A liquid crystal polymer material device

A liquid crystal polymer and equipment technology, applied in the field of liquid crystal polymer material equipment, can solve the problems of inconvenient operation, large installation space, and large number of equipment, and achieve the effects of improving stirring efficiency and facilitating cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

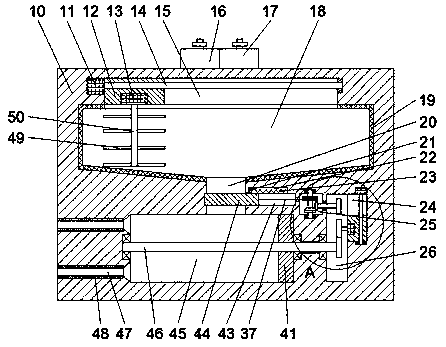

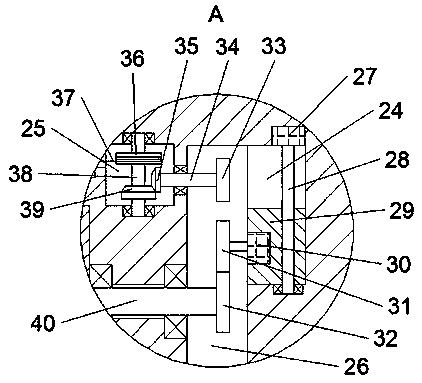

[0016] Such as figure 1 with figure 2 As shown, a liquid crystal polymer material device of the present invention includes a box body 10 and a first cavity 18 and a second cavity 45 sequentially arranged in the box body 10 from top to bottom, and the second cavity The right end of the cavity 45 is provided with a third cavity 26, the left end of the third cavity 26 is provided with a fourth cavity 25 located at the bottom end of the first cavity 18, and the inner wall of the top of the first cavity 18 is communicated with an opening. Downward first guide chute 15, the first guide chute 15 is slidably connected with the first guide slider 12, and the first guide slider 12 is internally threaded with the first threaded rod 14 extending left and right , the extension end of the right end of the first threaded rod 14 is rotationally connected with the inner wall of the right end of the first guide chute 15, and the extension end of the left end of the first threaded rod 14 is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com