Alternate use for low viscosity liquids and method to gel liquid

a low-viscosity liquid and gel-liquid technology, applied in the field of photovoltaics and solar cells, can solve the problems of affecting the quality affecting the performance of solar cell substrates, and the spin-on dopant may not be designed to transition through the gel-state, etc., to achieve the effect of enhancing the high-viscosity characteristics of a dopant material and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]In the present specification, an embodiment showing a singular component should not be considered limiting. Rather, the subject matter encompasses other embodiments including a plurality of the same component, and vice-versa, unless explicitly stated otherwise herein. Moreover, applicants do not intend for any term in the specification or claims to be ascribed an uncommon or special meaning unless explicitly set forth as such. Further, the present subject matter encompasses present and future known equivalents to the known components referred to herein by way of illustration.

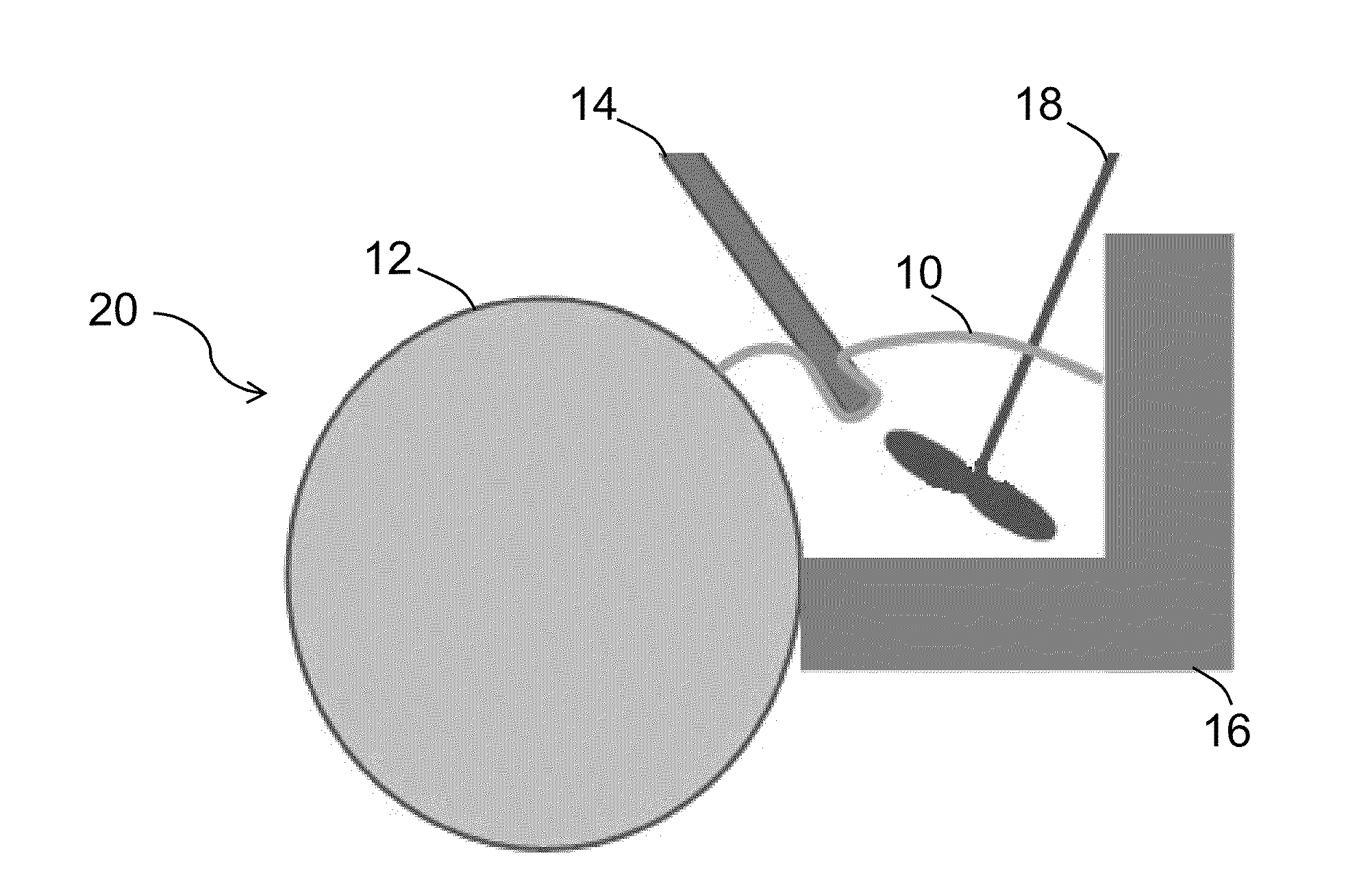

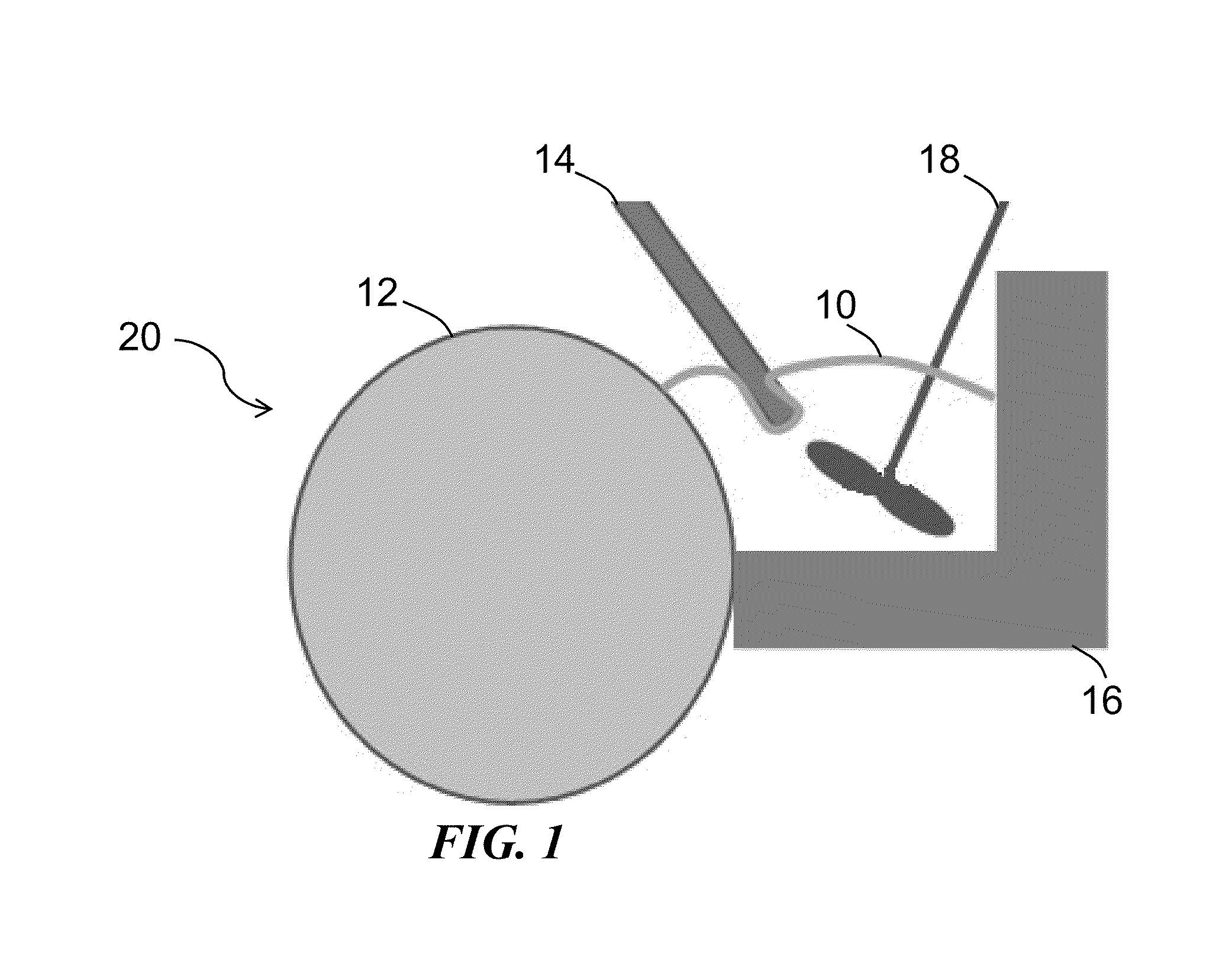

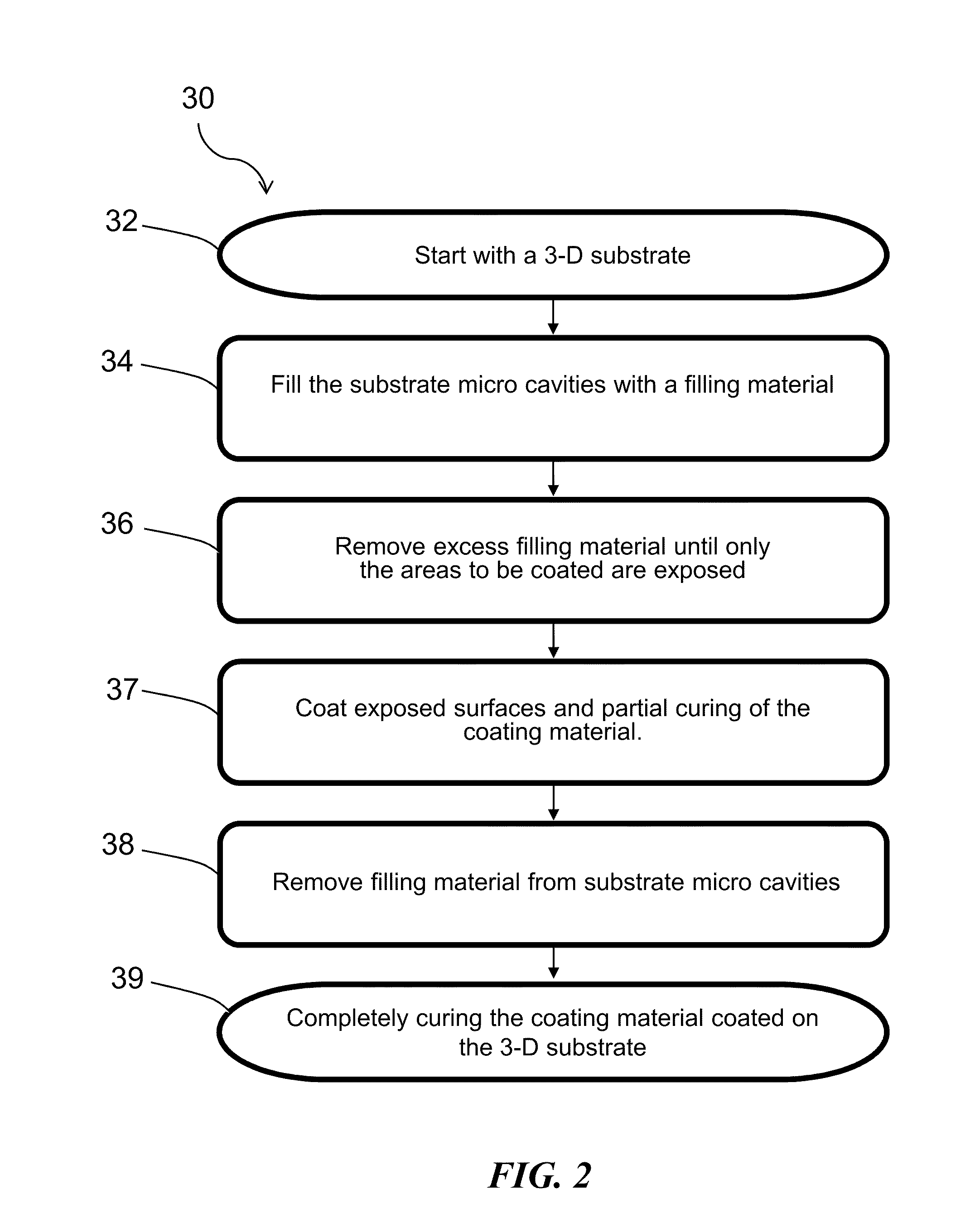

[0019]The subject matter of the present disclosure may be applied in the preparation of a gelatinous dopant material, which could be used, for example, with a solar cell substrate. Such a solar cell substrate is disclosed in the commonly referenced pending U.S. patent application Ser. No. 12 / 193,415 filed Aug. 18, 2008 entitled “METHODS OF LIQUID TRANSFER COATING OF THREE-DIMENSIONAL SUBSTRATES” by invento...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com