Shaft sinking tubular steel derrick

A technology of derrick and steel pipe is applied in the field of shaft engineering construction, which can solve the problem of unsuitable steel pipe derrick for sinking, and achieve the effects of increasing the lifting capacity of a single hook, reducing the time of underground operation, and increasing the over-coil height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

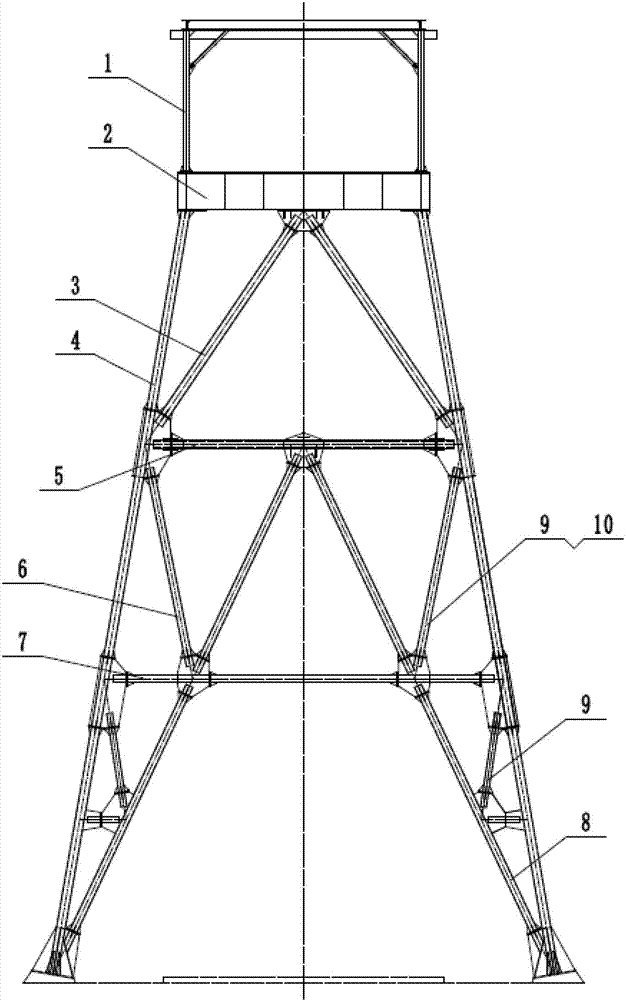

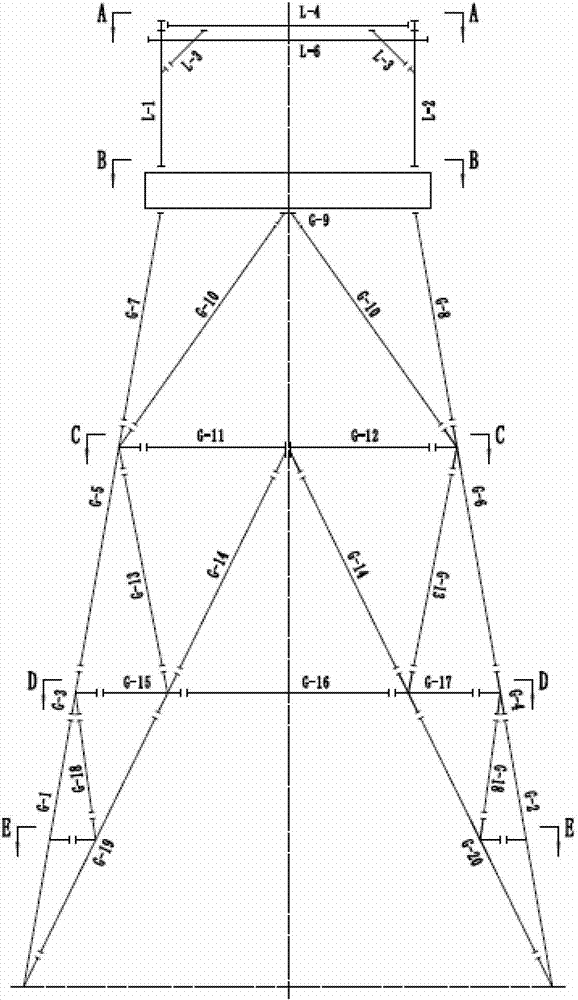

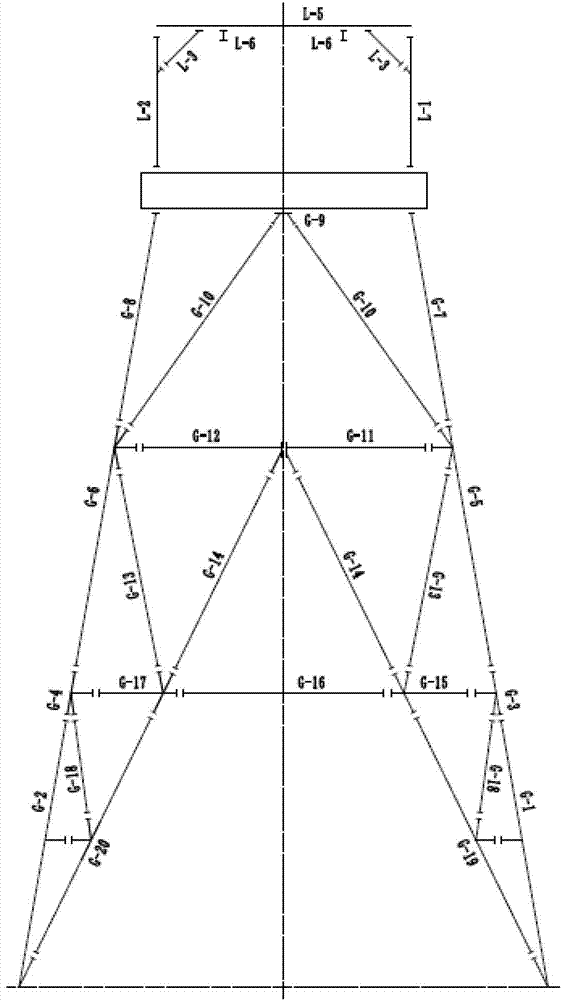

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0042] In order to clearly show the derrick involved in the embodiment and the installation method, the center line of the derrick is drawn in each drawing of this embodiment, which is located at the center of each drawing.

[0043] Such as figure 1 As shown, this embodiment provides a sinking steel pipe derrick, which is fixed on the foundation of the derrick, and includes a sky wheel house 1, a sky wheel platform 2, a sky wheel platform support bar 3, a main support bar 4, a middle Platform 5, middle platform support bar 6, turning gangue platform 7, turning gangue platform support bar 8 and turning gangue platform boom 10, the sky wheel house 1 is fixed on the sky wheel platform 2:

[0044] The structural shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com