Template transfer technology for preparing double-side multilayer printed circuit

A printed circuit and template technology, which is applied in multi-layer circuit manufacturing, printed circuit, printed circuit manufacturing, etc., can solve problems such as the inability to use double-sided printed circuits, and the inability to achieve through-hole metal deposition by printing conductive inks, so as to reduce the Pollution and cost, the effect of less cost and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

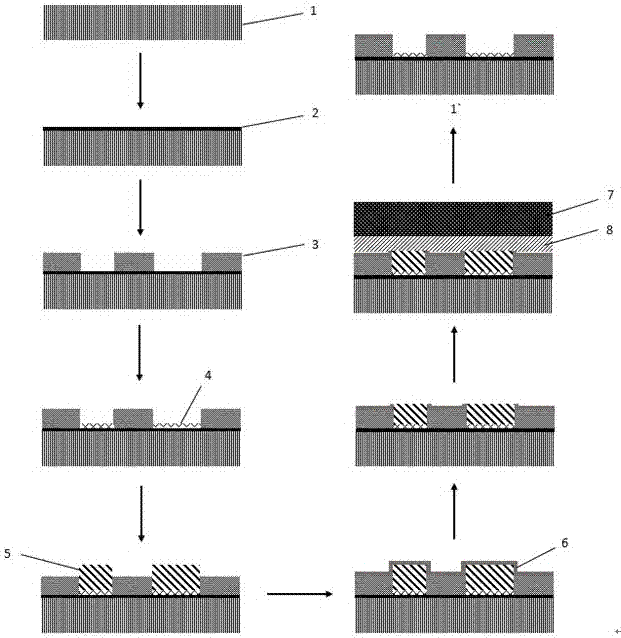

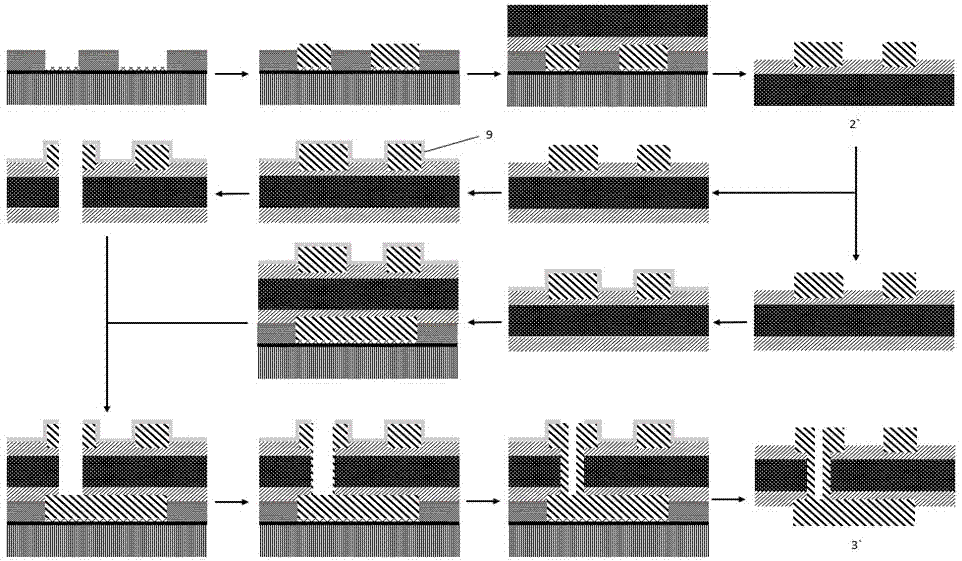

Method used

Image

Examples

Embodiment 1

[0038] Template preparation:

[0039] (1) Commercially available 50-micron calendered copper foil is used as the carrier foil, and a 50-micron thick PET film is bonded to one side of the copper foil, and the adhesive is thermoplastic EVA film;

[0040] (2) Degreasing. A 2 g / L sodium dodecylsulfonate solution was prepared, and the pH was adjusted to 9-10 with sodium hydroxide to obtain a degreasing solution. Immerse the carrier copper foil in the degreasing solution at 50°C for 5 minutes, and wash it with water after taking it out;

[0041] (3) In addition to the oxide layer. Immerse the degreased carrier copper foil in 50g / L sulfuric acid solution, remove the surface oxide layer at 50°C for 5min, take it out, wash it with deionized water, and dry it;

[0042] (4) Prepare the mask. Using a commercially available 35 micron thick photosensitive dry film as a mask, the photosensitive dry film is closely attached to the surface of the copper foil, selectively exposed under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com