Patents

Literature

113results about "Transfer patterning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

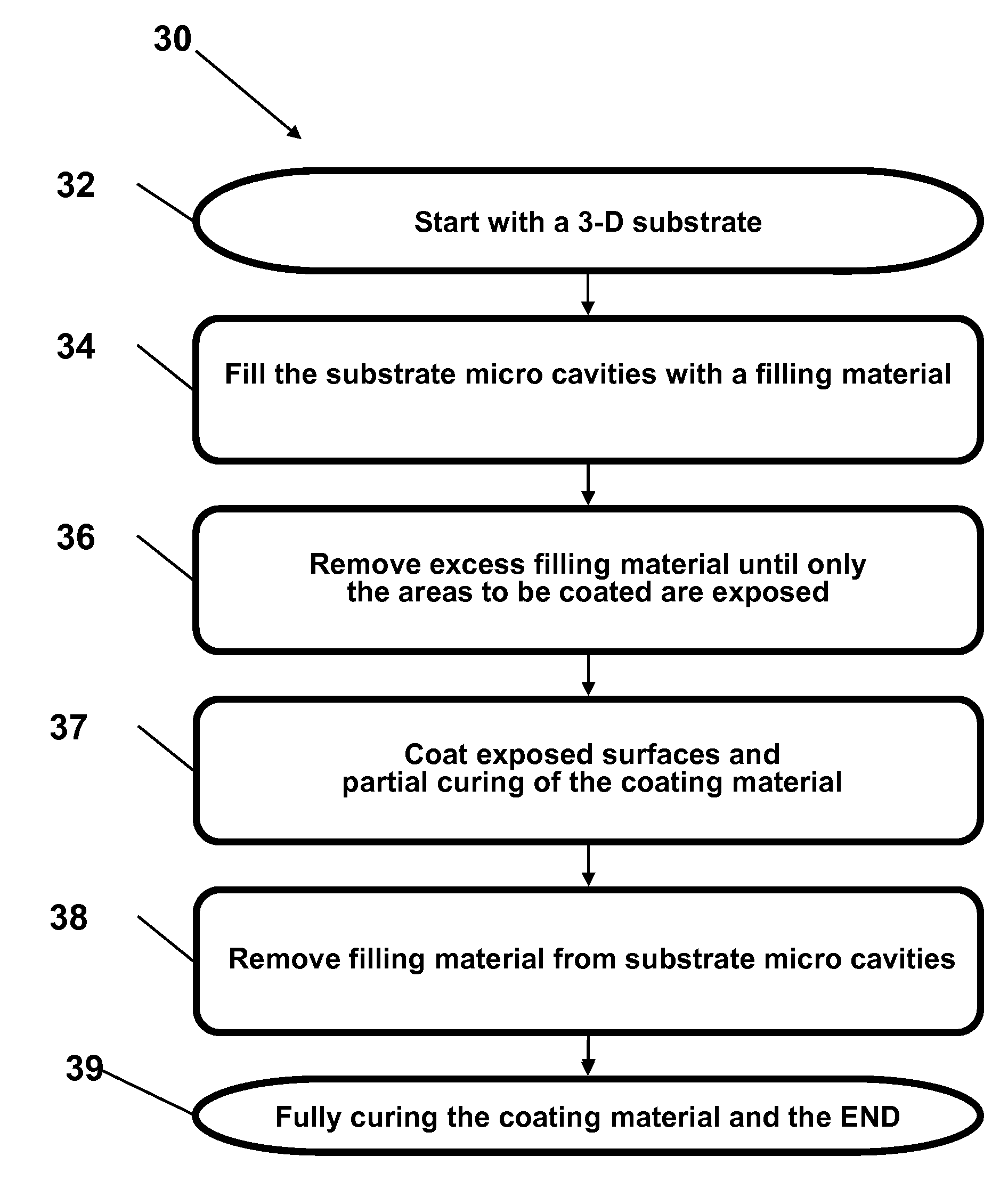

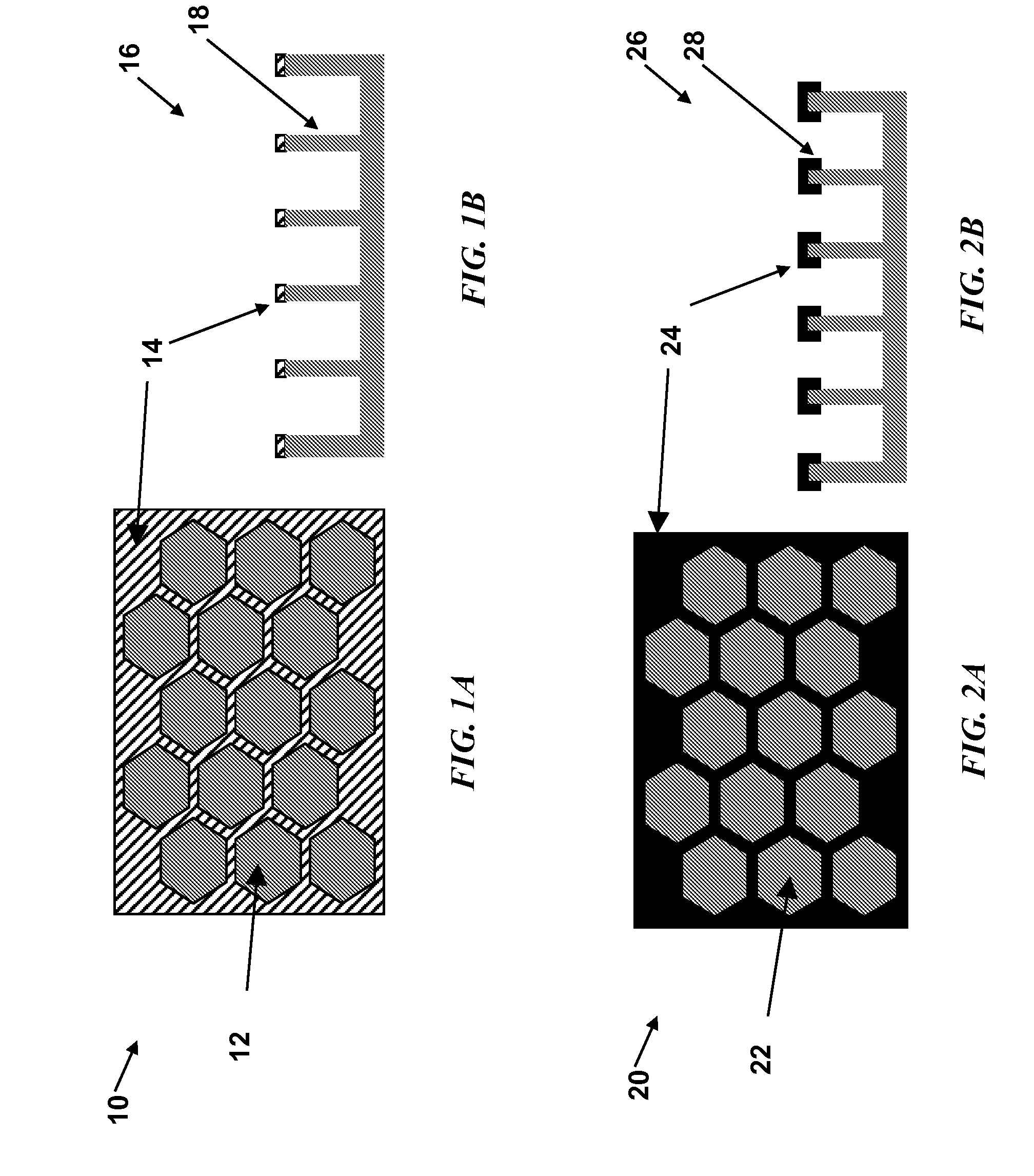

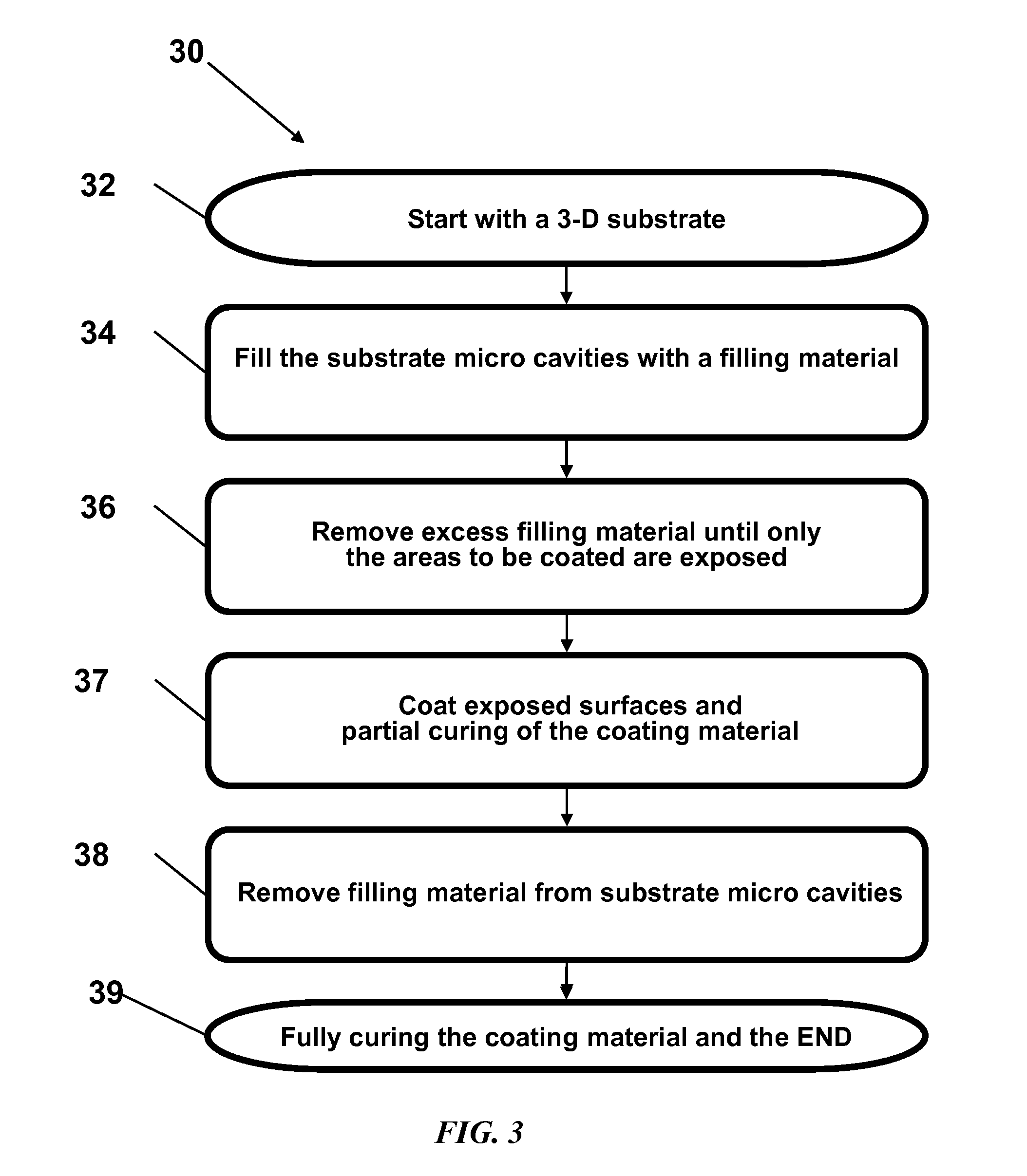

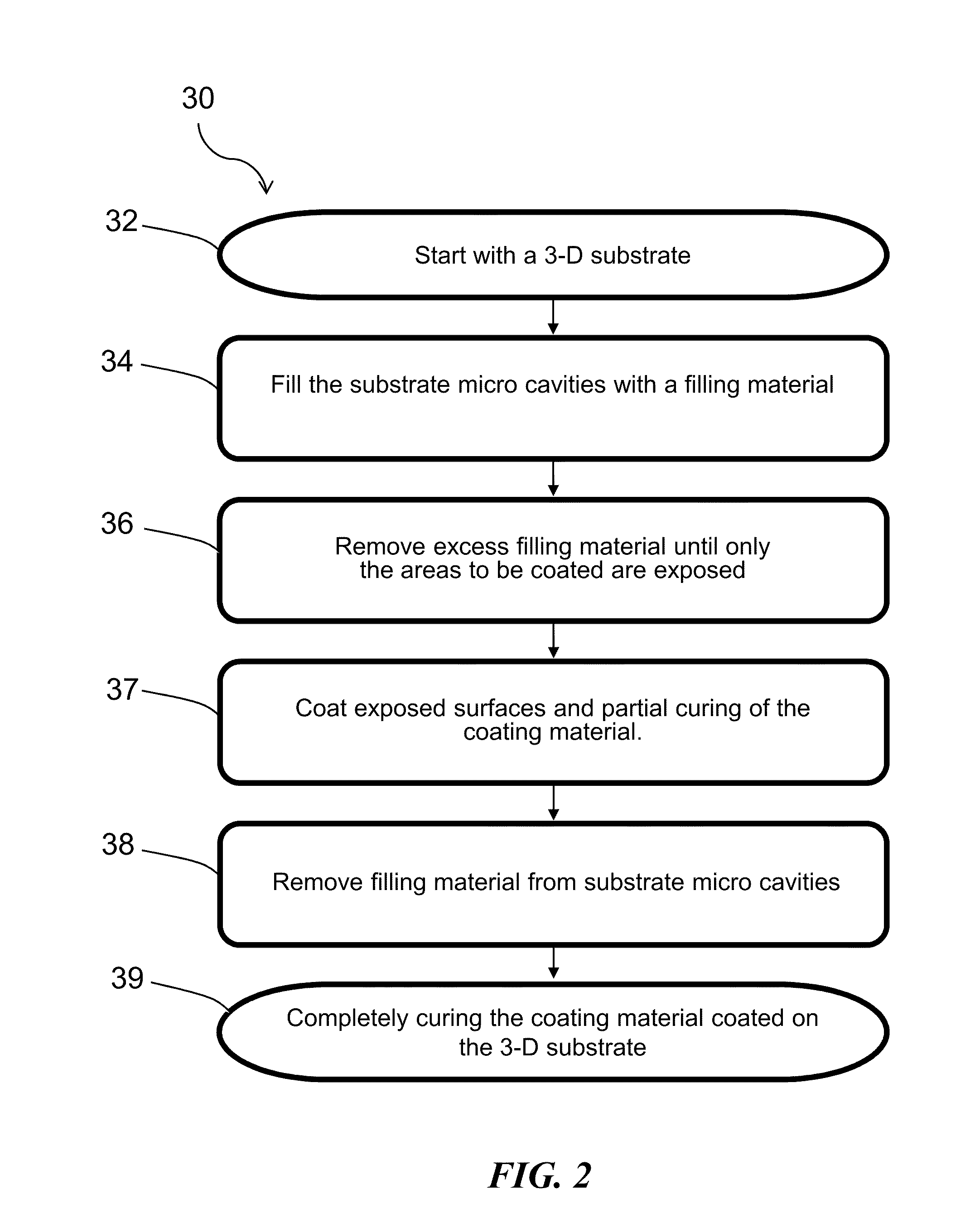

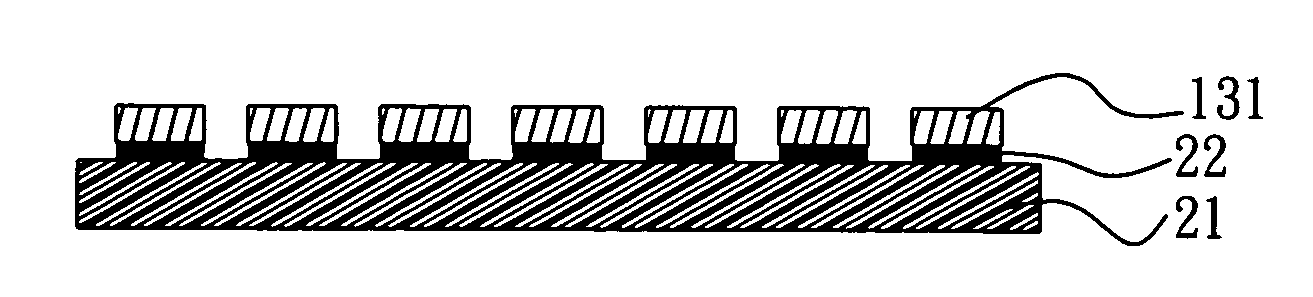

Methods for liquid transfer coating of three-dimensional substrates

InactiveUS20090042320A1Reduce surface tension3D rigid printed circuitsSemiconductor/solid-state device testing/measurementFilling materialsEngineering

Methods here disclosed provide for selectively coating the top surfaces or ridges of a 3-D substrate while avoiding liquid coating material wicking into micro cavities on 3-D substrates. The substrate includes holes formed in a three-dimensional substrate by forming a sacrificial layer on a template. The template includes a template substrate with posts and trenches between the posts. The steps include subsequently depositing a semiconductor layer and selectively etching the sacrificial layer. Then, the steps include releasing the semiconductor layer from the template and coating the 3-D substrate using a liquid transfer coating step for applying a liquid coating material to a surface of the 3-D substrate. The method may further include coating the 3-D substrate by selectively coating the top ridges or surfaces of the substrate. Additional features may include filling the micro cavities of the substrate with a filling material, removing the filling material to expose only the substrate surfaces to be coated, coating the substrate with a layer of liquid coating material, and removing said filling material from the micro cavities of the substrate.

Owner:BEAMREACH SOLAR INC

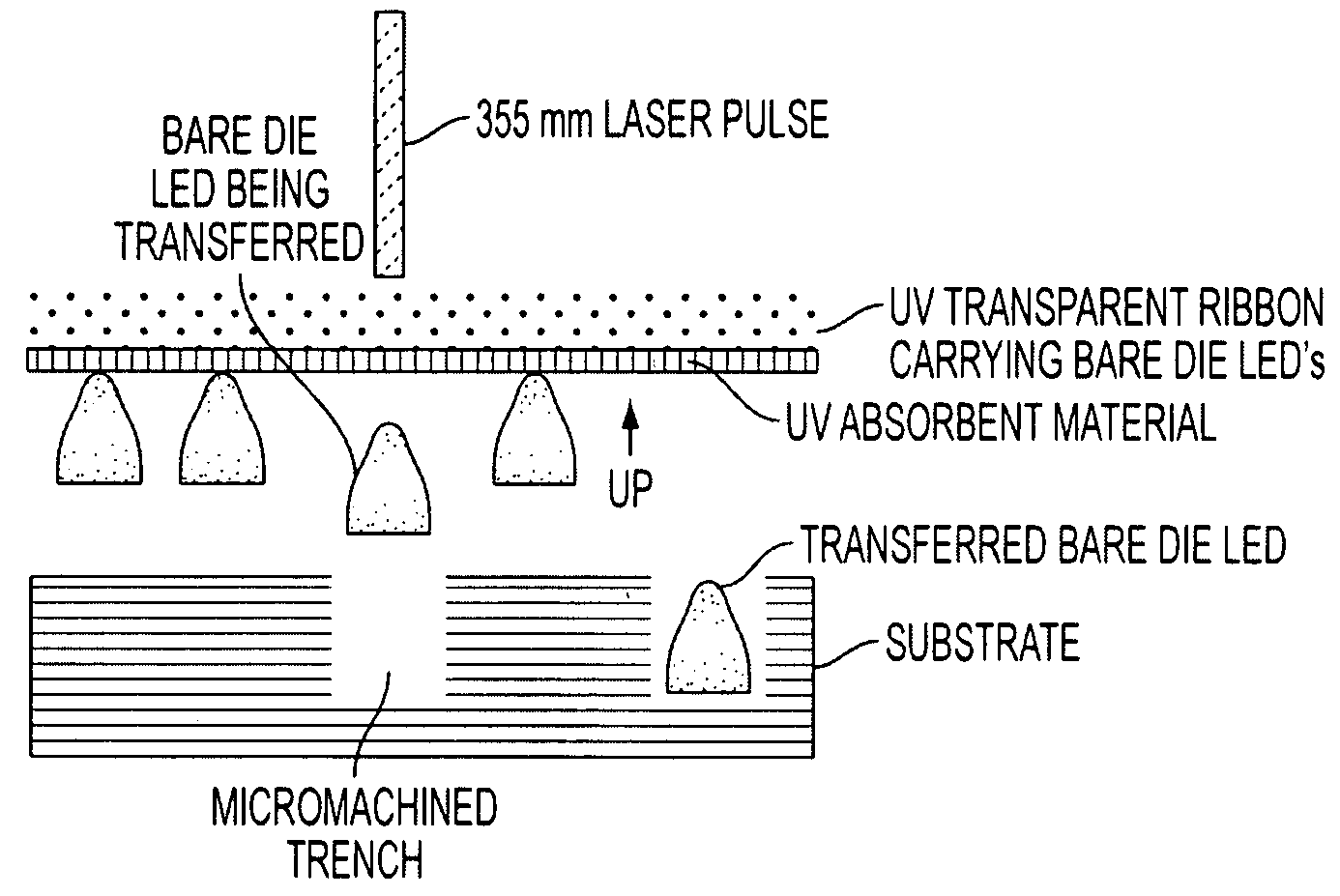

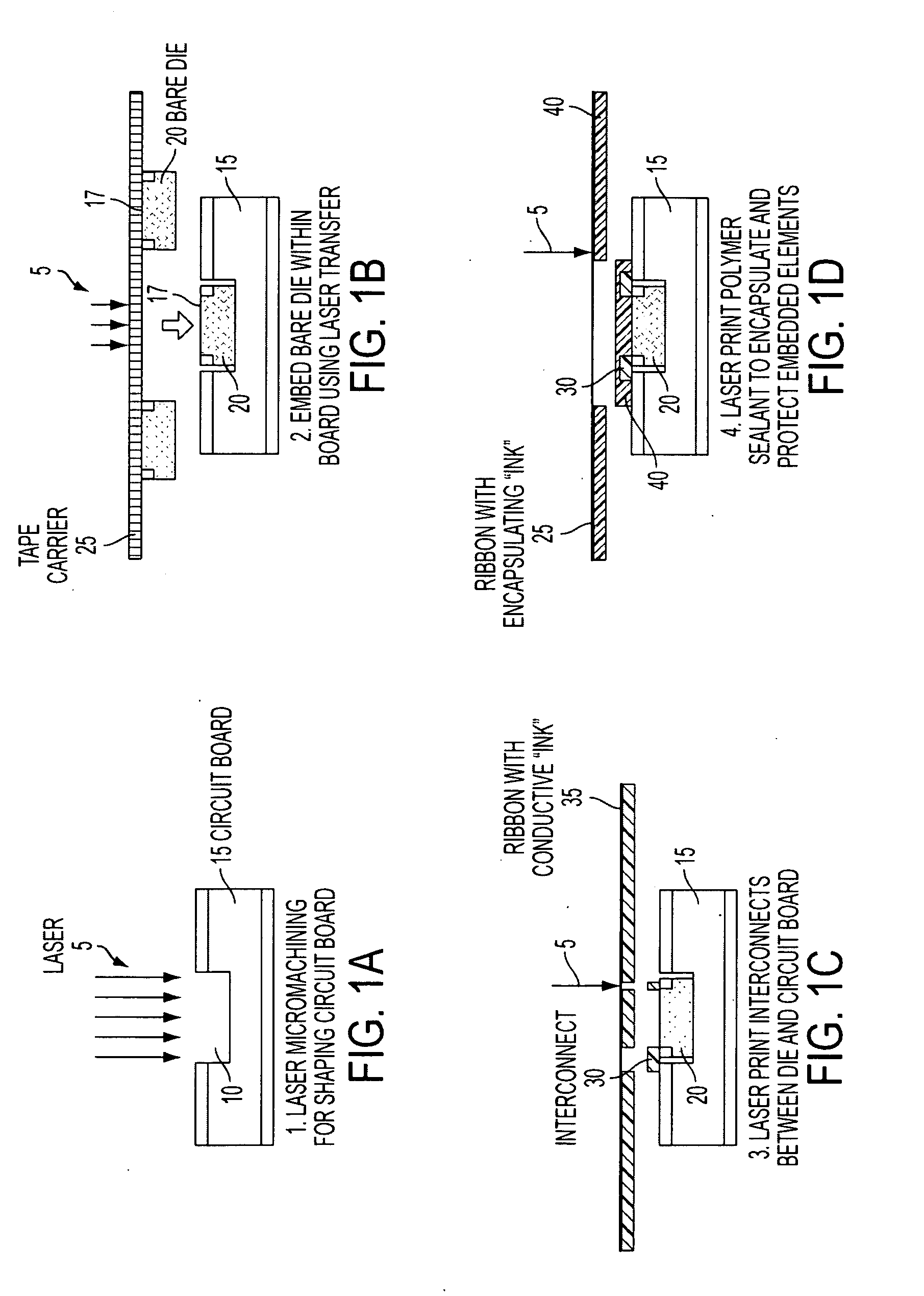

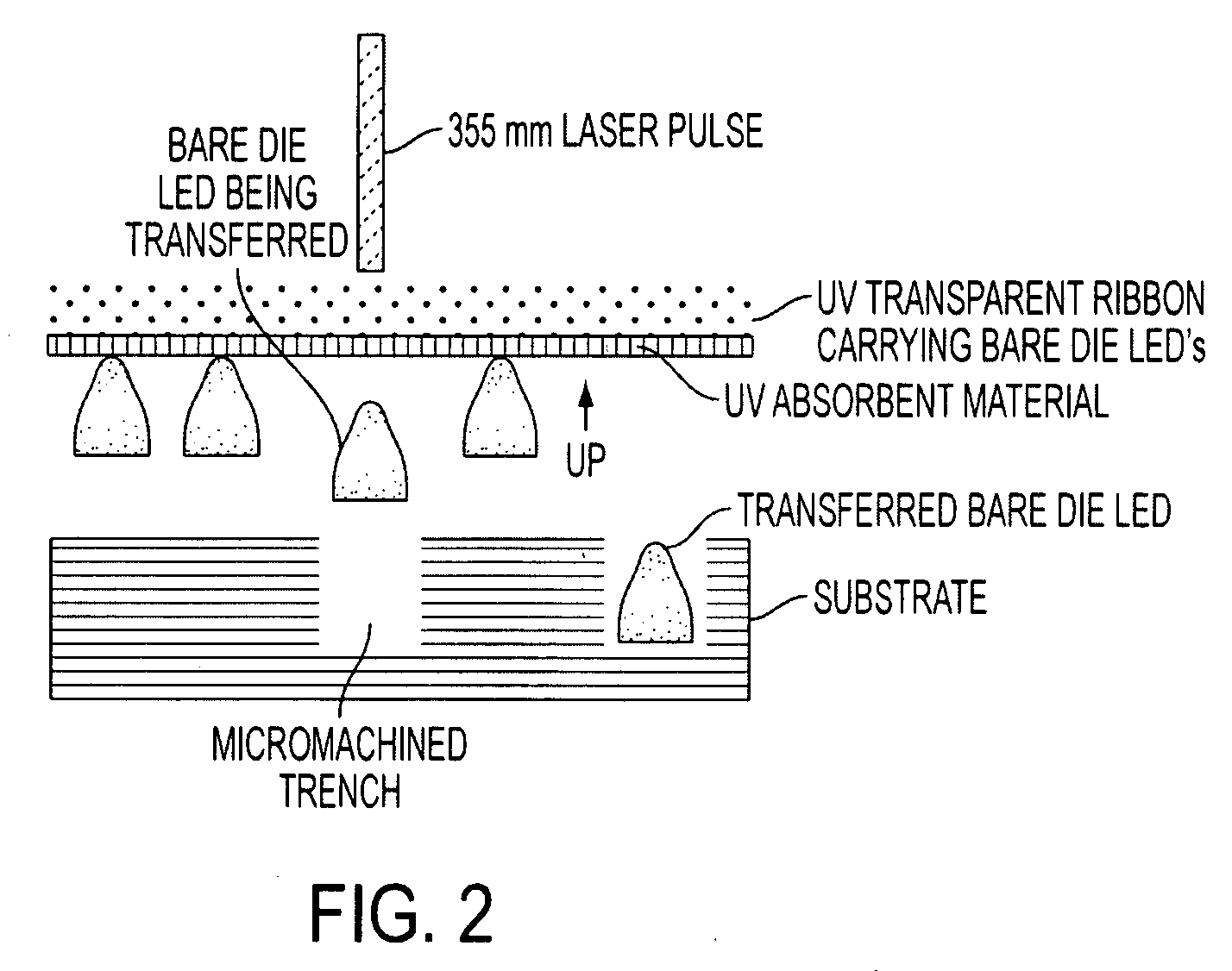

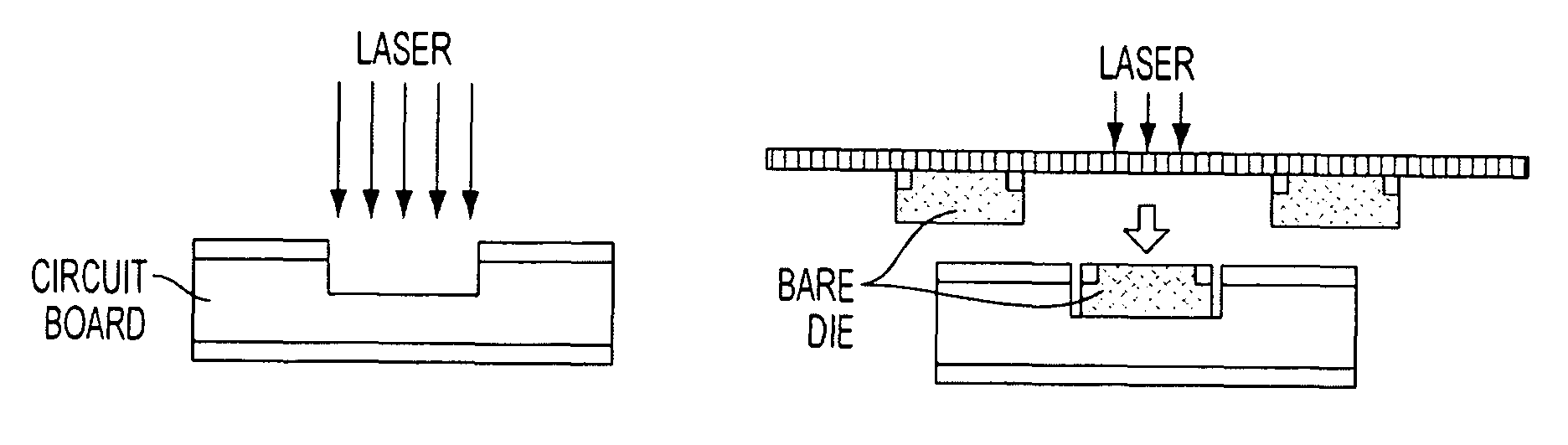

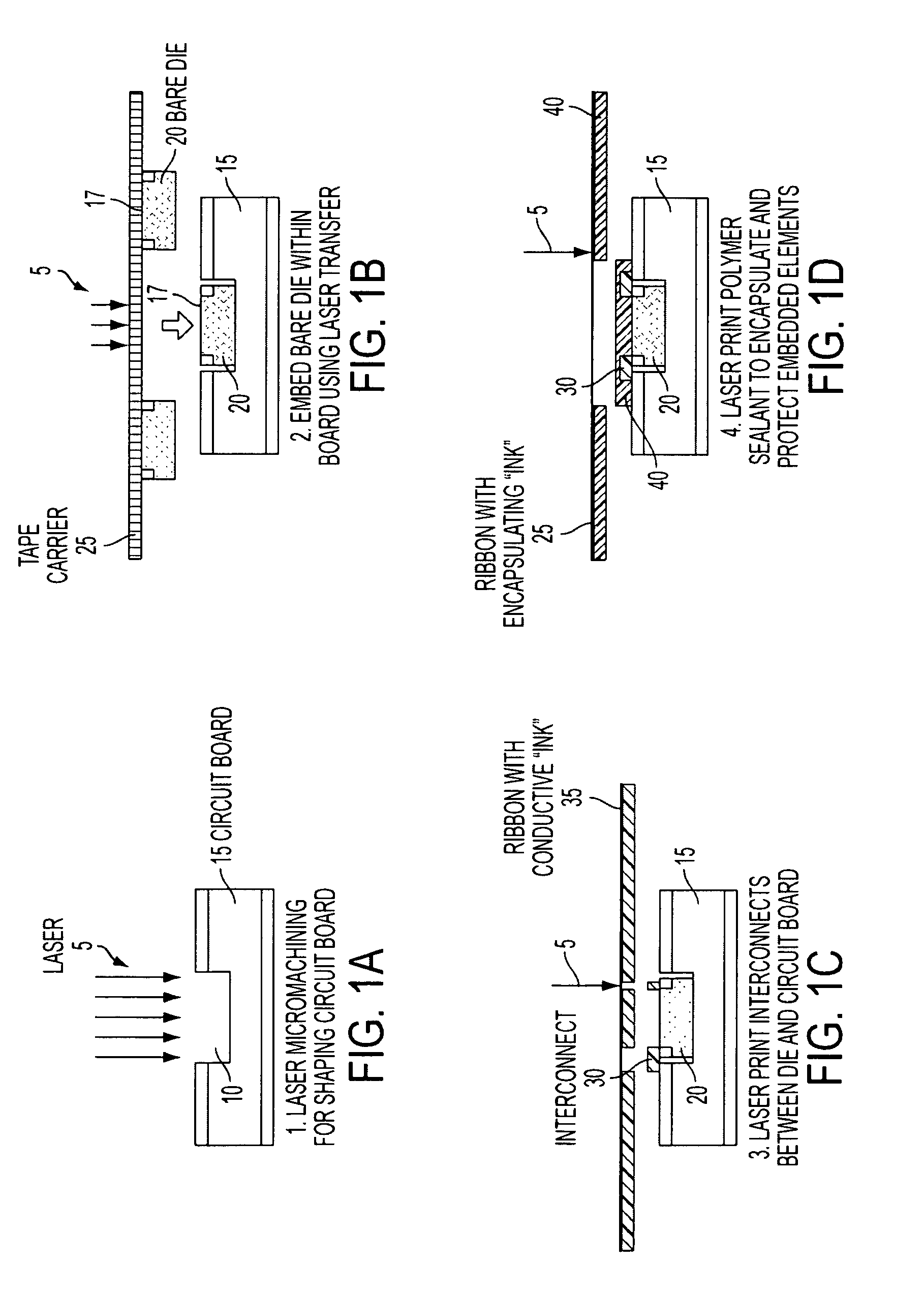

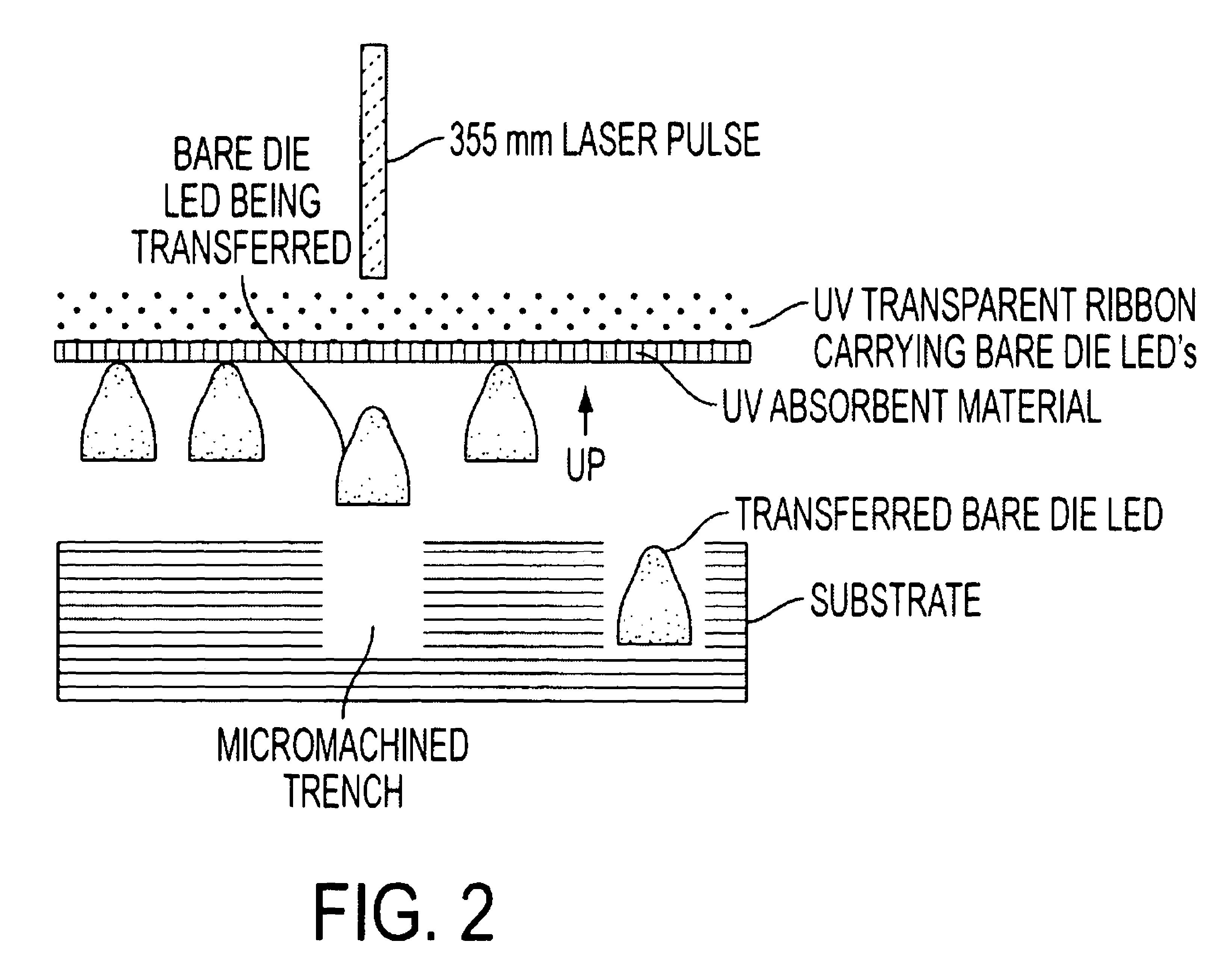

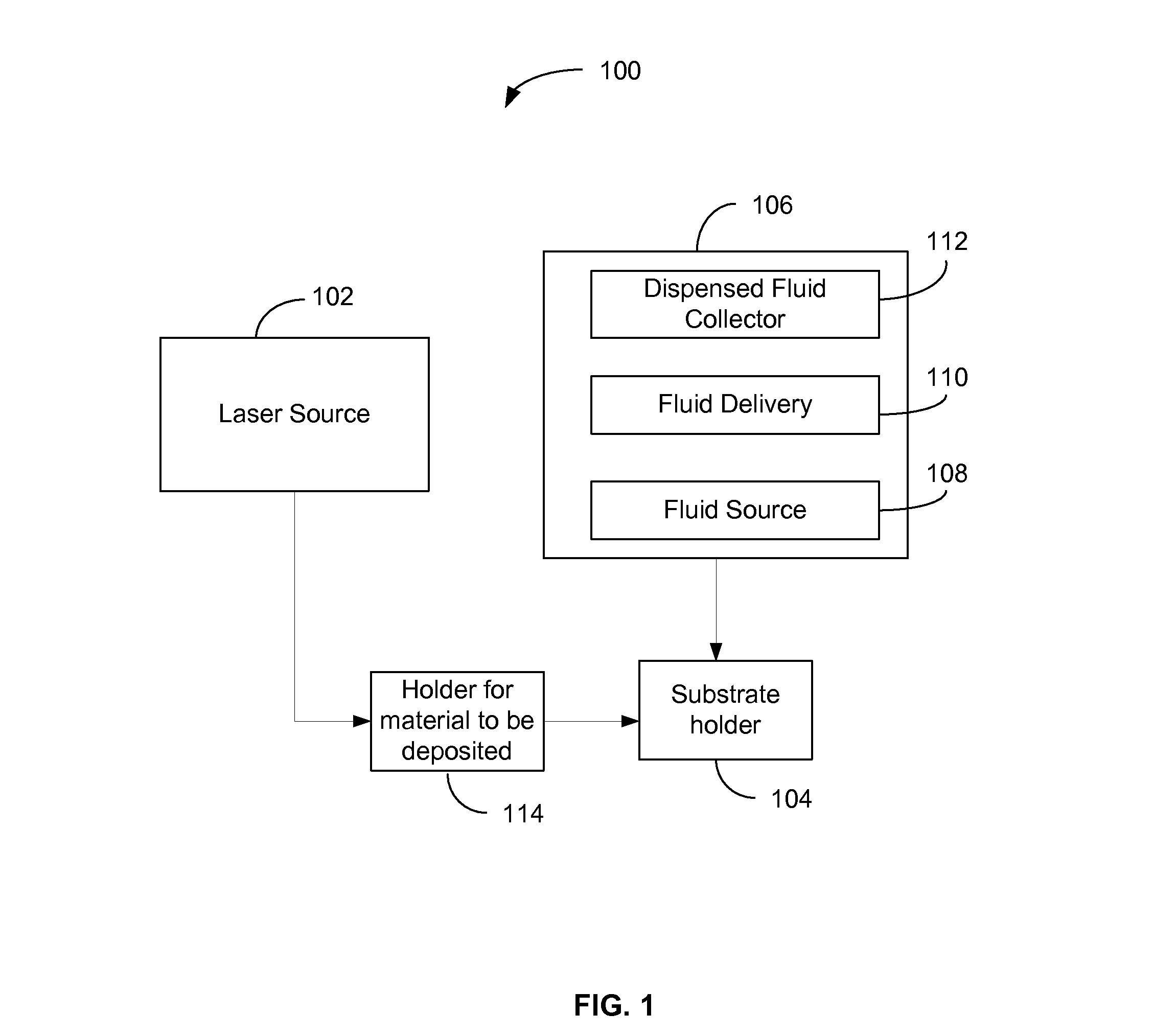

Laser-based technique for the transfer and embedding of electronic components and devices

ActiveUS20090217517A1Printed circuit assemblingTransfer patterningElectronic systemsSurface mounting

A laser direct write method used to transfer entire single components such as semiconductor bare dies or surface mount passive and active components on a substrate or inside recess in a substrate for making embedded microelectronics is disclosed. This method laser-machine the pockets, laser-transfer the individual components inside those pockets, and then laser-print the interconnects required to “wire” the components, thus resulting in a fully assembled embedded circuit required to make a fully functional microelectronic system.

Owner:USA AS REPRESENTED BY THE SEC OF THE NAVY THE

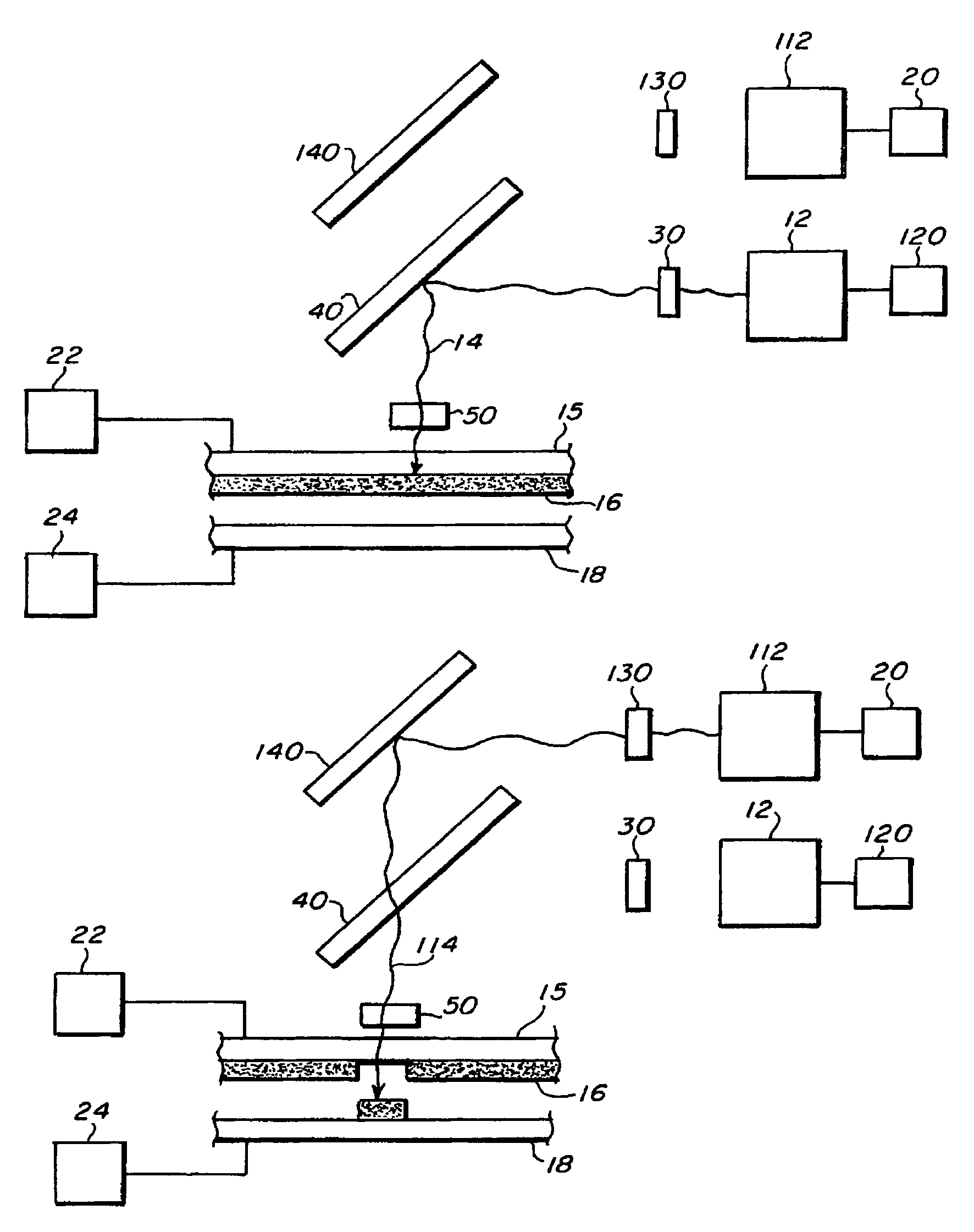

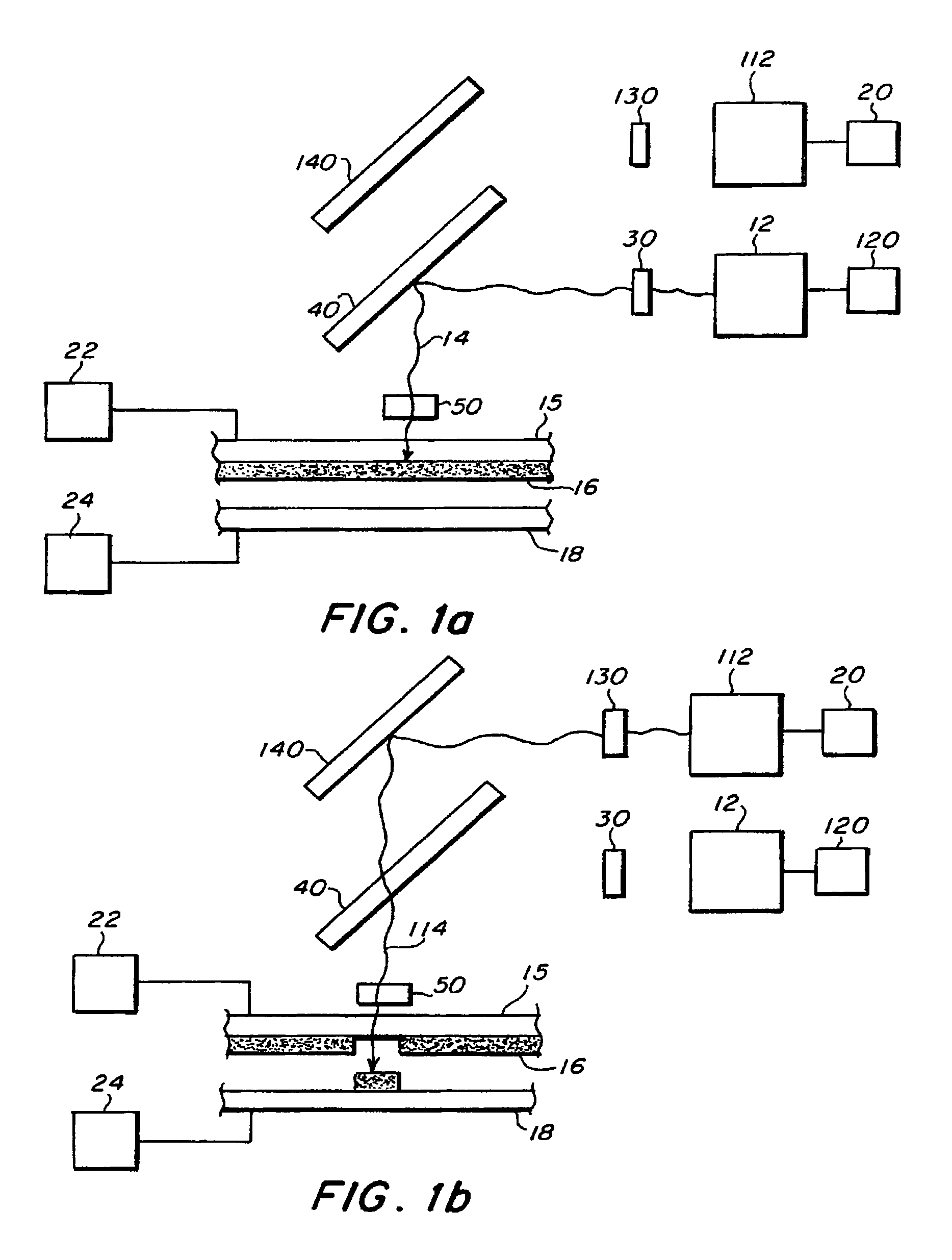

Direct-write laser transfer and processing

A device and method for depositing a material of interest onto a receiving substrate includes a first laser and a second laser, a receiving substrate, and a target substrate. The target substrate comprises a laser transparent support having a back surface and a front surface. The front surface has a coating that comprises the source material, which is a material that can be transformed into the material of interest. The first laser can be positioned in relation to the target substrate so that a laser beam is directed through the back surface of the target substrate and through the laser-transparent support to strike the coating at a defined location with sufficient energy to remove and lift the source material from the surface of the support. The receiving substrate can be positioned in a spaced relation to the target substrate so that the source material is deposited at a defined location on the receiving substrate. The second laser is then positioned to strike the deposited source material to transform the source material into the material of interest.

Owner:NAVY UNITED STATES OF AMERICA AS

Patterns formed by transfer of conductive particles

InactiveUS20060181600A1Improve accuracyThin conductiveRecording apparatusTransfer patterningGramOptoelectronics

The invention relates to a transfer element comprising a base having thereon a transfer layer of inorganic conductive particles in a polymer matrix wherein said transfer layer of inorganic conductive particles has an adhesion to said base of between 20 and 400 grams / cm.

Owner:EASTMAN KODAK CO

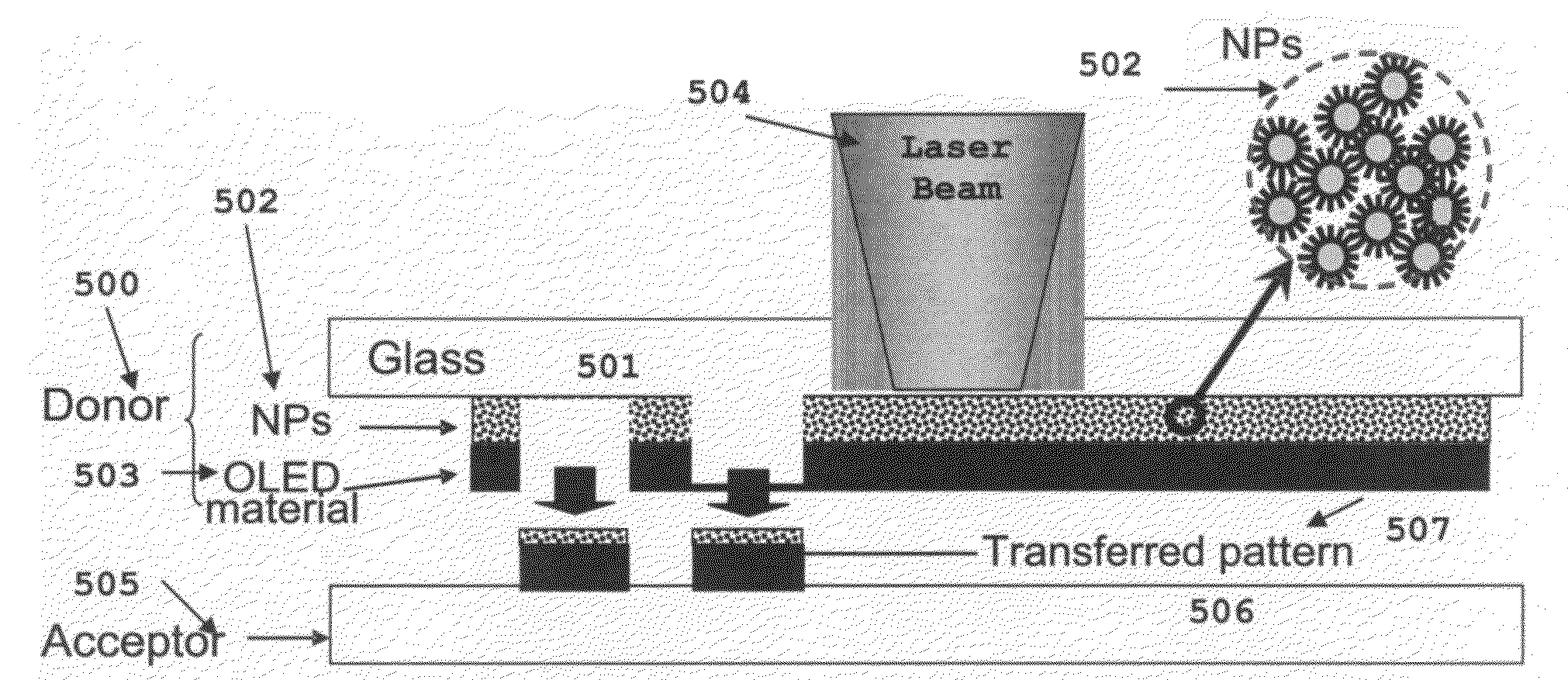

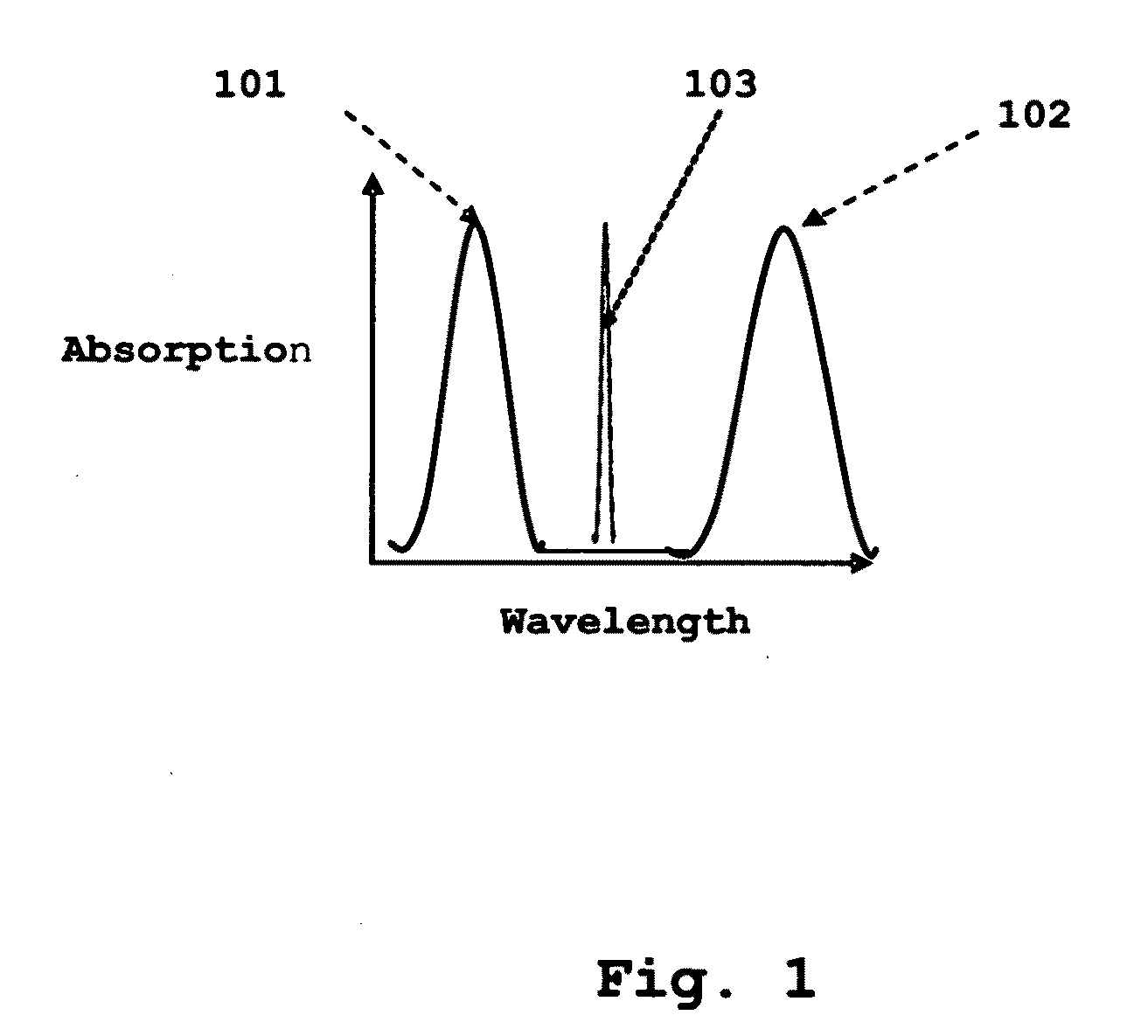

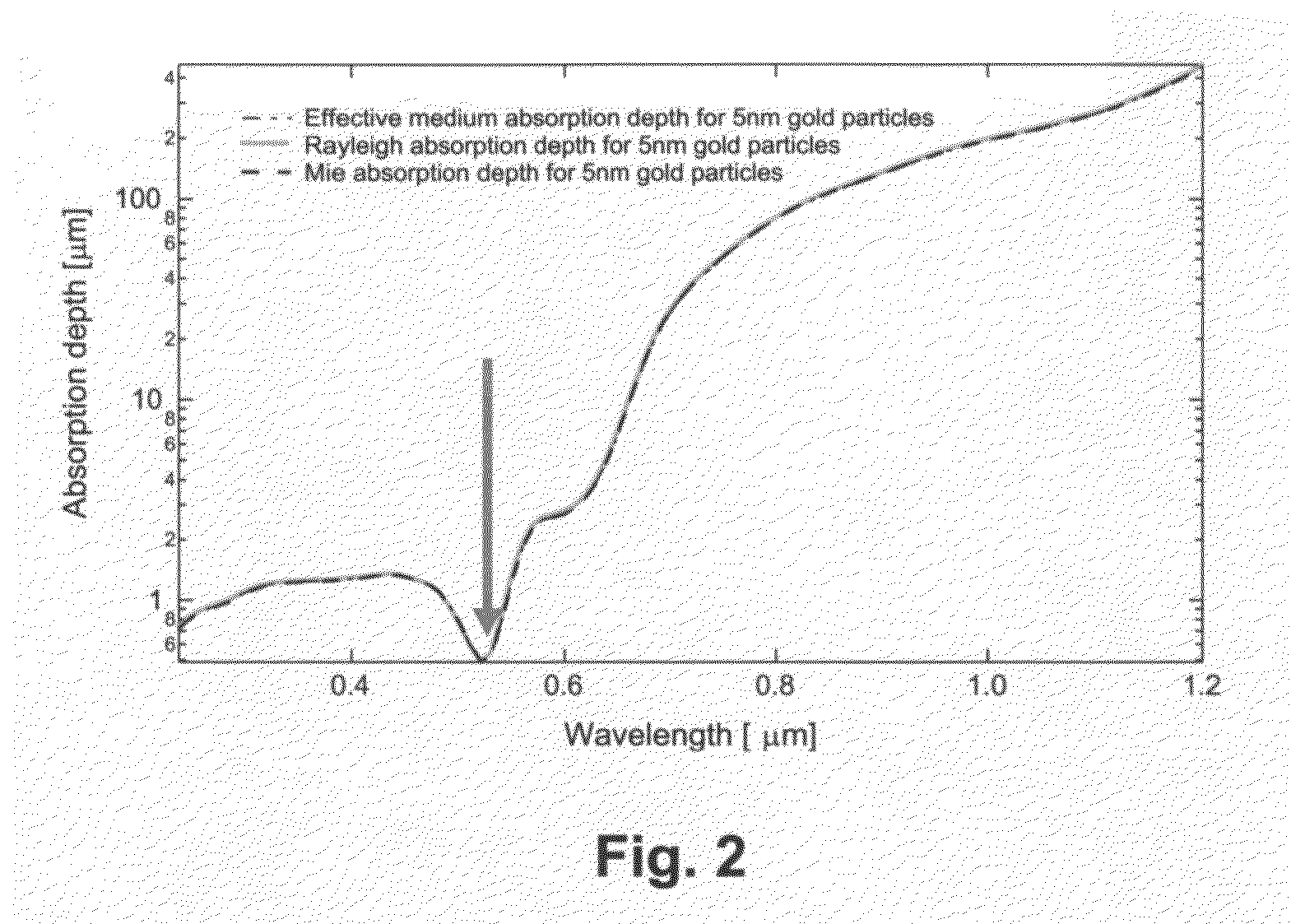

Nanomaterial facilitated laser transfer

InactiveUS20090130427A1Facilitate deposition/removalLayered productsTransfer patterningNanoparticleSelf-assembled monolayer

The invention relates to the deposition or transfer of material using a laser induced forward transfer process. More specifically, the invention relates to the transfer of material using a laser induced forward transfer process wherein the transfer process is facilitated or enabled by nanomaterials. Nanomaterials in the form of nanoparticles or nanofilms may be employed, optionally including a surface coating or self-assembled monolayer surface coating, making use of properties of the nanomaterials that allow the laser induced forward transfer process to be practiced at irradiation energies and temperatures lower than commonly used. The technique may be well suited for depositing organic layers.

Owner:RGT UNIV OF CALIFORNIA +1

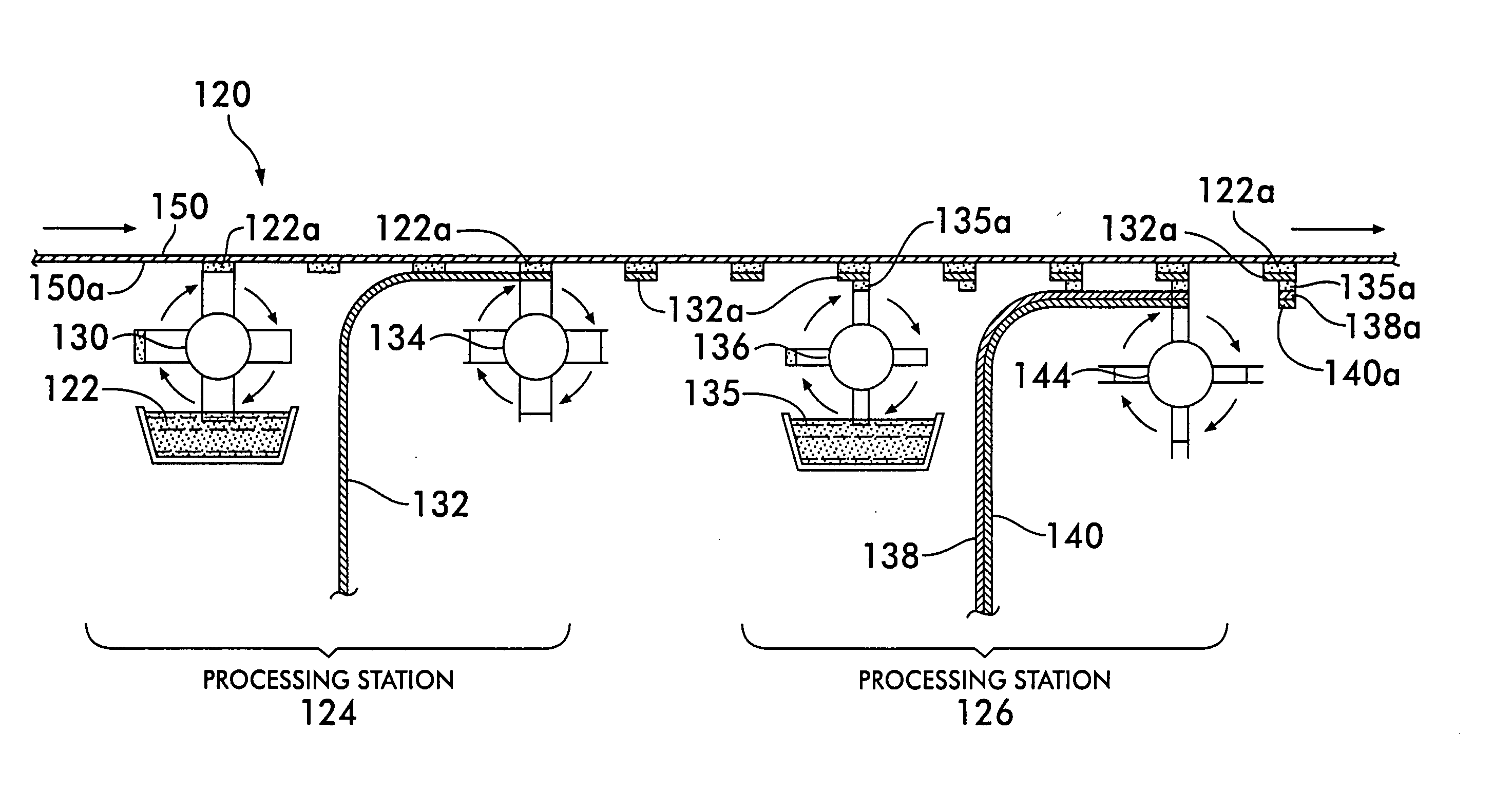

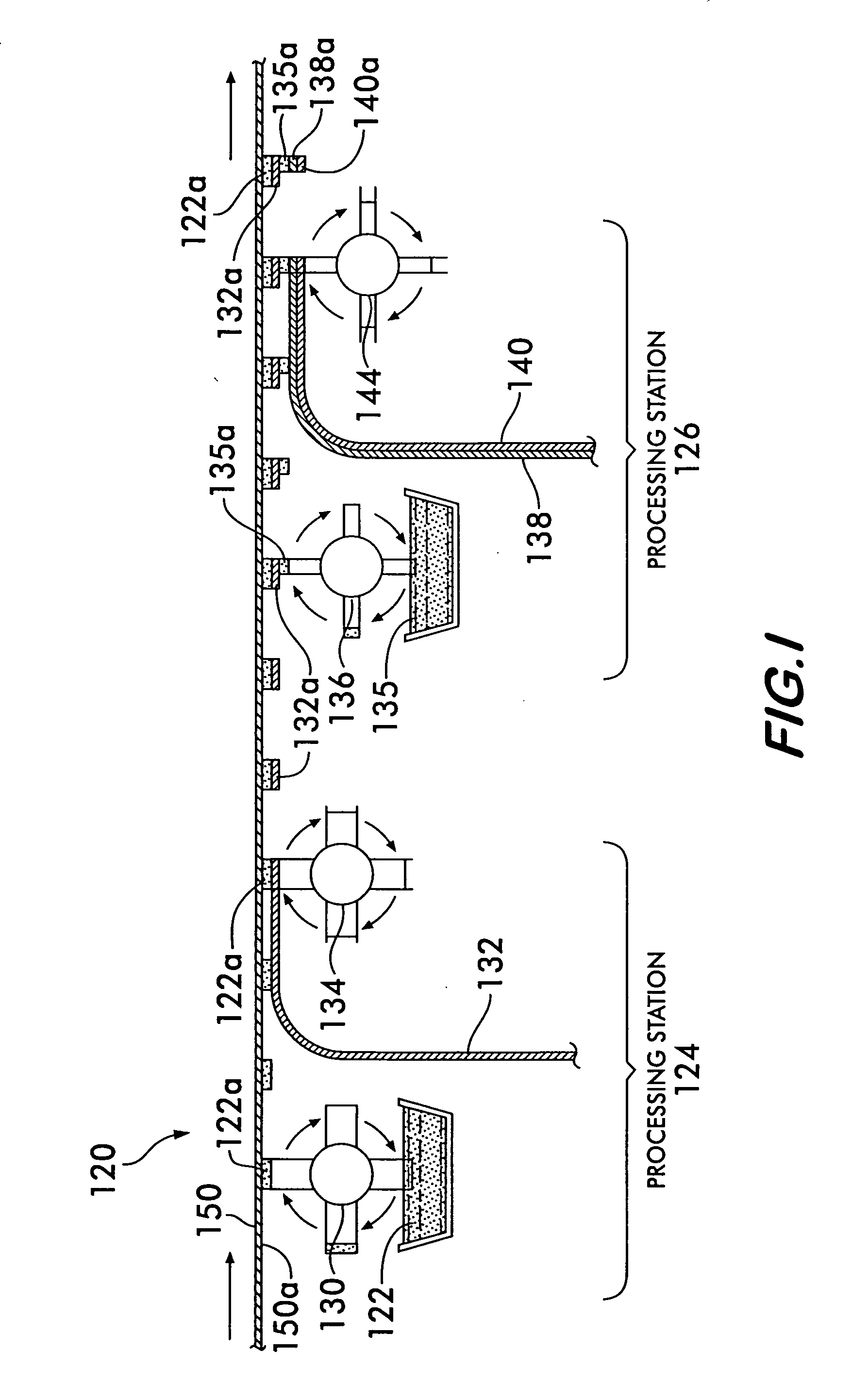

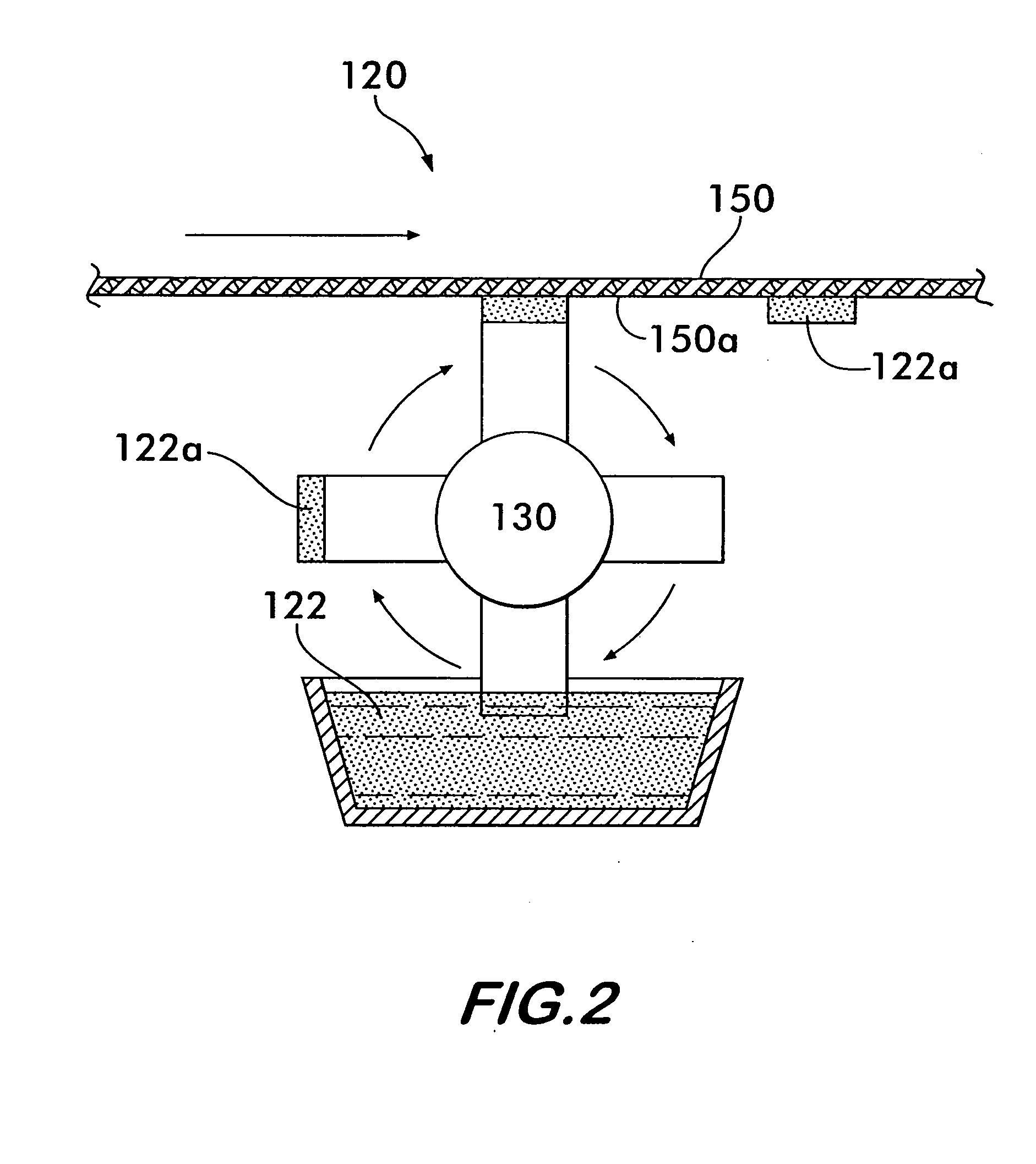

Security tag system for fabricating a tag including an integrated surface processing system

A method of fabricating a tag includes the steps of applying a first patterned adhesive to the surface of the substrate and applying a first electrically conductive foil to the first patterned adhesive. A portion of the first electrically conductive foil not adhered to the first patterned adhesive is removed and a second patterned adhesive is applied to a portion of a surface area of the tag. A preformed second electrically conductive foil is applied to the second patterned adhesive to adhere the second electrically conductive foil to the surface of the substrate and portions of the first and second electrically conductive foils are electrically coupled to each other to form a tag circuit. A second patterned adhesive can be disposed between the first and second electrically conductive foils.

Owner:CHECKPOINT SYST INC

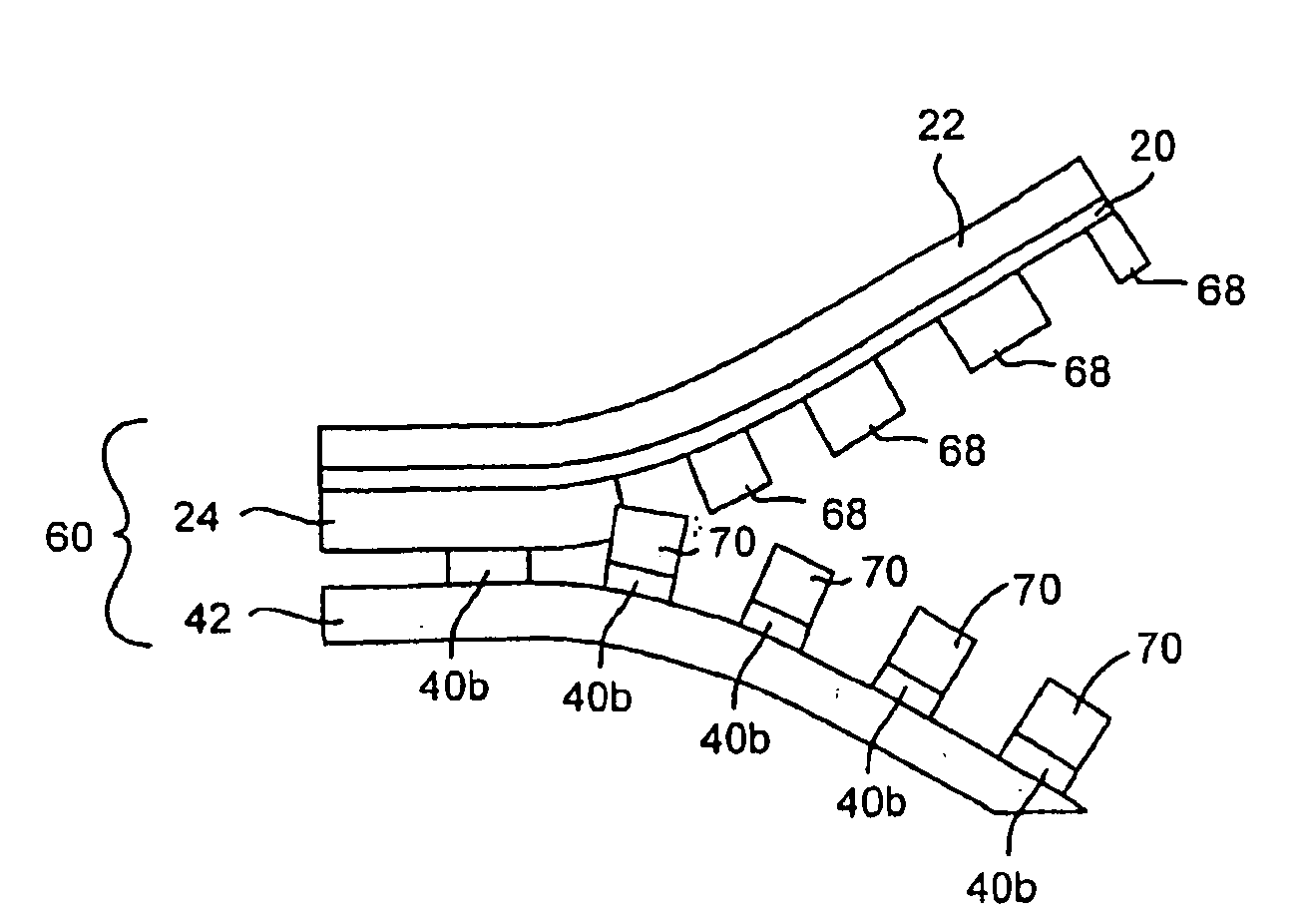

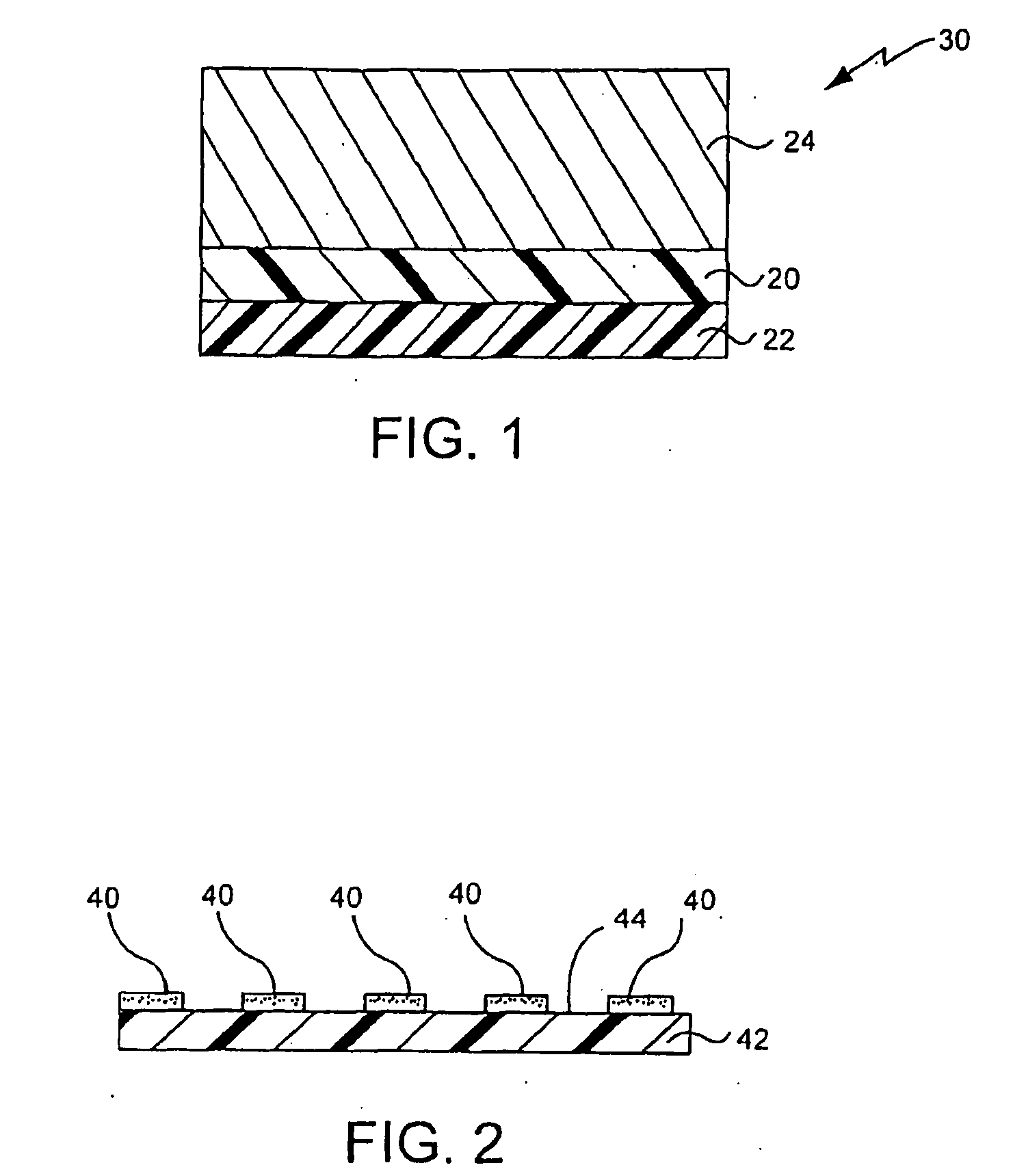

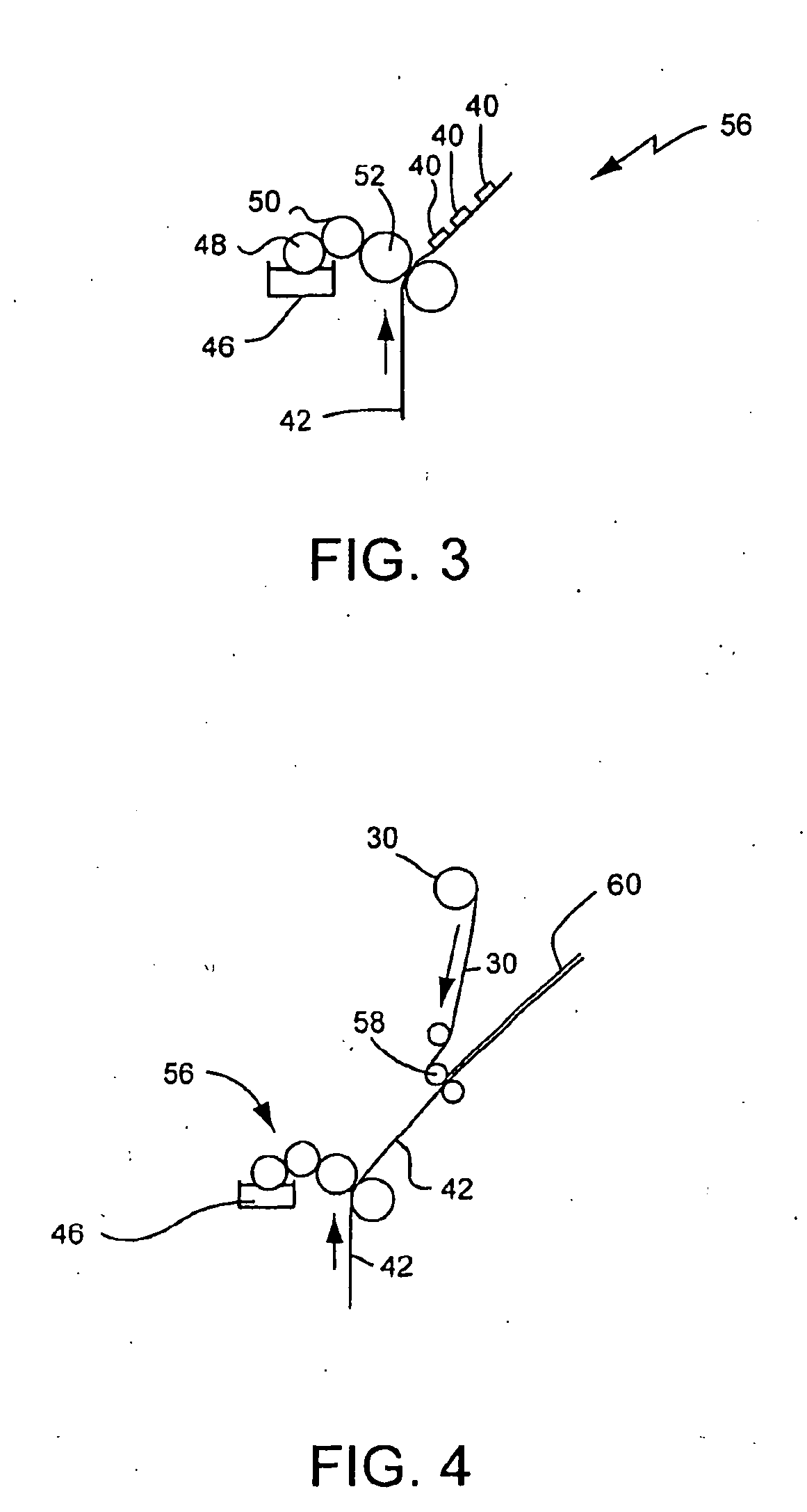

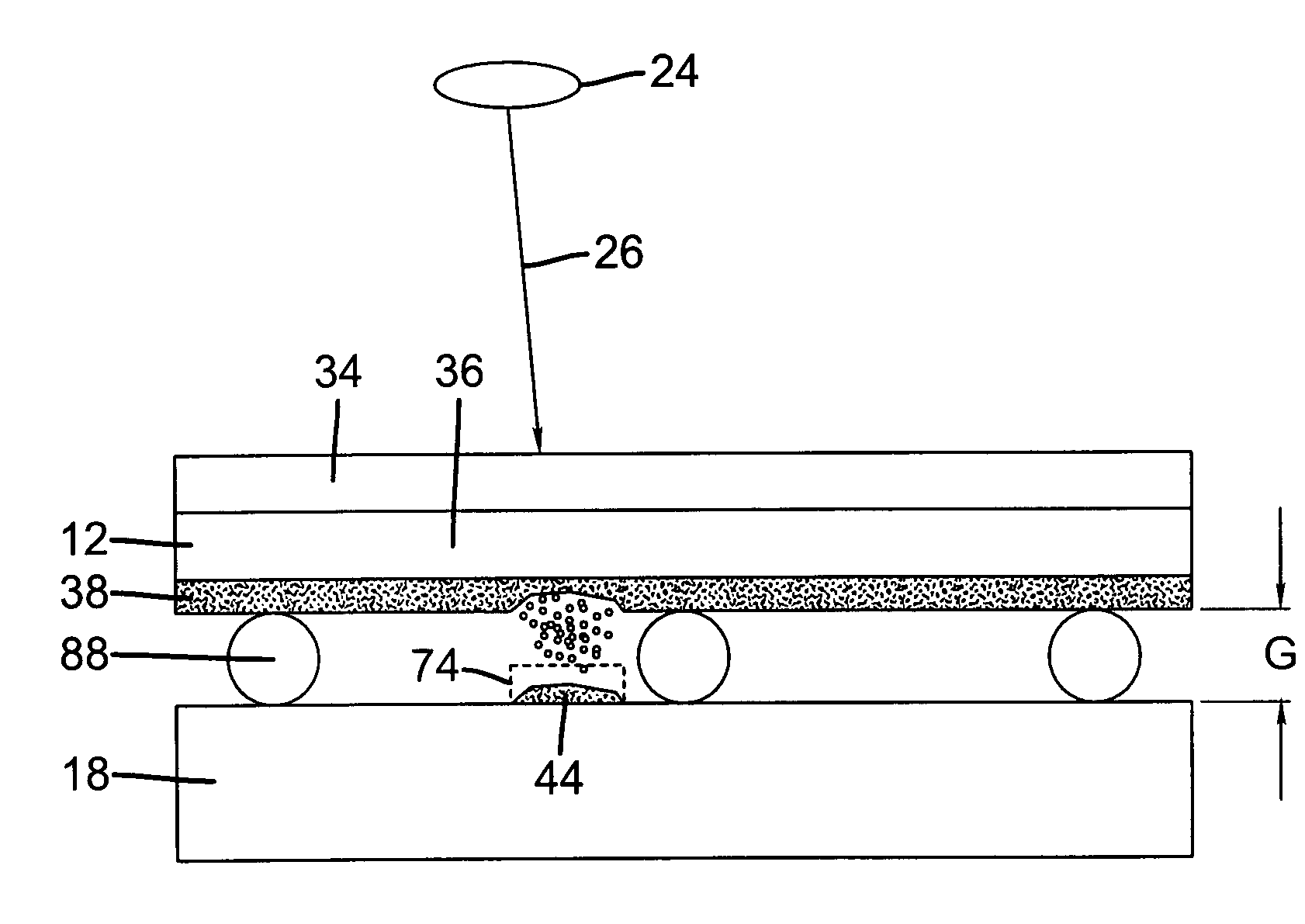

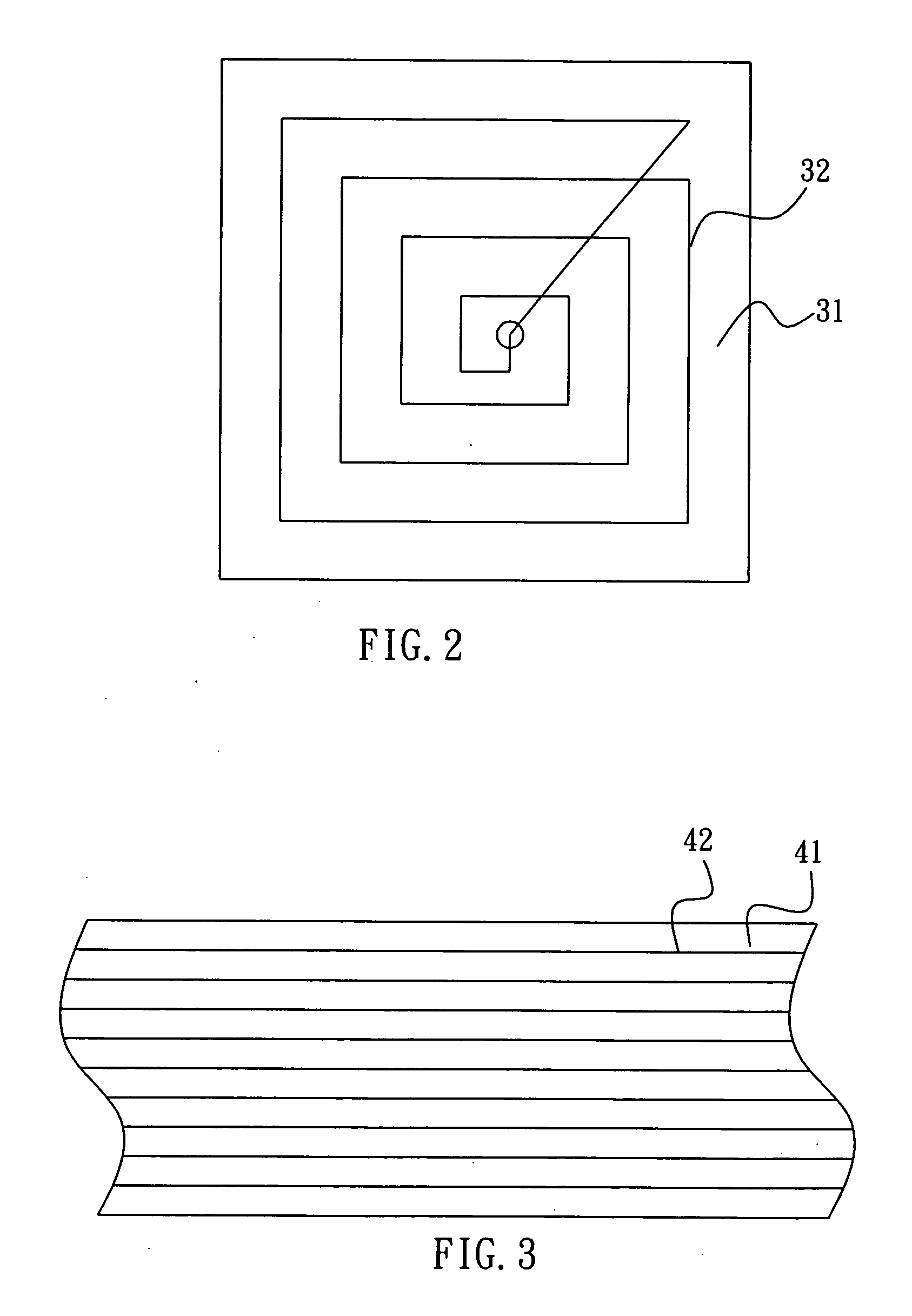

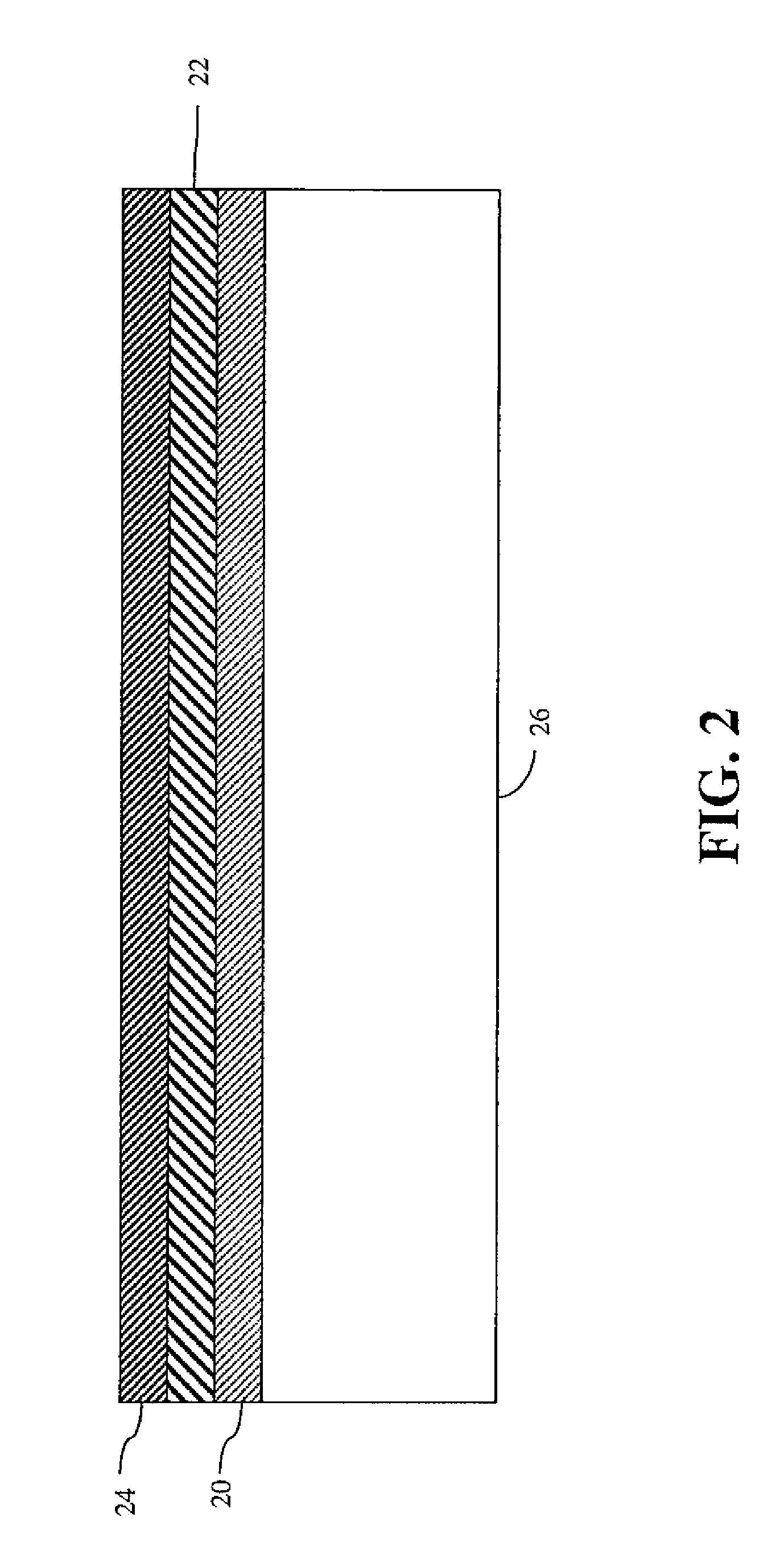

Method and Material for Manufacturing Electrically Conductive Patterns, Including Radio Frequency Identification (RFID) Antennas

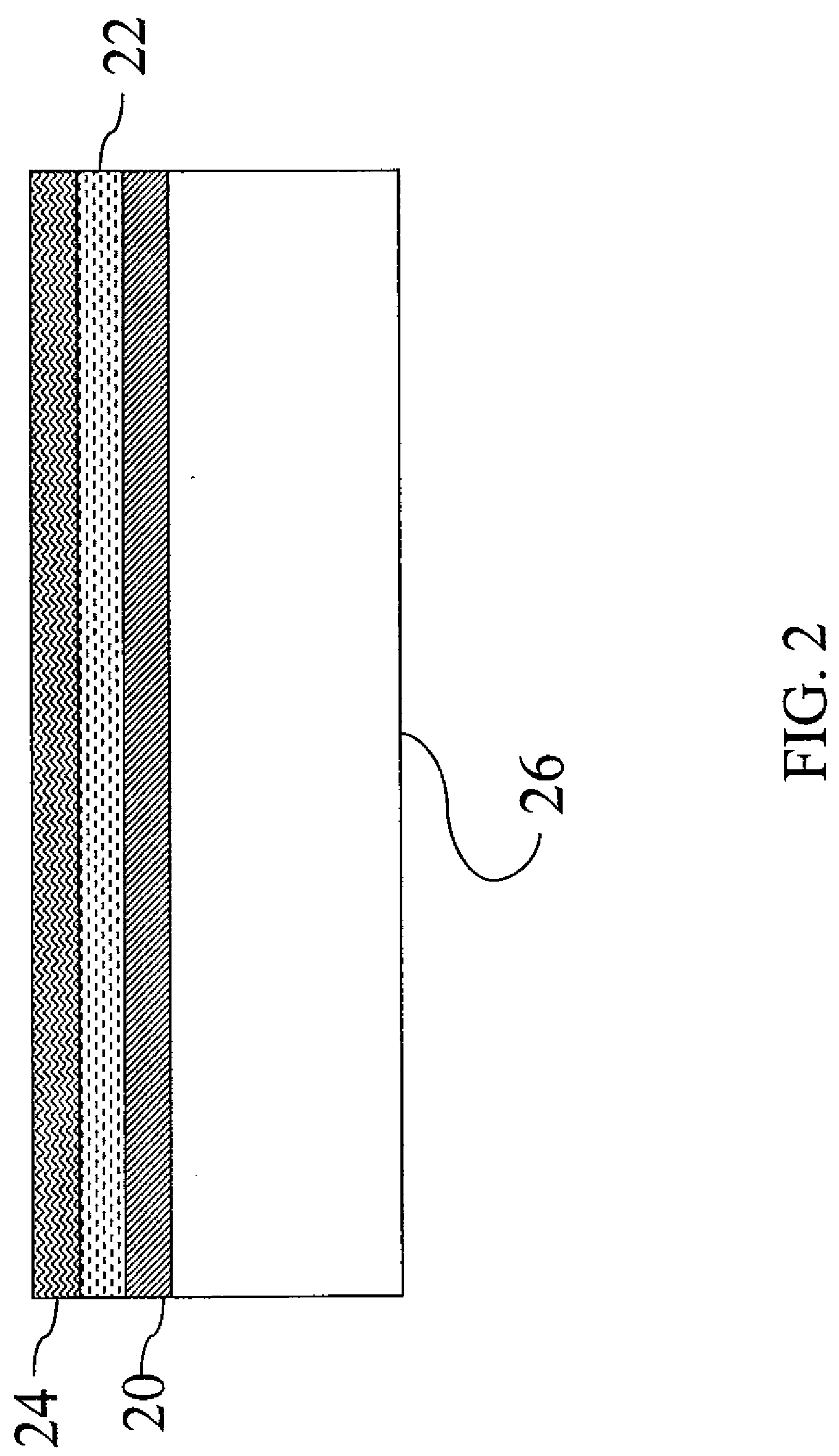

A method of making an electrically conductive patterned film (74), such as an RFID antenna, is disclosed. The method includes the steps of providing a layer of conductive metal (24) adjacent a layer of release coating (20); providing a patterned adhesive layer (400) adjacent a target substrate (42); contacting the layer of conductive metal (24) and the patterned adhesive layer (40), such that a corresponding portion (70) of the layer of conductive metal (24) contacts the patterned adhesive layer (40); and the patterned adhesive layer (40) stripping the corresponding portion (70) of the layer of conductive metal (24) from the release coating (20). The patterned adhesive layer (40) can be formed in the shape of an RFID antenna. An electrical component or a computer chip (80) can be directly applied to the layer of conductive metal (24). An RFID device, such as an RFID tag or label is also disclosed.

Owner:K B

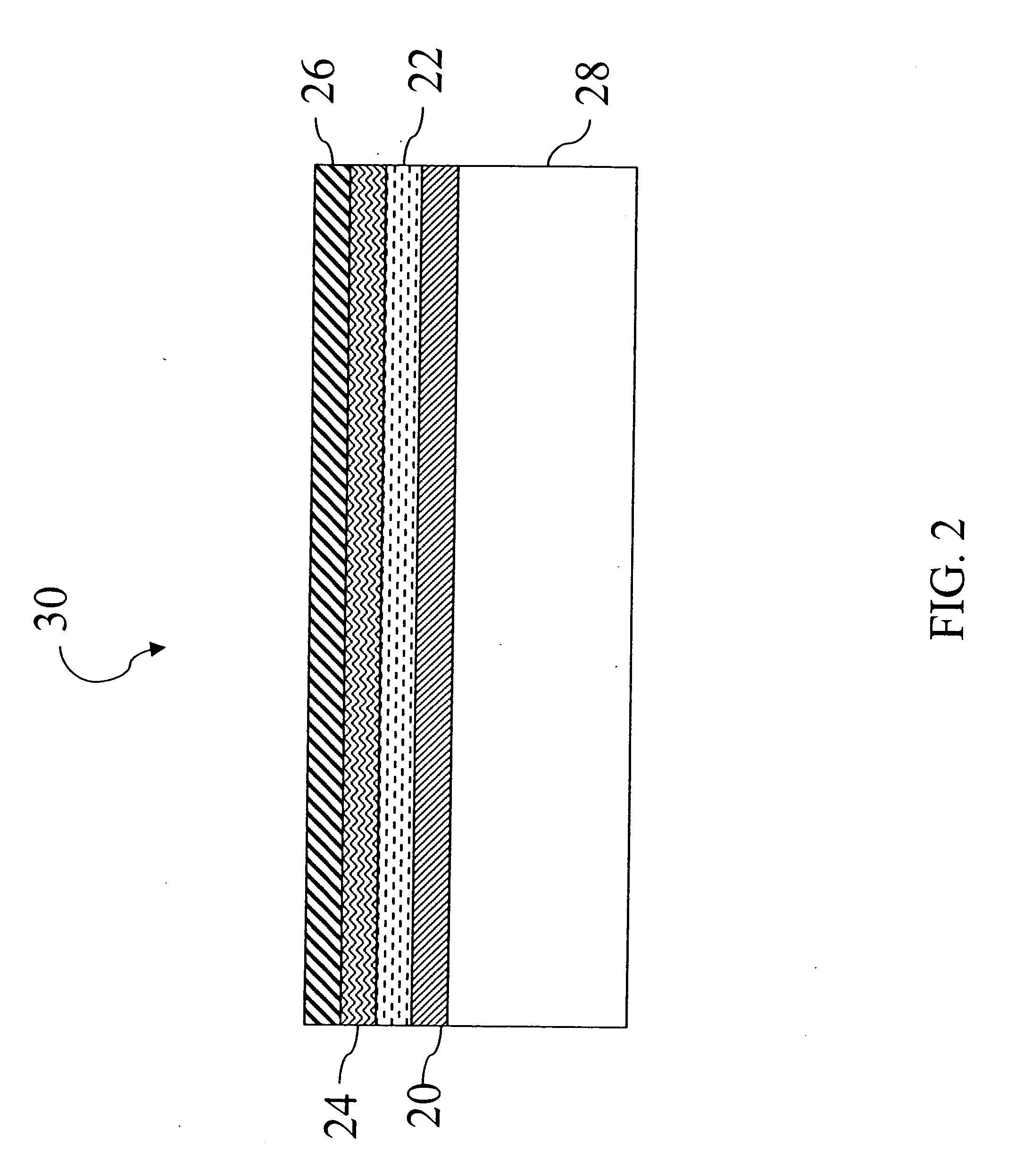

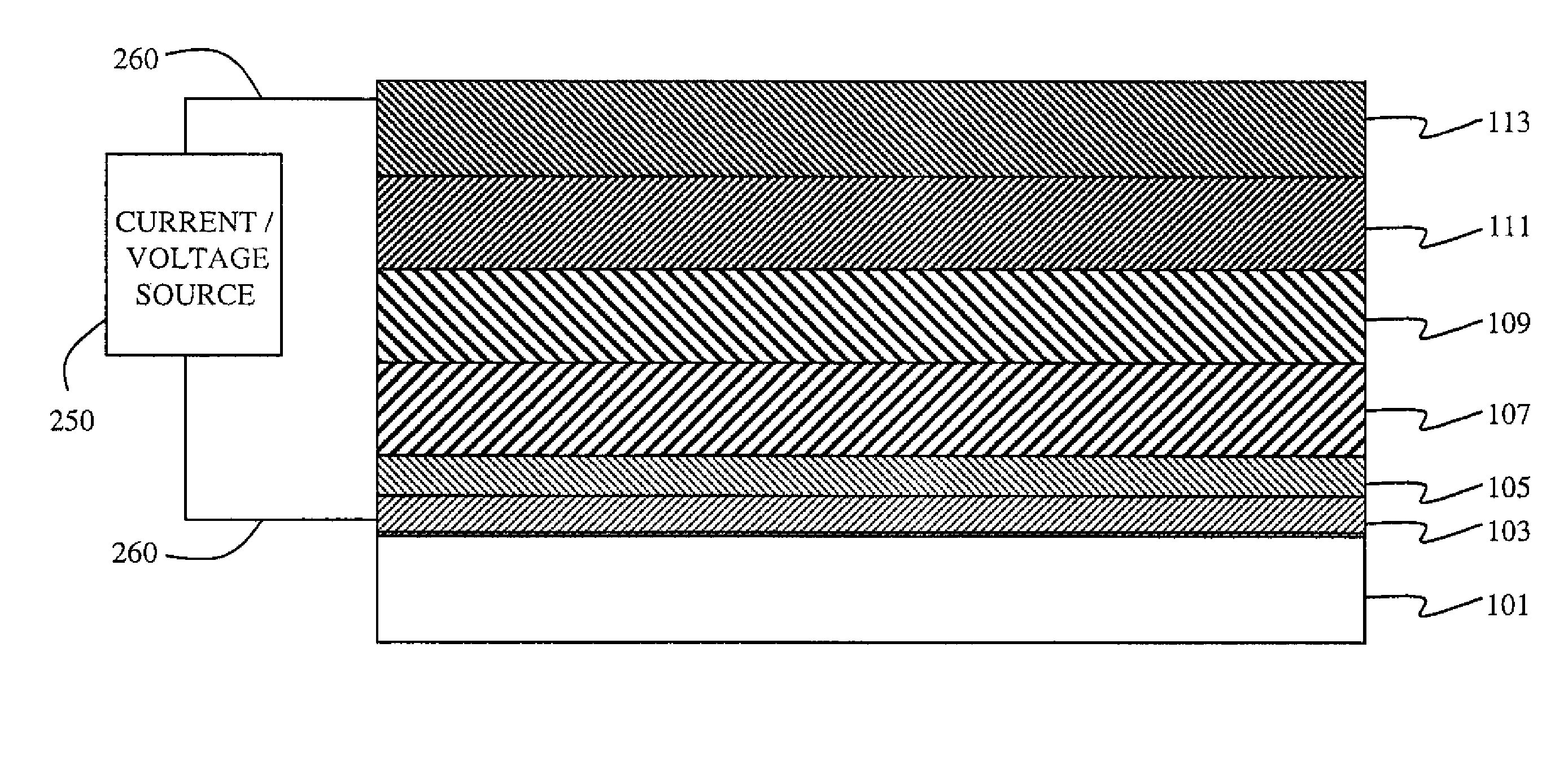

Polymeric conductor donor and transfer method

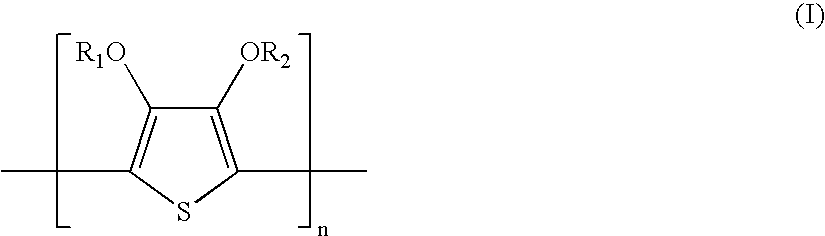

ActiveUS20060088698A1Transfer patterningDecorative surface effectsElectrical conductorConductive polymer

The present invention relates to a donor laminate for transfer of a conductive layer comprising at least one electronically conductive polymer on to a receiver, wherein the receiver is a component of a device. The present invention also relates to methods pertinent to such transfers.

Owner:EASTMAN KODAK CO

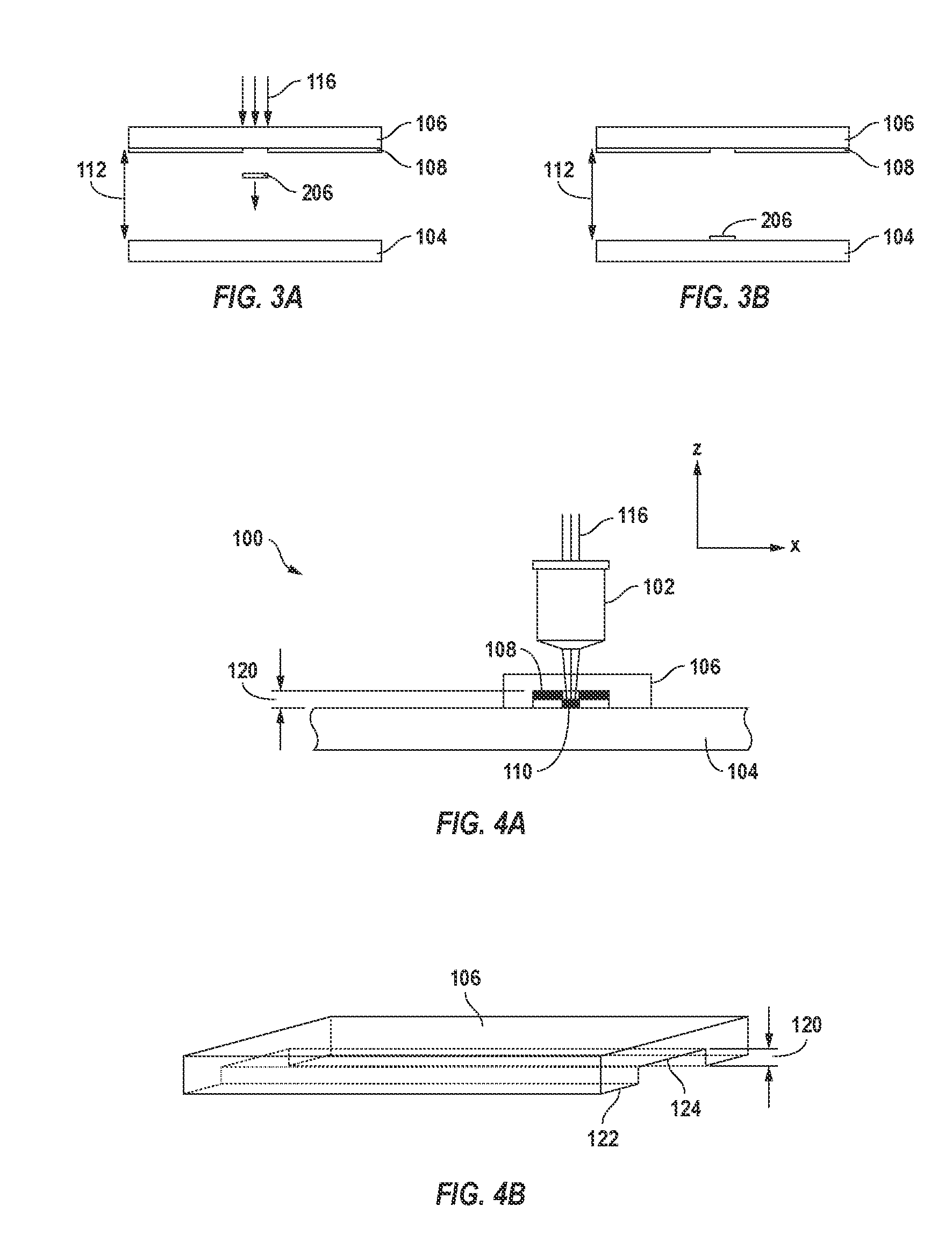

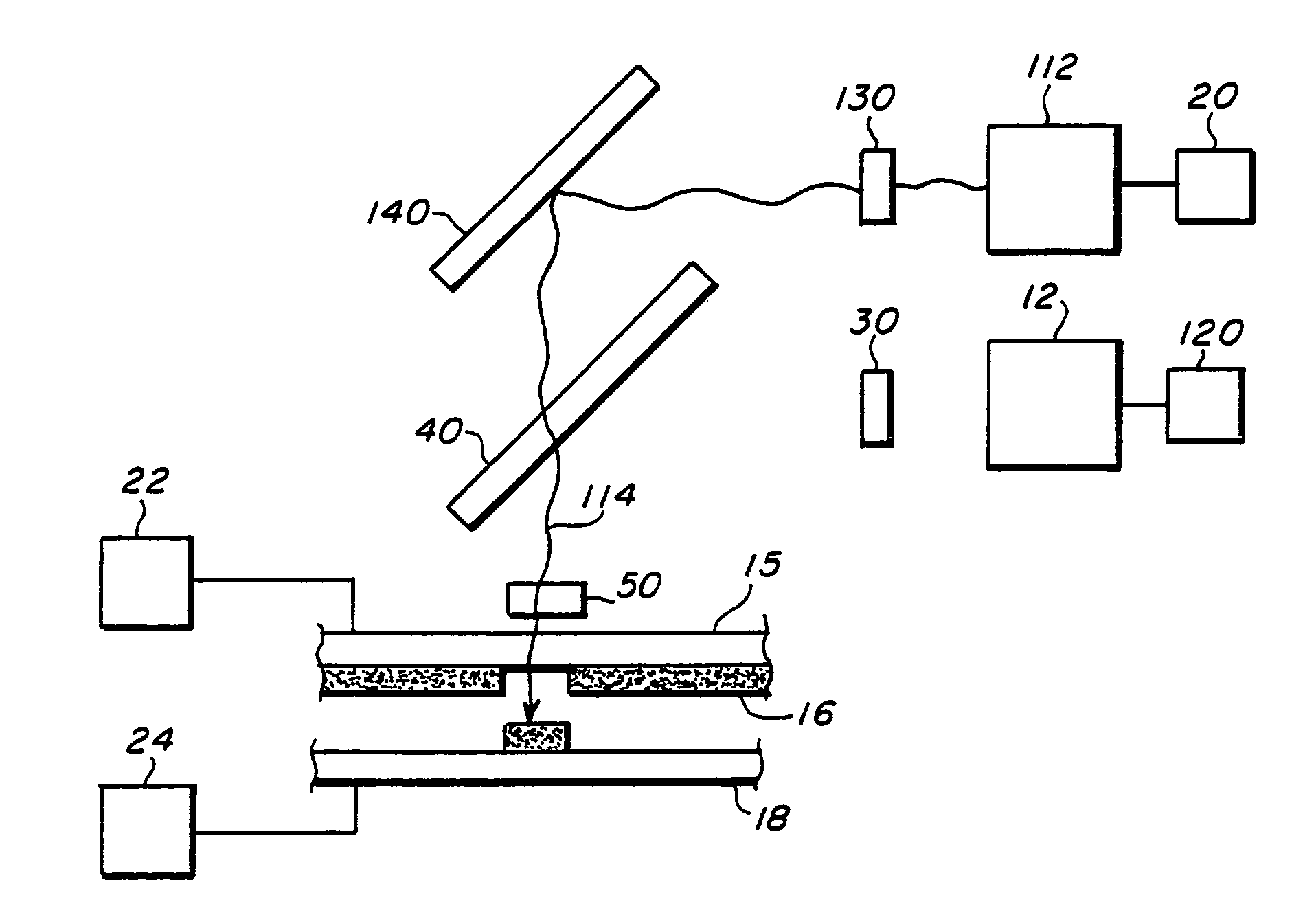

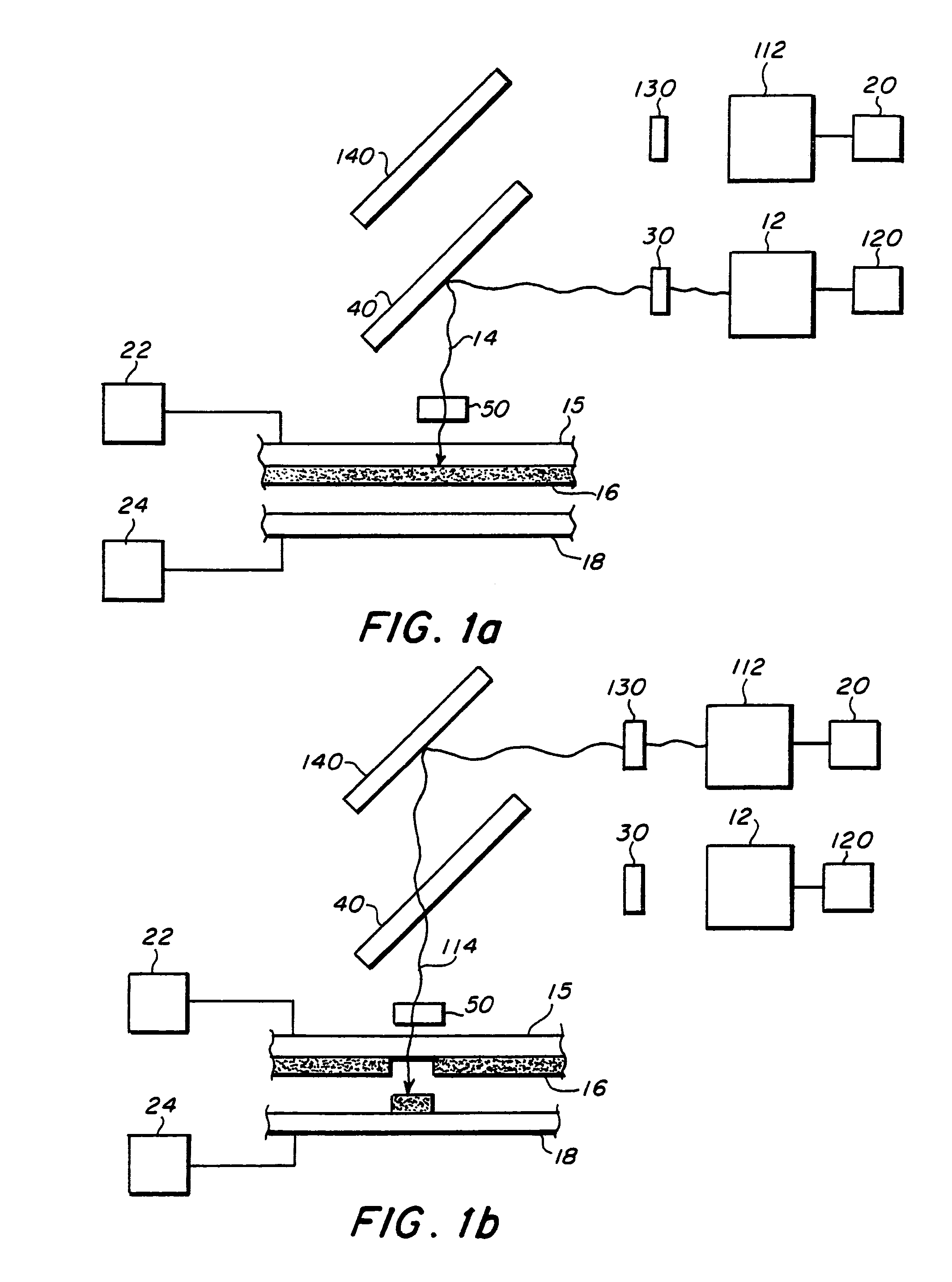

Laser decal transfer of electronic materials

ActiveUS20090074987A1Dampening any shear forceHigh viscosityElectric discharge heatingTransfer patterningThin layerOptoelectronics

A laser decal transfer is used to generate thin film features by directing laser pulses of very low energy at the back of a target substrate illuminating an area of a thin layer of a high viscosity rheological fluid coating the front surface of the target. The illuminated area is shaped and defined by an aperture centered about the laser beam. The decal transfer process allows for the release and transfer from the target substrate to the receiving substrate a uniform and continuous layer identical in shape and size of the laser irradiated area. The released layer is transferred across the gap with almost no changes to its initial size and shape. The resulting patterns transferred onto the receiving substrate are highly uniform in thickness and morphology, have sharp edge features and exhibit high adhesion, independent of the surface energy, wetting or phobicity of the receiving substrate.

Owner:PHOTON DYNAMICS +1

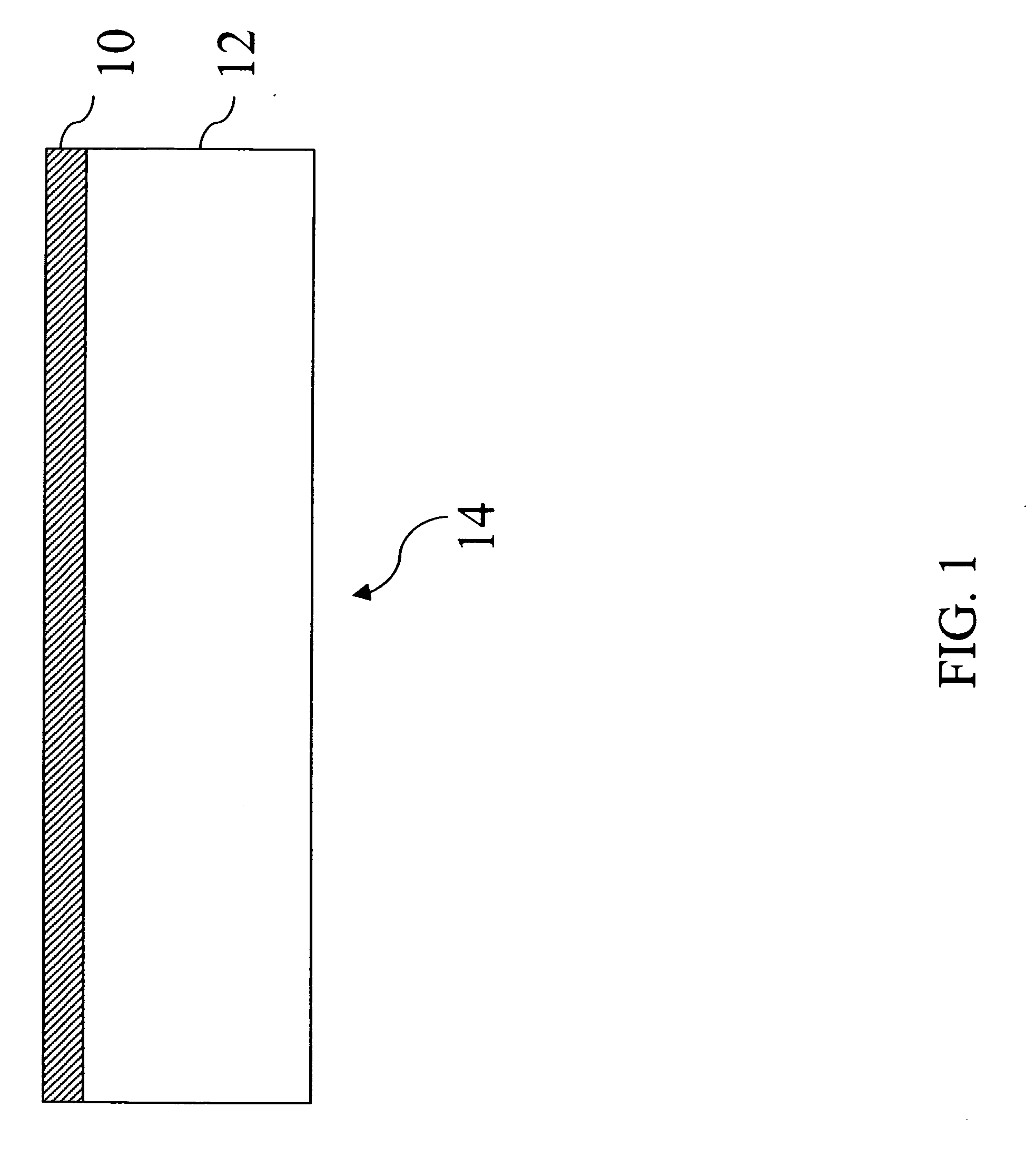

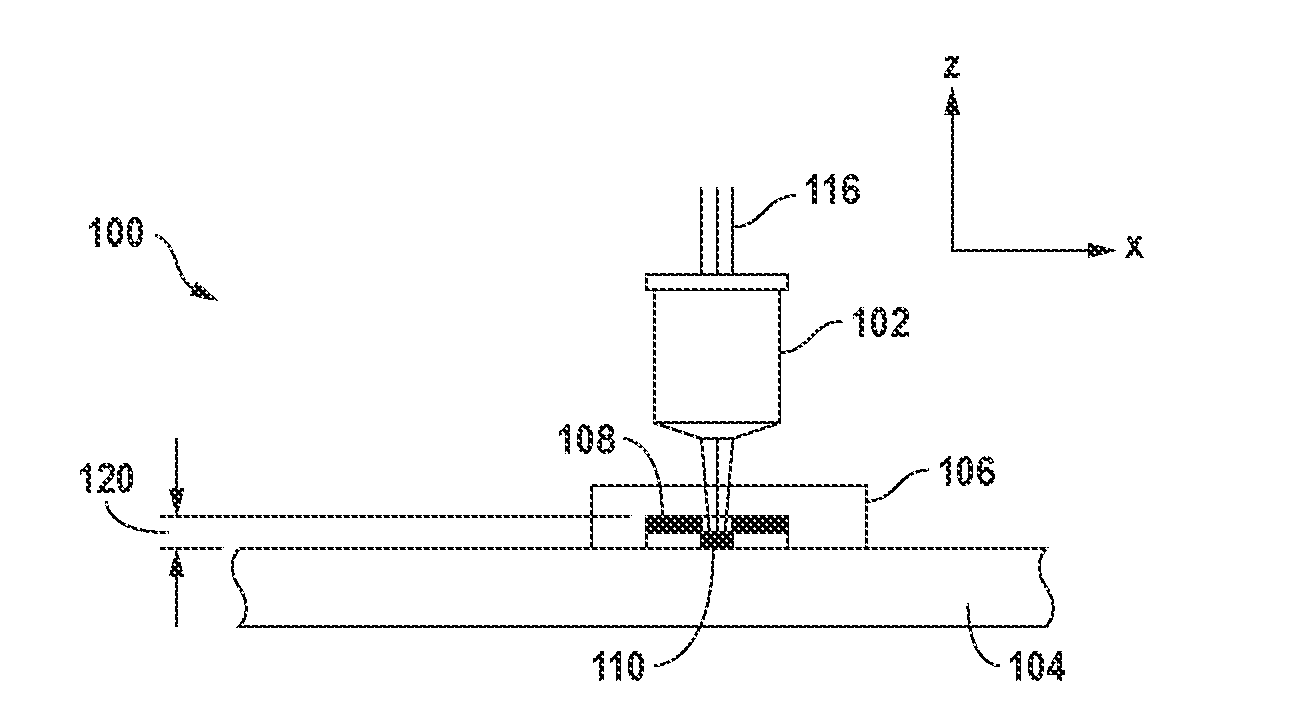

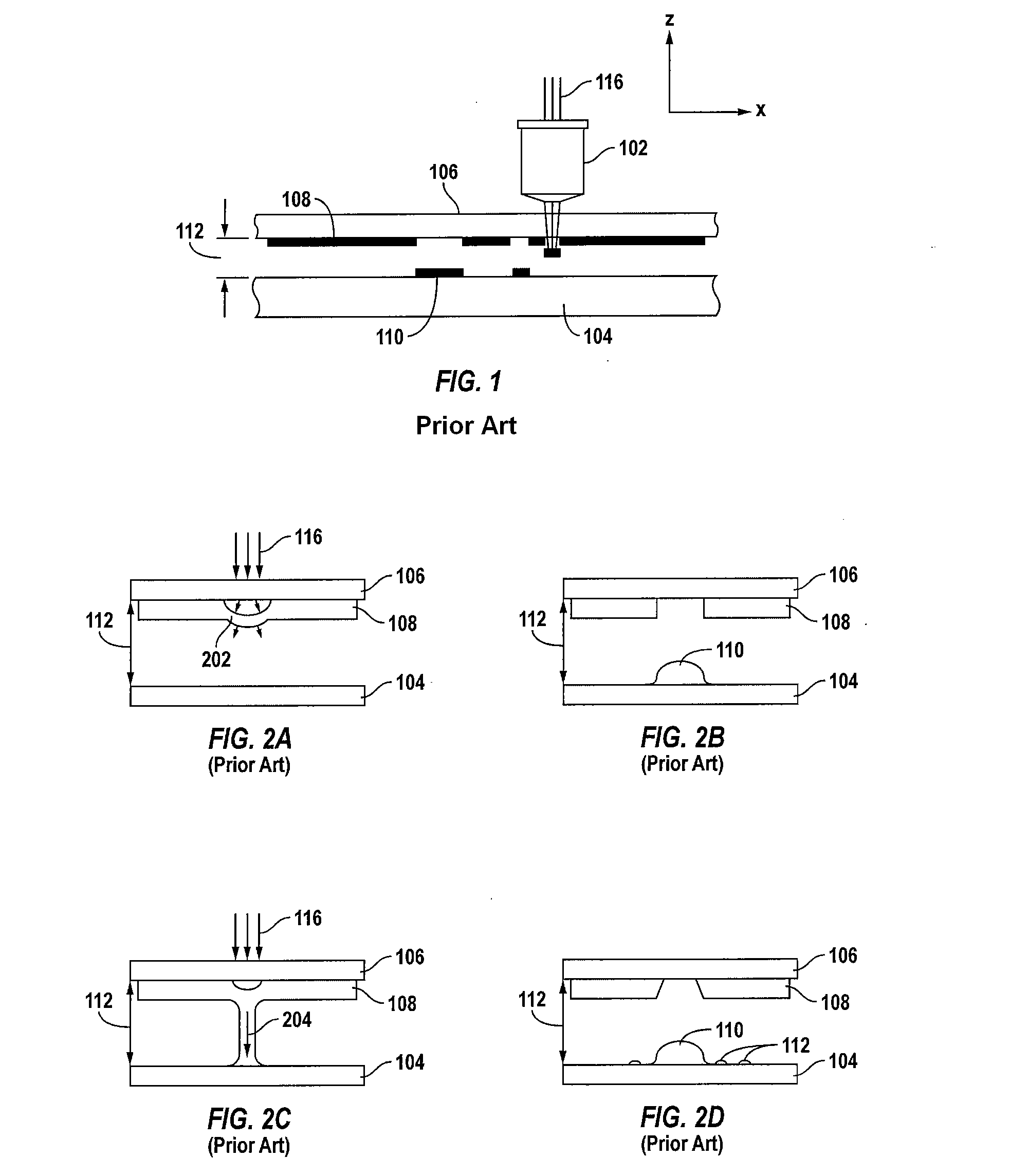

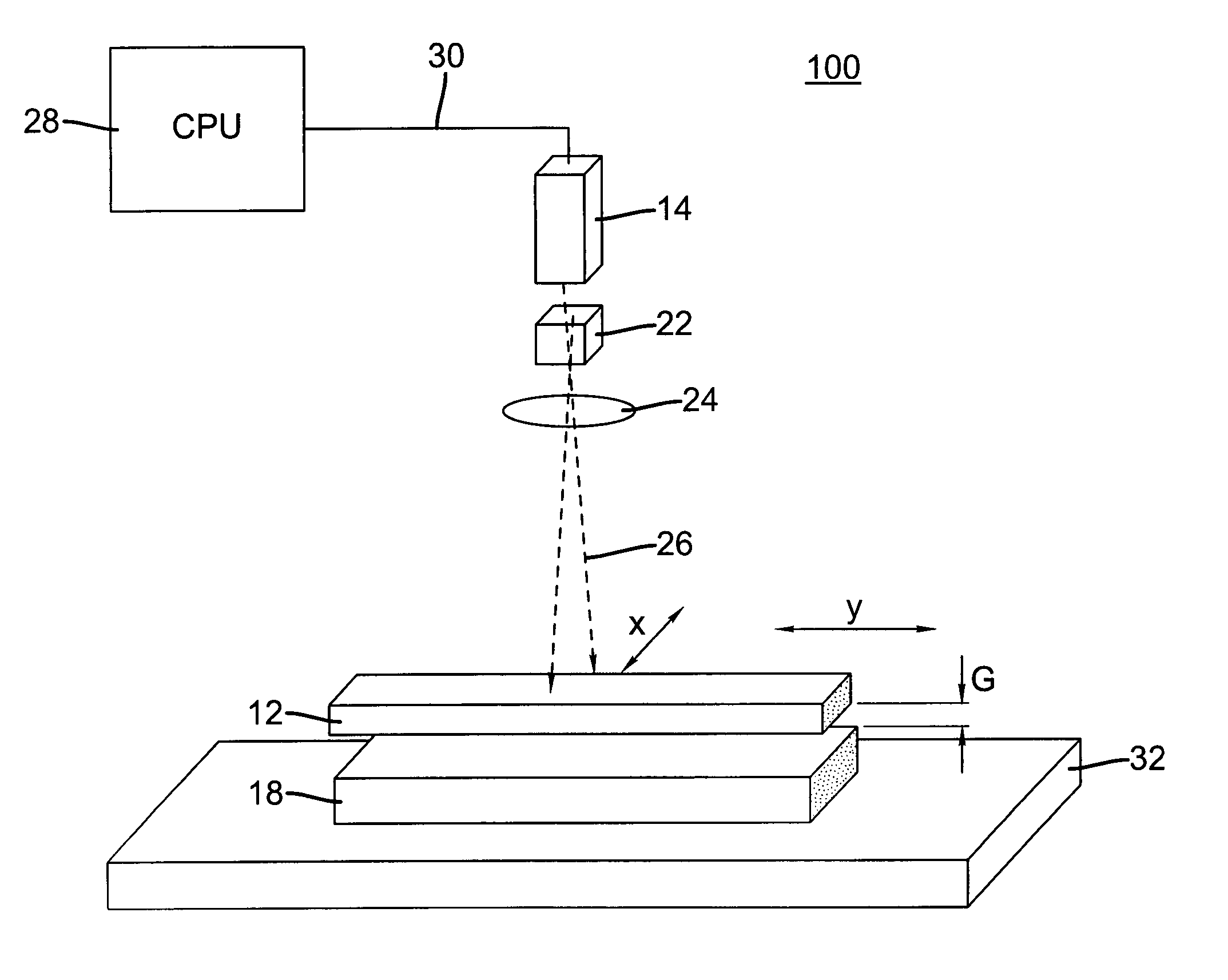

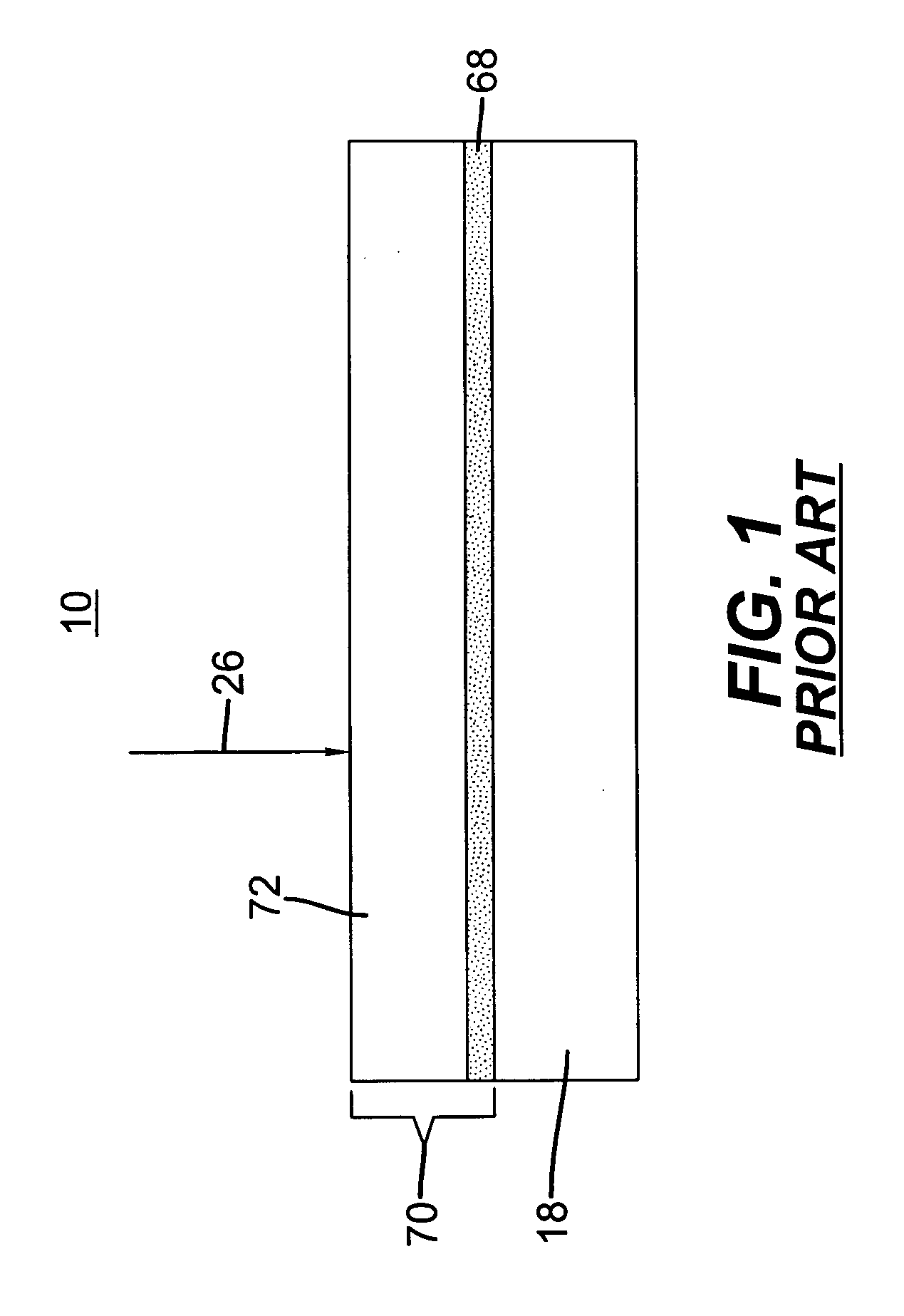

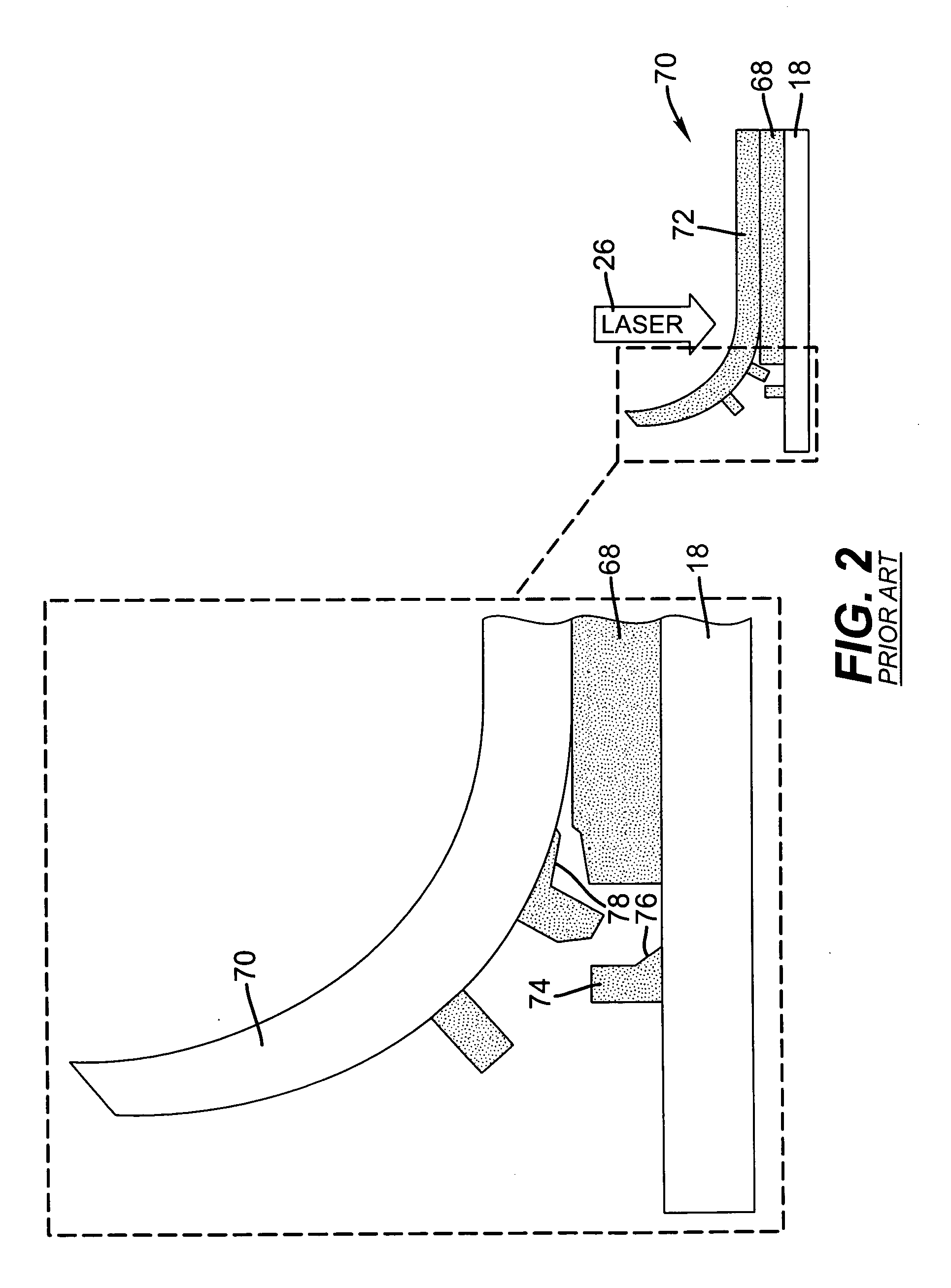

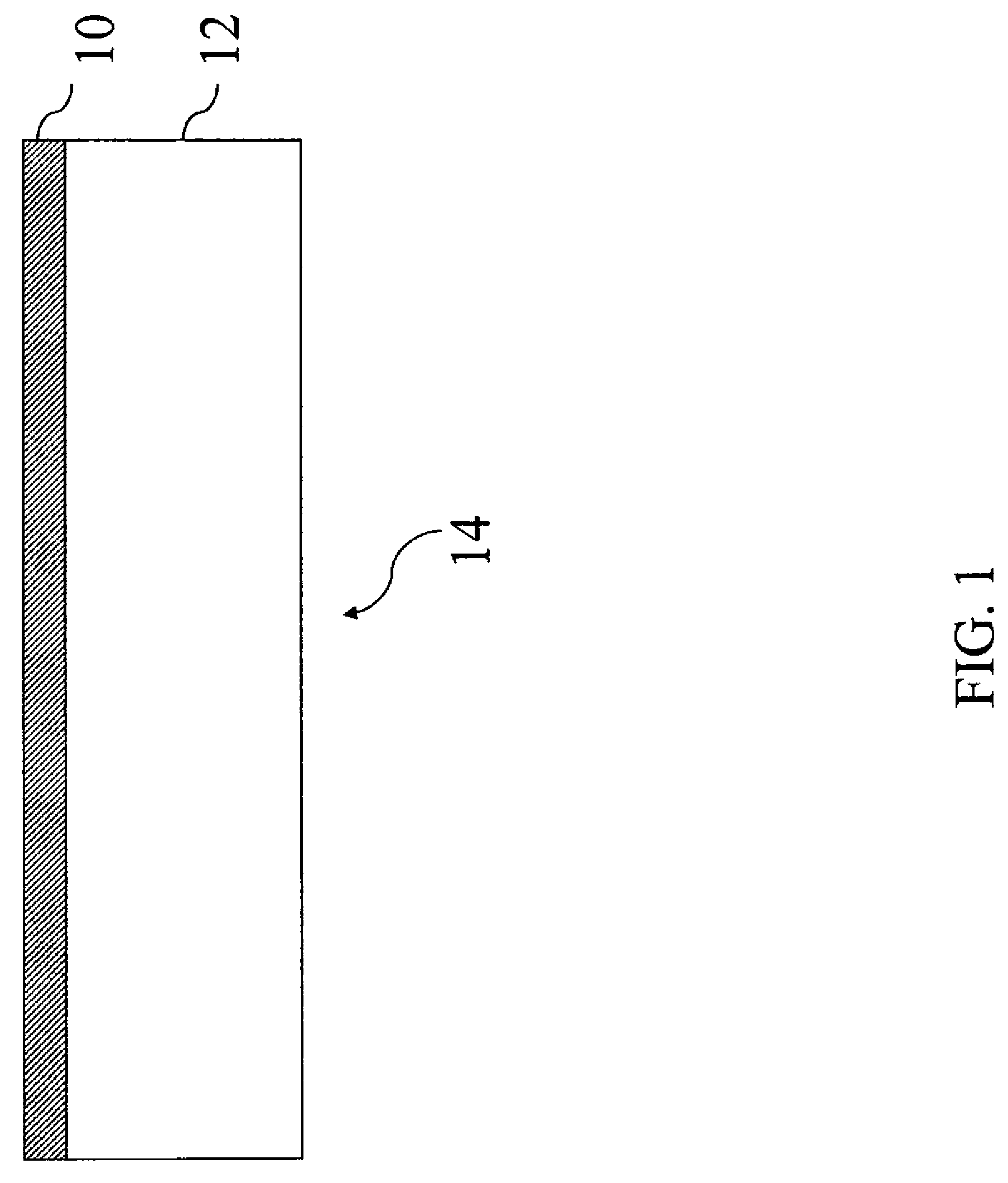

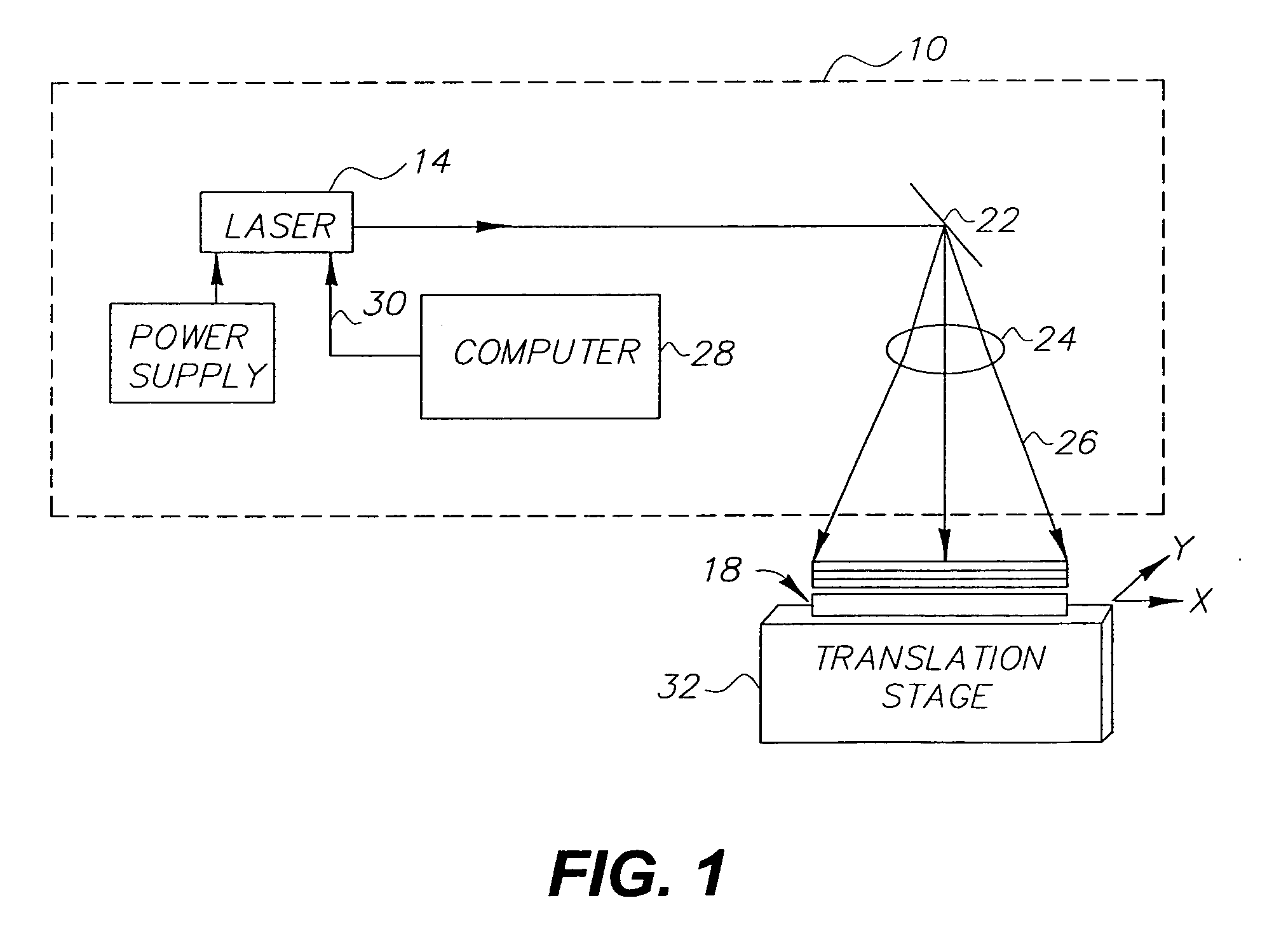

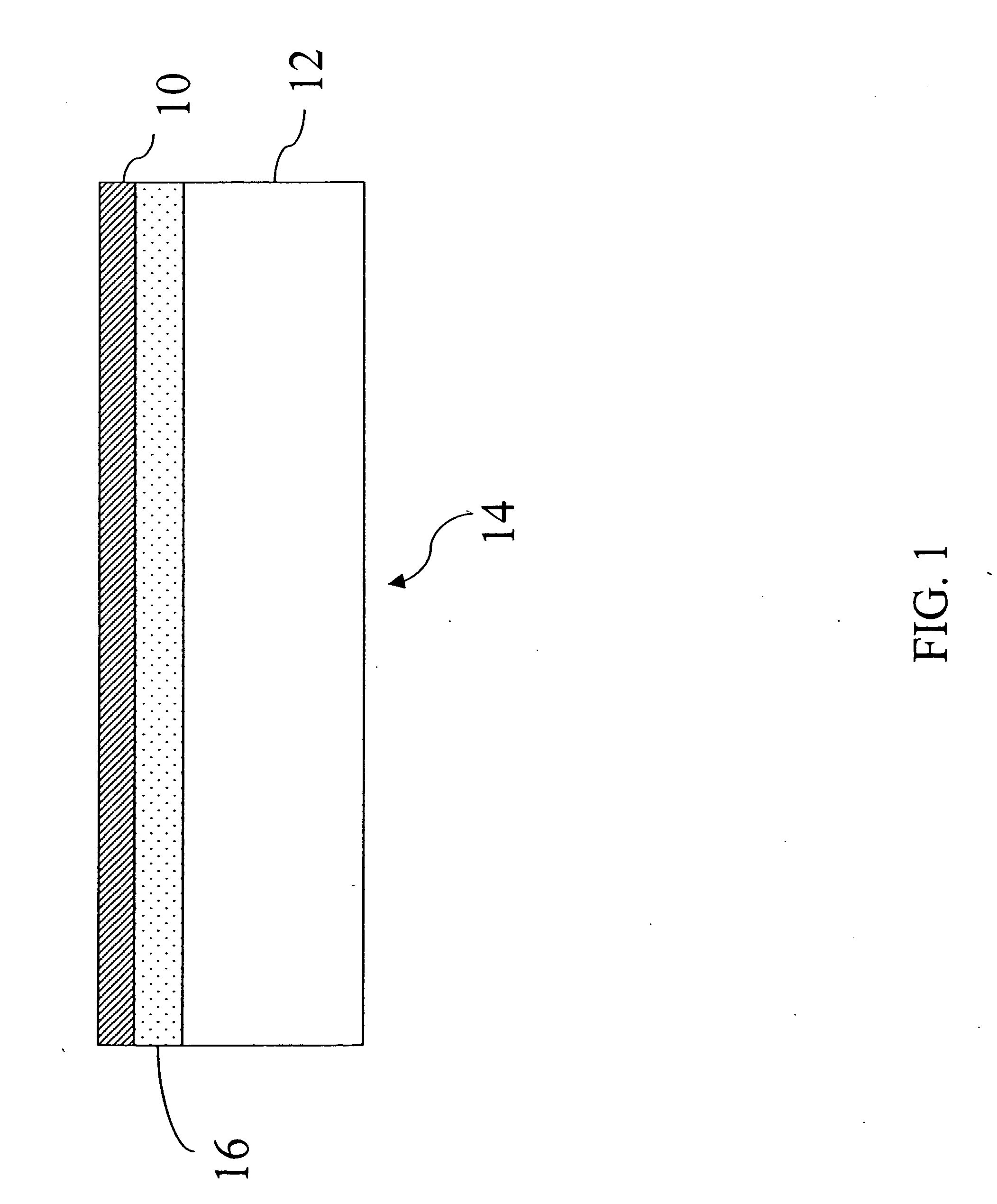

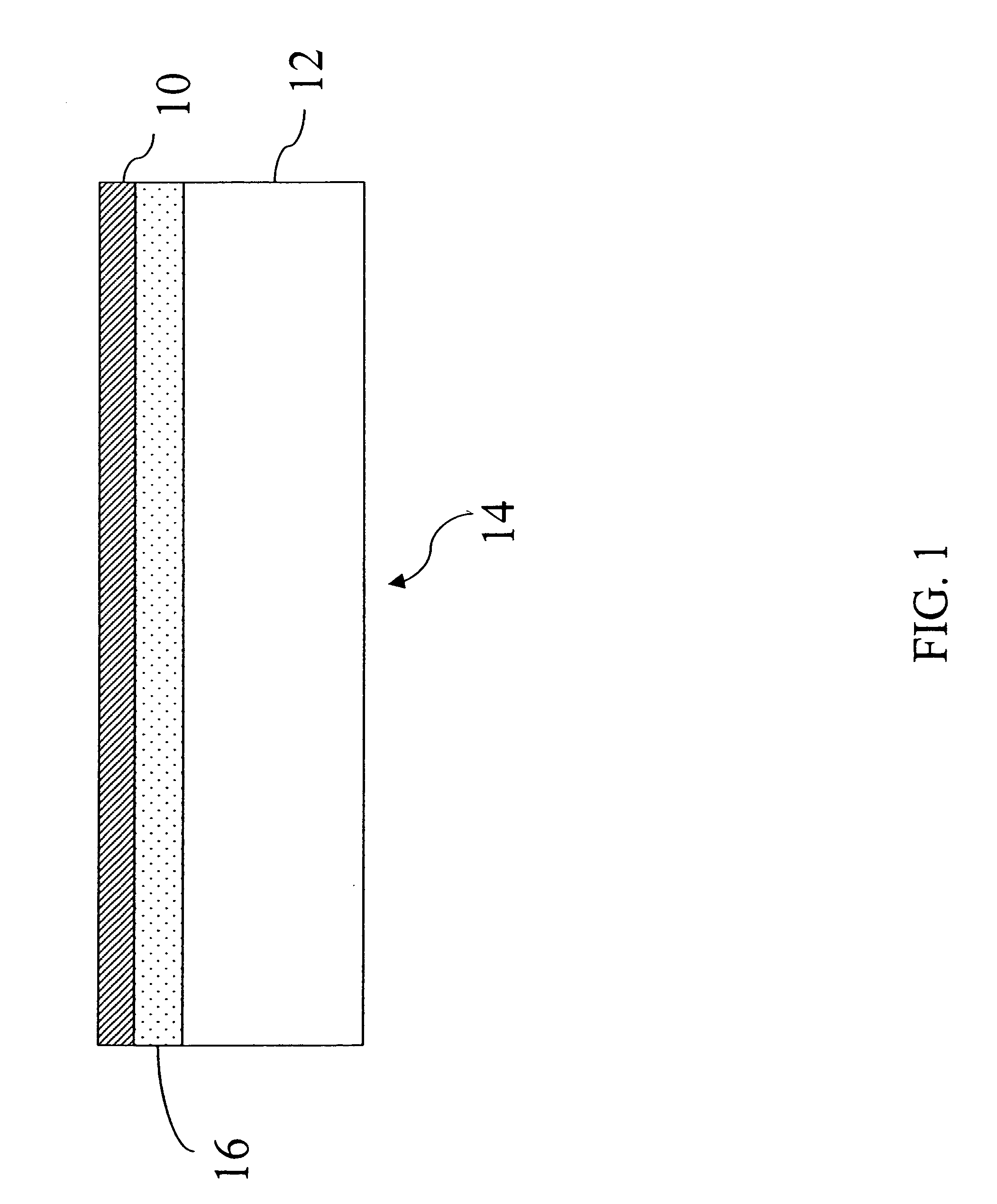

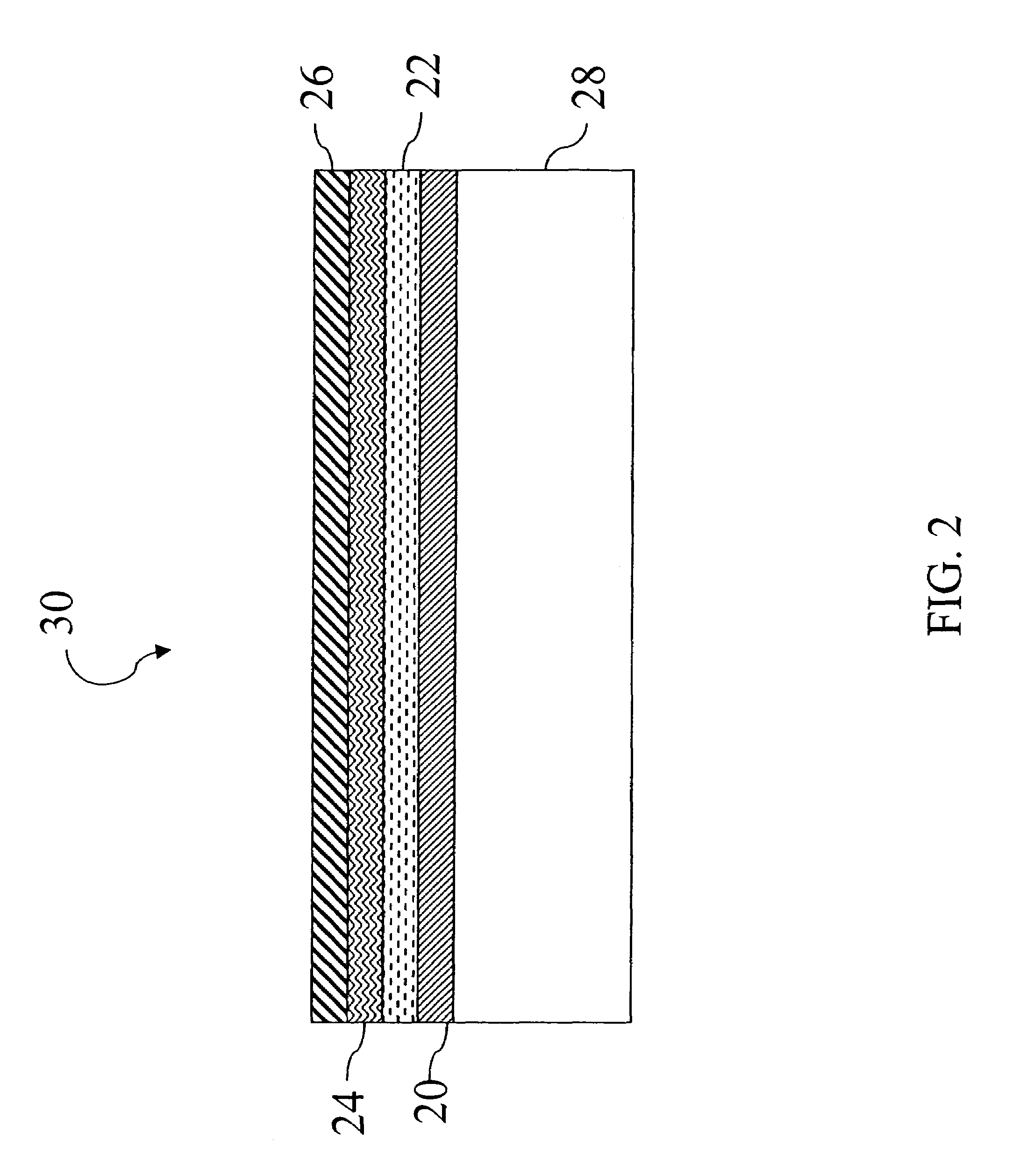

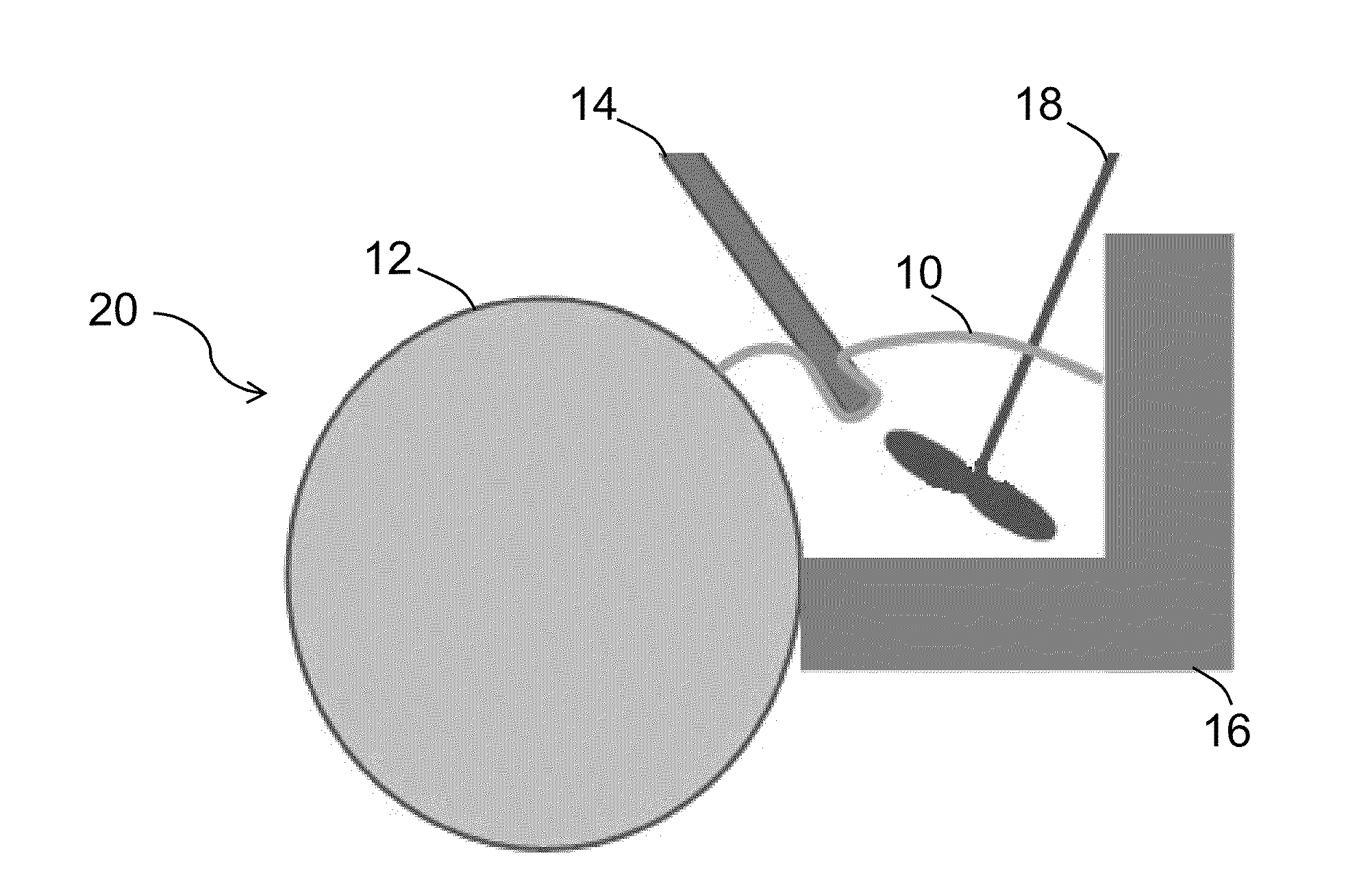

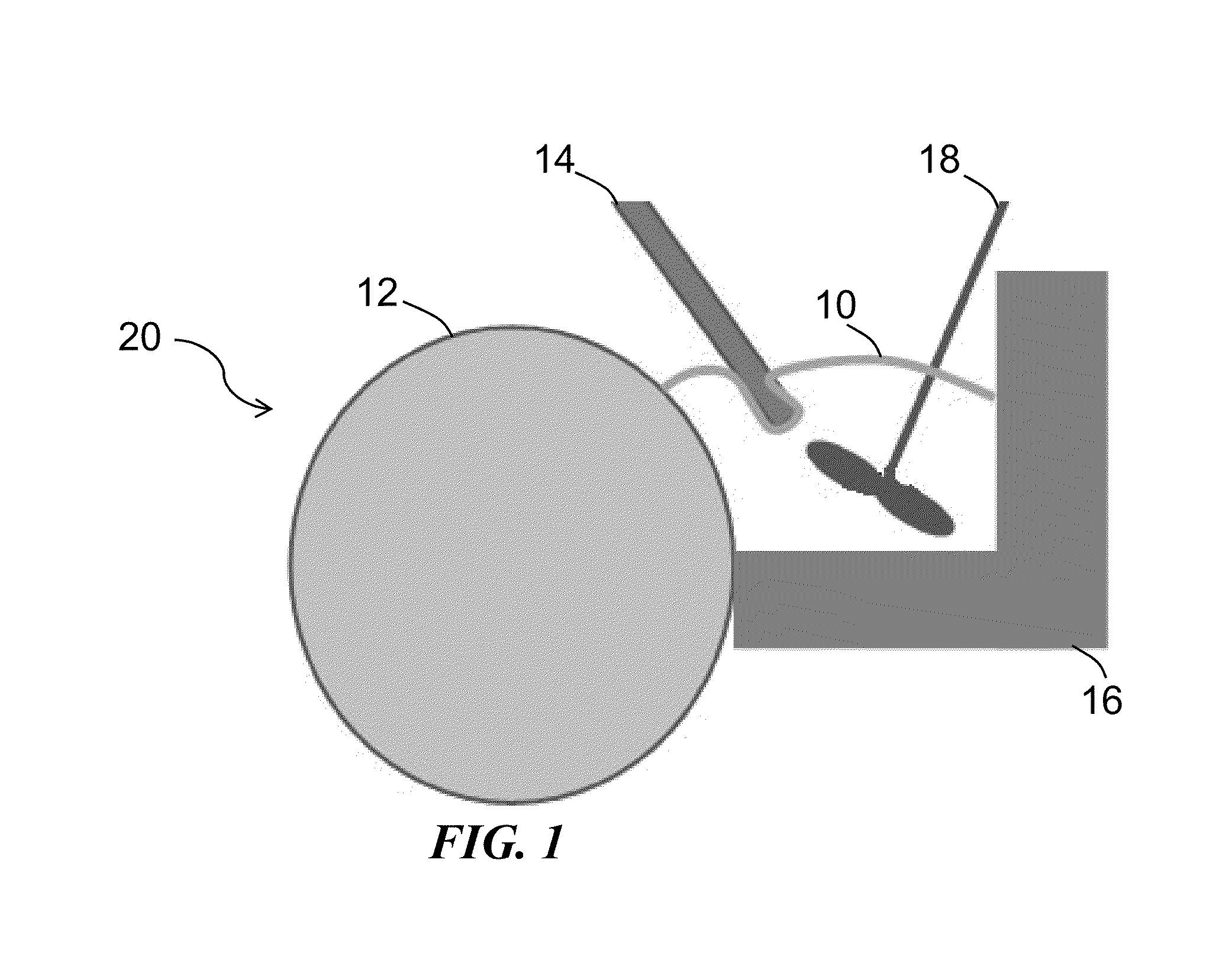

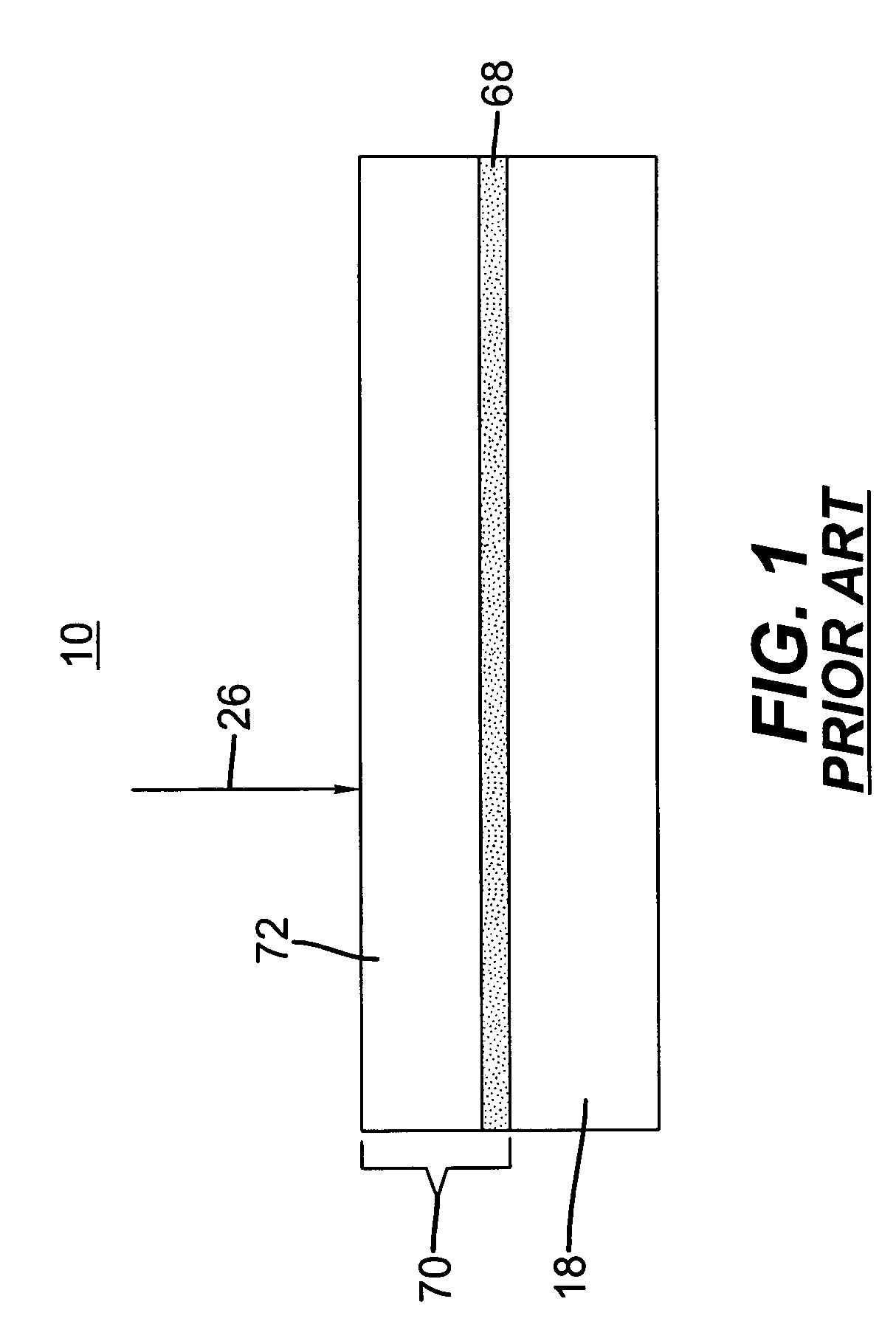

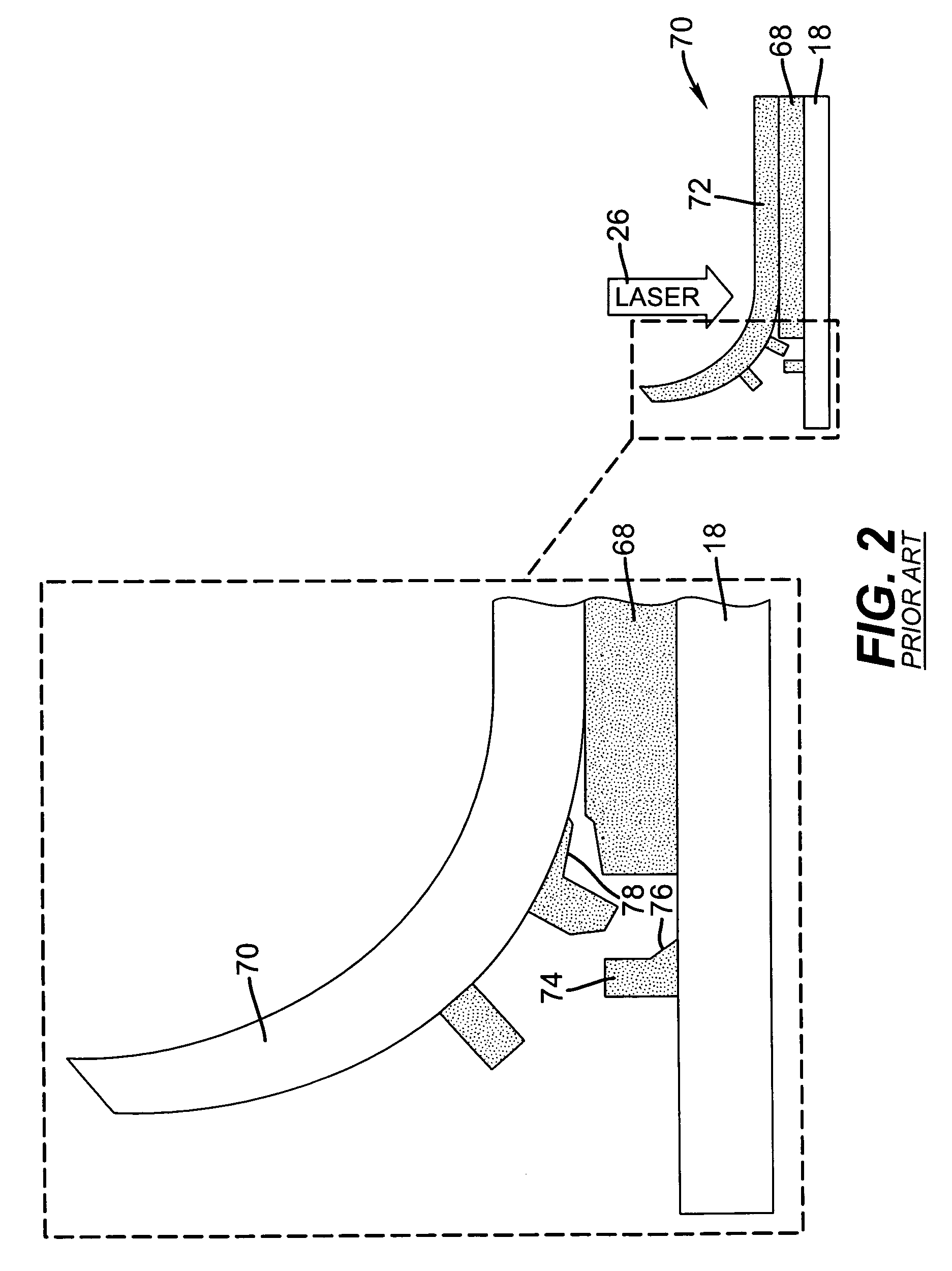

Laser resist transfer for microfabrication of electronic devices

A method for forming a resist pattern on a substrate (18) places a donor element (12) having a layer of thermoresist material proximate the substrate. A gap is maintained such that the surface of the layer of thermoresist material is spaced apart from the surface of the substrate by a number of spacing elements. Thermal energy is directed toward the donor element (12) according to the resist pattern, whereby a portion of thermoresist material is transferred from the donor element (12) across the gap by ablative transfer and is deposited onto the substrate (18) forming the resist pattern.

Owner:EASTMAN KODAK CO

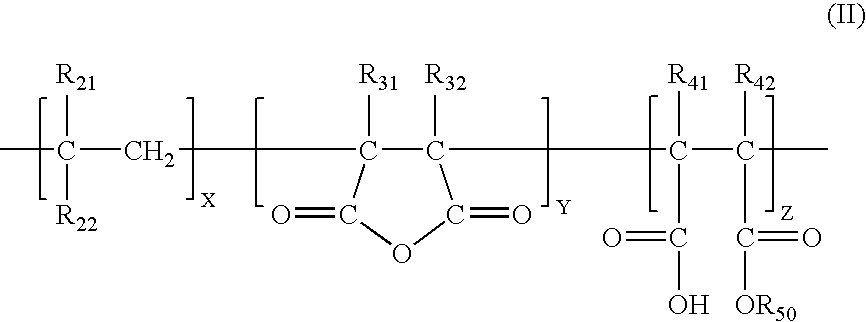

Polymeric conductive donor and transfer method

InactiveUS20100118243A1Accurate transferIncrease contrastLiquid crystal compositionsHybrid capacitor electrodesInorganic particleConductive polymer

A donor laminate for transfer of a conductive layer has a transparent substrate and a conductive layer comprising at least one electronically conductive polymer that is present in an amount of at least 40 weight %, a polyanion, and inorganic particles having an average particle size of less than 100 nanometers (nanoparticles). This donor laminate can be used to transfer the conductive layer to a suitable receiver element to prepare various electronic devices.

Owner:EASTMAN KODAK CO

Direct-write laser transfer and processing

A device and method for depositing a material of interest onto a receiving substrate includes a first laser and a second laser, a receiving substrate, and a target substrate. The target substrate comprises a laser transparent support having a back surface and a front surface. The front surface has a coating that comprises the source material, which is a material that can be transformed into the material of interest. The first laser can be positioned in relation to the target substrate so that a laser beam is directed through the back surface of the target substrate and through the laser-transparent support to strike the coating at a defined location with sufficient energy to remove and lift the source material from the surface of the support. The receiving substrate can be positioned in a spaced relation to the target substrate so that the source material is deposited at a defined location on the receiving substrate. The second laser is then positioned to strike the deposited source material to transform the source material into the material of interest.

Owner:U S A AS REPRESENTED BY THE SEC OF THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCCIP THE

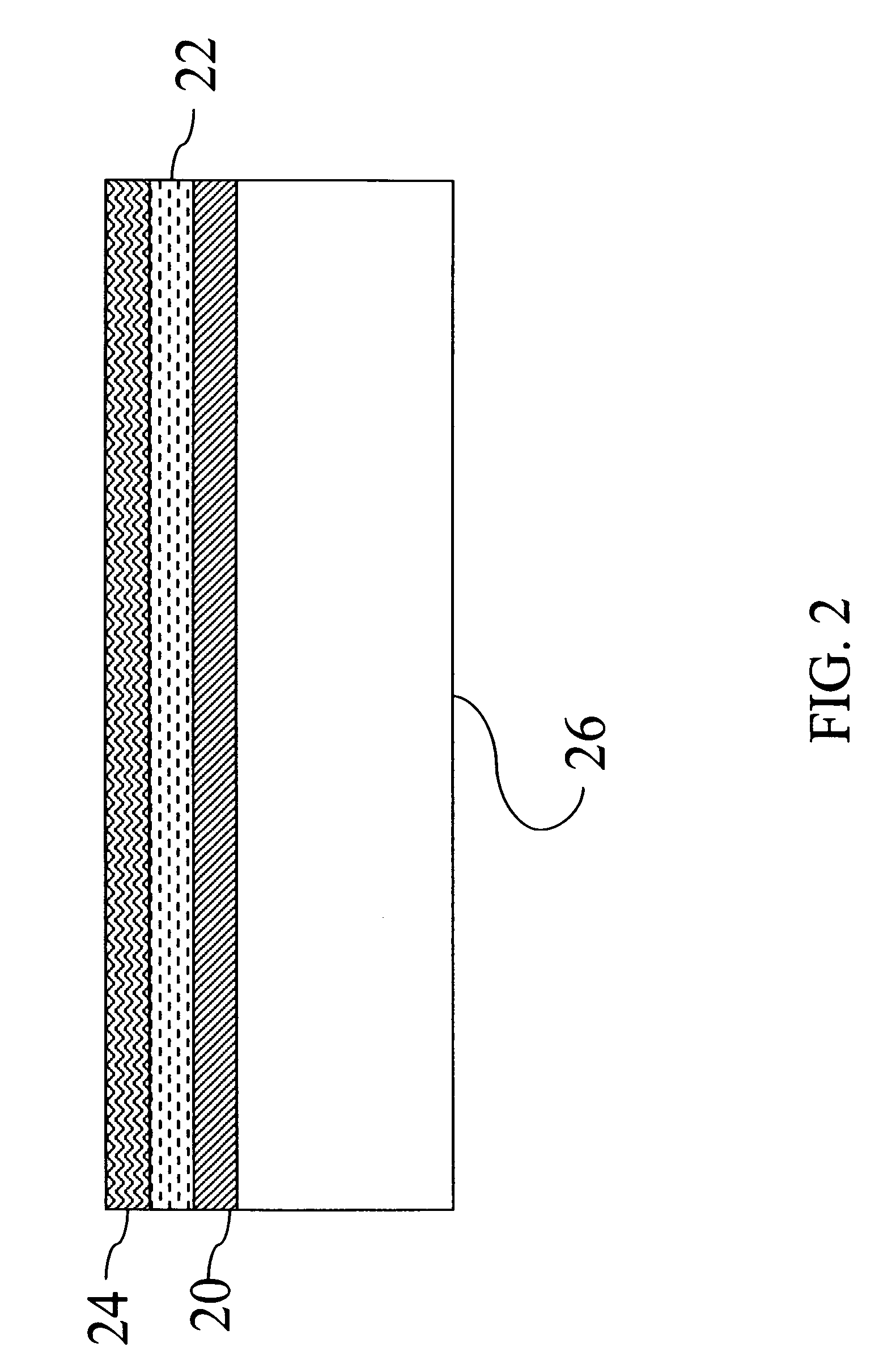

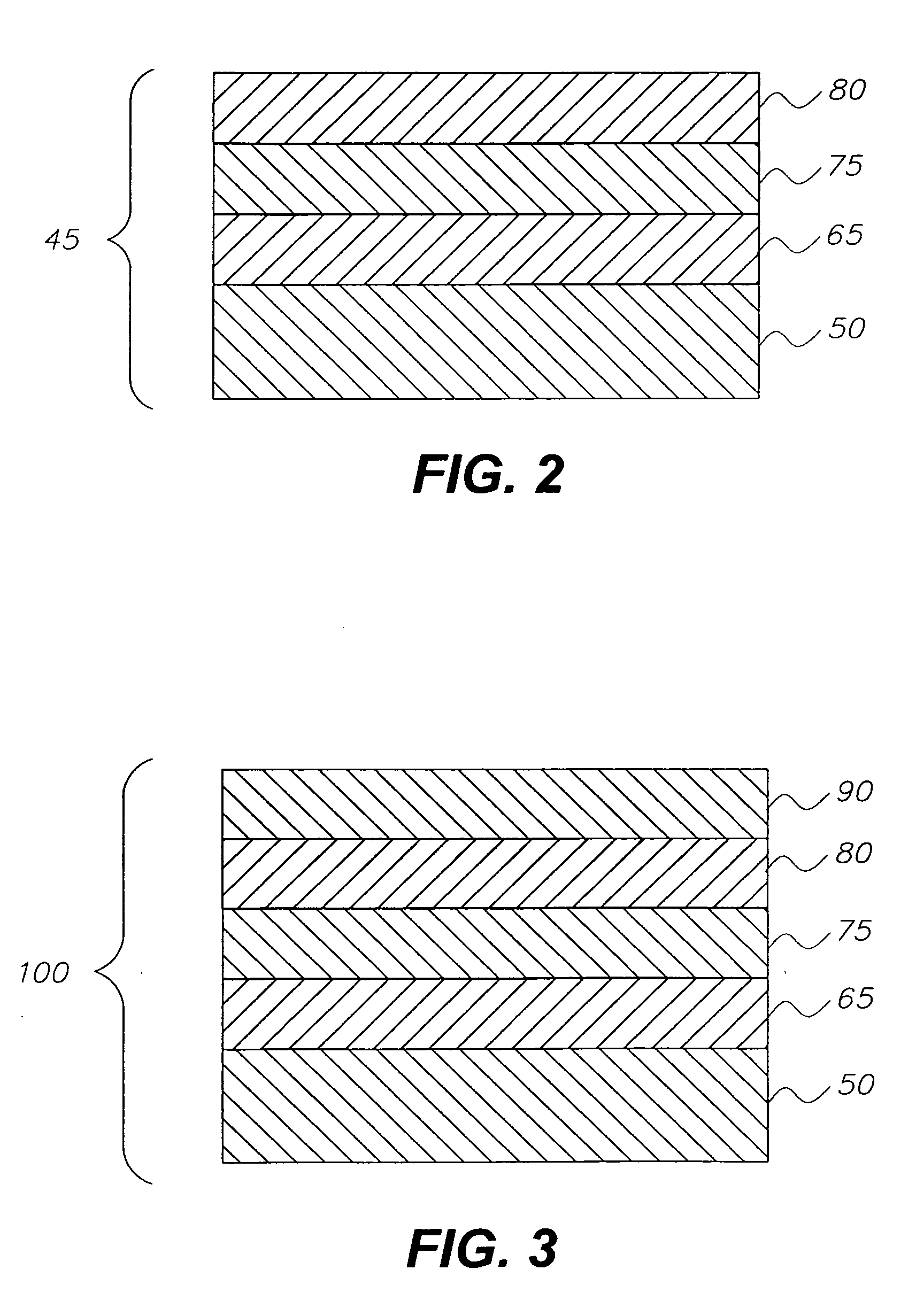

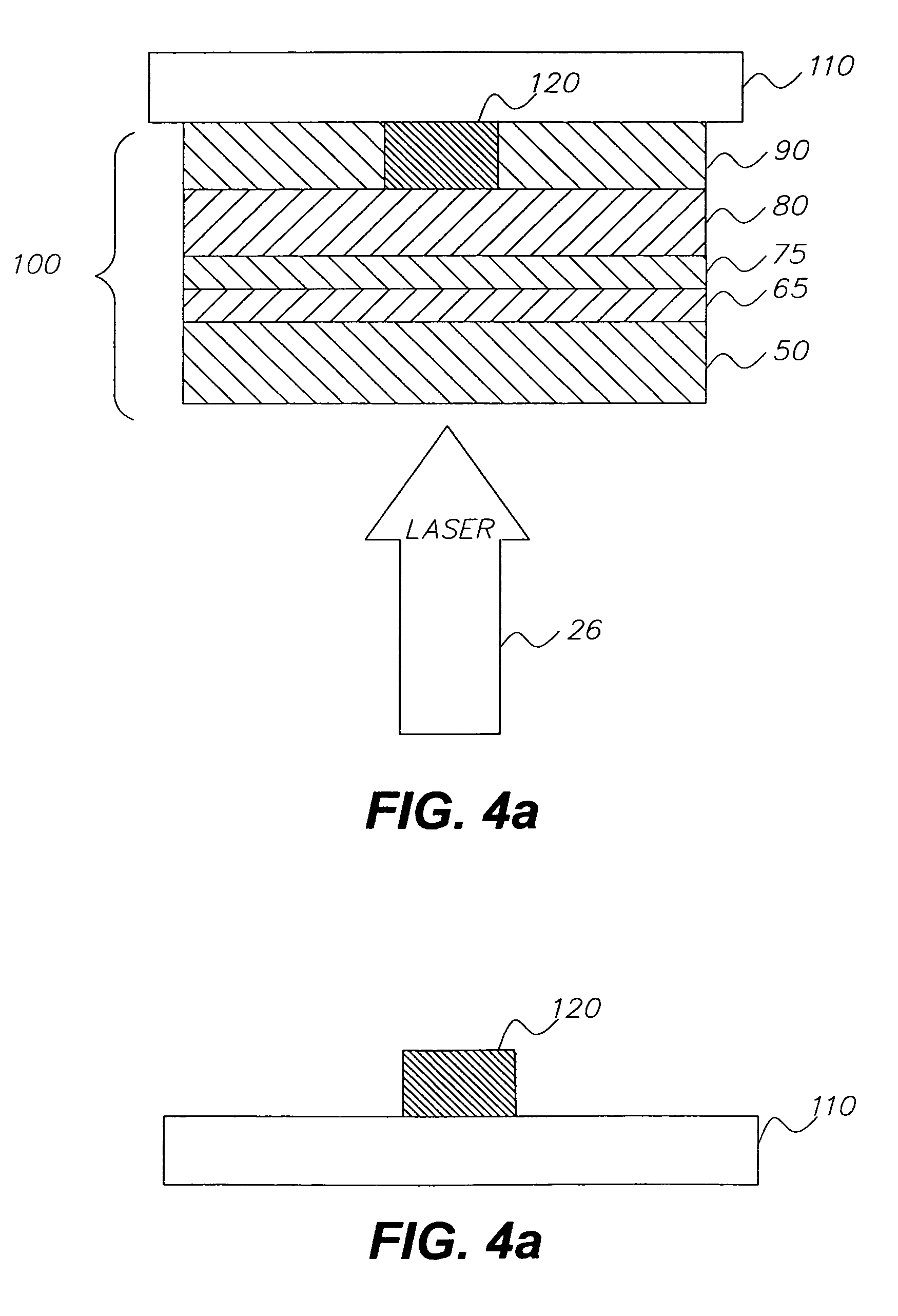

Forming a patterned metal layer using laser induced thermal transfer method

InactiveUS20060263725A1Material nanotechnologyLight absorption dielectricsOptoelectronicsConductive materials

A method of forming a pattern of electrical conductors on a receiving substrate (110) comprises forming metal nanoparticles of a conductive material. A donor substrate (45) is formed. A layer of release material (75) is deposited on a first side of the donor substrate. The metal nanoparticles are deposited on the release material. The metal nanoparticulate layer are placed in contact with the receiving substrate. A pattern is written on a sandwich formed by the donor substrate and the receiving substrate, causing metal nanoparticles from the nanoparticulate layer (90) to anneal and transfer to the receiving substrate to form the pattern of electrical conductors on the receiving substrate.

Owner:EASTMAN KODAK CO

Polymeric conductor donor and transfer method

ActiveUS20060131703A1Transfer patterningSemiconductor/solid-state device detailsElectrical conductorConductive polymer

The present invention relates to a donor laminate for transfer of a conductive layer comprising at least one electronically conductive polymer on to a receiver, wherein the receiver is a component of a device. The present invention also relates to methods pertinent to such transfers.

Owner:EASTMAN KODAK CO

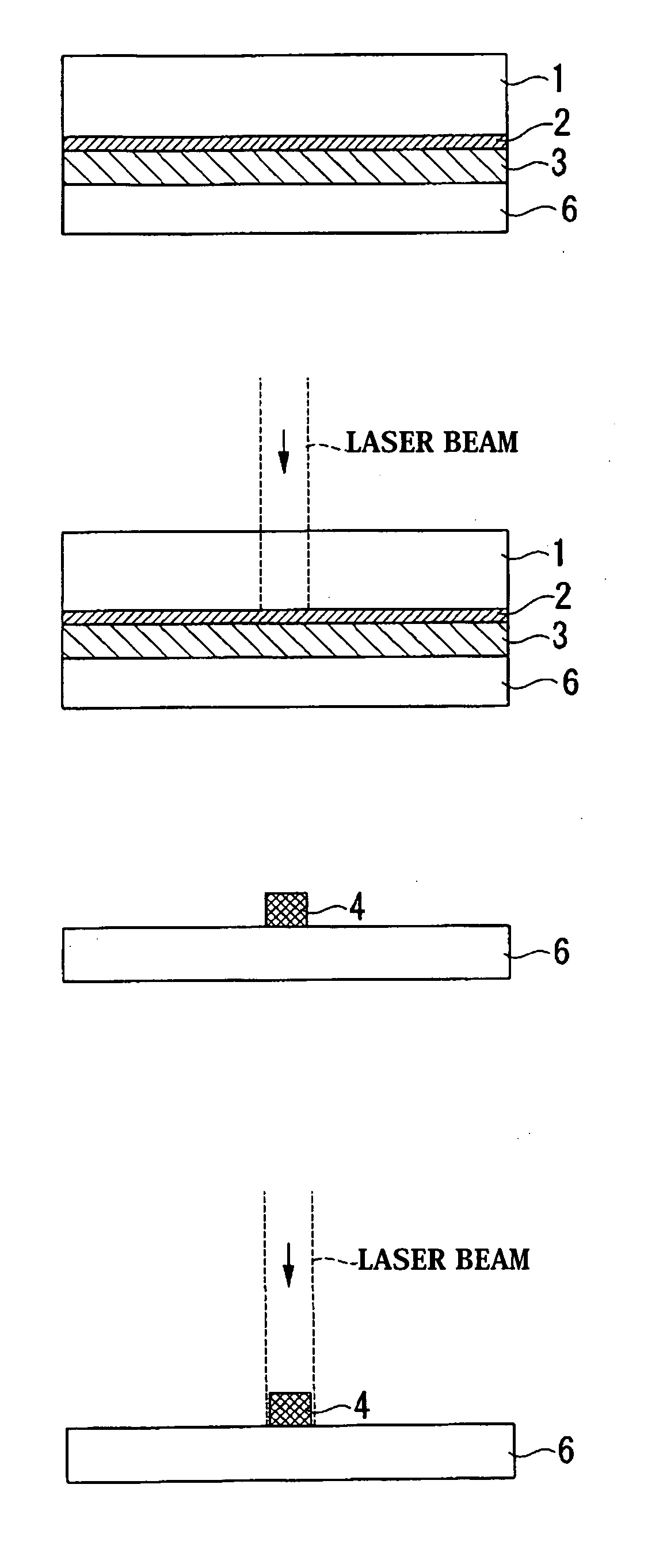

Laser-based technique for the transfer and embedding of electronic components and devices

A laser direct write method used to transfer entire single components such as semiconductor bare dies or surface mount passive and active components on a substrate or inside recess in a substrate for making embedded microelectronics is disclosed. This method laser-machine the pockets, laser-transfer the individual components inside those pockets, and then laser-print the interconnects required to “wire” the components, thus resulting in a fully assembled embedded circuit required to make a fully functional microelectronic system.

Owner:USA AS REPRESENTED BY THE SEC OF THE NAVY THE

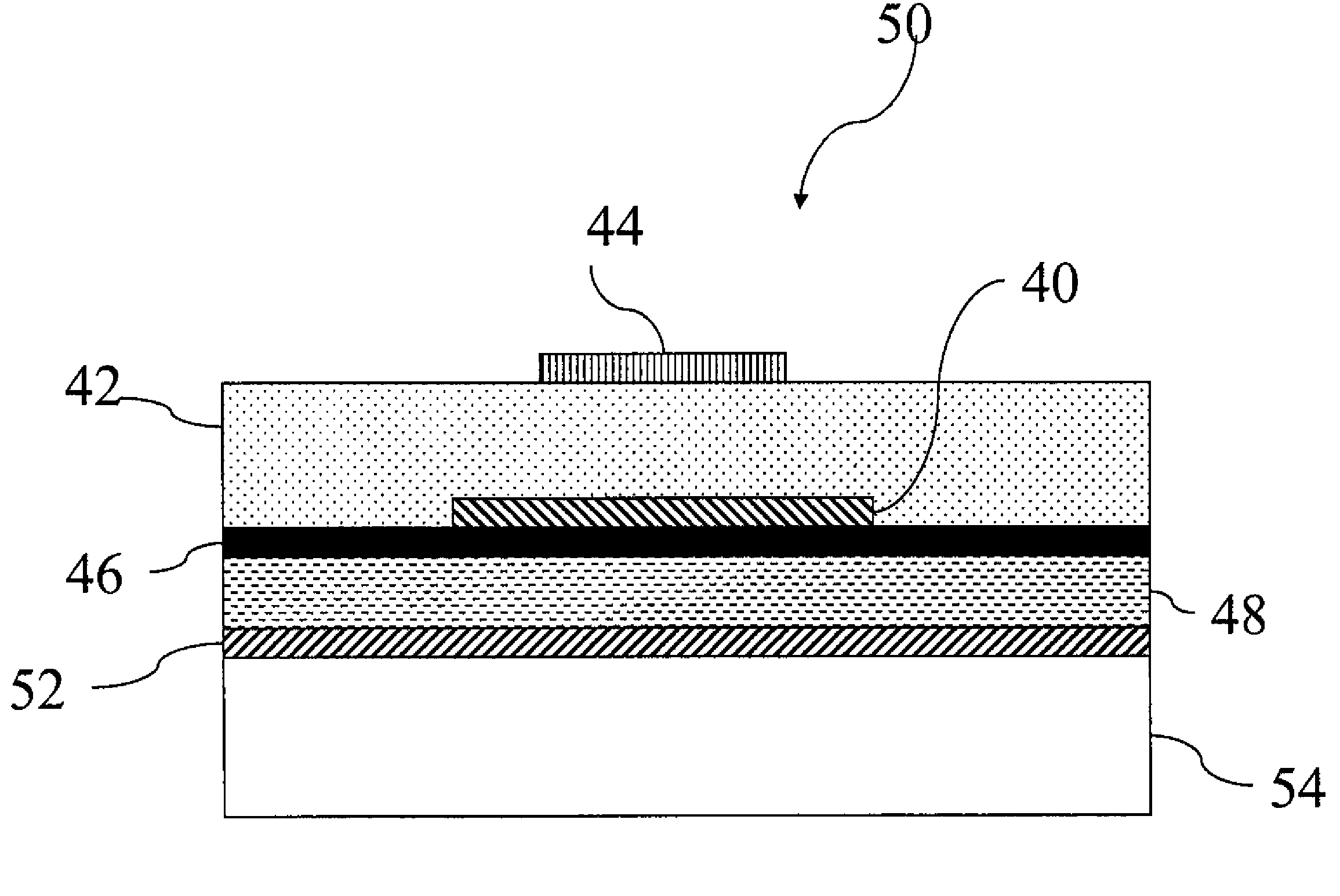

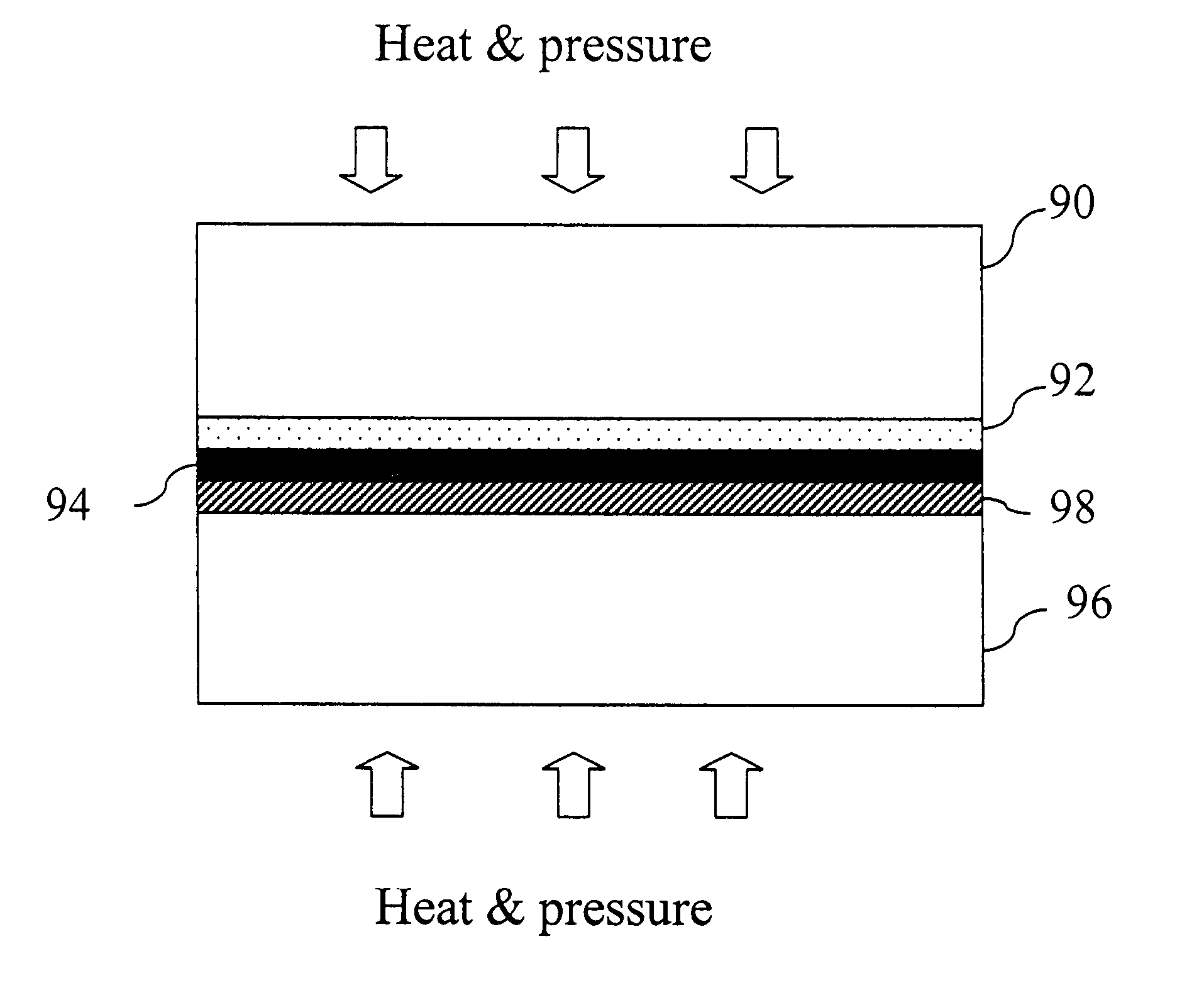

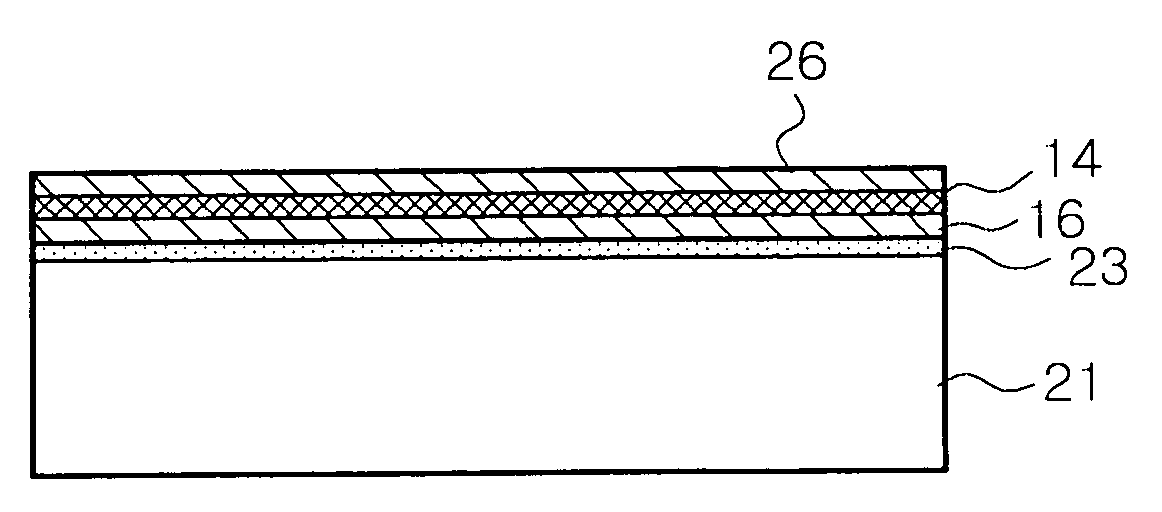

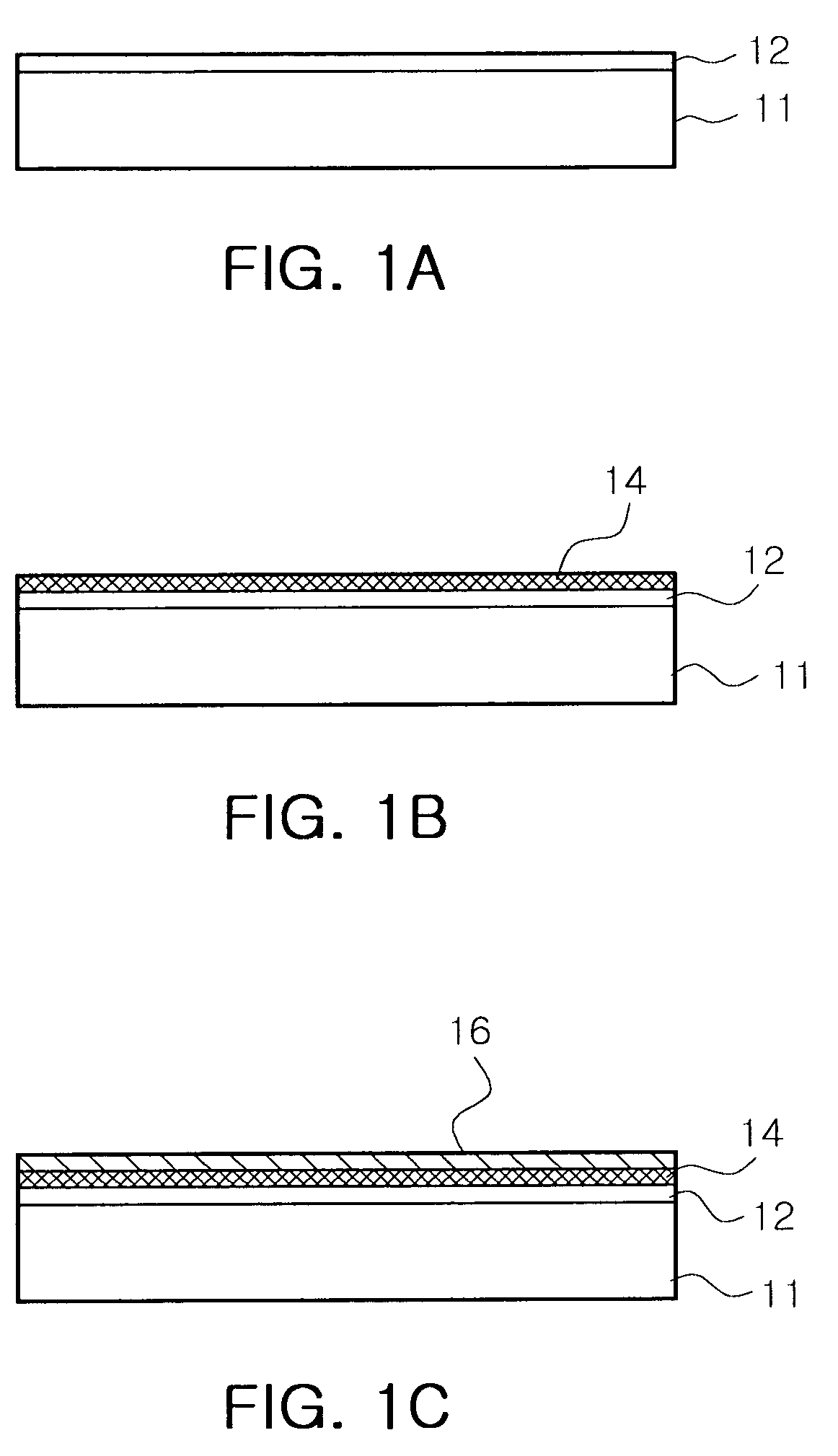

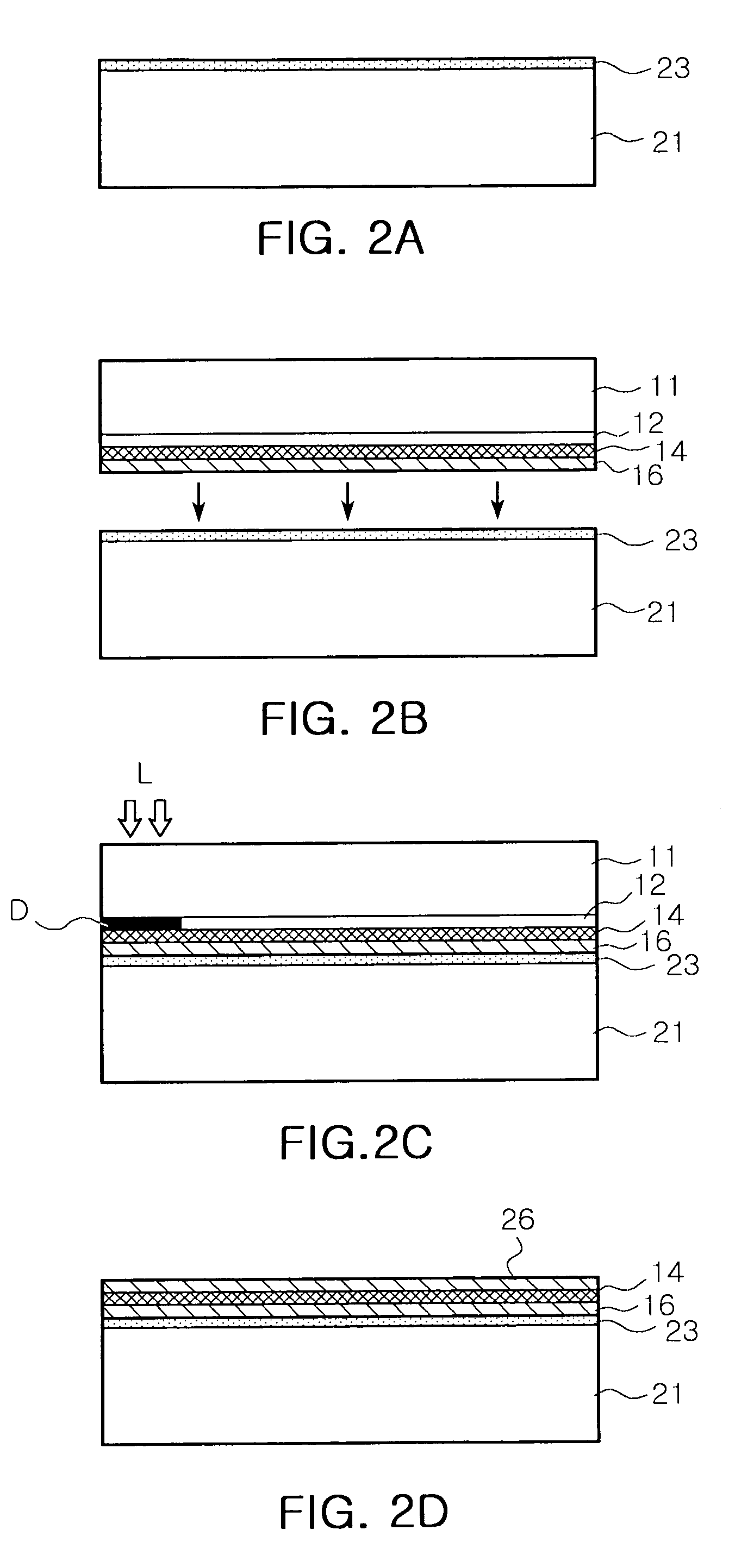

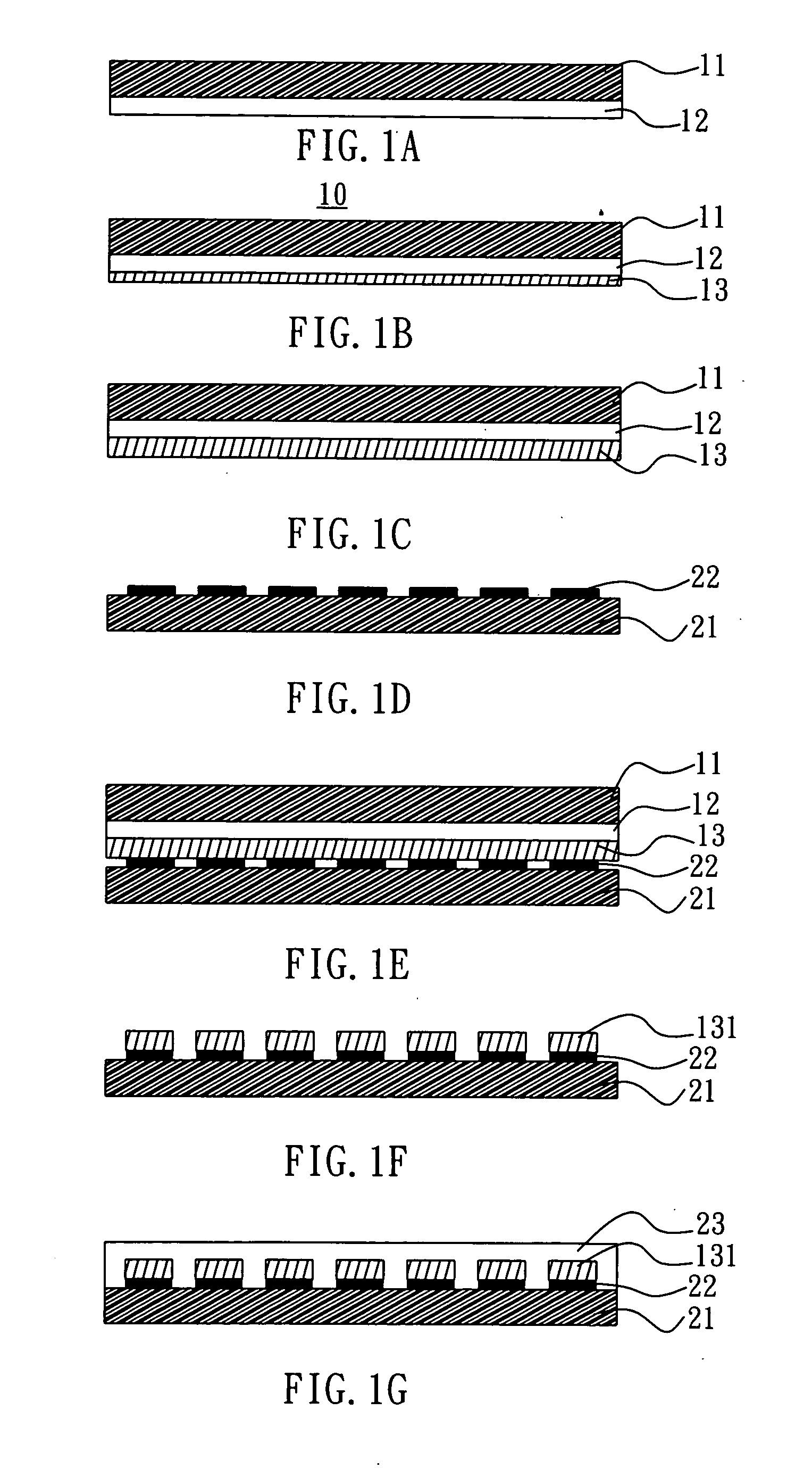

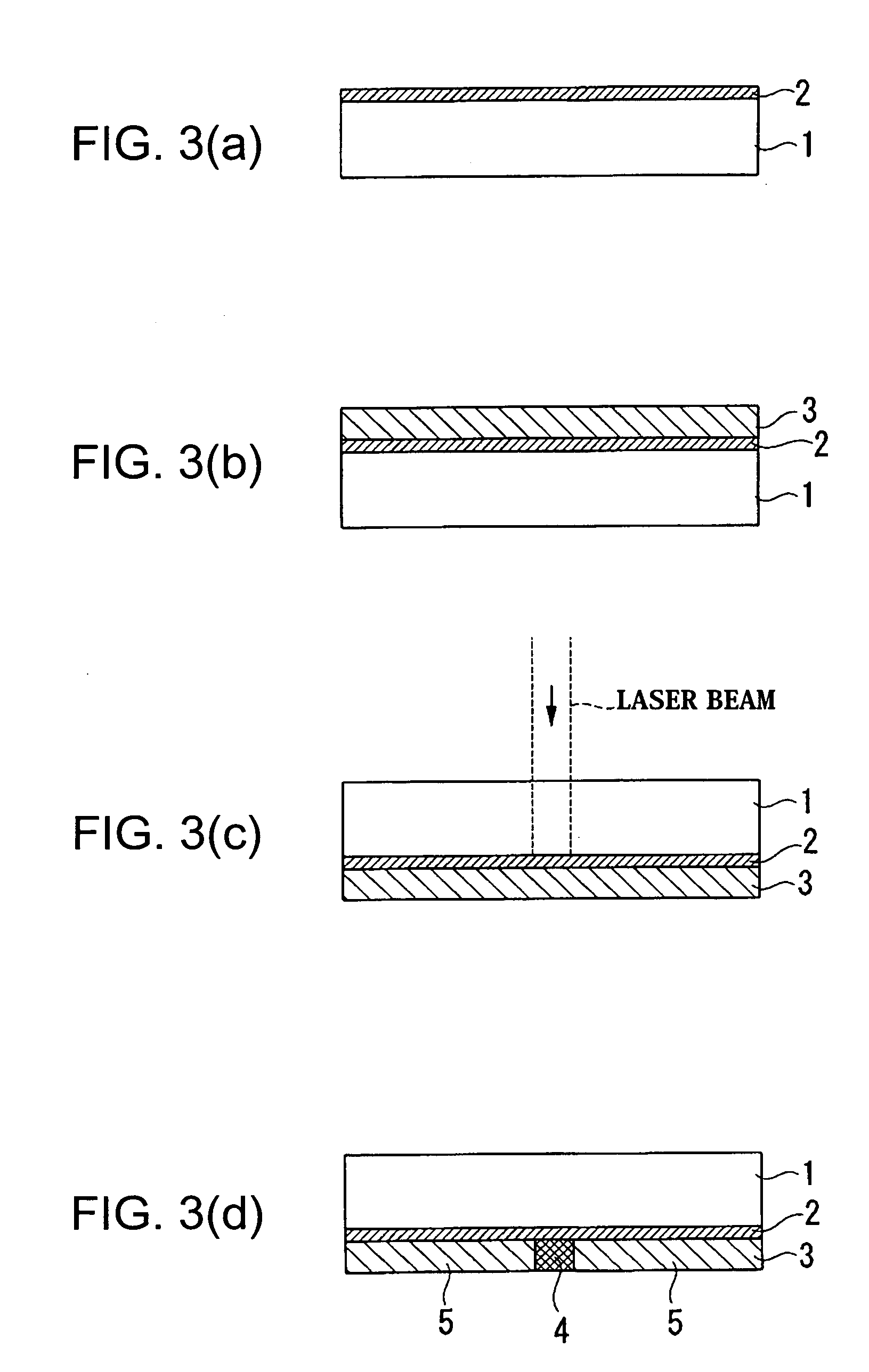

Method of manufacturing circuit board embedding thin film capacitor

InactiveUS20080158770A1Minimize damagePrinted circuit assemblingFixed capacitor electrodesOptoelectronicsDielectric layer

A method of manufacturing a circuit board embedding a thin film capacitor, the method including: forming a sacrificial layer on a first substrate; forming a dielectric layer on the sacrificial layer; forming a first electrode layer on the dielectric layer; disposing the first substrate on the second substrate in such a way that the first electrode layer is bonded to a top of a second substrate; decomposing the sacrificial layer by irradiating a laser beam onto the sacrificial layer through the first substrate; separating the first substrate from the second substrate; and forming a second electrode layer on the dielectric layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Polymeric conductor donor and transfer method

ActiveUS7414313B2Transfer patterningSemiconductor/solid-state device detailsElectrical conductorConductive polymer

The present invention relates to a donor laminate for transfer of a conductive layer comprising at least one electronically conductive polymer on to a receiver, wherein the receiver is a component of a device. The present invention also relates to methods pertinent to such transfers.

Owner:EASTMAN KODAK CO

Alternate use for low viscosity liquids and method to gel liquid

InactiveUS20100154998A13D rigid printed circuitsSemiconductor/solid-state device testing/measurementDopantAlcohol

Owner:BEAMREACH SOLAR INC

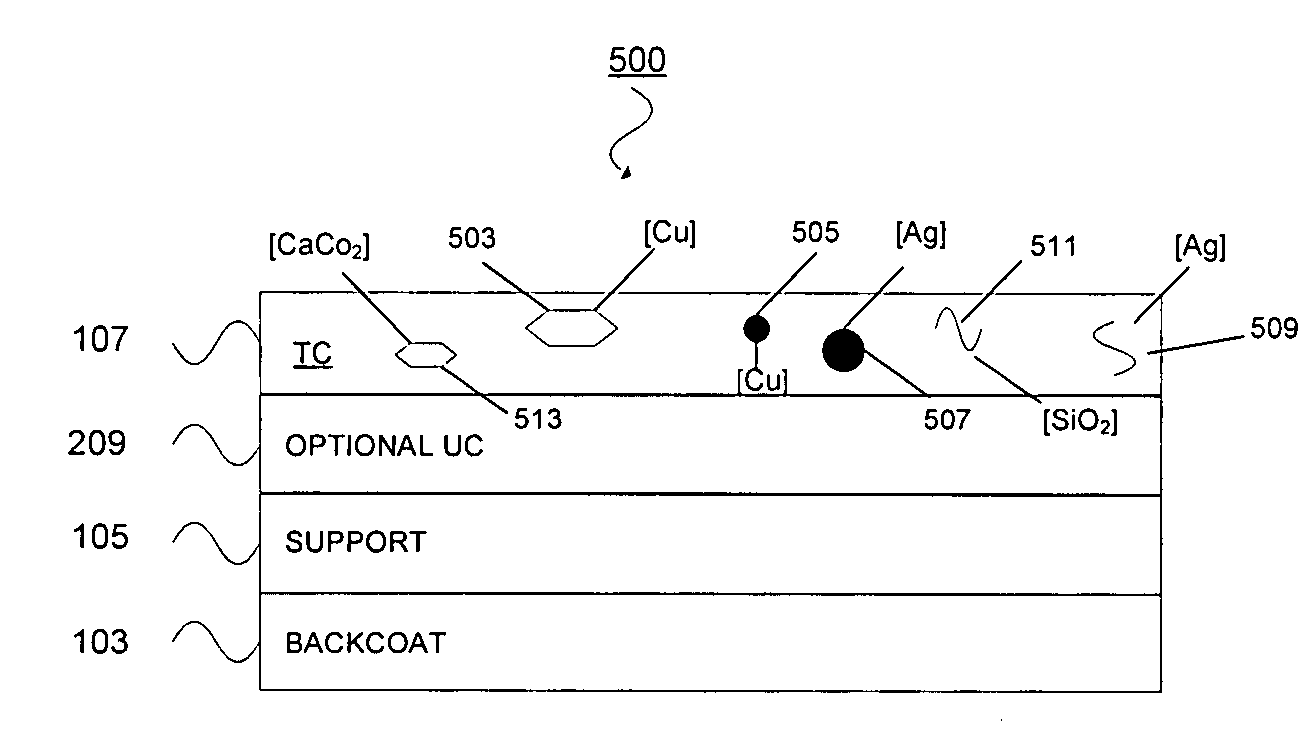

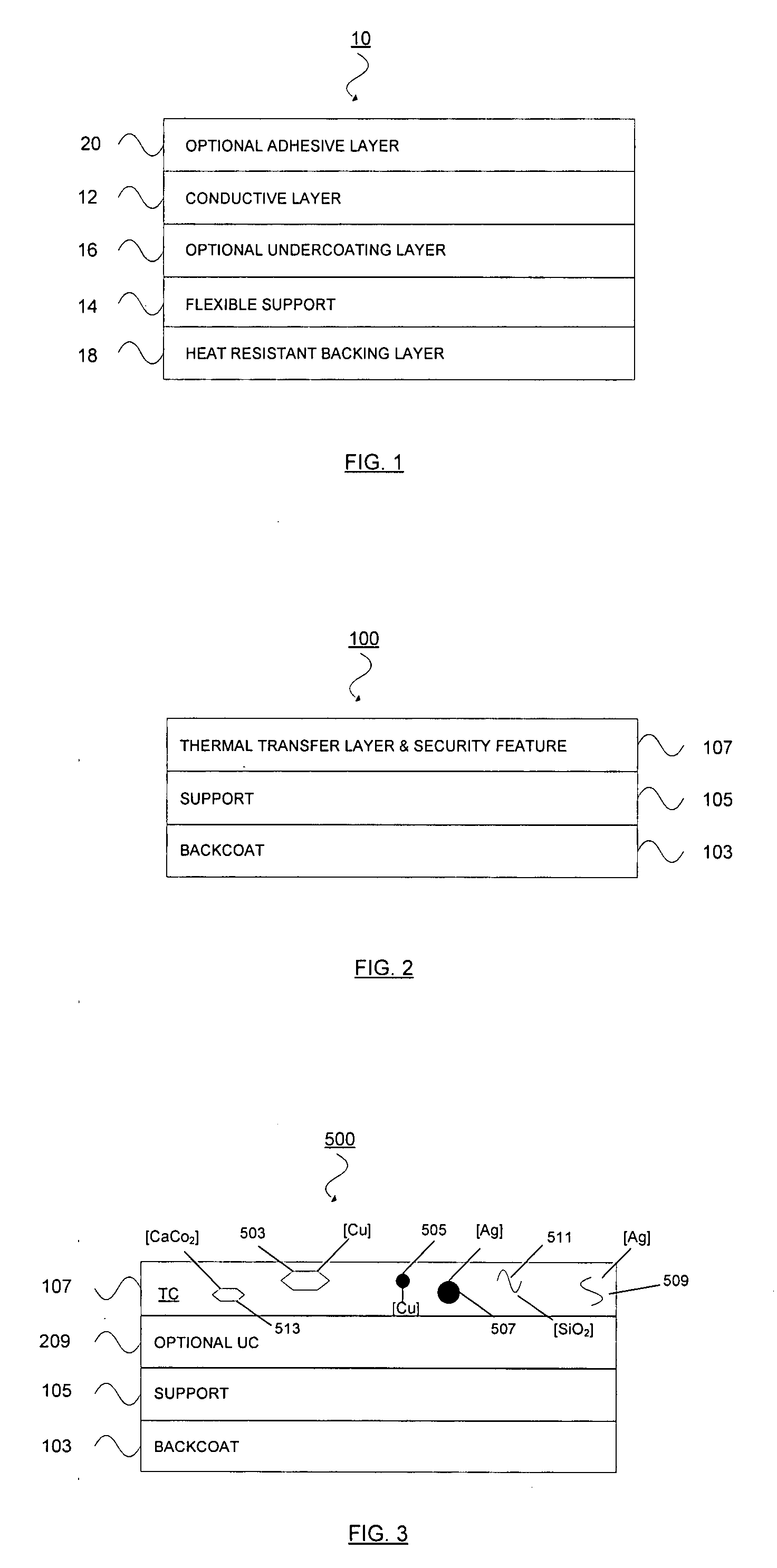

Conductive thermal transfer ribbon

A thermal transfer ribbon comprised of a support and an ink layer disposed above the support. The ink layer has a thickness of from about 0.1 to about 10 microns; it contains at least 75 weight percent of particulate conductive metal material and from about 1 to about 25 weight percent of binder; and it has a surface resistivity of less than about 1,000,000 ohms per square. When the ink layer is transferred to a substrate, the surface resistivity of the transferred ink is less than 100 ohms per square when printed onto a flexible substrate at a printing speed of 2 centimeters per second and a printing energy of 7.6 joules per square centimeter. The particulate conductive metal preferably contains a noble metal and has a melting point of at least 800 degrees Celsius and a particle size such that least about 95 weight percent of its particles are smaller than 50 microns.

Owner:INT IMAGING MATERIALS

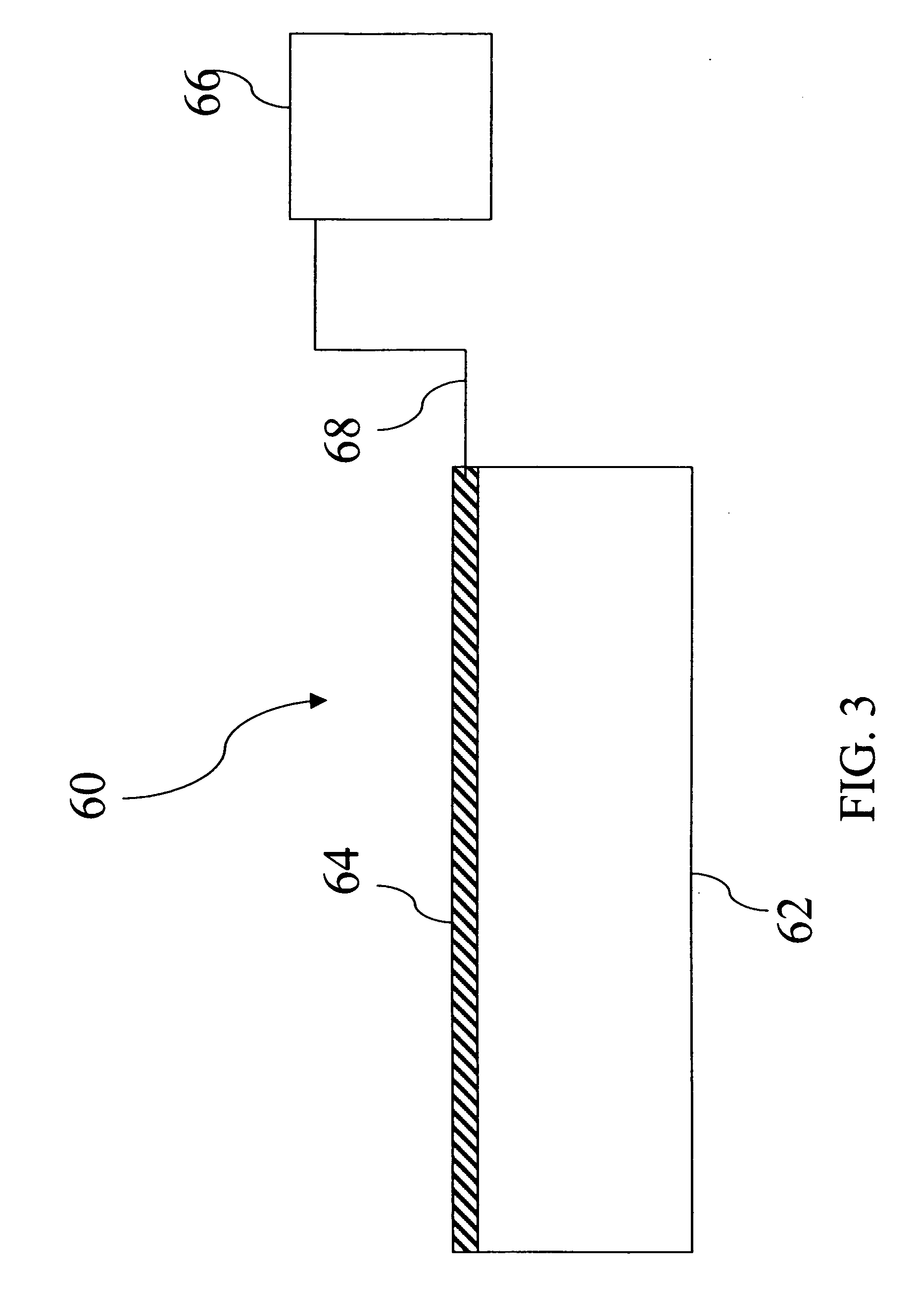

Laser resist transfer for microfabrication of electronic devices

A method for forming a resist pattern on a substrate (18) places a donor element (12) having a layer of thermoresist material proximate the substrate. A gap is maintained such that the surface of the layer of thermoresist material is spaced apart from the surface of the substrate by a number of spacing elements. Thermal energy is directed toward the donor element (12) according to the resist pattern, whereby a portion of thermoresist material is transferred from the donor element (12) across the gap by ablative transfer and is deposited onto the substrate (18) forming the resist pattern.

Owner:EASTMAN KODAK CO

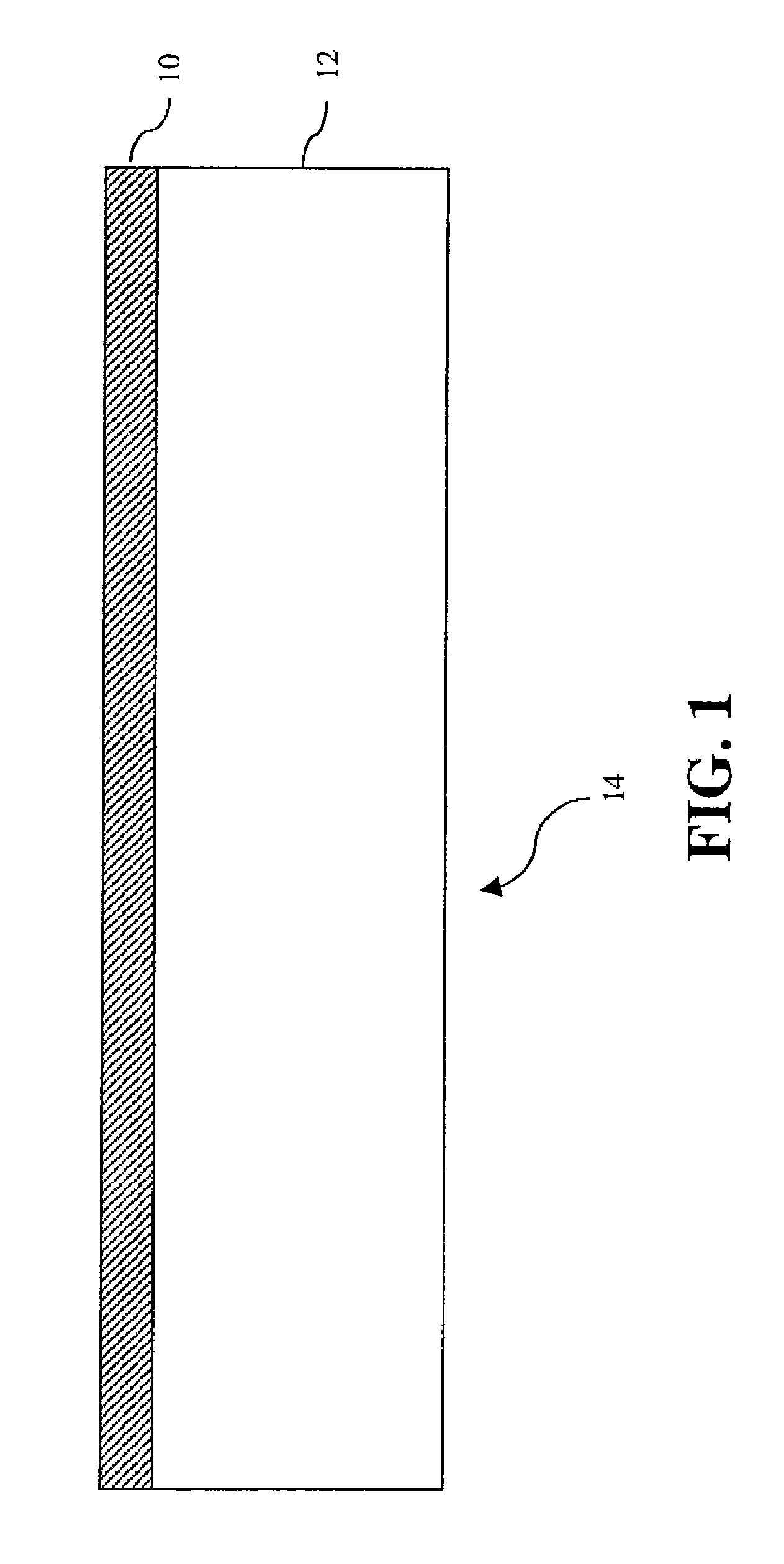

Substrate and negative imaging method for providing transparent conducting patterns

Provided are processes for making a transparent conducting pattern. The invention is also directed to electronic devices containing such transparent conducting patterns. Further provided is a substrate comprising a base film and a transparent conducting layer disposed on the base film; wherein the substrate has an OD of about 0.1 to 0.6 at 830 nm, and the transparent conducting layer comprises polyethylene dioxythiophene and has an OD of less than 0.1 in the range of 400 to 700 nm.

Owner:EI DU PONT DE NEMOURS & CO

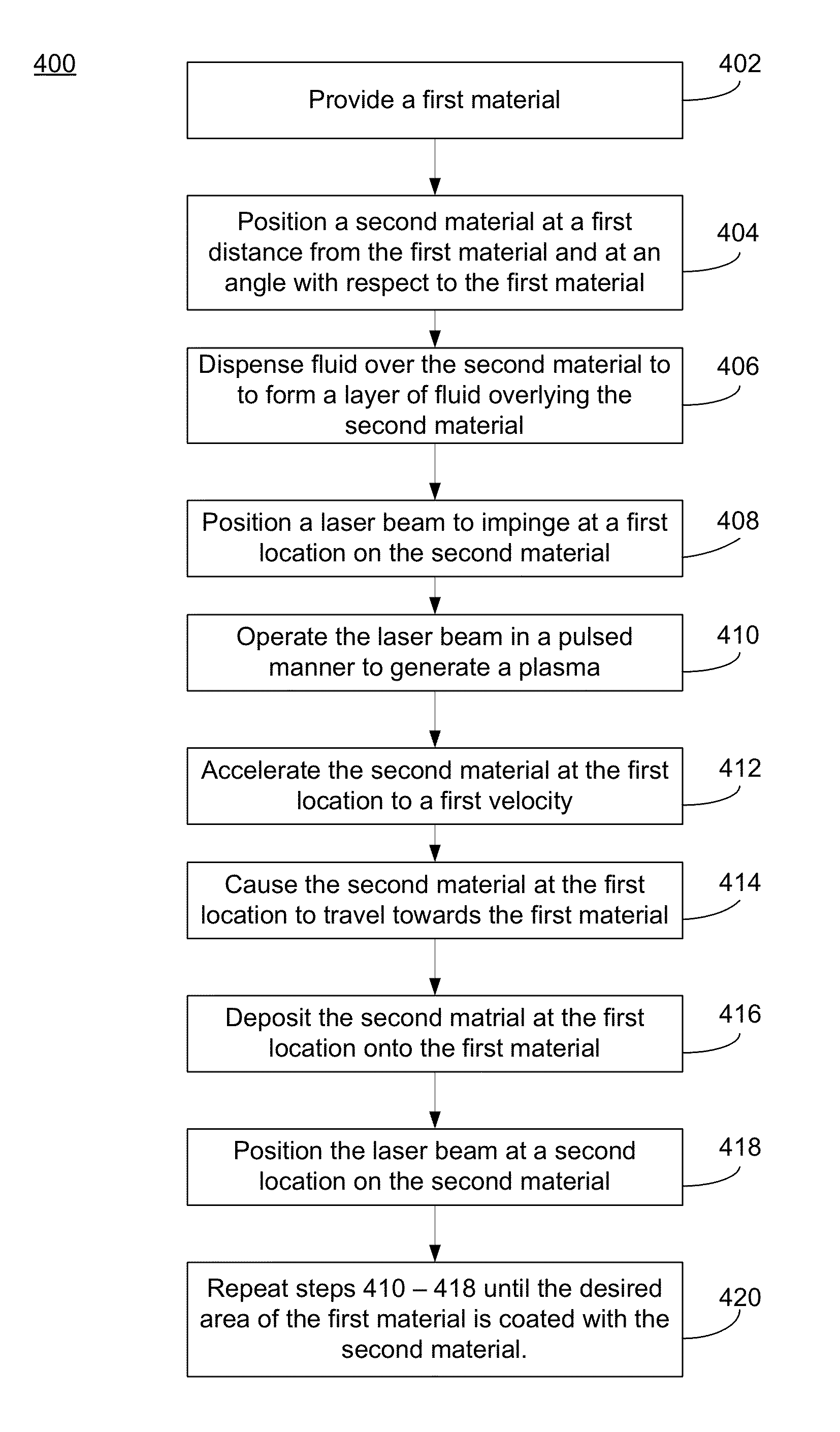

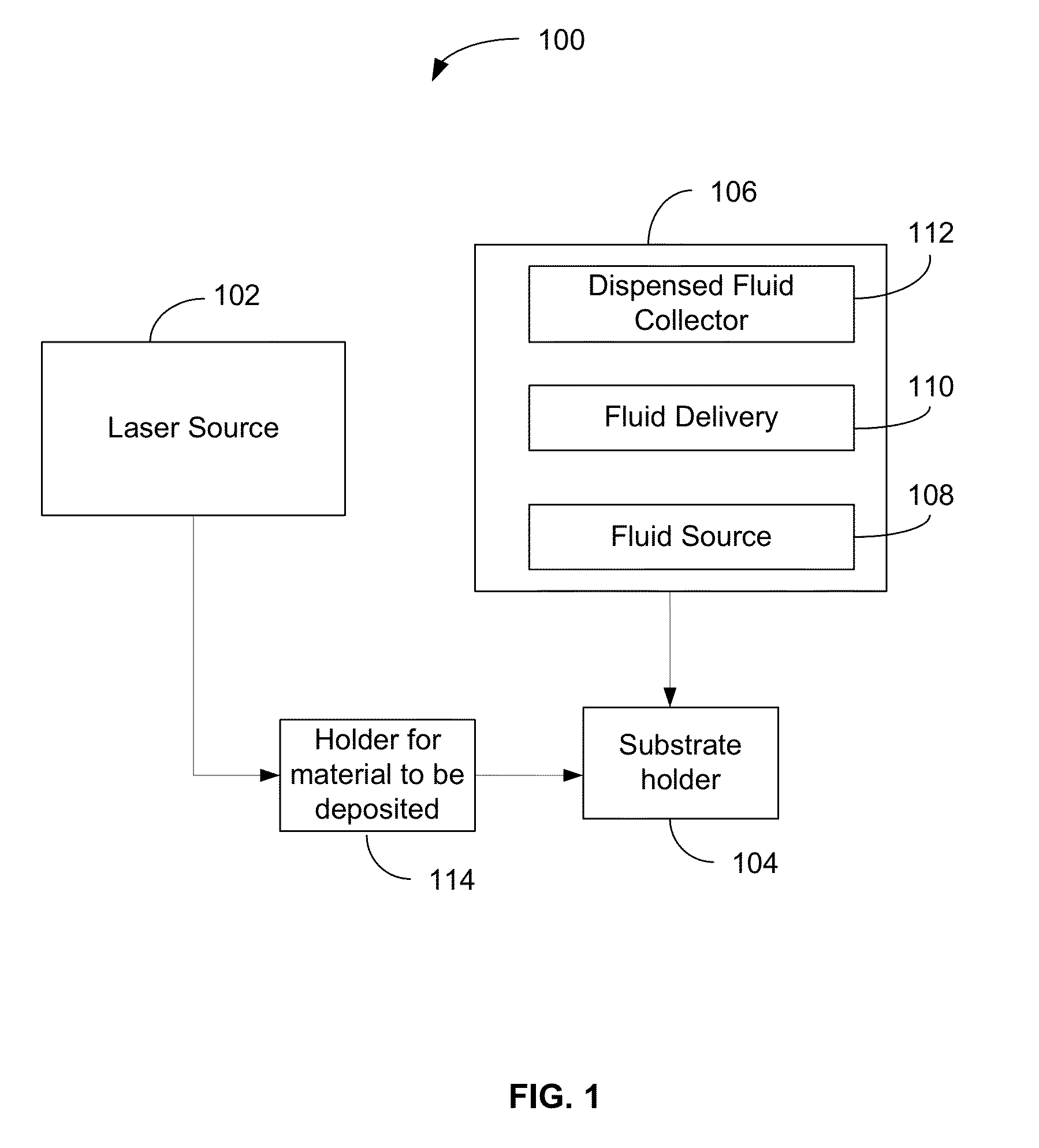

Methods and system for controlled laser-driven explosive bonding

ActiveUS9192056B2Improve adhesionSpeed up the flowElectric discharge heatingTransfer patterningOblique angleLaser beams

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

Manufacturing method for printing circuit

InactiveUS20070102103A1Simple manufacturing processLow production costTransfer patterningDecorative surface effectsProduction lineAdhesive

A manufacturing method for a printing circuit uses an adhesive as a printing material to print a line pattern of a printing circuit on a carrier by means of printing, and then cause an adhesive to stick with a mother film with a release type metal to allow a part of the carrier with the adhesive to pull and attach itself with a metal film, and another part without the adhesive does not pull and attach itself with the metal film such that a metal line is formed on the carrier. The manufacturing method can simplify the manufacturing process of the printing circuit, the line fabrication is very fast, the production efficiency can be enhanced and the production cost is low.

Owner:K LASER TECH

Polymeric conductor donor and transfer method

InactiveUS20090050855A1Lamination ancillary operationsDecorative surface effectsElectrical conductorConductive polymer

The present invention relates to a donor laminate for transfer of a conductive layer comprising at least one electronically conductive polymer on to a receiver, wherein the receiver is a component of a device. The present invention also relates to methods pertinent to such transfers.

Owner:EASTMAN KODAK CO

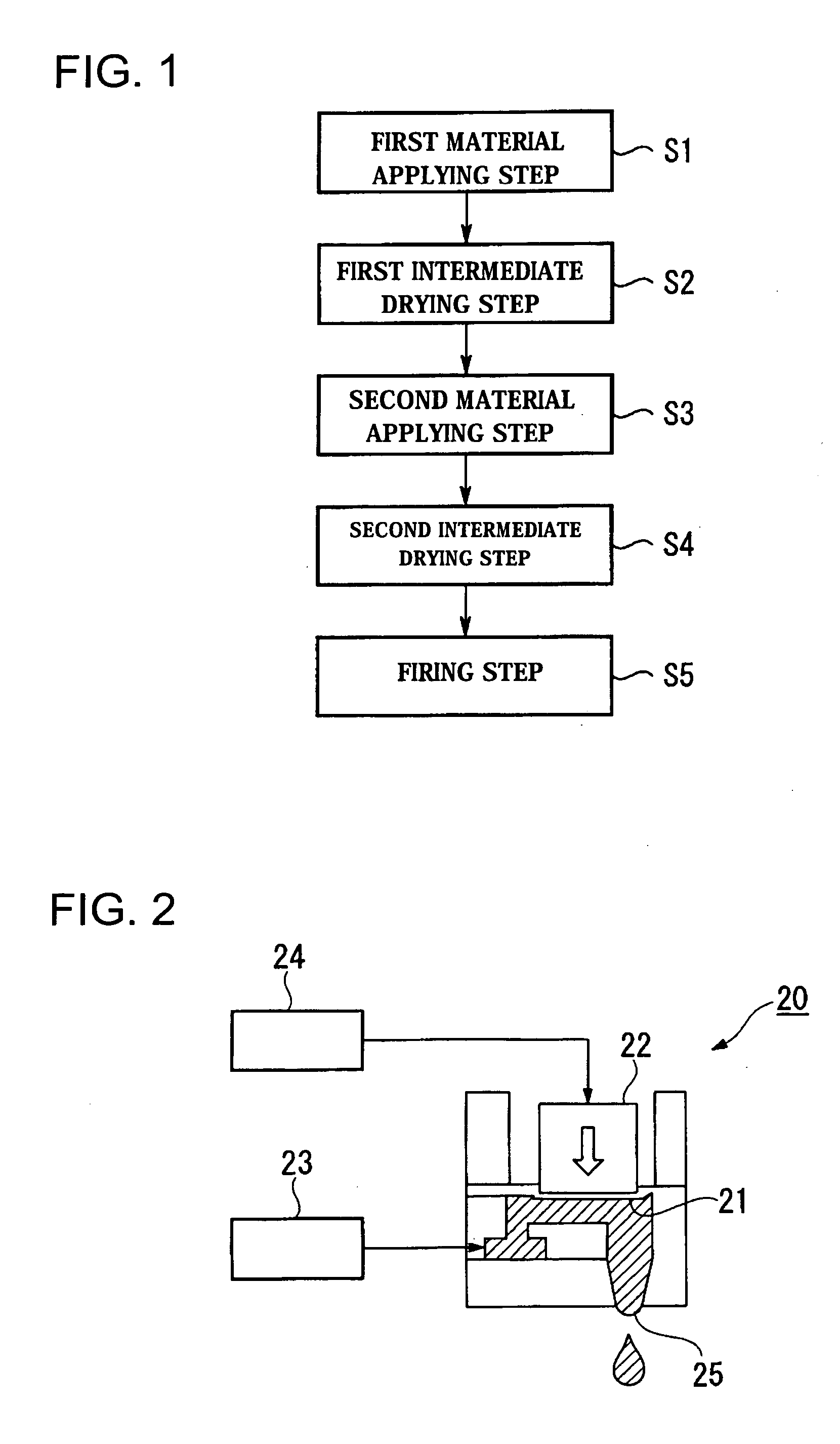

Method for forming patterned conductive film, electrooptical device, and electronic appliance

ActiveUS20050095866A1Develop its conductivityValid conversionDiffusion transfer processesPhotography auxillary processesLight energyPhotothermal conversion

Exemplary embodiments of the present invention provide a method to form a patterned conductive film by modifying a conductive thin film on a substrate irrespective of the material used for the substrate. Exemplary embodiments include a substrate having a conductive layer containing a conductive material and a photothermal conversion layer containing a photothermal conversion material that converts light energy into heat energy that is irradiated with a laser beam to fire at least part of the conductive layer with the photothermal conversion material.

Owner:INTELLECTUAL KEYSTONE TECH LLC

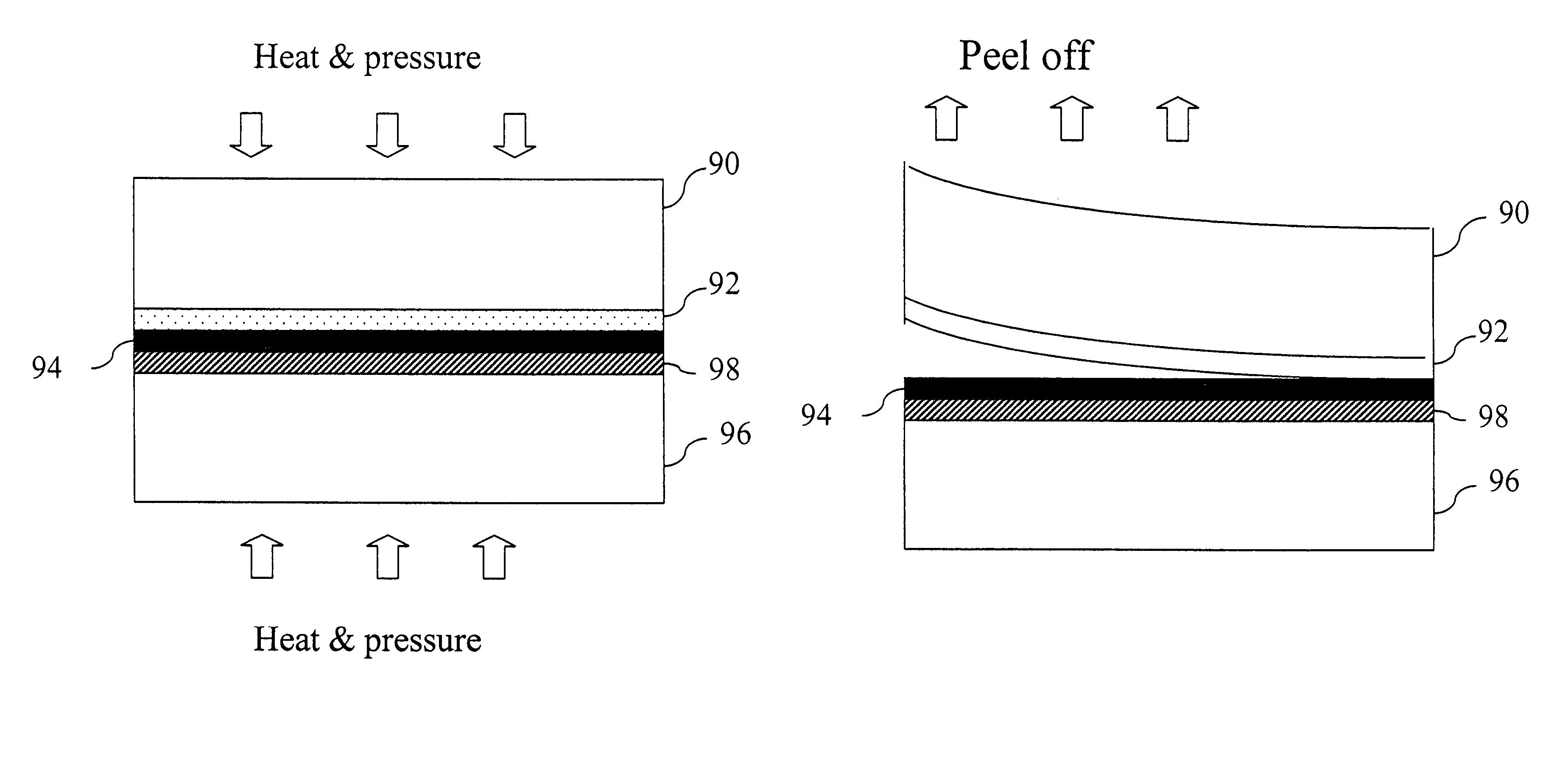

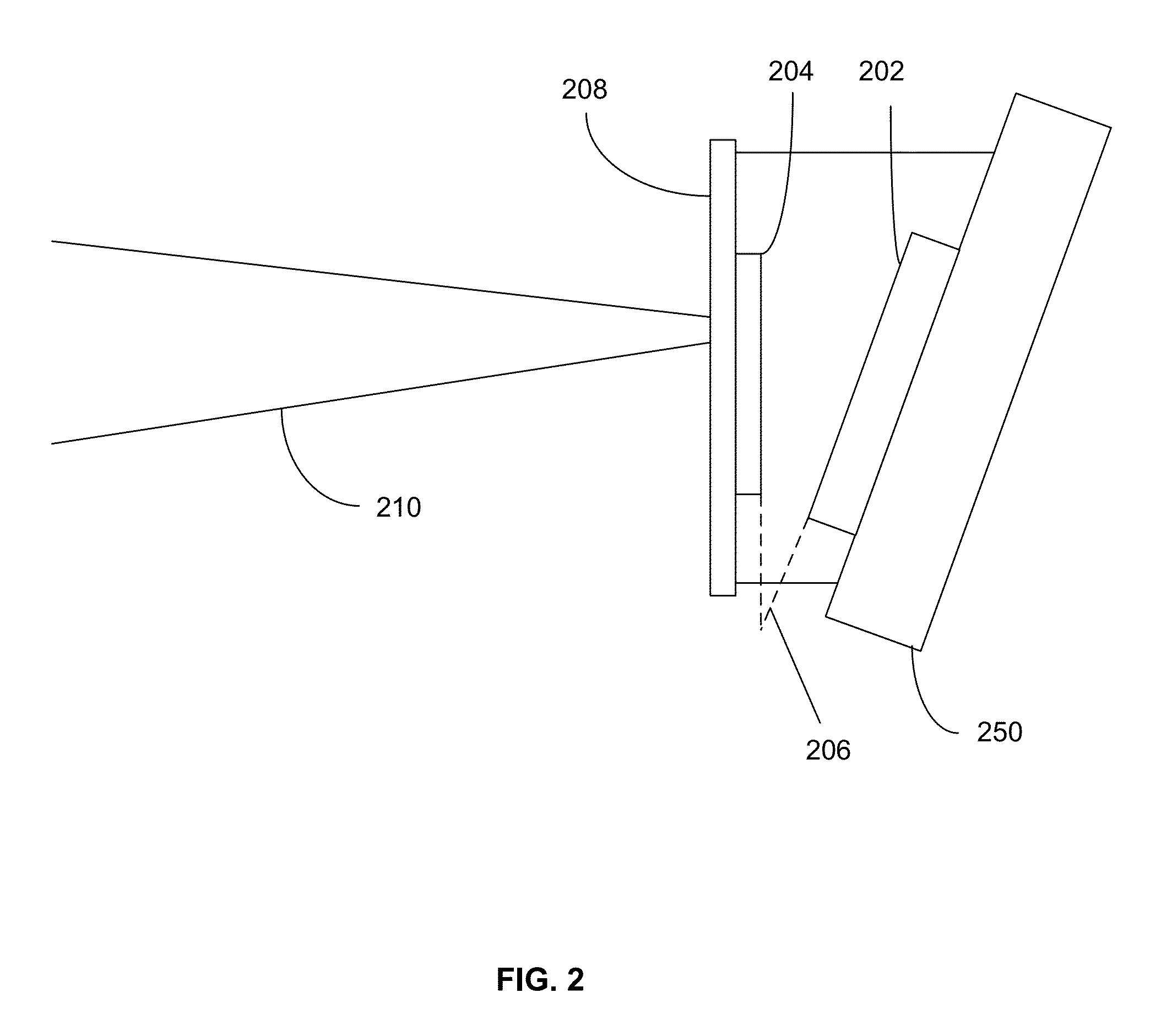

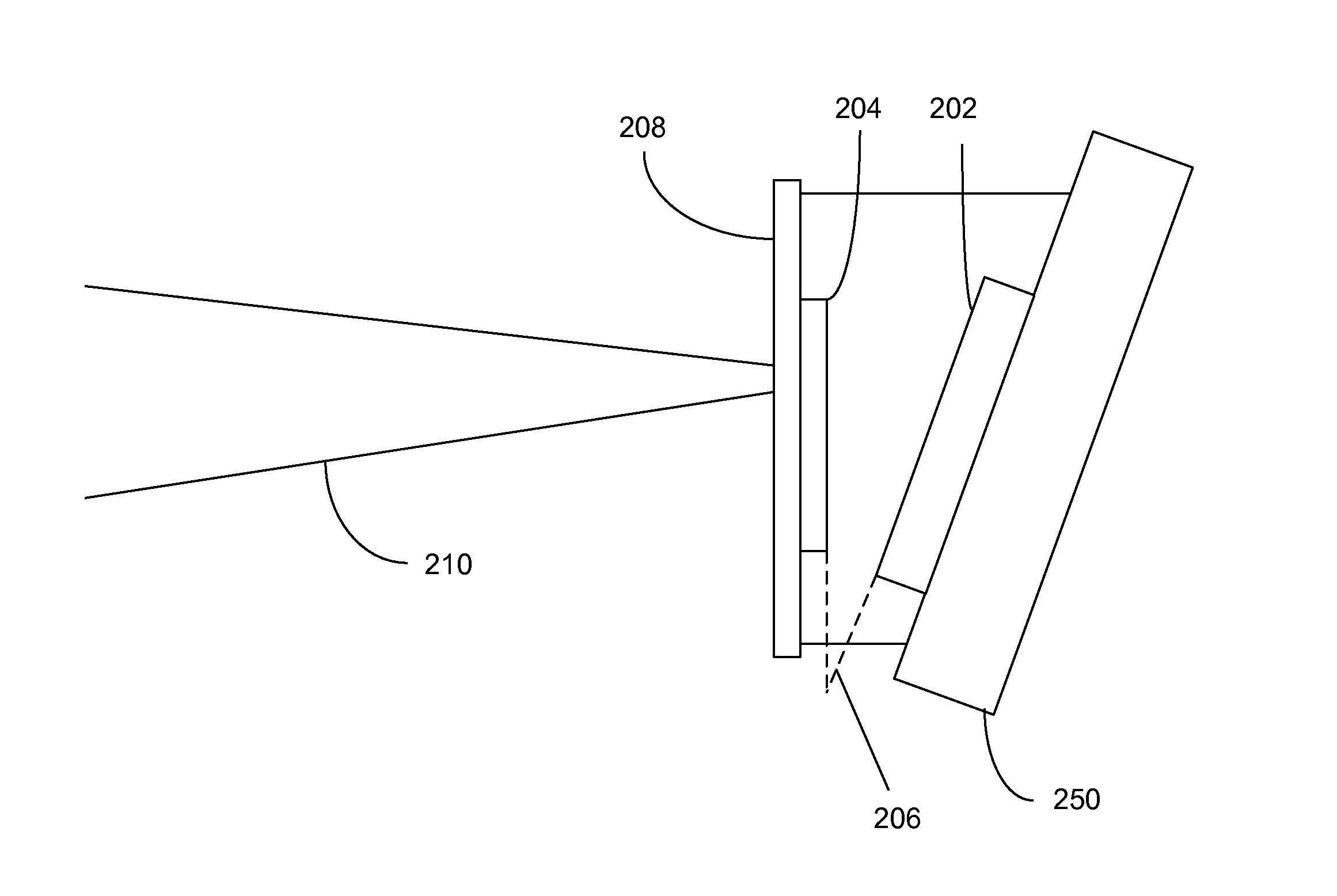

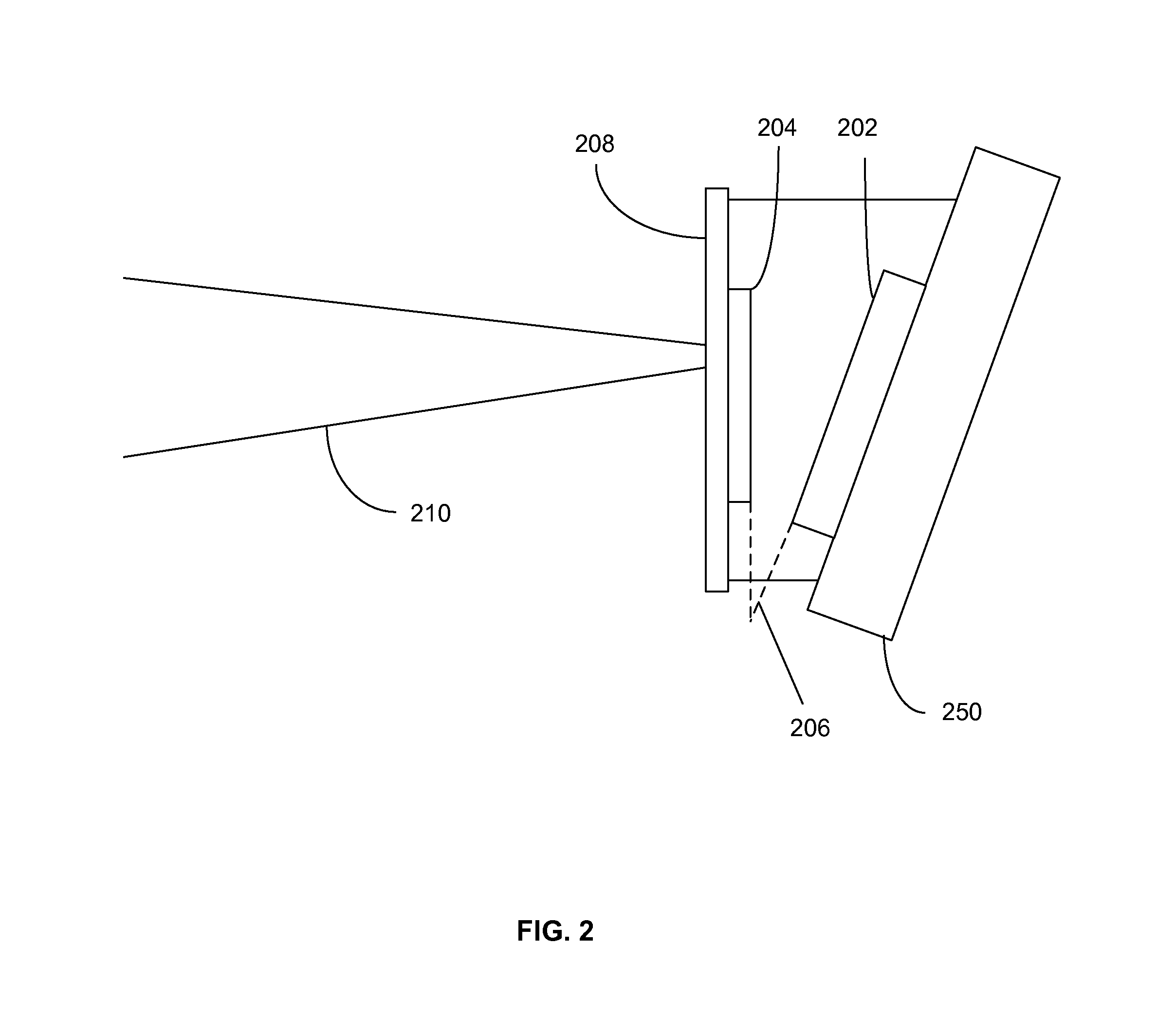

Methods and system for controlled laser-driven explosive bonding

ActiveUS20130064993A1Improve adhesionIncreases shear flow of materialLiquid surface applicatorsElectric discharge heatingOblique angleLaser beams

A technique for bonding two dissimilar materials includes positioning a second material over a first material at an oblique angle and applying a tamping layer over the second martial. A laser beam is directed at the second material that generates a plasma at the location of impact on the second material. The plasma generates pressure that accelerates a portion of the second material to a very high velocity and towards the first material. The second material impacts the first material causing bonding of the two materials.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC +1

PCB pad compensation design technology and application thereof

ActiveCN105792521AUniform shapeAvoid WeldingTransfer patterningComputer designed circuitsSolder maskManufacturing technology

The invention relates to a PCB pad compensation design technology and application thereof, and belongs to the technical field of PCB manufacture. In PCB pad compensation design technology, the line width of a CAM design circuit is greater than that of an original design drawing, the diameter of a solder mask window of CAM design is greater than that of the original design drawing, and a solder mask negative image of CAM design compensates a line-solder mask overlap portion beyond the pad range. Patterns of solder mask windows in a solder mask negative are compensated in design, the shapes of pads formed finally are relatively unified, problems as incomplete soldering and short circuit during tinning can be avoided, and the yield rate of production is improved.

Owner:PLOTECH TECH KUNSHAN CO LTD

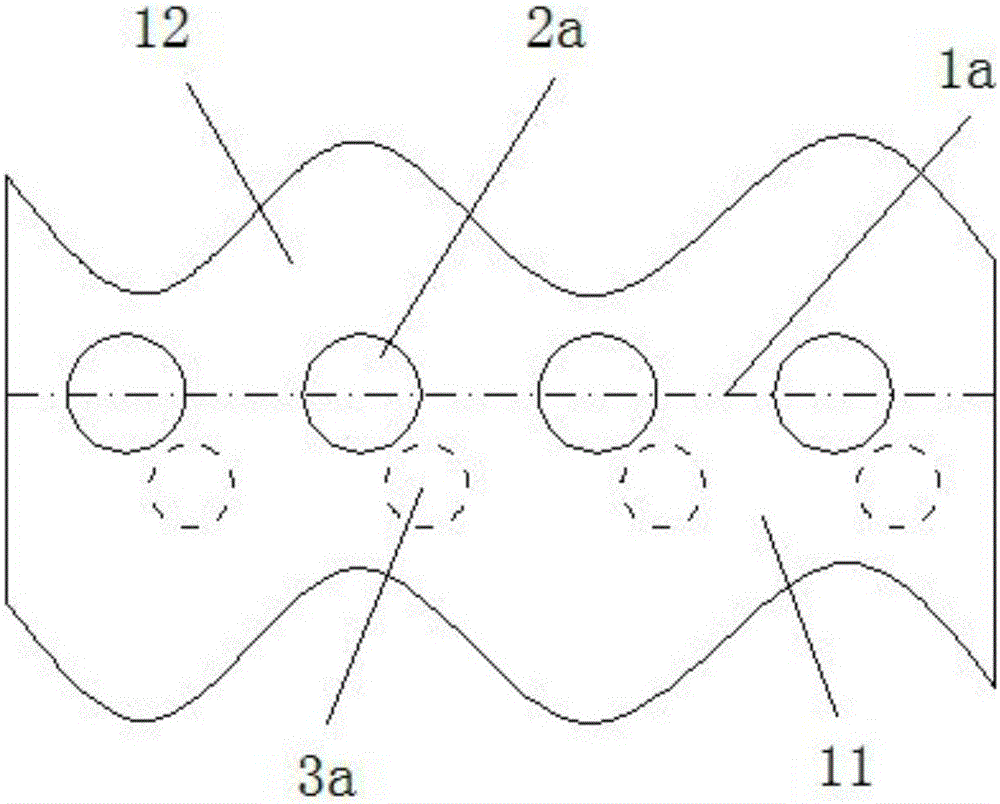

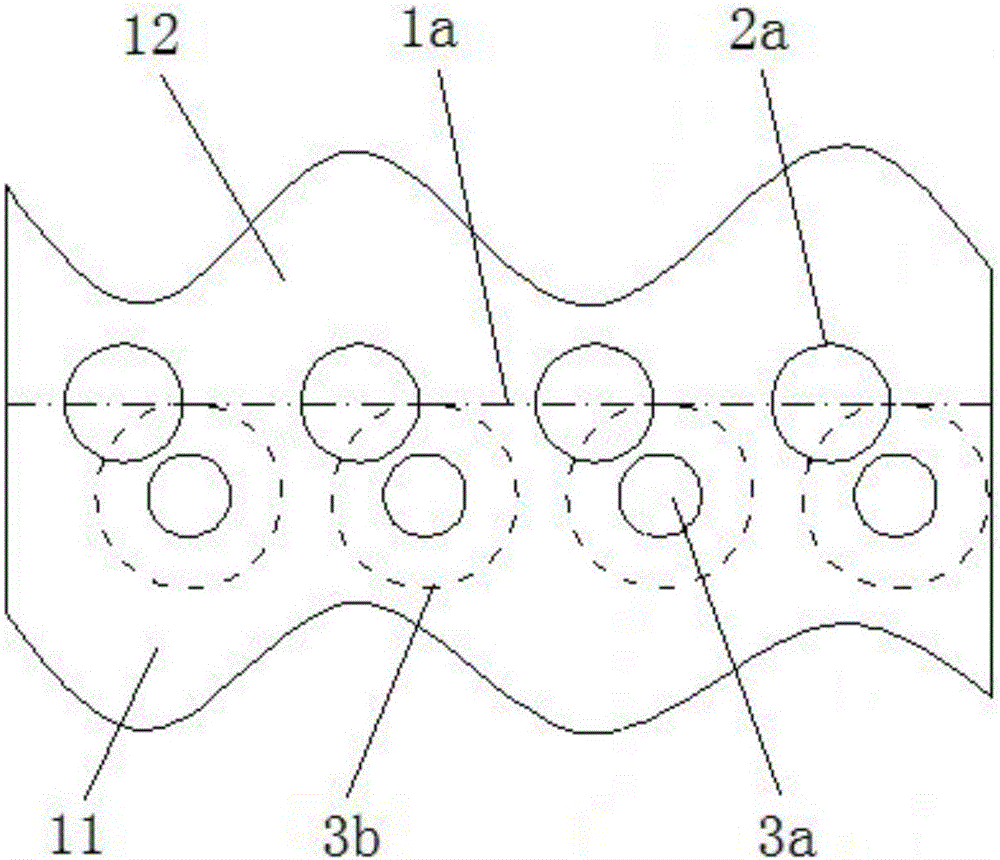

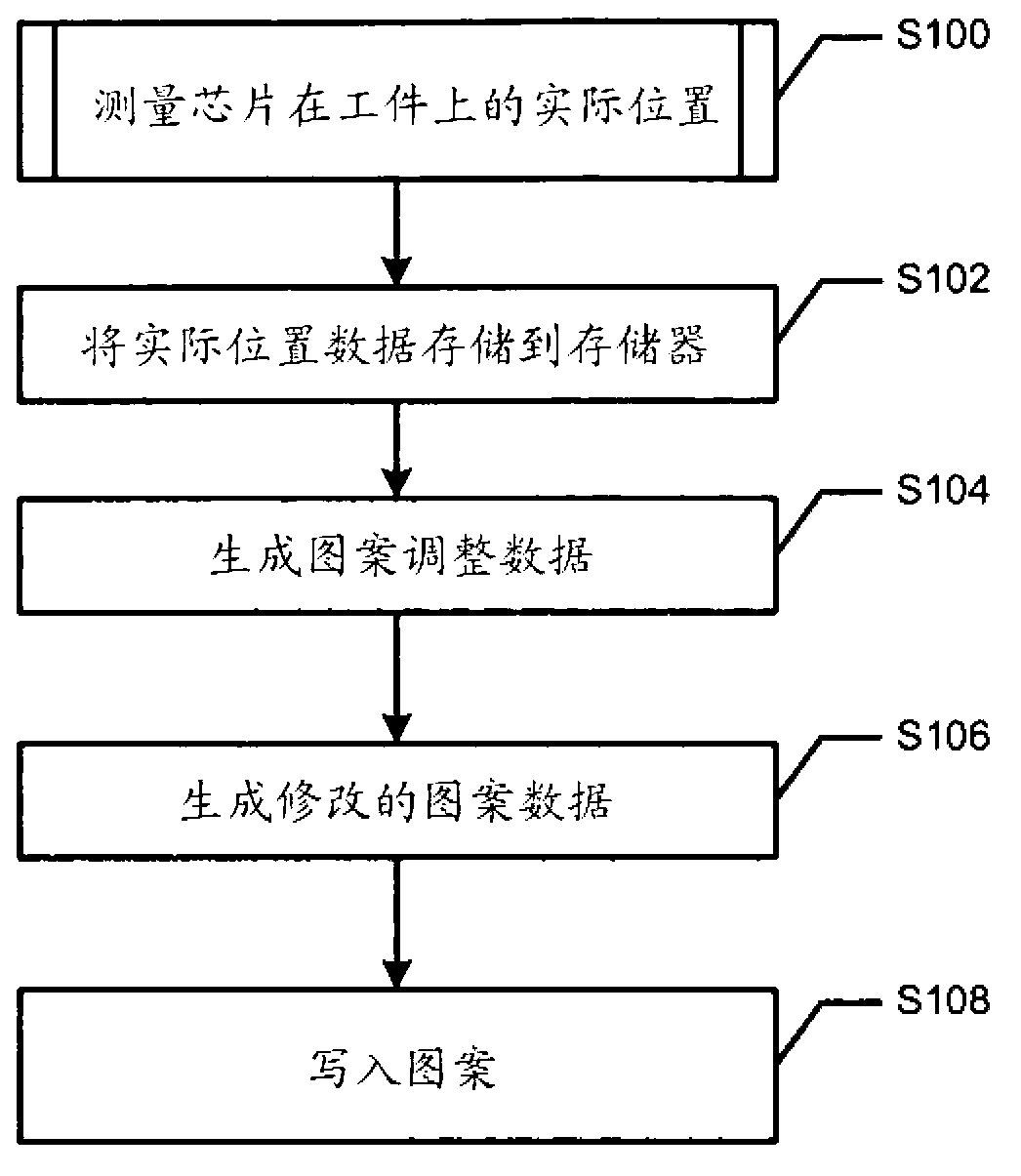

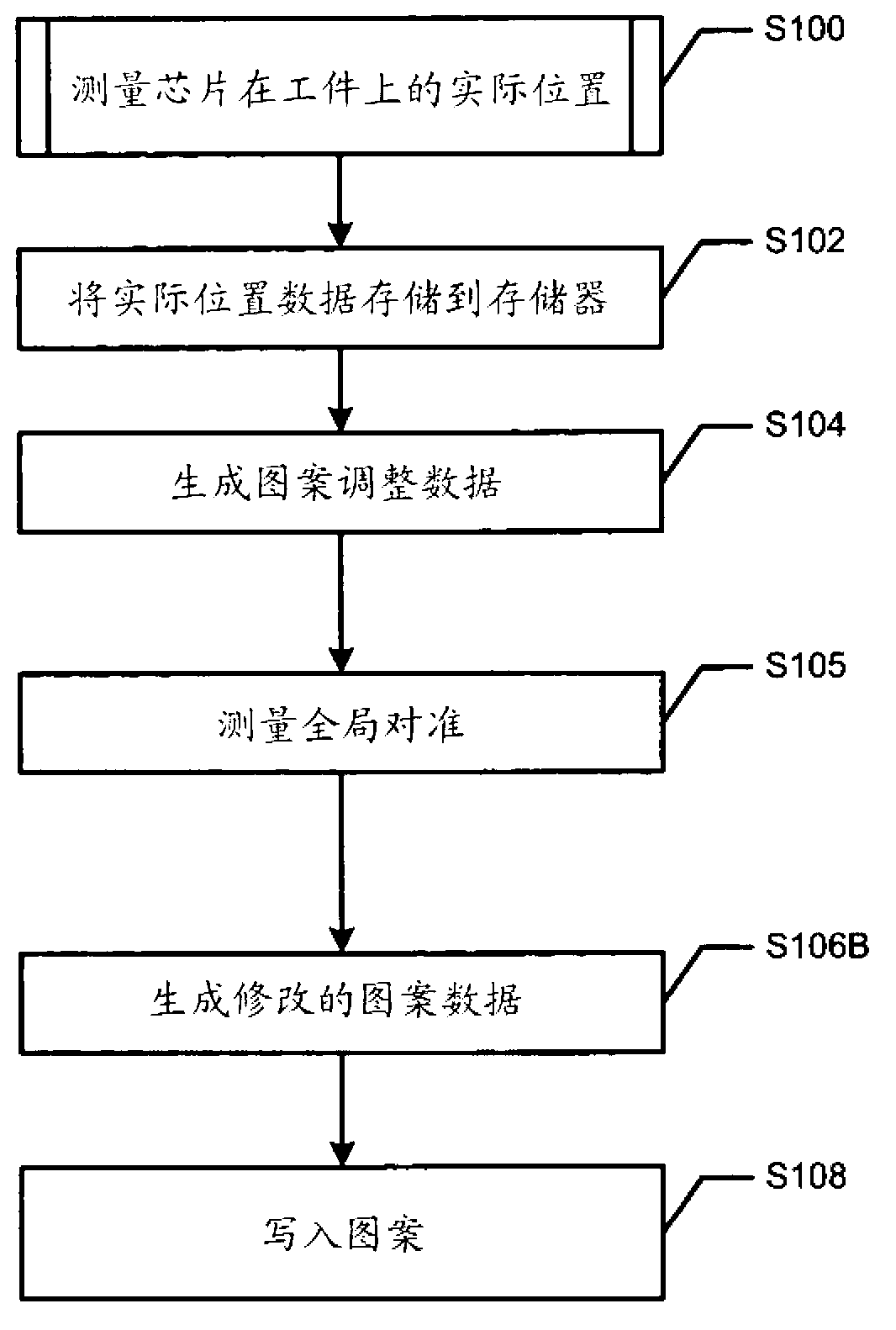

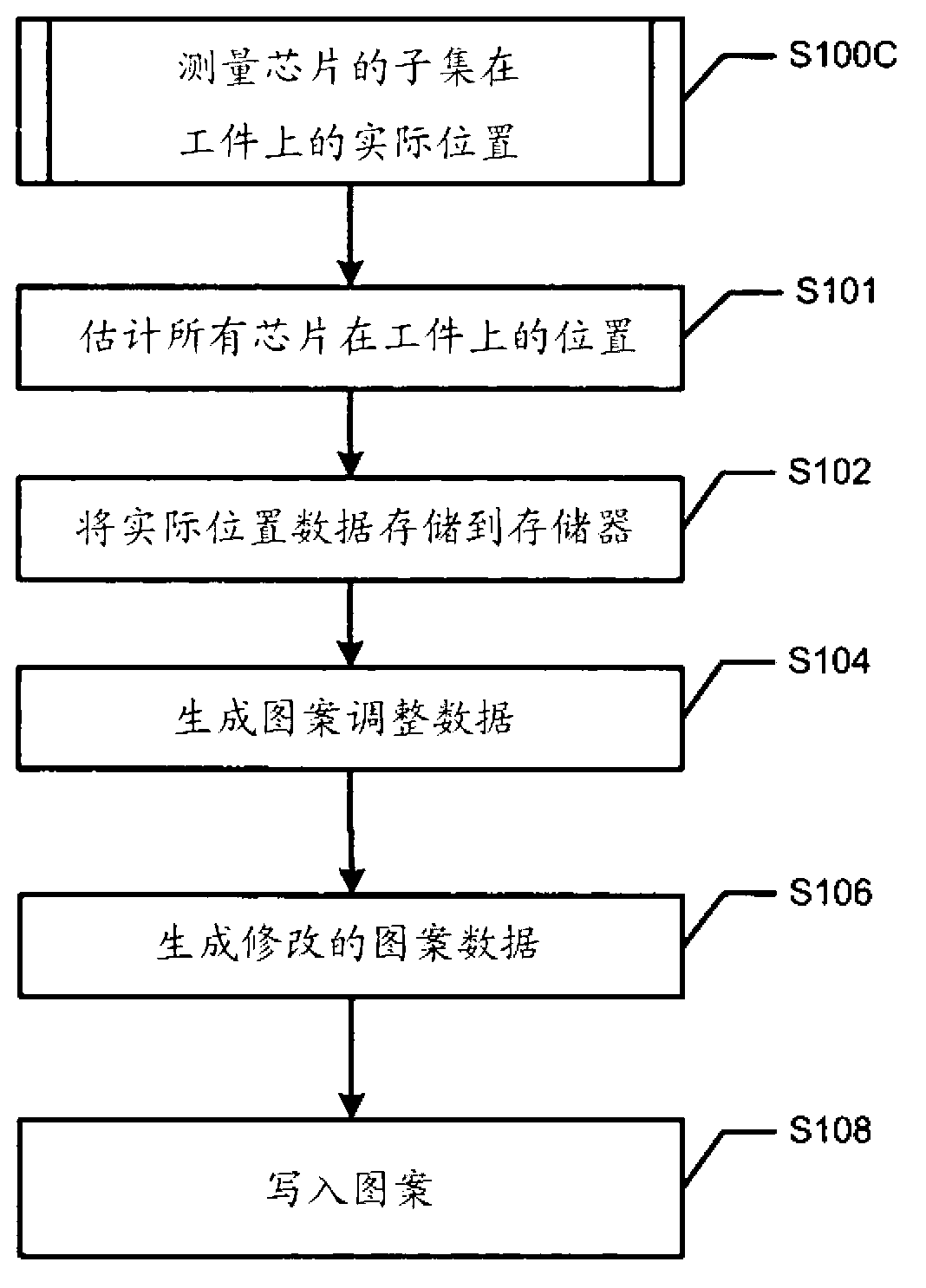

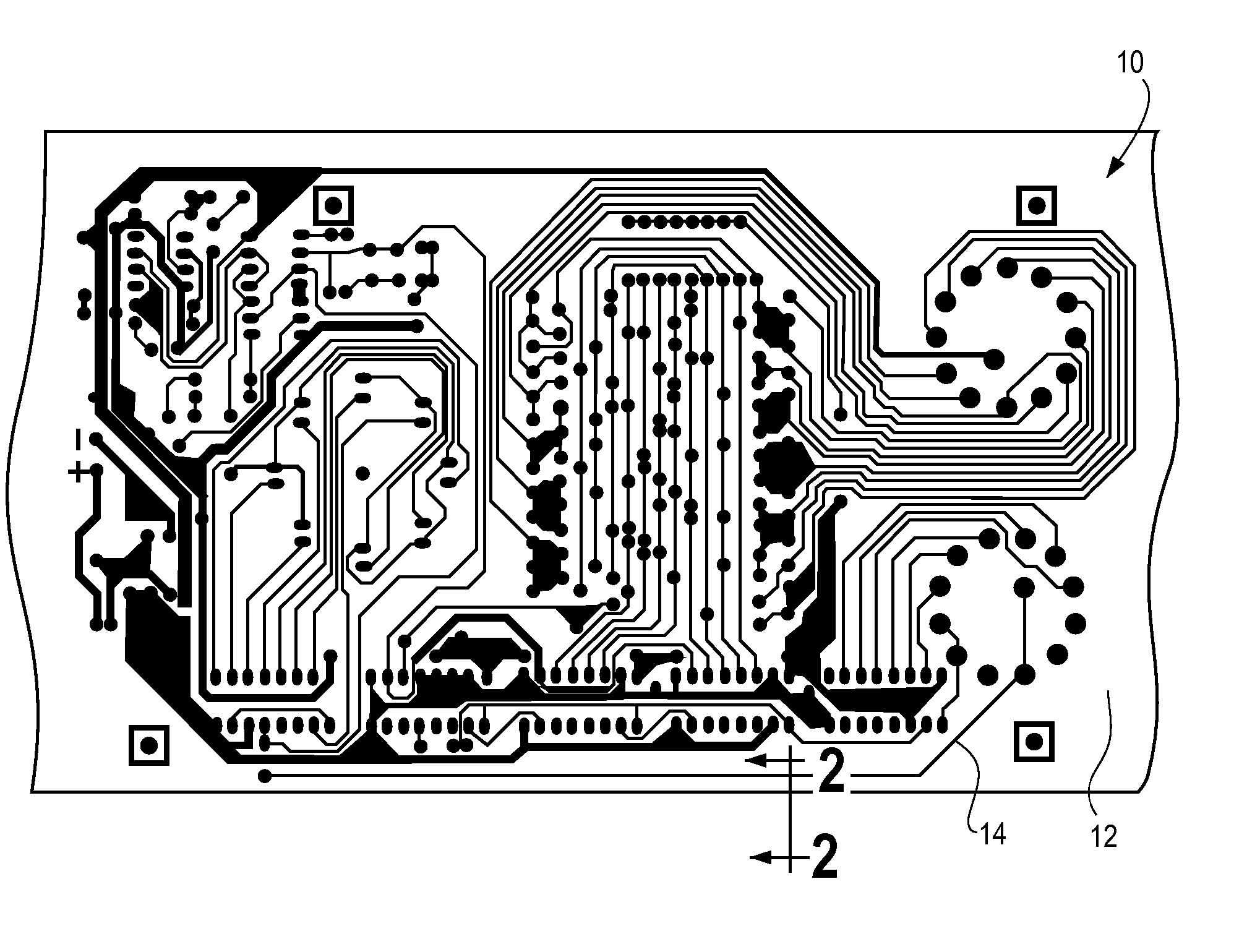

Methods and apparatuses for generating patterns on workpieces

ActiveCN103210483ATransfer patterningSemiconductor/solid-state device manufacturingMechanical engineeringEngineering

Owner:MICRONIC LASER SYST AB

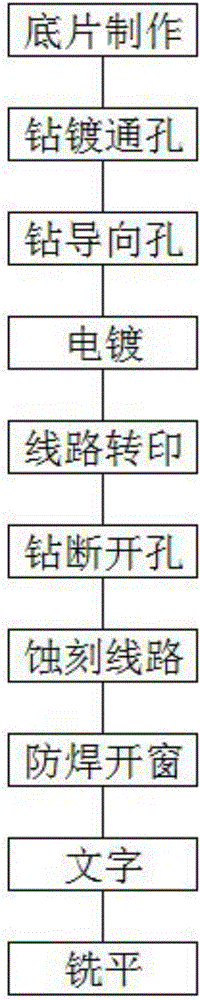

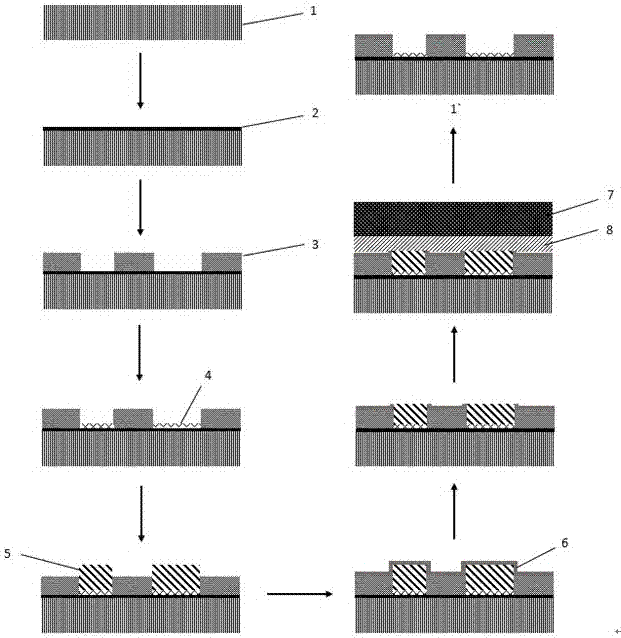

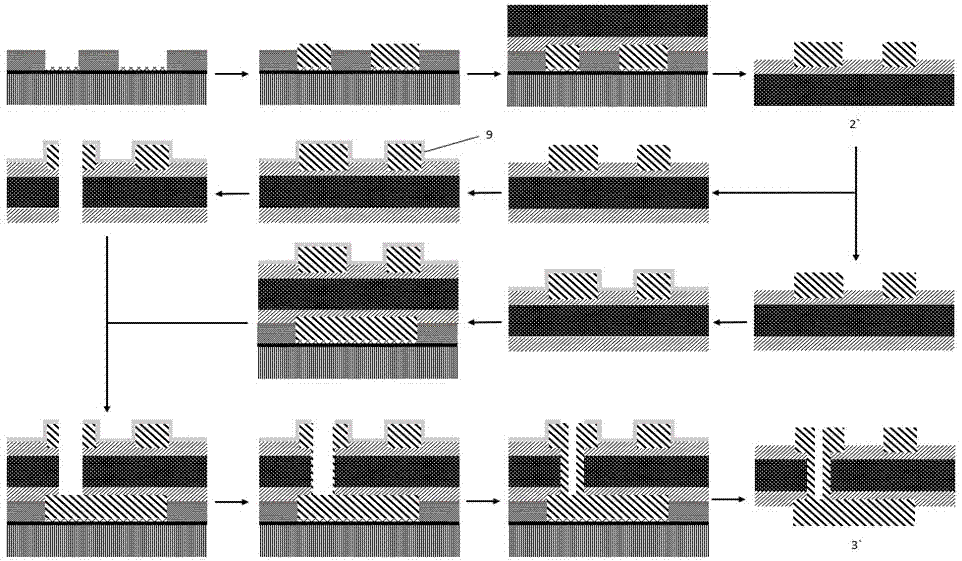

Template transfer technology for preparing double-side multilayer printed circuit

ActiveCN107105577ASimple stepsReduce wasteTransfer patterningMultilayer circuit manufactureCopper platingMetal foil

The invention relates to an additional preparation technology of a double-side multilayer printed circuit. An electroplating template is prepared, a single-side circuit board is prepared, holes are drilled in the single-side circuit board, another electroplating template is adhered, the holes are metalized by chemical coppering, the holes are thickened by electro-coppering, the other electroplating template is peeled to obtain the needed double-side printed circuit board, and the multi-layer printed circuit is obtained by repeating the above steps. The electroplating template for preparing conductive lines can be reused via post processing, repeated mask layer preparation in traditional circuit board preparation is avoided, and development of the mask layer and pollution of a waste liquid are both reduced. According to a template transfer technology, as the additional preparation technology, etching of metal foils is not needed, there is no waste of metal, and the cost of handling waste liquid pollution and treating waste water caused by metal etching is reduced. Thus, compared with a traditional reduction type corrosion method for preparing the double-side multilayer printed circuit, the technology has the advantages of being waste-free and low in pollution and reducing the cost, and is worthy of application.

Owner:FUDAN UNIV

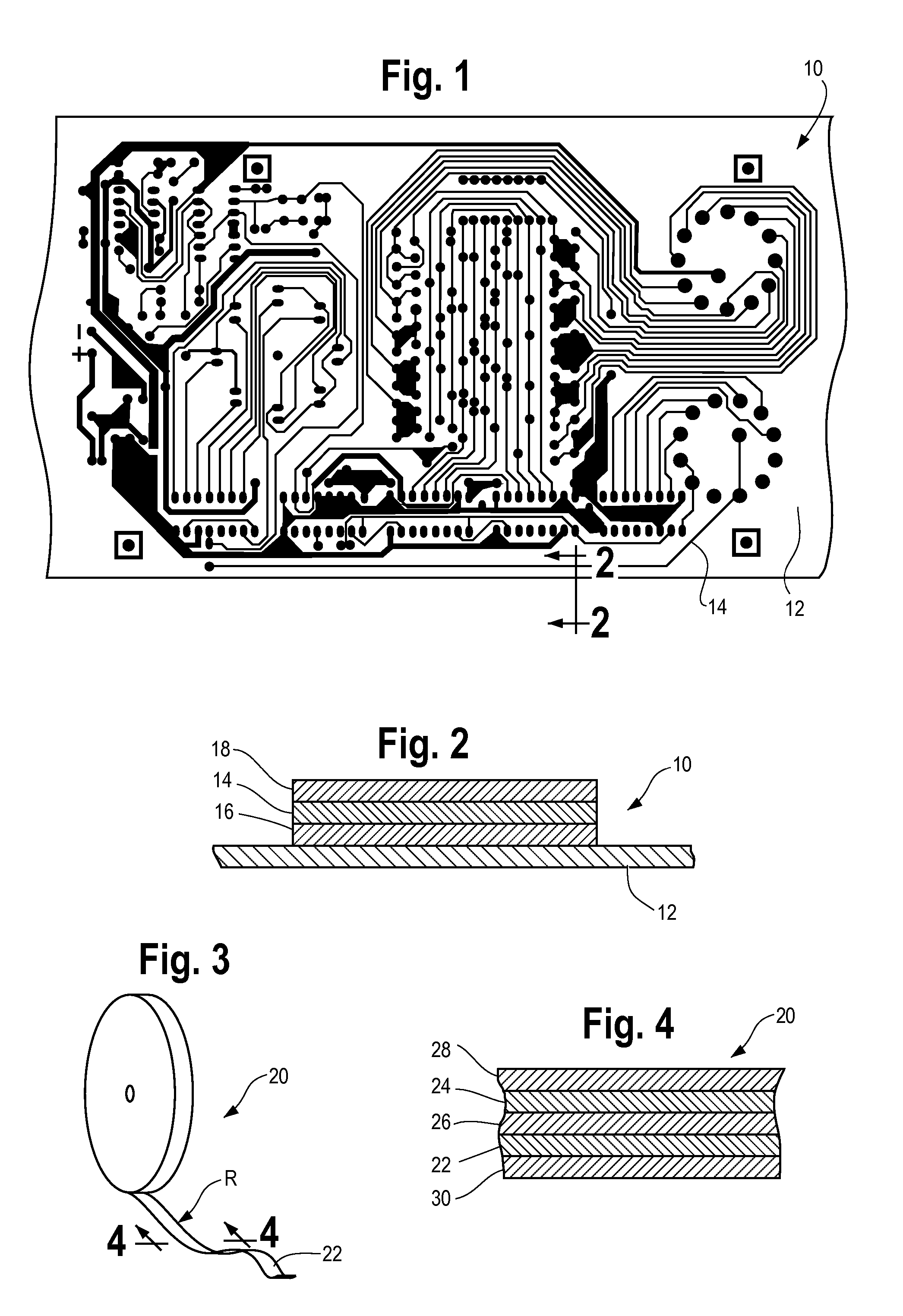

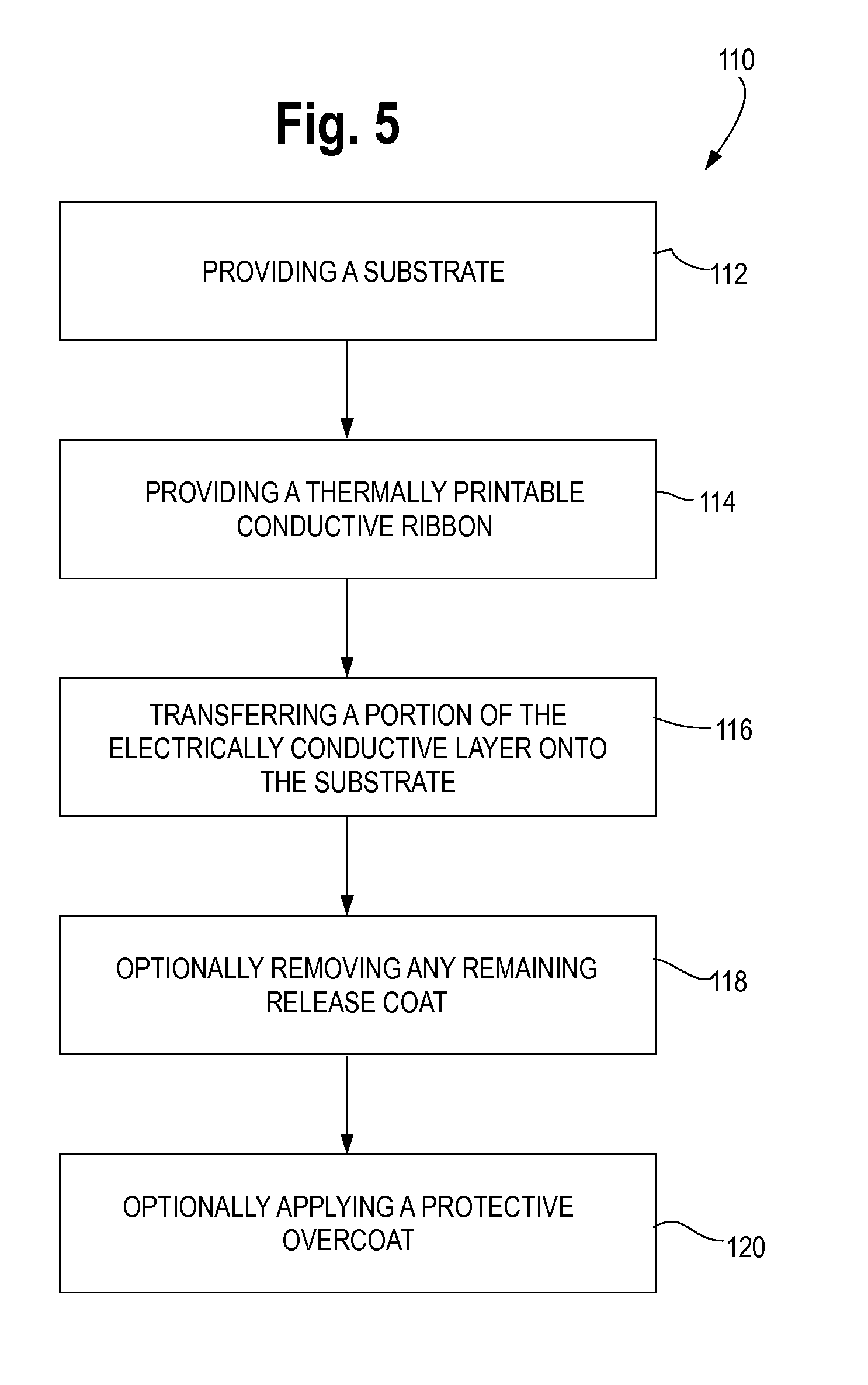

Thermally printable electrically conductive ribbon and method

InactiveUS20070218378A1Avoid timeAvoid expensesTransfer patterningElectrographic process apparatusEngineeringElectrical and Electronics engineering

A thermally transferable electrically conductive ribbon includes a carrier web having first and second sides and an electrically conductive layer disposed on the first side of the carrier web. A portion of the electrically conductive layer is transferable to an associated object to form an electrically conductive circuit thereon. A method for making and using the ribbon are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com