Laser resist transfer for microfabrication of electronic devices

a technology of electronic devices and laser resists, applied in the direction of diffusion transfer processes, instruments, circuit masks, etc., can solve the problems of difficulty and cost of combining steps (i)-v) in any type of automated, continuous fabrication system or apparatus, and the requirement for careful control of ambient illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0068] A donor element comprising a 102 microns polyethylene teraphthalate support containing a subbing layer of 0.43 g / m2 gelatin hardened with dihydroxydioxane was subsequently coated with a transfer assist layer containing (0.332 g / m2) polycyanoacrylate, (0.054 g / m2) IR dye 1, with the following structure:

from a mixture of cyclopentanone, N-methylpyrollidone, and methanol with 0.01 wt % surfactant Silwet L7001 (GE Silicones). This assembly was then overcoated with the resist transfer layer comprising (1.08 g / m2) Foral 85 (hydrogenated rosin ester, Hercules Corp.) binder, (1.08 g / m2) Organic Pigment T-11 from DayGlo Corporation (solid dye solution in a Thermoset Resin Bead of 4-5 micron diameter), (0.118 g / m2) polyvinyl butyral, (0.027 g / m2) Rhodamine 6G dye, and DC1248 (Dow Corning), a silicone surfactant at 0.02 wt % of the solution, from a mixture of methyl ethyl ketone and ethyl alcohol.

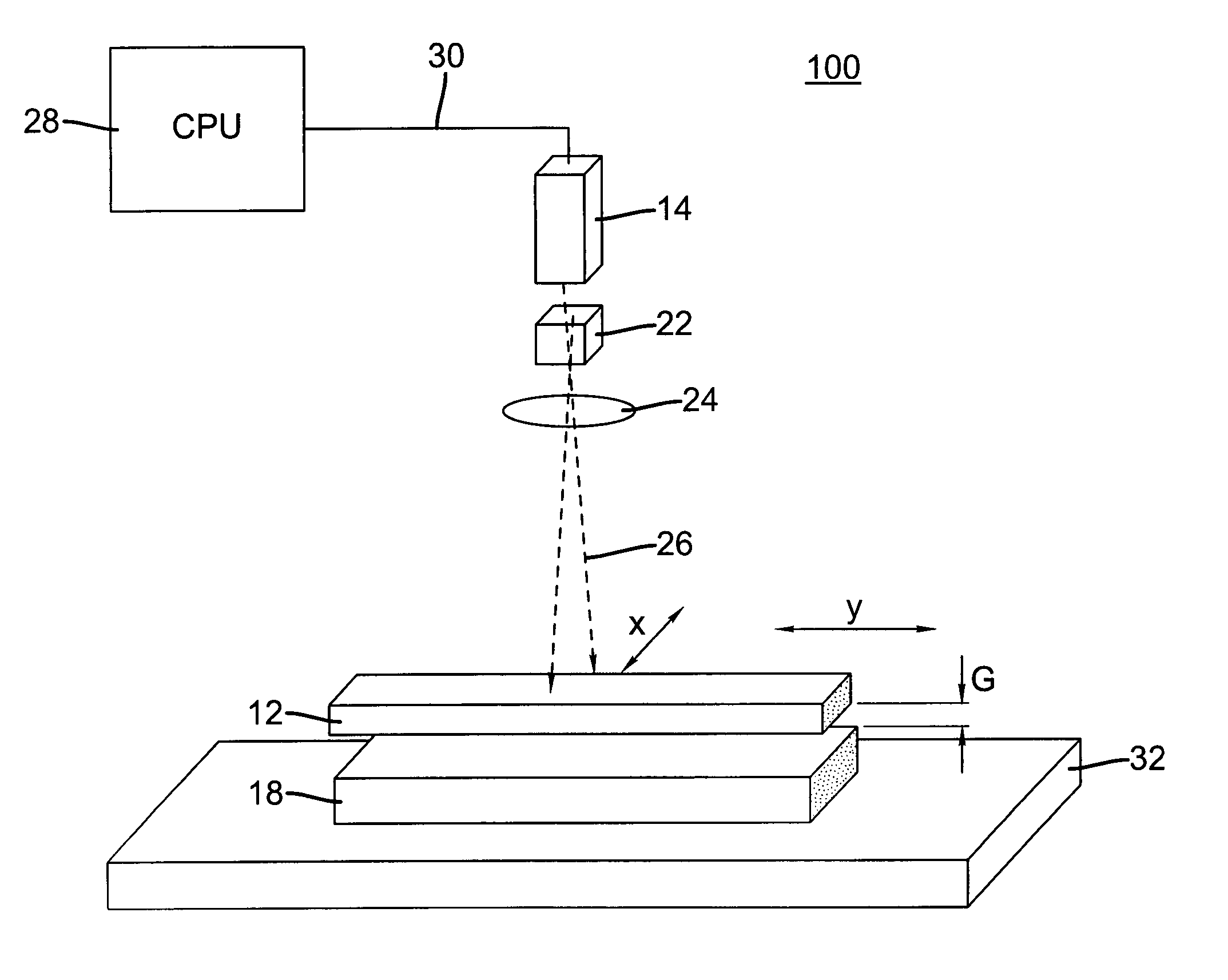

[0069] Donor element 12 was placed on substrate 18, which was composed of a glass plate...

example 2

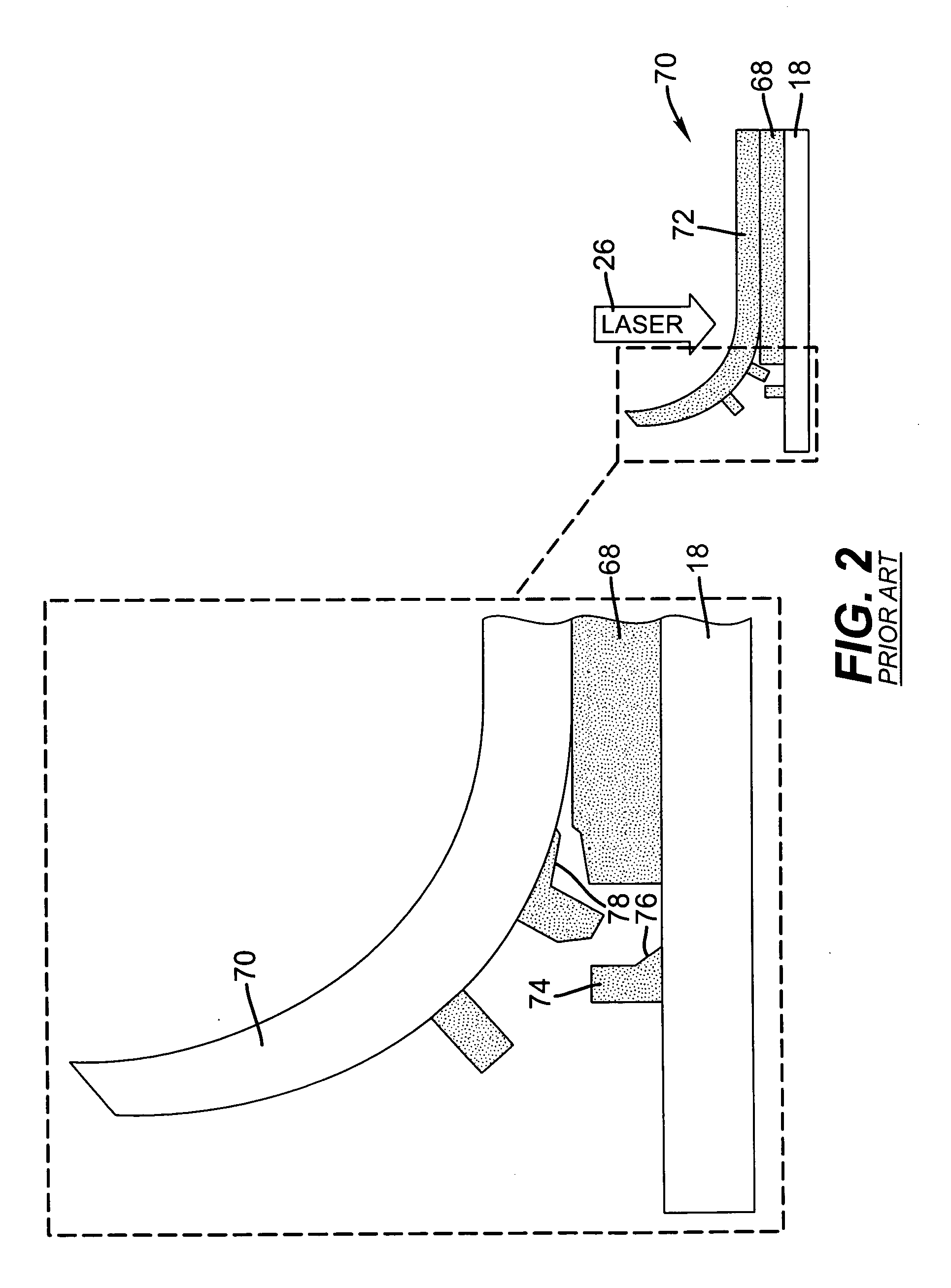

[0071] For this two-pass example, the steps of Example 1 were completed in a first pass. Then, as the second pass, a second resist material was applied, this time where no spacer particles or beads were used between donor element 12 and substrate 18. This is permissible since existing structures formed in the first pass provide the needed gap G (FIG. 4). That is, for the second pass, existing surface features 74 that were formed during the first pass effectively act as spacers, eliminating the need for spacers 88 as were shown in FIG. 4. Donor element 12 for the second pass used a 4 mil PET support, coated with a first subbing layer of tetrabutoxy titanate (Tyzor TBT, Dupont) coated from a mixture of n-butanol and n-propyl acetate, and a second transfer layer of 0.16 g / m2 cellulose acetate propionate, 0.054 g / m2 IR-2, 0.077 g / m2 Cyan Dye 1, with structure:

0.075 Magenta Dye 1, with structure:

0.069 g / m2 Yellow Dye 1, with structure:

coated from a mixture of MIBK (40%), n-propy...

example 3

[0073] This example followed the same process steps as those described for Examples 1 or 2, with minor exceptions, as follows: [0074] (i) the coated material on the glass substrate is poly silicon; and [0075] (ii) the etch gas atmosphere is sulfur hexafluoride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com