Nodular cast iron pipe curing pool system

A technology for ball-milling cast iron and cast pipes, which is applied to load hanging components, ceramic molding machines, manufacturing tools, etc., can solve the problems of easy shaking, long lifting time of ball-milling cast pipes, affecting health effects, etc., and achieves short lifting and transport time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

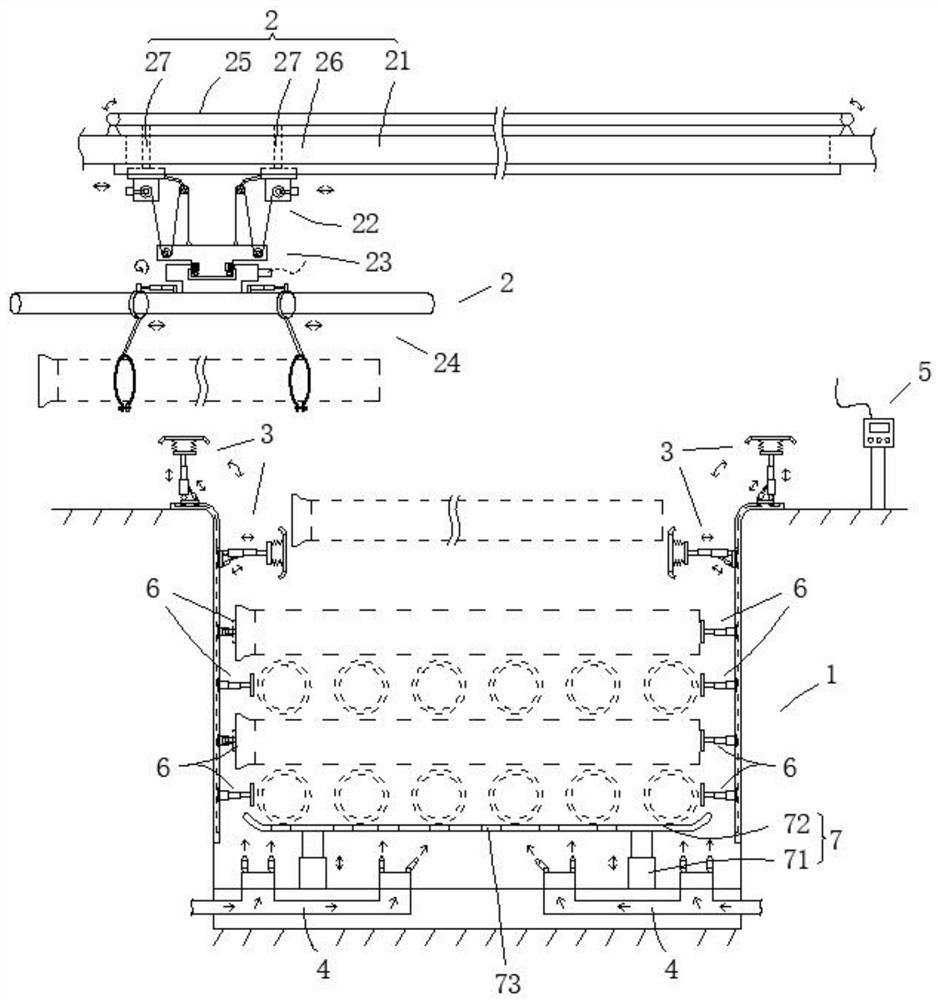

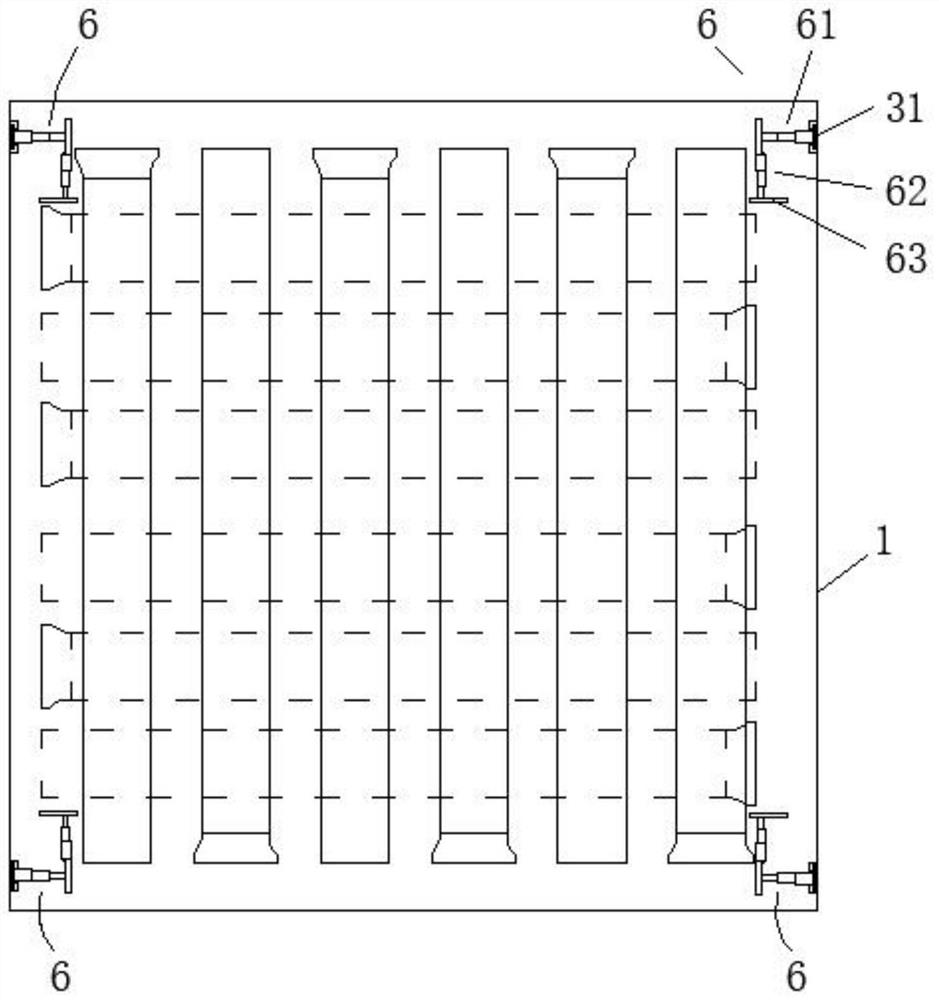

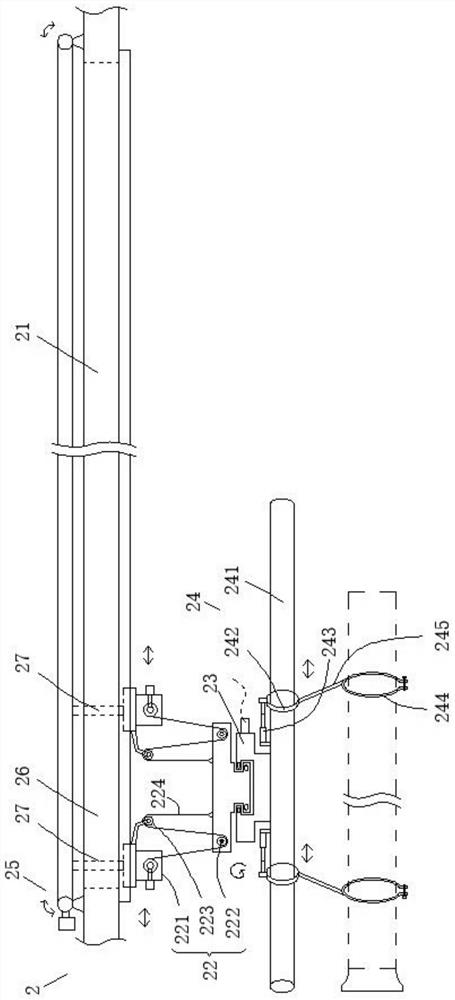

[0038] As a specific implementation of a ball mill cast iron pipe health pool system provided by the present invention, please refer to Figure 1 to Figure 6 The hoisting mechanism 2 includes a hoisting rail 21, a hoisting assembly 22, a rotating assembly 23 and a grasping assembly 24, the hoisting rail 21 is arranged horizontally above the health pool 1; there are multiple hoisting assemblies 22, all of which are slidingly arranged at the lower end of the hoisting rail 21, It can be lifted and lifted. Multiple lifting components 22 are controlled by the control mechanism 5. The lifting components 22 are provided with a driver 25 for driving the lifting components 22 to slide. The driver 25 is controlled by the control mechanism 5; the rotating component 23 is located at the lower end of the lifting component 22 And can lift by means of the lifting assembly 22, the rotating assembly 23 can rotate circumferentially in the horizontal plane, the rotating assembly 23 is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com