPump componentsEngineering

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

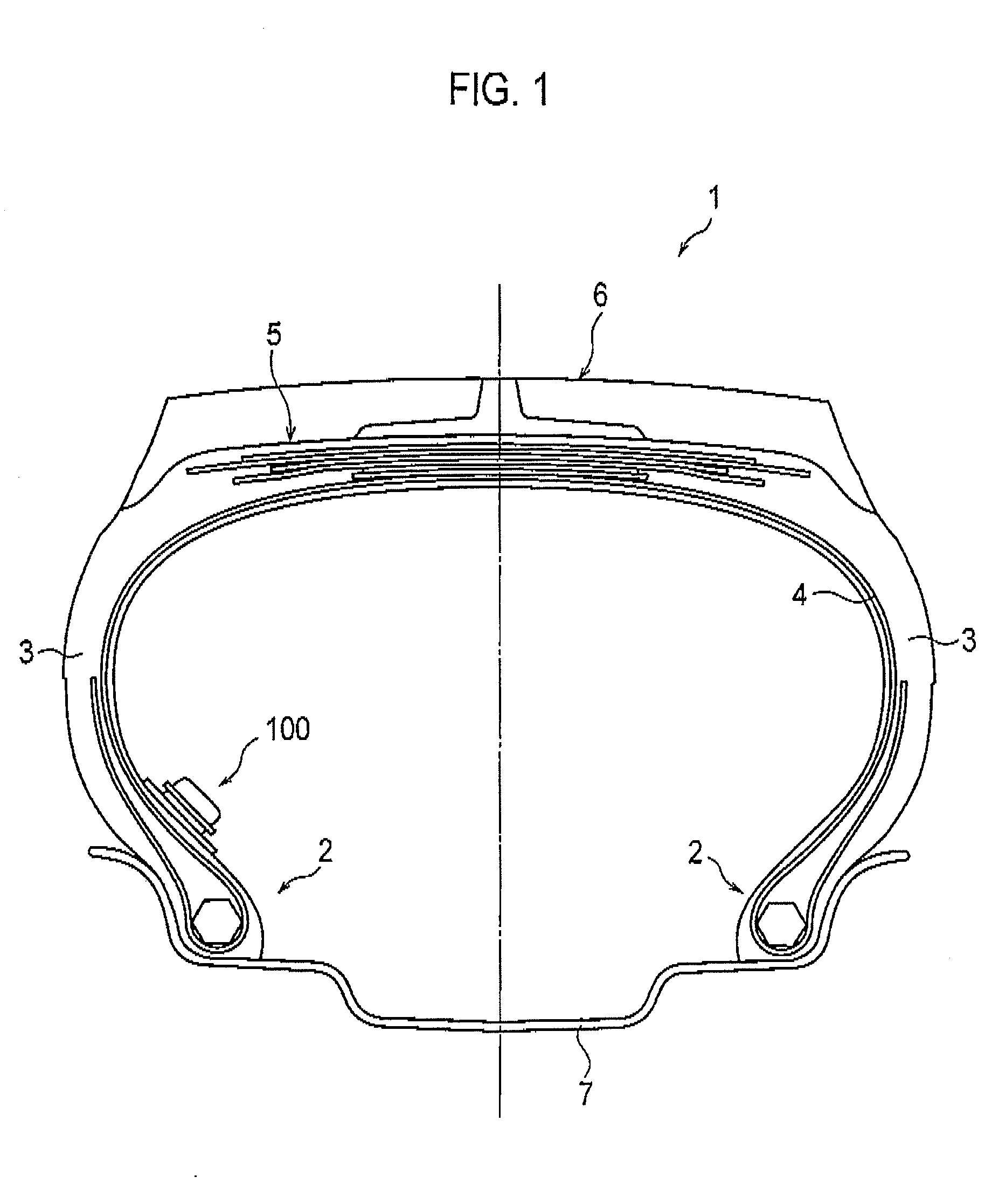

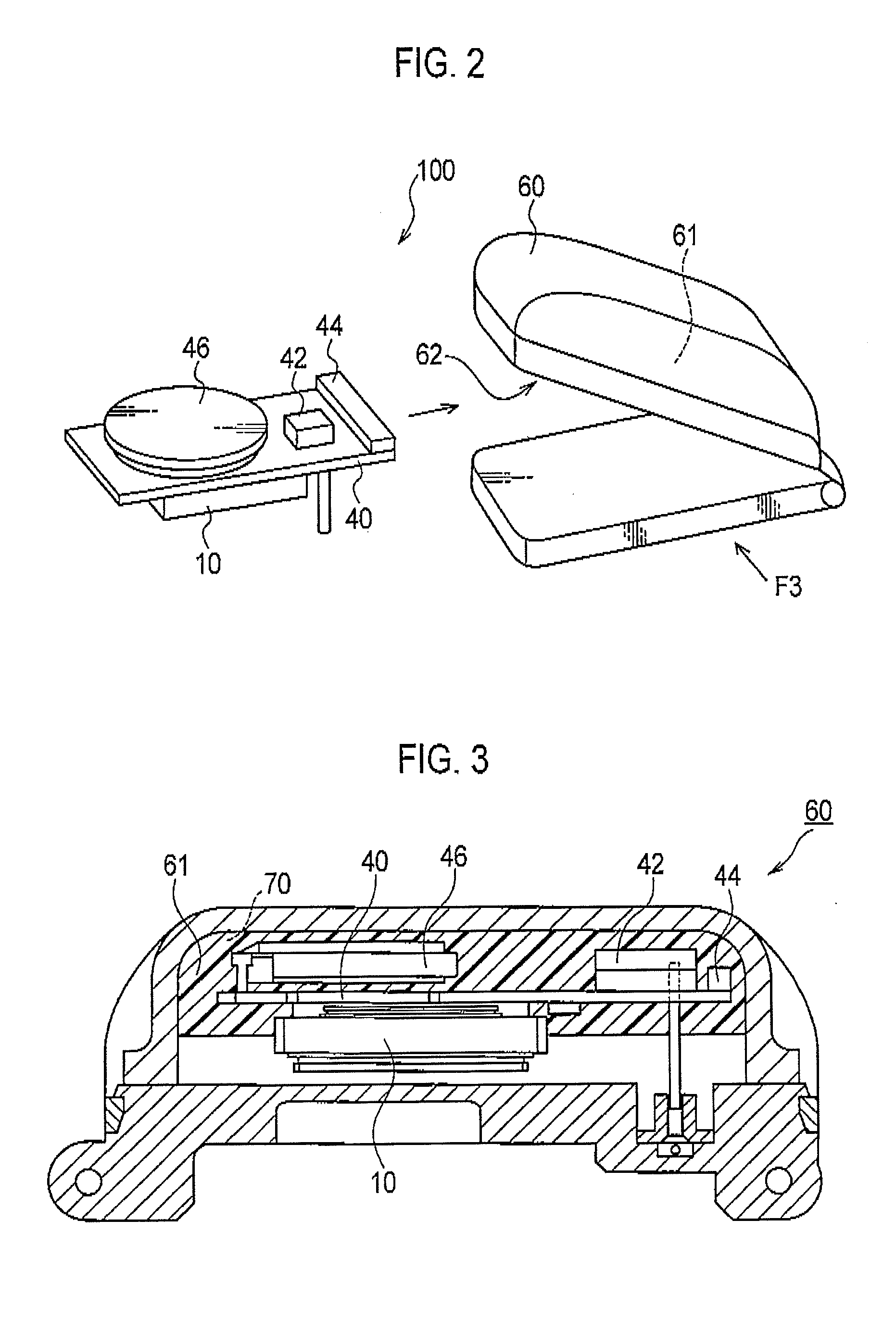

Device for acquiring information regarding the inside of a tire

ActiveUS20110292630A1Lower temperatureReduce the temperatureMeasurement apparatus componentsTyre measurementsElectronic circuitWater resistance

A tire inside information acquiring device (100) attached inside a tire-wheel assembly, includes a housing body (10) configured to house a receiving antenna for receiving a radio signal and an electronic circuit unit connected to the receiving antenna, the electronic circuit unit constitutes the tire inside information acquiring device (100), and a substrate (40) on which the housing body (10) and a component constituting the tire inside information acquiring device (100) are disposed. The housing body (10) is formed of a nonmetallic inorganic material. The component is only formed of parts having water resistance.

Owner:BRIDGESTONE CORP

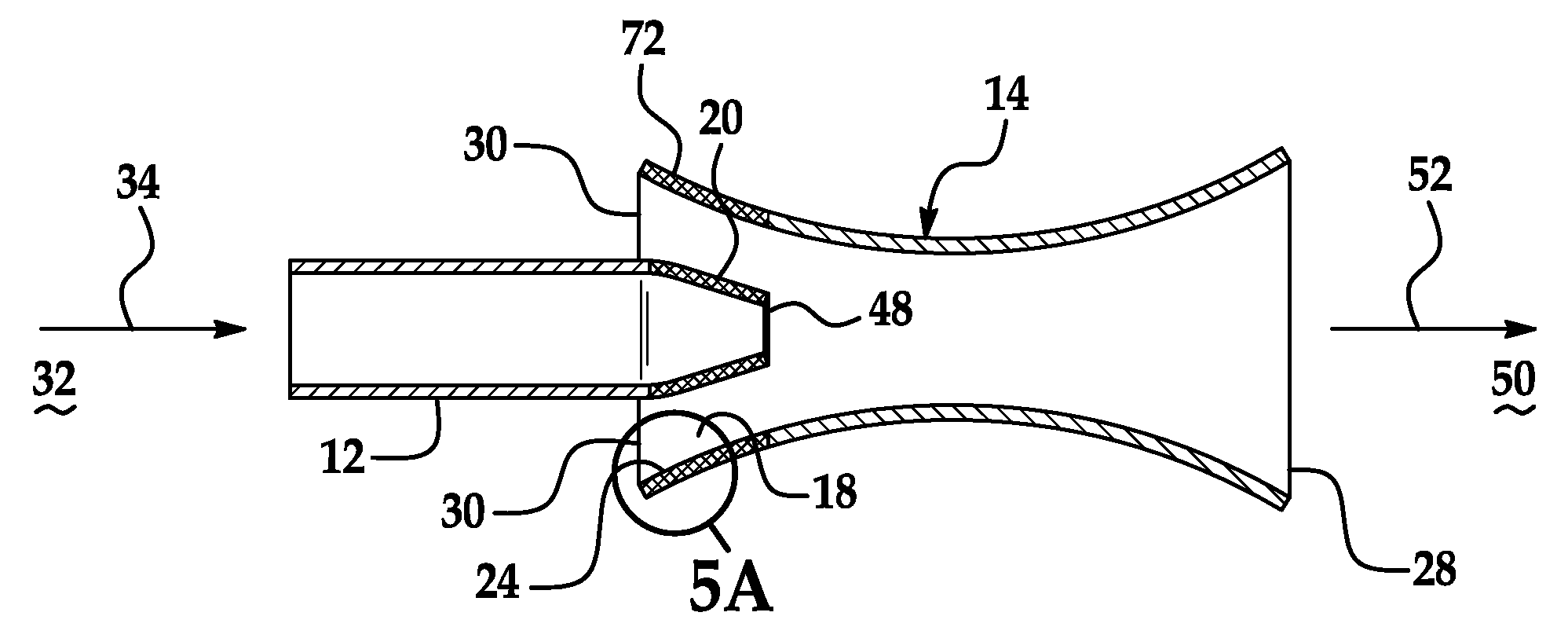

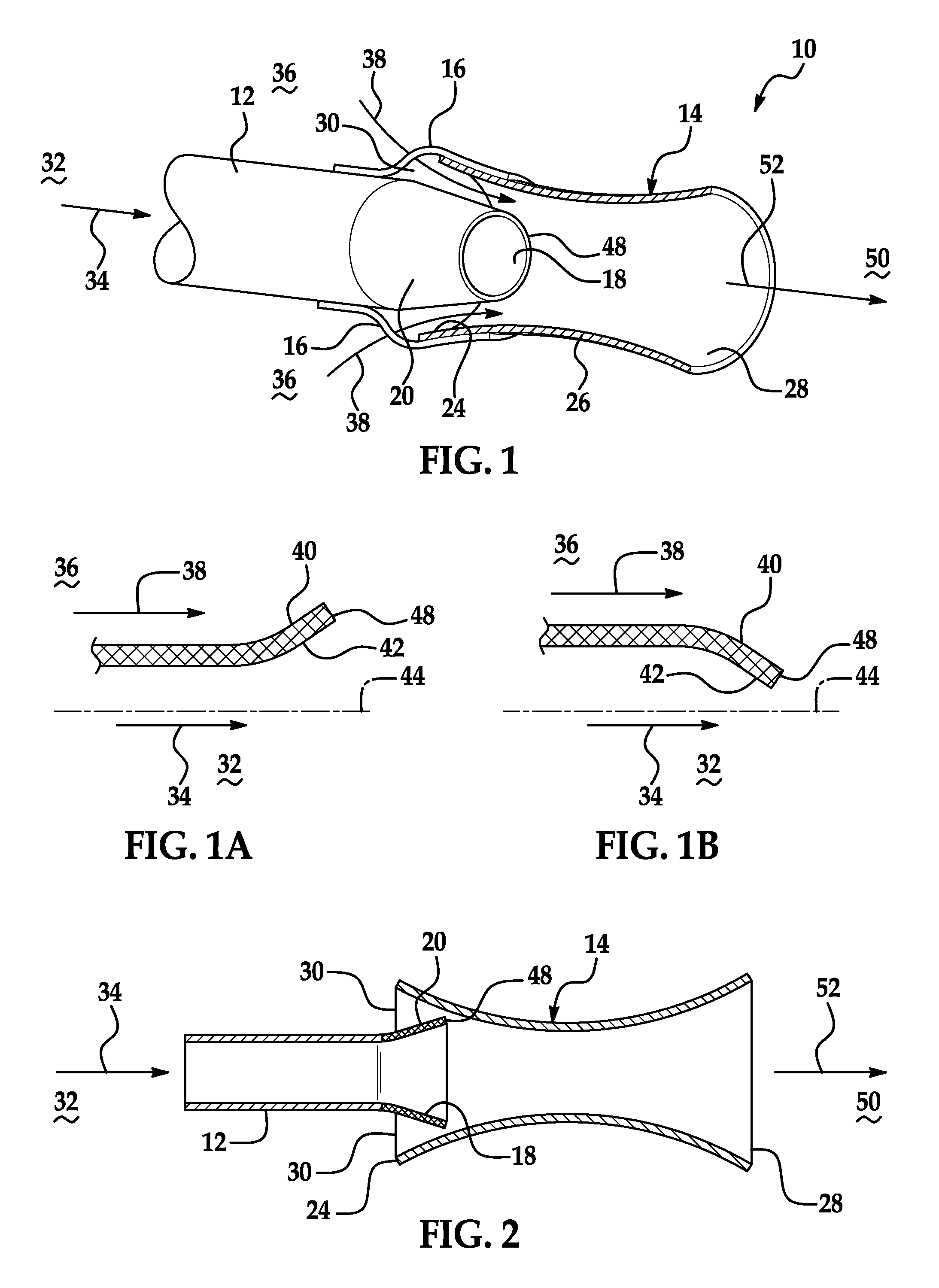

Apparatus and method for cooling an exhaust gas

InactiveUS20100126155A1Lower temperatureInternal combustion piston enginesSilencing apparatusExhaust gasExhaust fumes

An exhaust gas cooling apparatus and method for cooling an exhaust gas is provided. The exhaust cooling apparatus having a first fluid conduit having a variable nozzle opening disposed at one end of the first fluid conduit, the variable nozzle opening being defined by a shape memory alloy extending from the first fluid conduit; and a second fluid conduit having an inlet end and an outlet end, the variable nozzle opening being disposed in the second fluid conduit proximate to the inlet end of the second fluid conduit such that a fluid inlet opening is disposed about an outer periphery of the variable nozzle opening and an inner surface of the inlet end of the second fluid conduit, the shape memory alloy varying the size of the variable nozzle opening by moving toward or away from a center line of the first fluid conduit in response to a temperature of an exhaust gas flowing through the first fluid conduit.

Owner:GM GLOBAL TECH OPERATIONS LLC

Continuous coarse ash depressurization system

ActiveUS20100266460A1Reduce amount of gasLower temperatureCombination devicesFluidized bed combustionProcess engineeringMoving parts

A system for depressurizing and cooling a high pressure, high temperature dense phase solids stream having coarse solid particles with entrained gas therein. In one aspect, the system has an apparatus for at least partially depressurizing and cooling the high pressure, high temperature dense phase solids stream having gas entrained therein and a pressure letdown device for further depressurization and separating cooled coarse solid particles from a portion of the entrained gas, resulting in a lower temperature, lower pressure outlet of solid particles for downstream processing or discharge to a storage silo for future use and / or disposal. There are no moving parts in the flow path of the solids stream in the system.

Owner:THE SOUTHERN CO

Oxygen storage/release material and exhaust gas purifying catalyst comprising the same

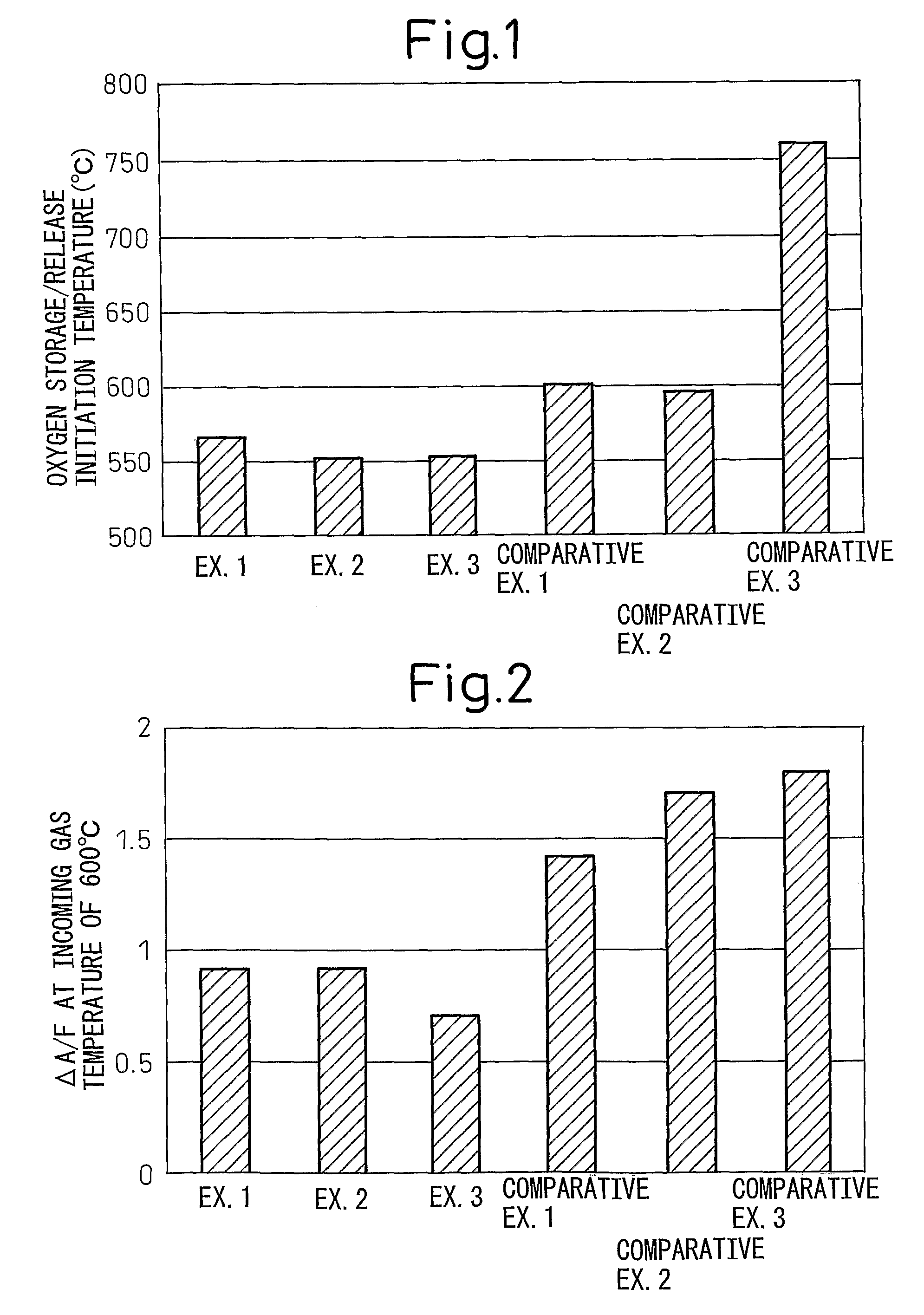

ActiveUS20100130350A1Oxygen storage/release capacity be lowLower temperatureInternal combustion piston enginesDispersed particle separationExhaust gasChemistry

There is provided an oxygen storage / release material using a rare earth oxysulfate or oxysulfide, which has a high oxygen storage / release capacity even at lower temperatures. The oxygen storage / release material of the present invention comprises a compound consisting of Pr2O2SO4 and / or Pr2O2S and at least one metal selected from the group consisting of Pt, Rh and Fe supported thereon.

Owner:NATIONAL UNIVERSITY +1

Ignition system of an internal combustion engine

InactiveUS20060225692A1Improve qualityLower temperatureCombustion-air/fuel-air treatmentCombustion enginesInternal combustion engineIgnition system

An ignition system of an internal combustion engine, of a motor vehicle in particular, having at least one device for igniting a jet of a fuel / air mixture which has a chamber enclosing a process space in which the ignition of the fuel / air mixture takes place. The chamber has a device for enriching the process space with oxygen radicals.

Owner:ROBERT BOSCH GMBH

Image forming apparatus and image forming method

ActiveUS20120162304A1Lower temperatureSuppress generationOther printing apparatusEngineeringMechanical engineering

An apparatus and method which can suppress the occurrence of set off when recording media are stacked on a discharge unit. Ink droplets are ejected to a sheet by inkjet heads in a drawing section, and an image is fixed to the sheet by heating in a fixing section. After that, during the sheet is conveyed by a conveying belt, cooling air is sent to plural fans by a cooler such that the cooling air is blown against the fans, and air is blown to the sheet by the plural fans. Accordingly, the sheet which is after fixing is cooled. The sheet, which has been cooled during being conveyed by the conveying belt, is stacked on a discharge tray.

Owner:FUJIFILM CORP

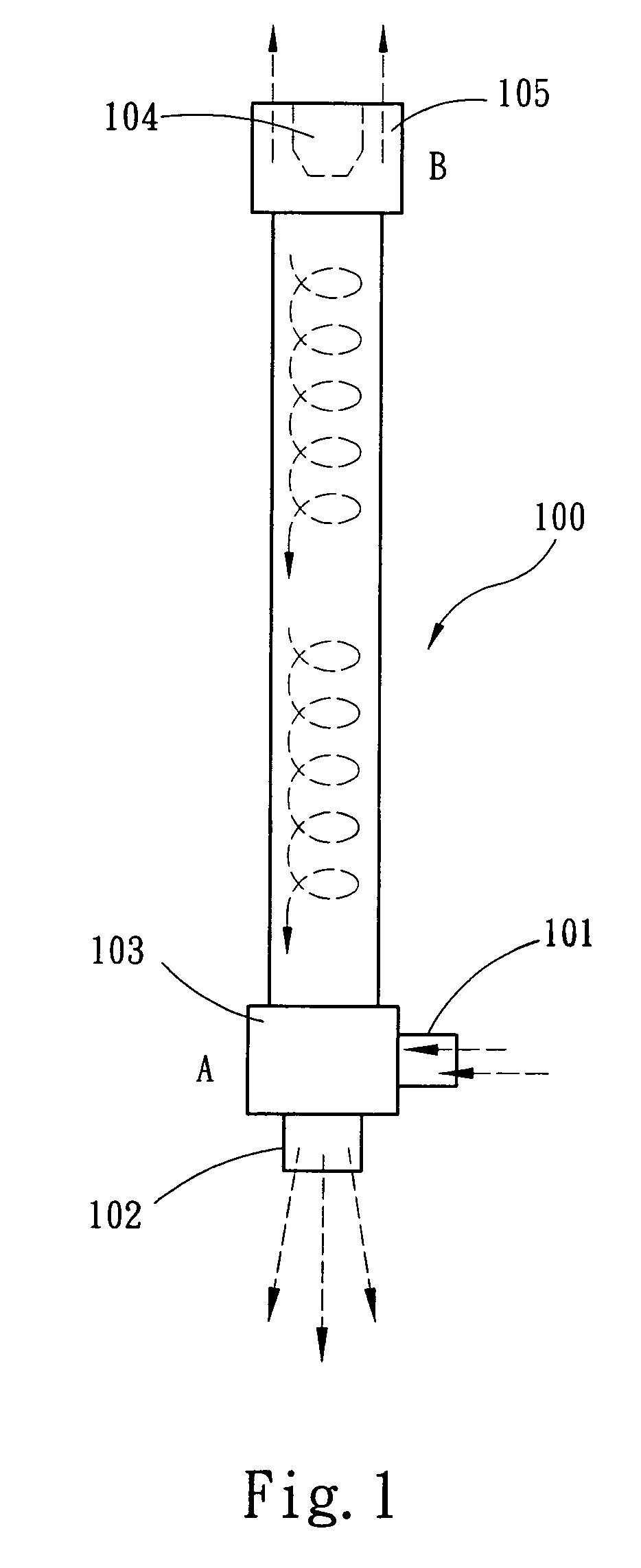

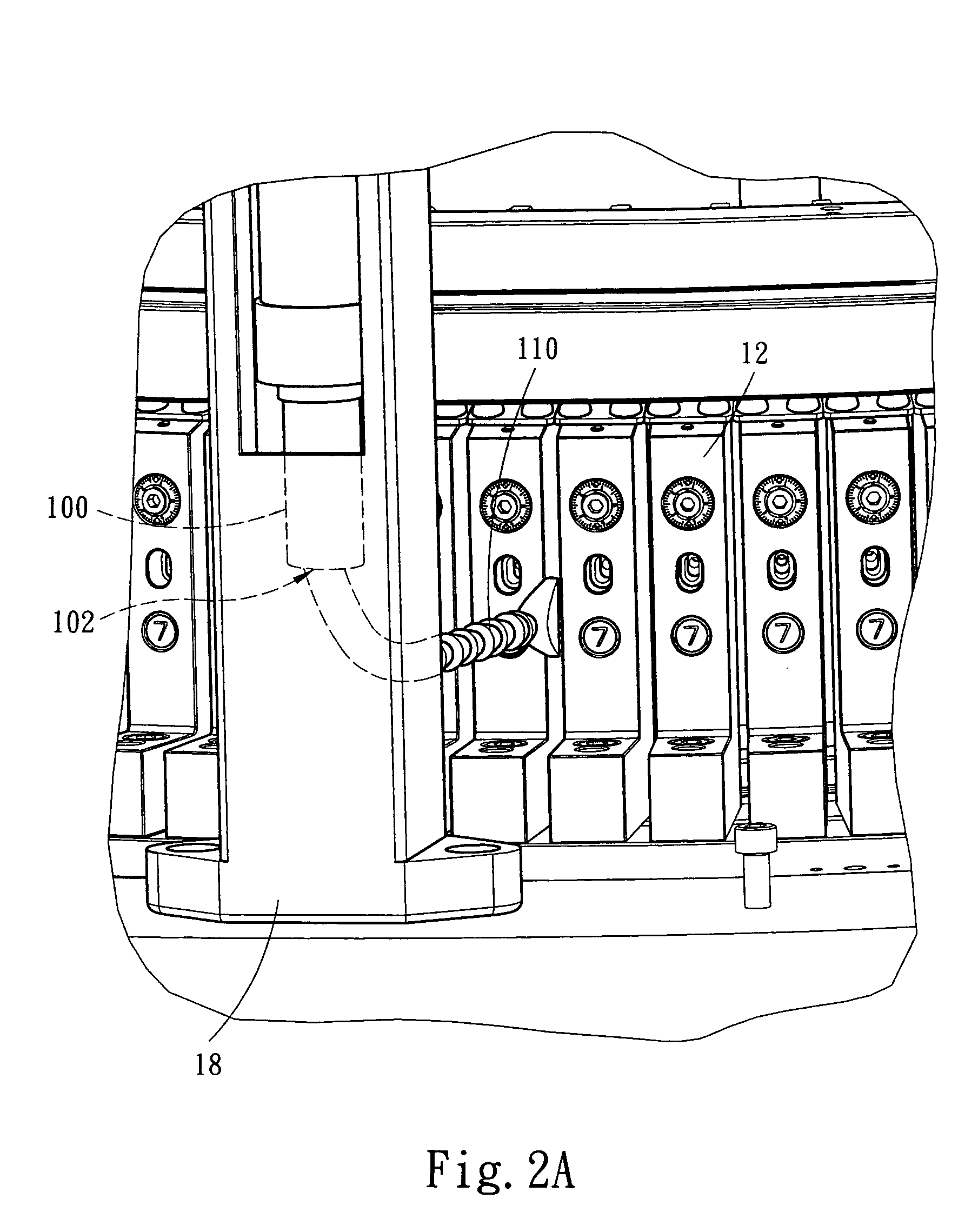

Heat dissipating system of high-speed circular knitting machine

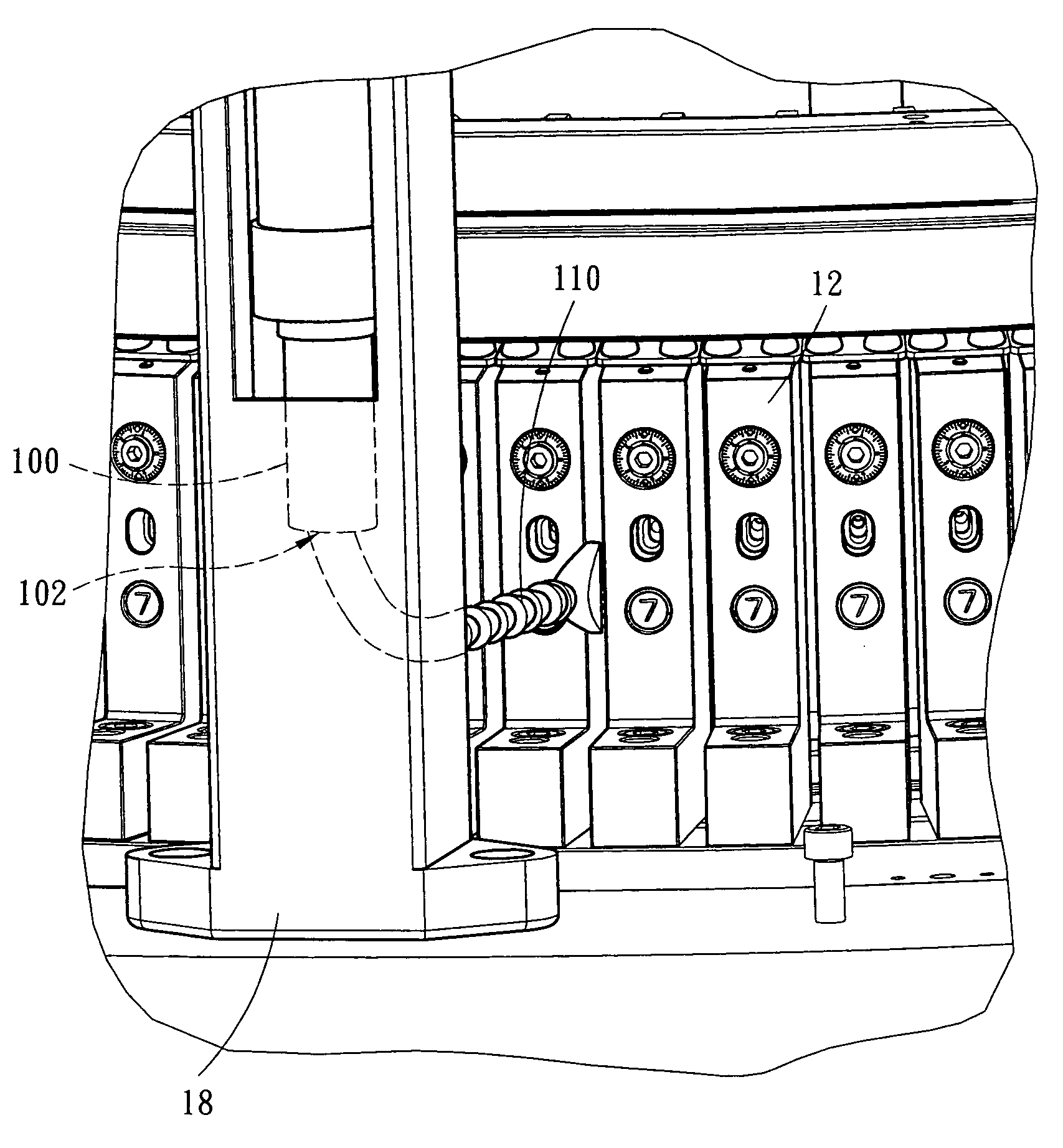

InactiveUS7036340B1Lower temperatureMaximize heat dissipate effectCircular knitting machinesYarnEngineering

A heat dissipating system of a high-speed circular knitting machine includes a super low temperature air gun. Cold air is ejected from a cold air outlet of the super low temperature air gun for carrying away the high heat produced by a cylinder base during a knitting process. The super low temperature air gun is connected to an extension pipe and extended to a gap between a cutting disc and a pressing plate, or saddle bases, or a lower rhombus ring and two saddle bases, or yarn feeding nozzles. Cold air ejected from the cold air outlet passes through the gap to the cylinder base or other peripheral components of the high-speed circular knitting machine to achieve the heat dissipating effect. The super low temperature air gun is installed inside a leg for supporting a yarn supplying device or on its external surface or on a yarn feeding ring.

Owner:PAI LUNG MACHINERY MILL CO LTD

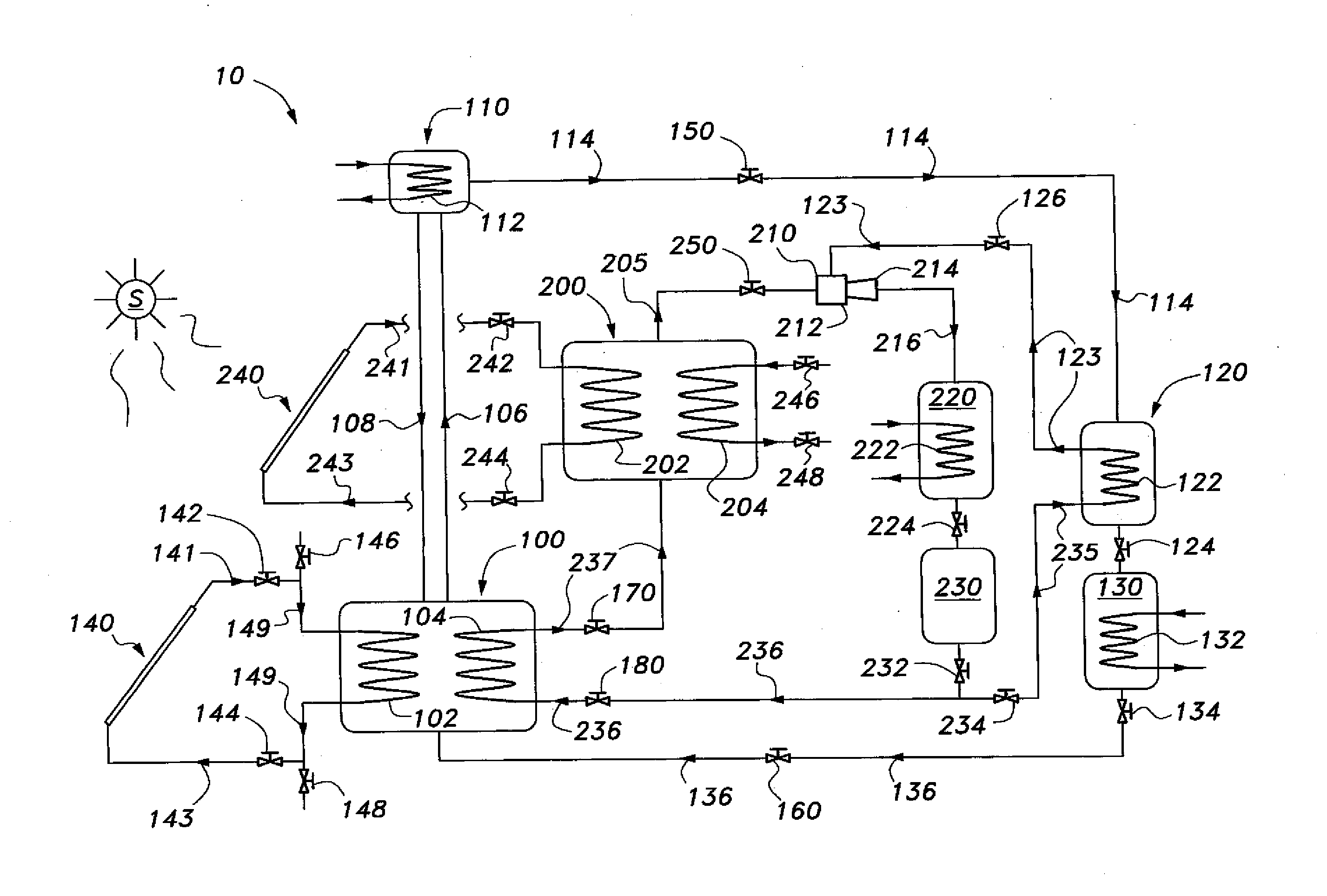

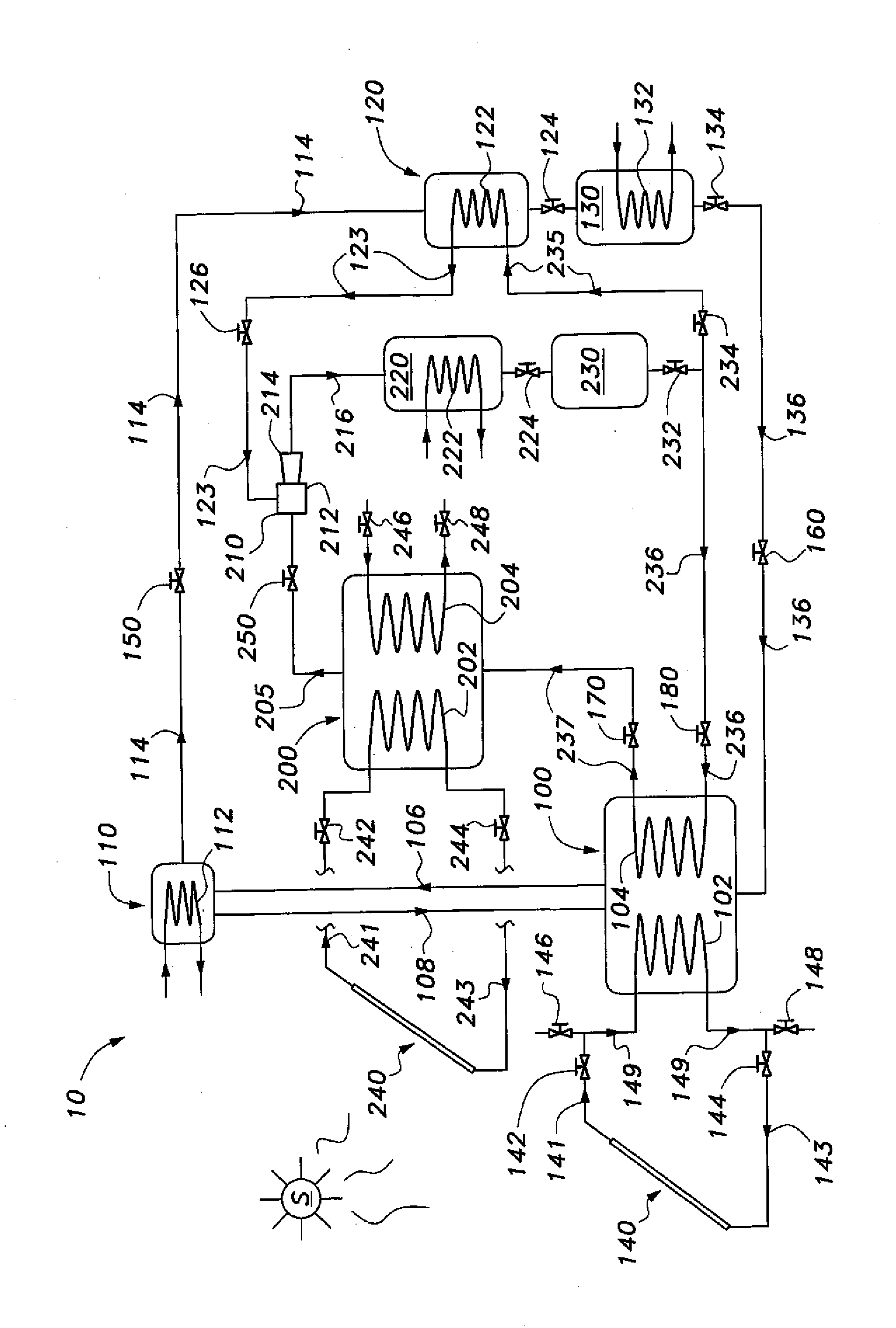

Intermittent absorption refrigeration system

The intermittent absorption refrigeration system includes a primary circuit having a generator / absorber, a dephlegmator, a condenser, an evaporator, and solar collectors to provide heat to the generator. The system also includes an ejector-based secondary circuit having a generator / absorber, an ejector, a condenser, a refrigerant storage unit, and solar collectors. Both circuits are aqua-ammonia systems, using ammonia as the refrigerant and water as the absorber liquid. The ejector permits evaporation during the daytime and storage of liquid ammonia refrigerant that is used for cooling in the heat exchanger of the primary circuit condenser and in the primary circuit absorber, thus permitting the primary circuit evaporator to operate at lower temperatures for low temperature freezing applications in the daytime, even at high ambient temperature.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

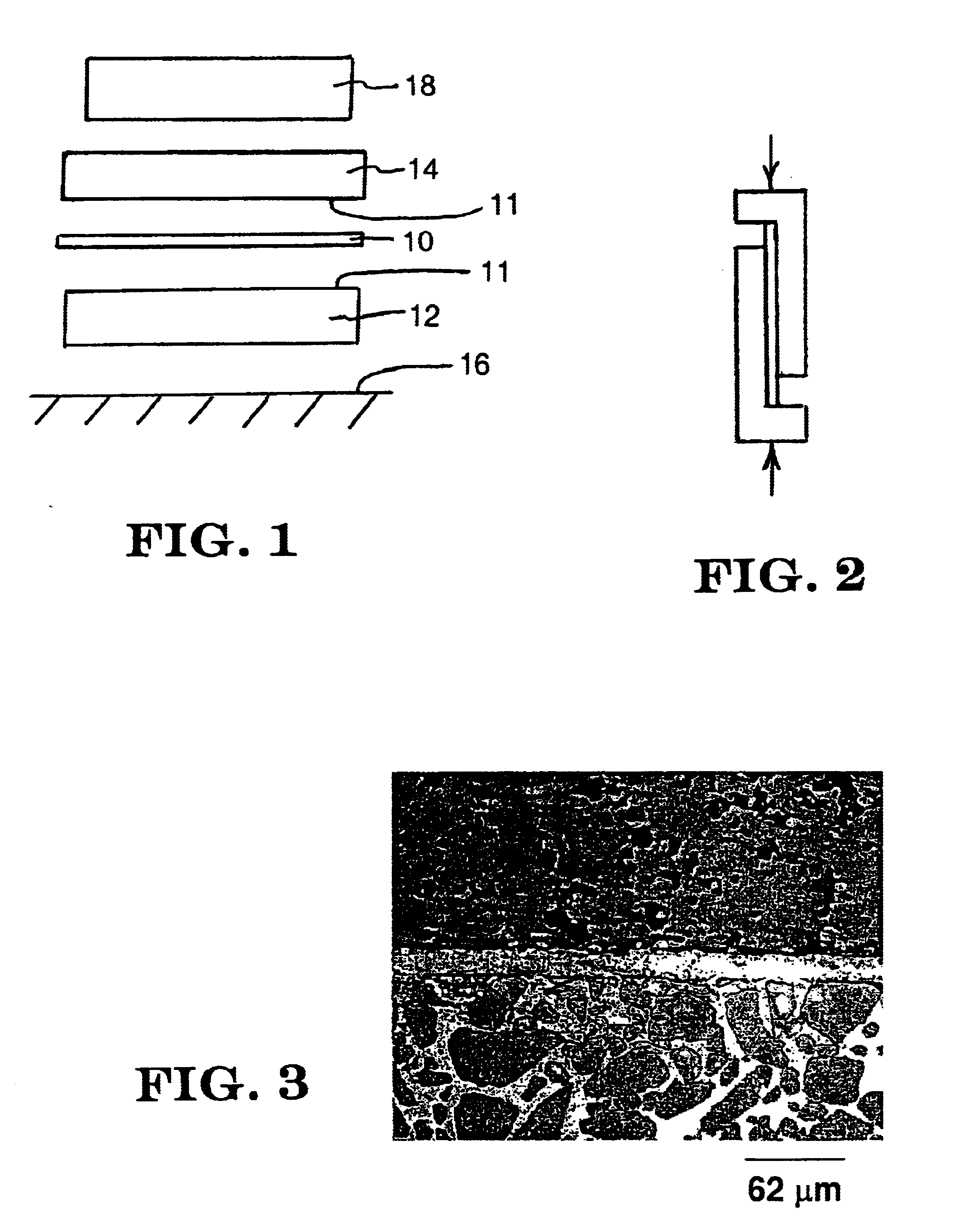

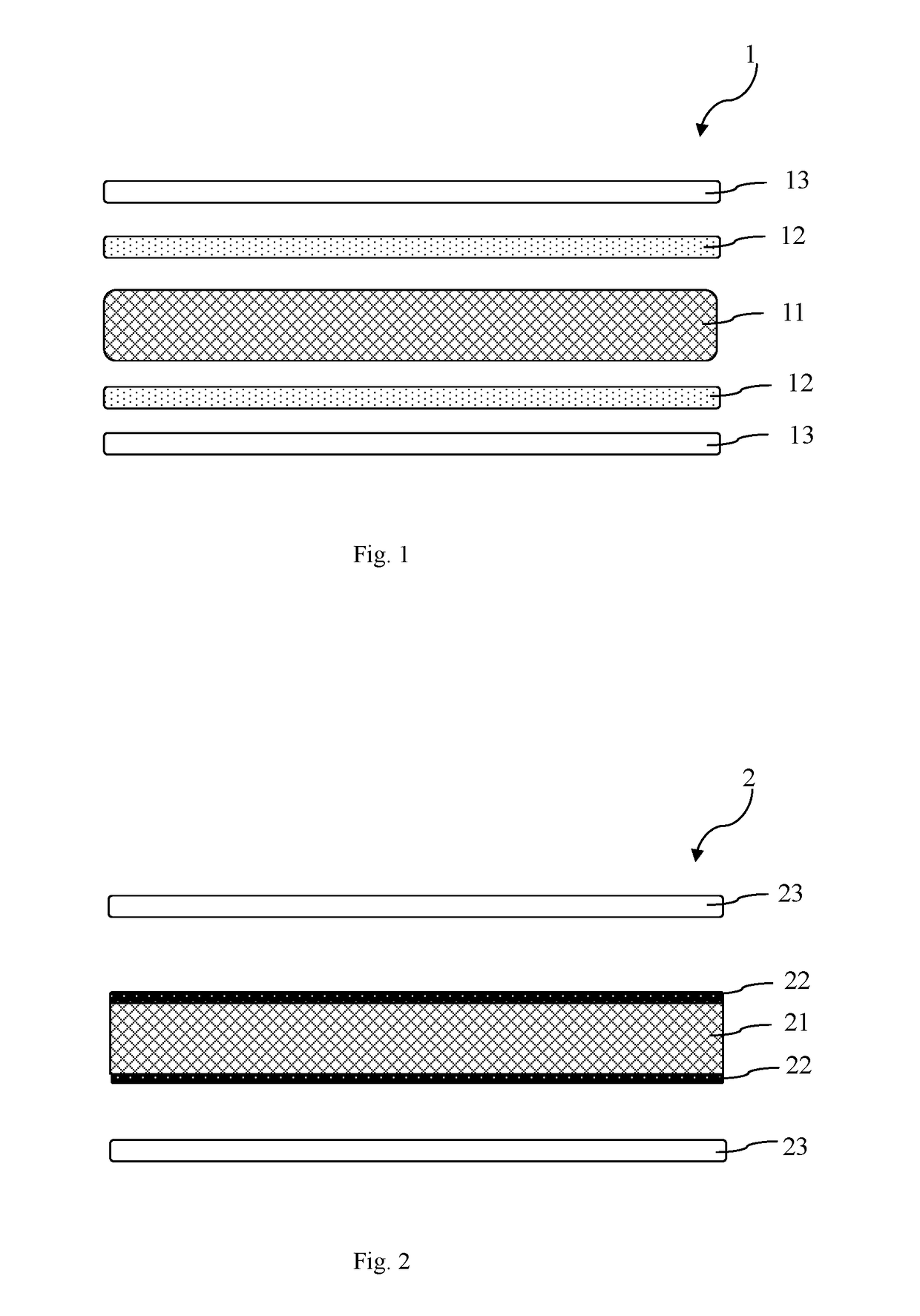

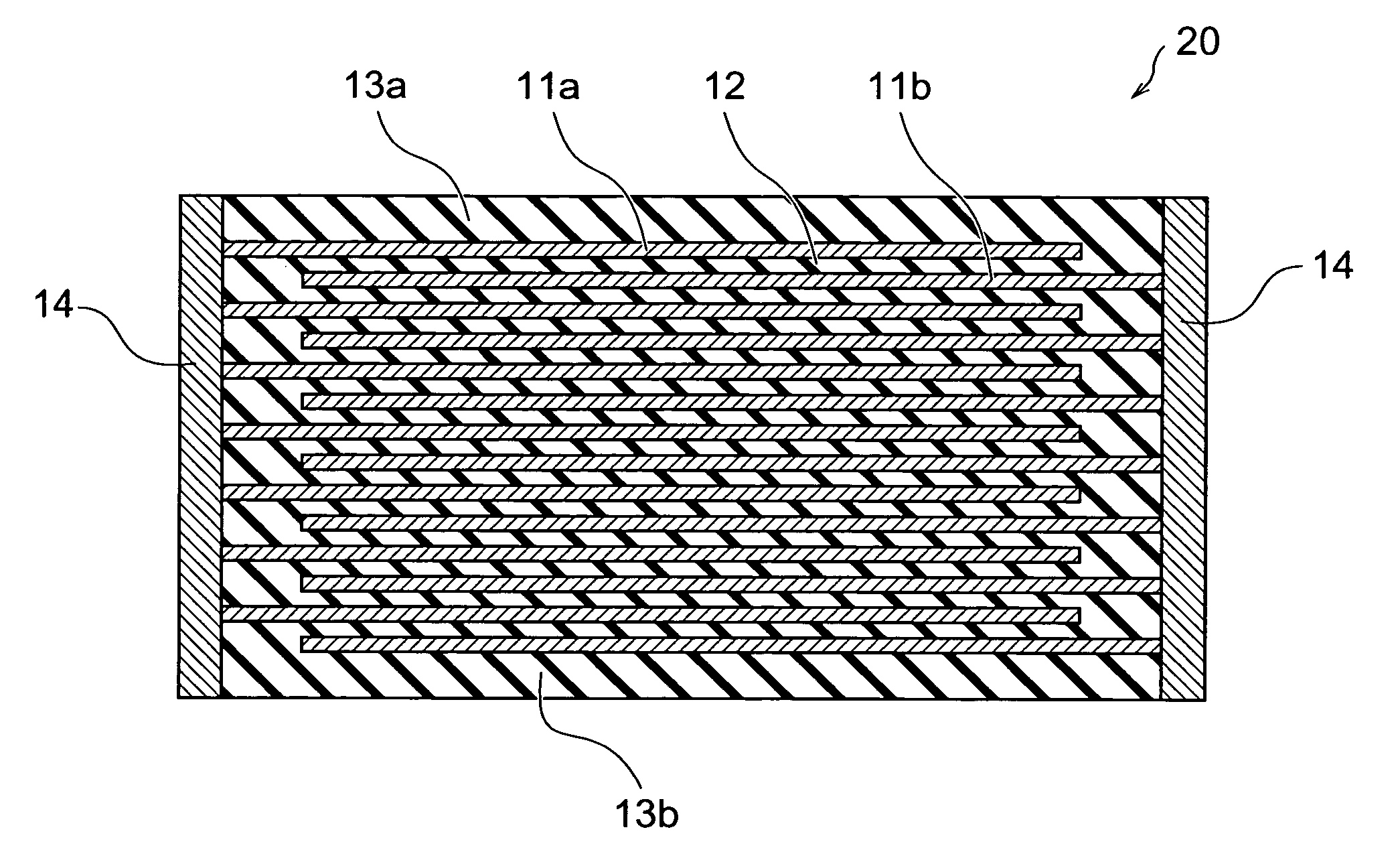

Method of manufacturing metal-clad laminate and uses of the same

ActiveUS20180339493A1Lower temperatureInsulating substrate metal adhesion improvementLamination ancillary operationsMetalPolymer solution

A method of manufacturing a metal-clad laminate and uses of the same are provided. The method comprises the following steps:(a) impregnating a reinforcement material with a first fluoropolymer solution, and drying the impregnated reinforcement material under a first temperature to obtain a first prepreg;(b) impregnating the first prepreg with a second fluoropolymer solution, and drying the impregnated first prepreg under a second temperature to obtain a second prepreg; and(c) laminating the second prepreg and a metal-clad to obtain a metal-clad laminate,wherein the first fluoropolymer solution has a first fluoropolymer, the second fluoropolymer solution has a second fluoropolymer, and the first fluoropolymer and the second fluoropolymer are different.

Owner:TAIWAN POWDER TECH CO LTD

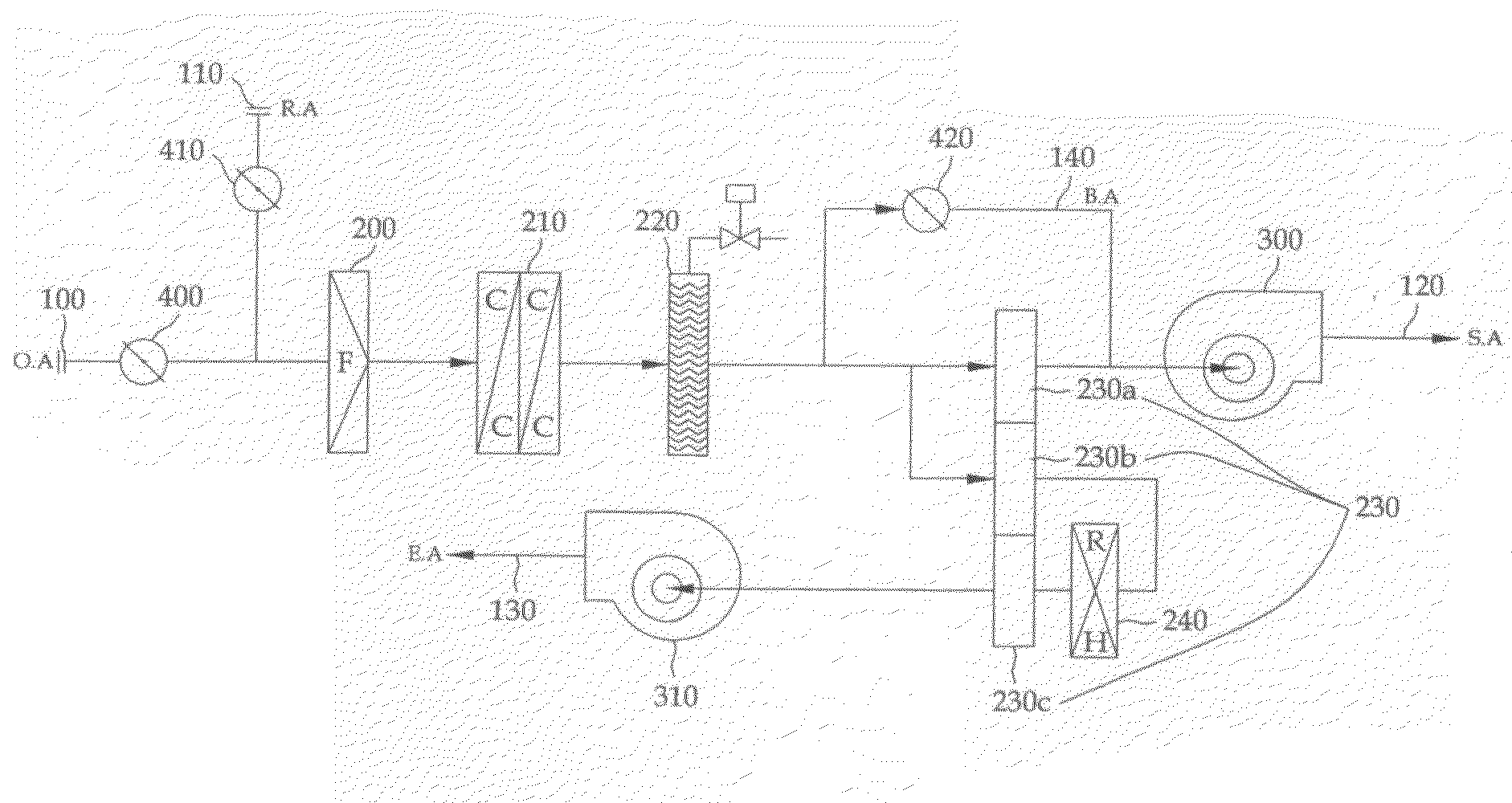

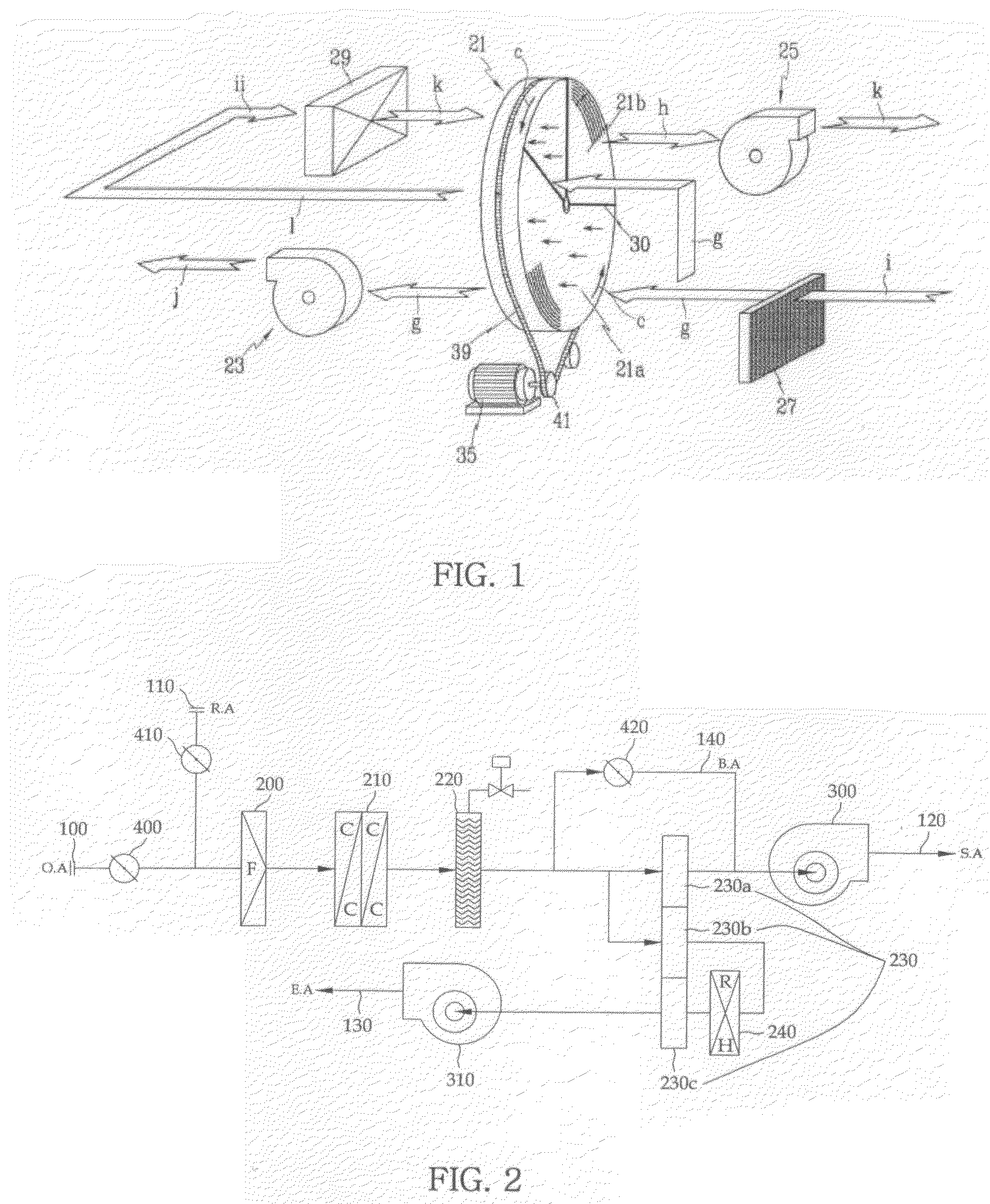

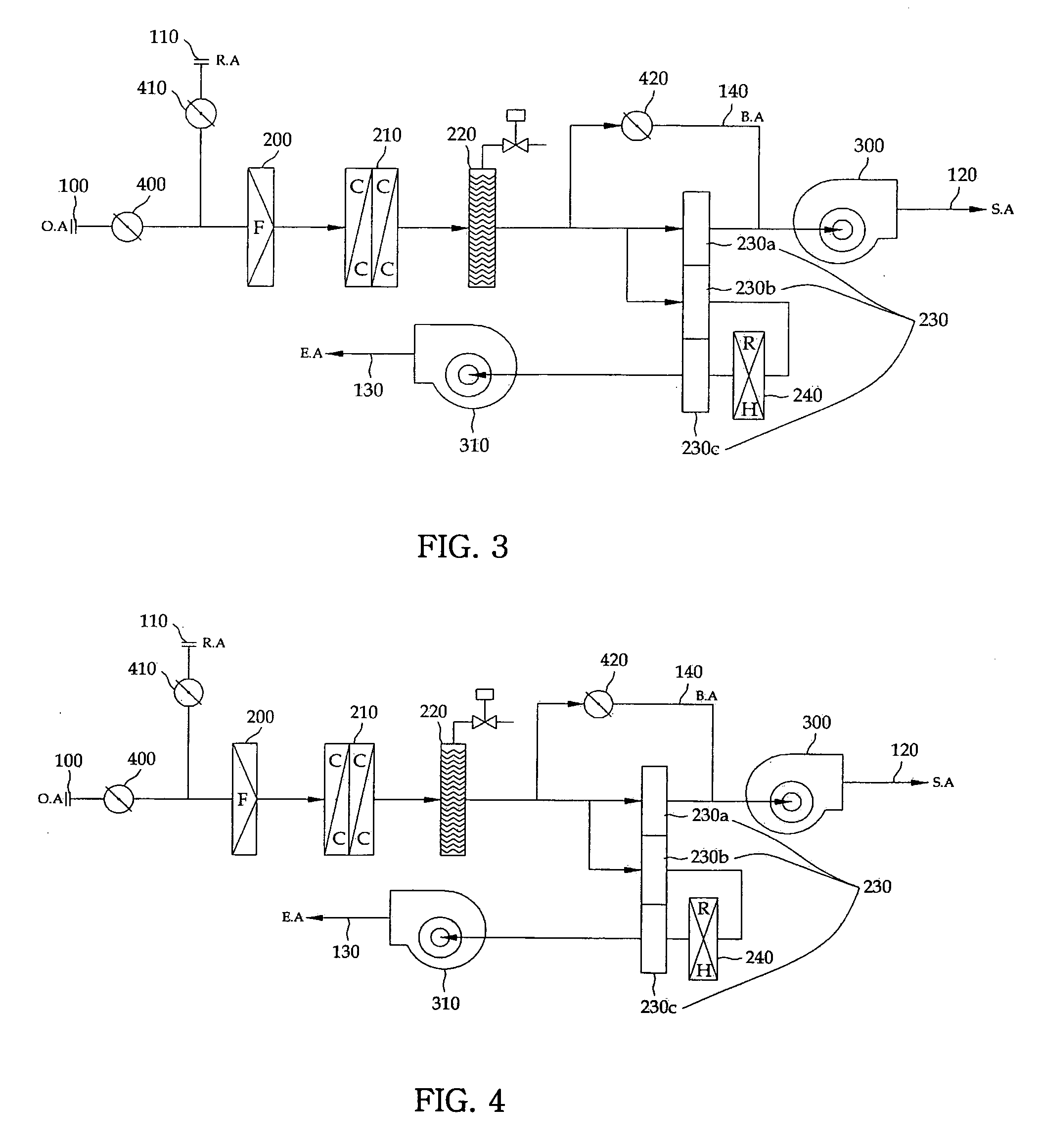

Desiccant dehumidifier

InactiveUS20090044555A1Lower temperatureImprove qualityAir treatment detailsDomestic cooling apparatusExhaust gasCooling coil

Provided is a desiccant dehumidifier characterized in that: external air is introduced through a cooling coil and an eliminator; the introduced external air is bifurcated into a desiccant rotor and a bypass line in front of the desiccant rotor; the external air bifurcated to the desiccant rotor passes through the desiccant rotor disposed at a dehumidifying section to perform dehumidification, and the bypass air passed through the bypass line is mixed with the air passed through the desiccant rotor behind the desiccant rotor to form suction air to be supplied through a suction fan; and a part of the external air bifurcated to the desiccant rotor passes through the desiccant rotor disposed at a purge section, and then passes through the desiccant rotor disposed at a recycling section via a recycling heater to form exhaust air to be exhausted through an exhaust fan, wherein ventilation air is introduced through a separate path on a path through which the external air is introduced and then mixed with the external air.Therefore, the bypass line is installed to bypass the desiccant rotor during an external air dehumidification process so that the bypass air passed through the bypass line is mixed with the suction air dehumidified through the desiccant rotor and the internal air is mixed with the external air to improve quality of the internal air.

Owner:AIR TECH ENG CO LTD

Shape-controlled ceramic fillers for enhanced piezoelectric properties of structured composites

ActiveUS20180083183A1Improve piezoelectric propertyLower temperaturePiezoelectric/electrostrictive device manufacture/assemblyNiobium compoundsShape controlLithium

Owner:SABIC GLOBAL TECH BV

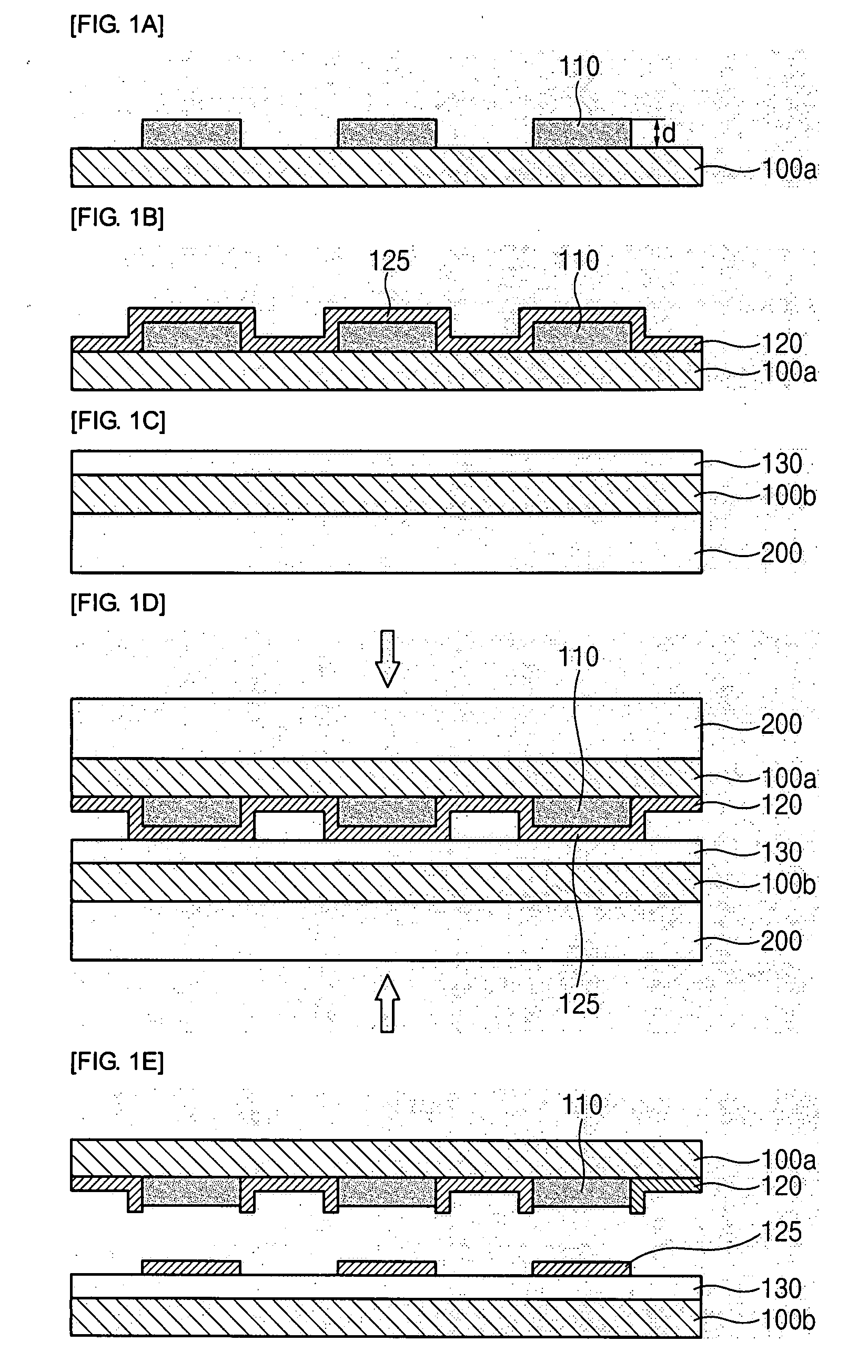

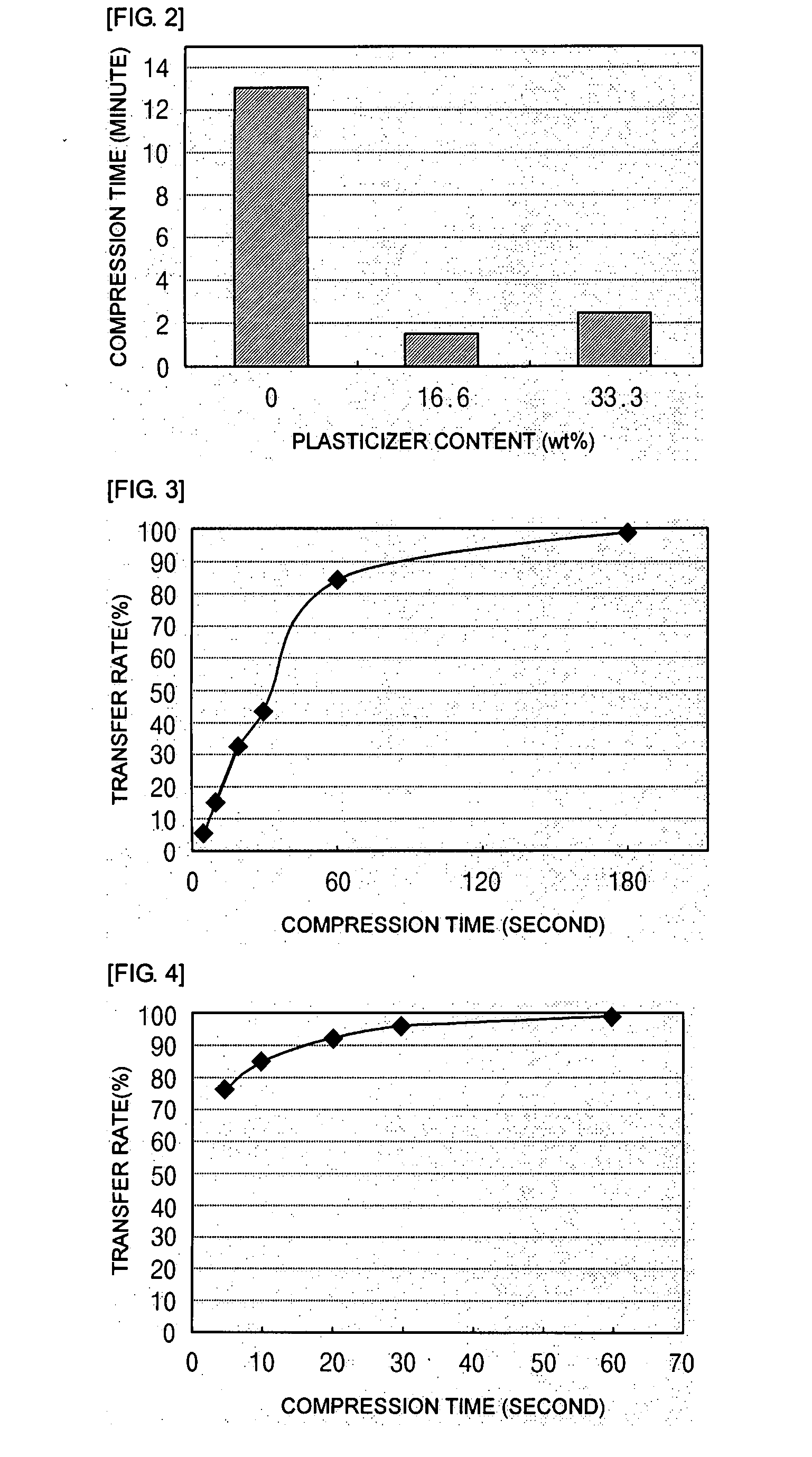

Method of manufacturing electrode pattern

InactiveUS20070249141A1Short timeLower temperatureFixed capacitor electrodesTransfer patterningThermal compressionEngineering

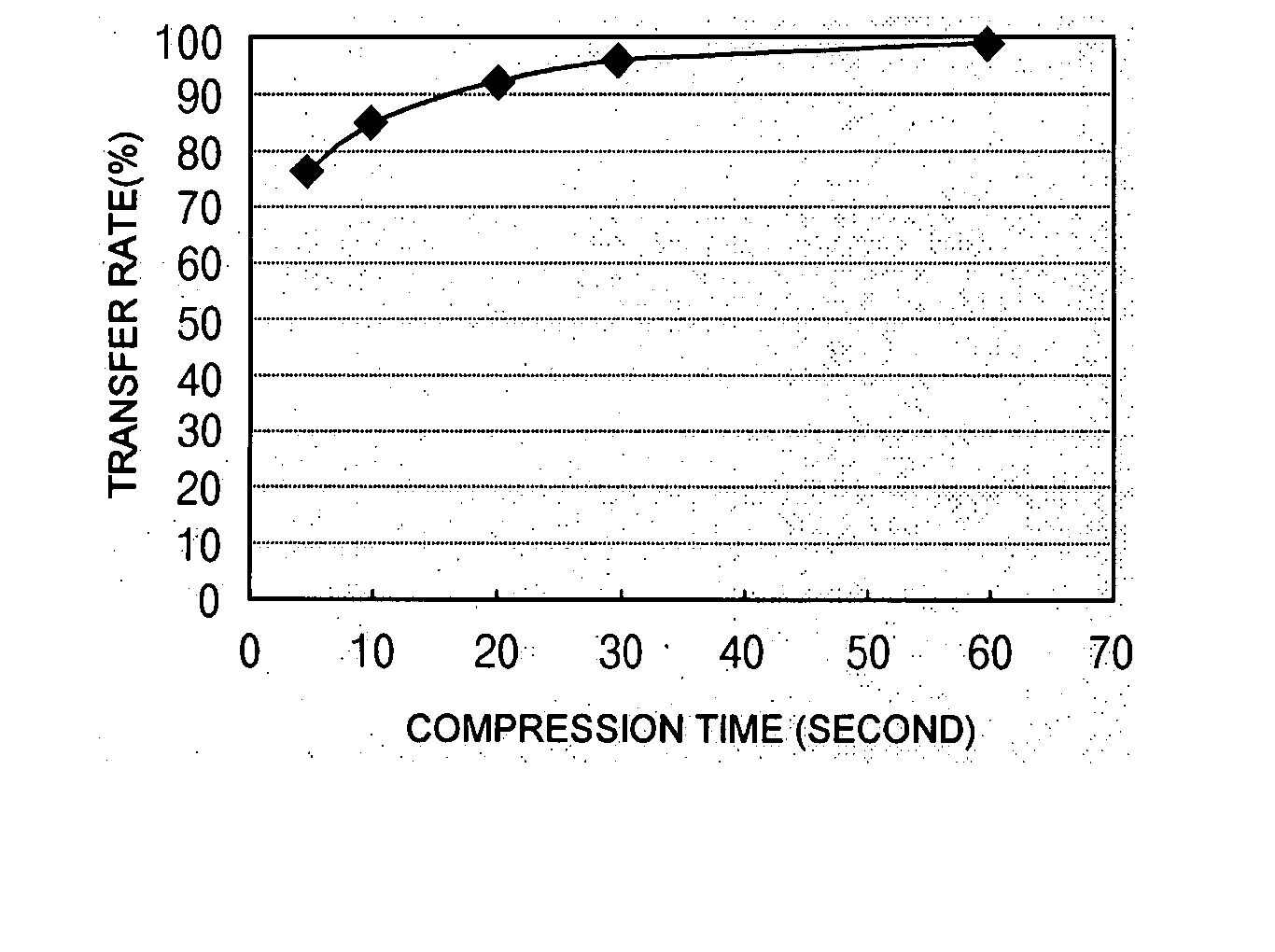

A method of manufacturing an electrode pattern comprises preparing a first support film; forming a mold release pattern on one surface of the first support film, the mold release pattern defining an internal electrode formation region; forming an electrode layer on the mold release pattern by using a thin film technique; preparing a second support film; forming a transfer target layer on one surface of the second support film; disposing the electrode layer of the first support film and the transfer target layer of the second support film such that the electrode layer and the transfer target layer face each other; thermally compression-bonding the first and second films disposed to face each other such that the electrode layer positioned on the mold release pattern is transferred onto the transfer target layer; and separating the first and second films from each other.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

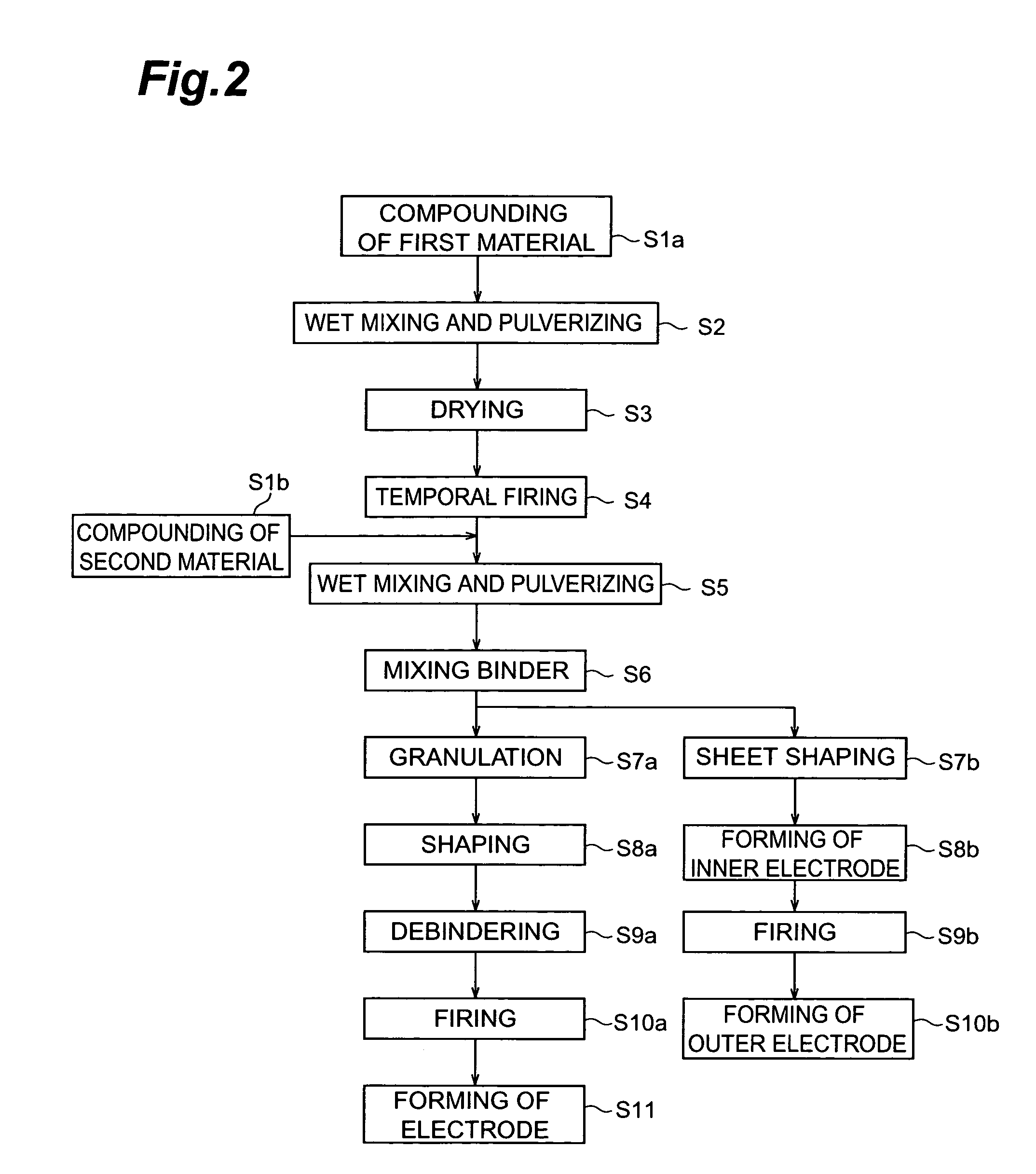

Piezoelectric porcelain composition, piezoelectric device, and methods of making thereof

InactiveUS7067965B2Low ratioLower temperaturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesTungstatePerovskite

A piezoelectric porcelain composition containing a complex oxide having a perovskite structure mainly composed of Pb, Zr, and Ti; and the following component (a) and / or (b), or component (A) and / or (B):(a) Ag and / or an Ag compound, and Mo and / or an Mo compound(b) silver molybdate [Ag2MoO4](A) Ag and / or an Ag compound, Mo and / or an Mo compound, and W and / or a W compound(B) silver molybdate-tungstate [Ag2Mo(1−X)WXO4](where X is a number from 0.3 to 0.7)

Owner:TDK CORPARATION

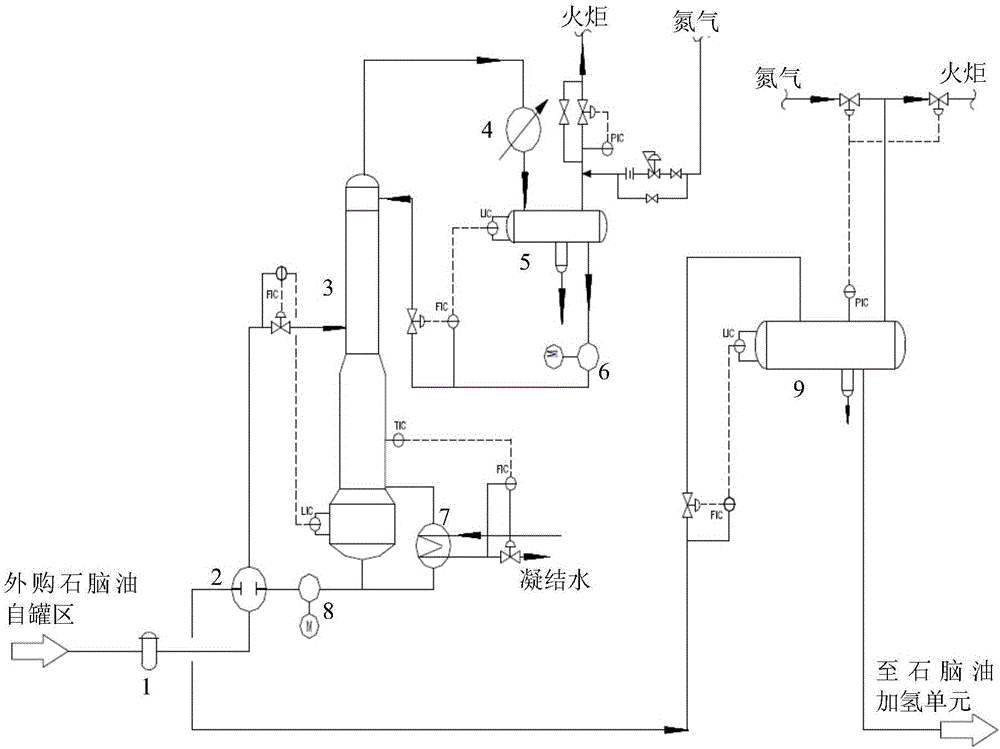

Method and system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha

ActiveCN105969421AReduce textureLower requirementTreatment with plural serial refining stagesTreatment with hydrotreatment processesNaphthaReboiler

The invention method and a system for optimizing hydrorefining low-pressure deoxygenation and feeding heat exchange for naphtha. The method includes that the naphtha is filtered and is subjected to heat exchange, then is fed into a deoxygenation tower to be subjected to deoxygenation treatment, the tower top pressures are flexibly controlled so that different working conditions can be adapted, tower-top gas phases are cooled and then are fed into a tower-top return tank, liquid phases completely return a tower top, and non-condensable gas on the top of the return tank is exhausted into a torch pipe network; a part of deoxygenated naphtha distilled at a tower bottom is fed into a reboiler at the bottom of the deoxygenation tower and is heated to obtain partial gas phases and partial liquid phases, and then the partial gas phases and the partial liquid phases return a tower kettle; heat is exchanged between another part of deoxygenated naphtha distilled at the tower bottom and filtered naphtha, and deoxygenated naphtha is used as a naphtha hydrogenation material after being subjected to heat exchange. The system comprises a naphtha feeding filter, a deoxygenation tower feeding and deoxygenated naphtha heat exchanger, the deoxygenation tower, a deoxygenation tower-top cooler, the deoxygenation tower-top return tank and the deoxygenation tower-bottom reboiler. The method and the system have the advantage that hydrorefining low-pressure deoxygenation and feeding heat exchange for the naphtha can be optimized by the aid of the method and the system.

Owner:BEIJING PETROCHEM ENG

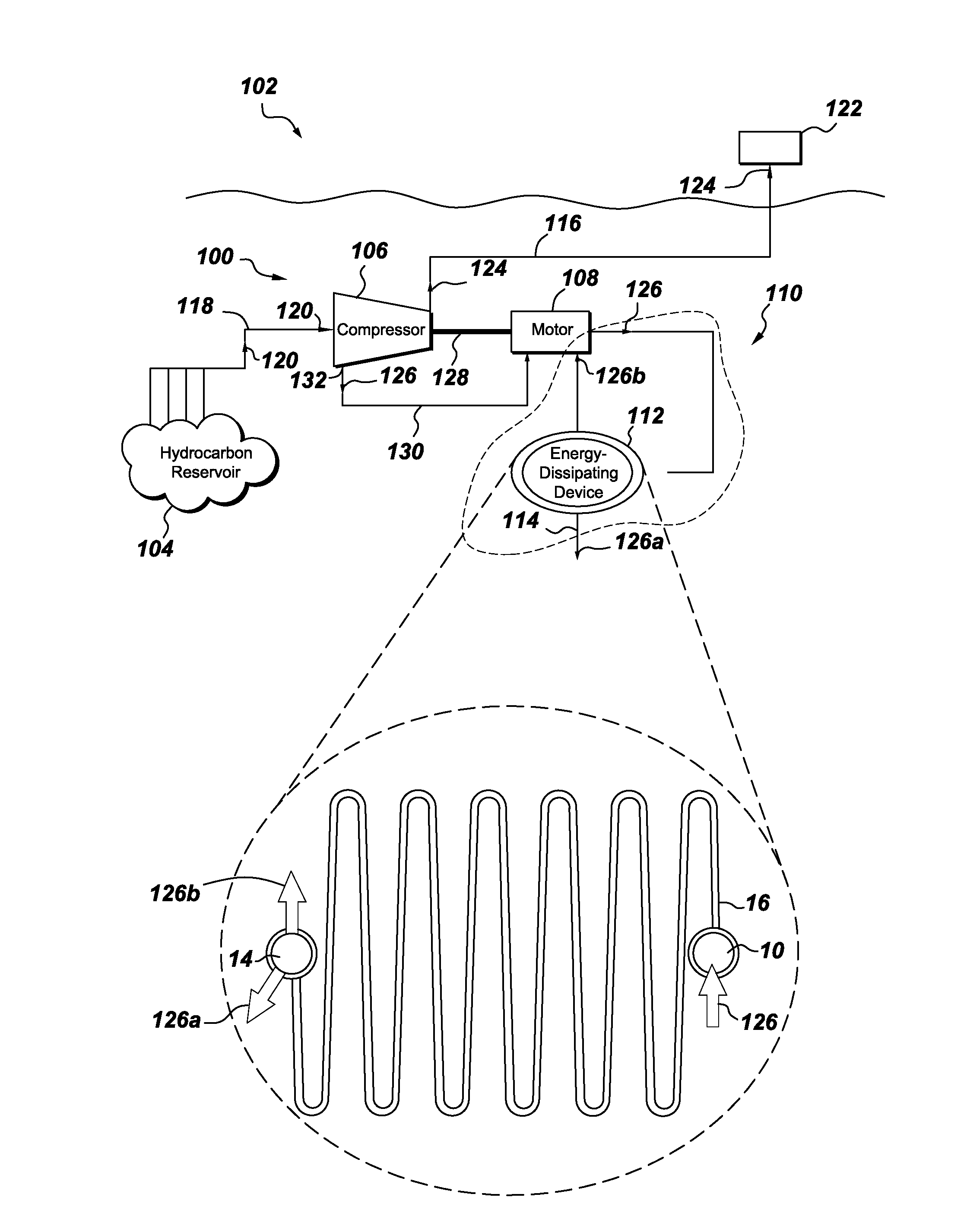

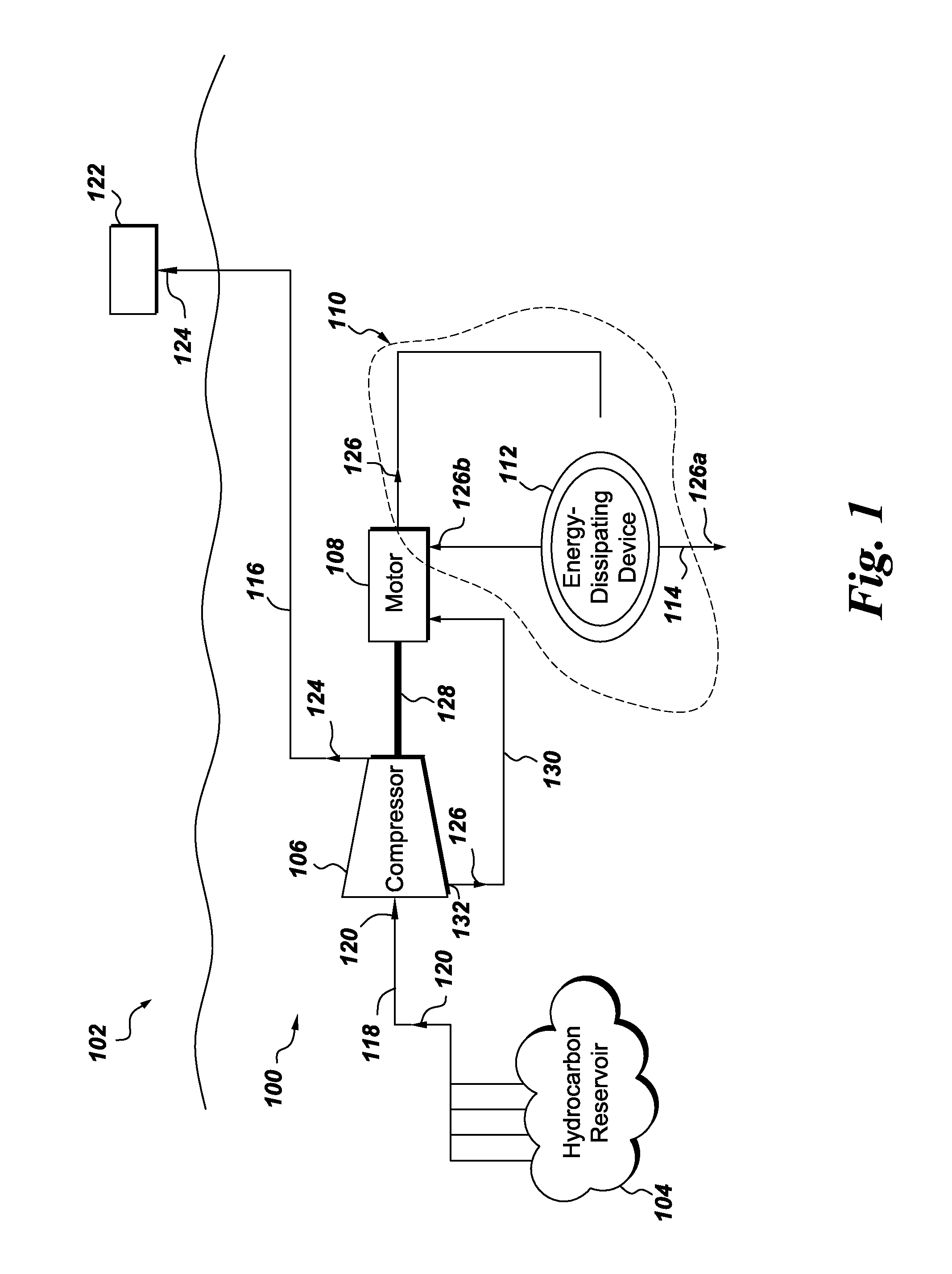

Fluid processing system

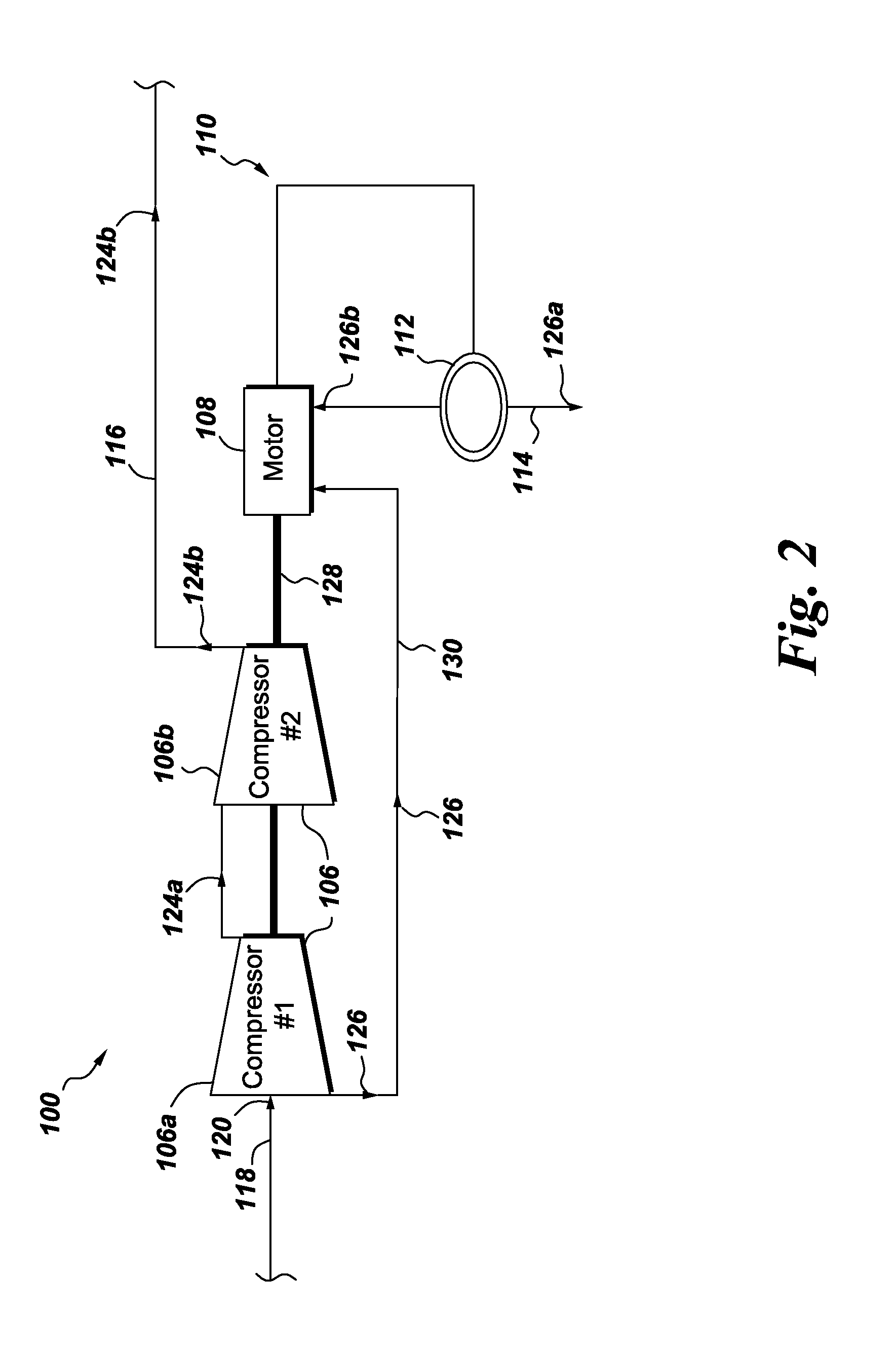

ActiveUS20160237800A1Efficiently handleLower temperaturePump componentsGaseous fuelsRe circulationOperating temperature

An energy-dissipating device and fluid processing system is provided containing a compressor, a motor, a secondary fluid re-circulation loop, a purge line, and a fluid conduit. The compressor is configured to receive a hot fluid including condensable and non-condensable components, and produce therefrom a primary compressed fluid stream and a secondary fluid stream. The motor is configured to drive the compressor and for ingress and egress of the secondary fluid stream. The secondary fluid re-circulation loop is configured to control an operating temperature of the motor. The secondary fluid re-circulation loop includes a first energy-dissipating device configured to remove excess heat from the secondary fluid stream. The purge line separates a first portion of the secondary fluid stream in the fluid re-circulation loop from a second portion of the secondary fluid stream being returned to the motor. The fluid conduit receives the primary compressed fluid stream from the compressor.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com