How to use the fast hoisting steel truss member

A technology for steel truss beams and rods, which is applied in the field of rapid hoisting of steel truss beams and members, can solve the problems of many auxiliary personnel, offset of the center of gravity of steel truss beams and members, and high cost, so as to achieve fewer cooperating operators and reduce construction costs. , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

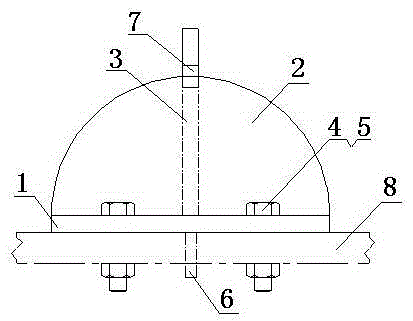

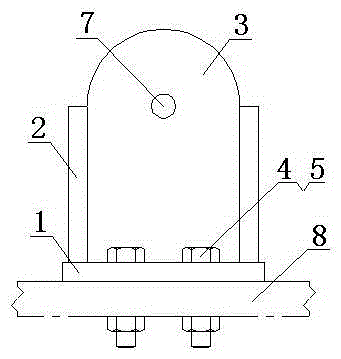

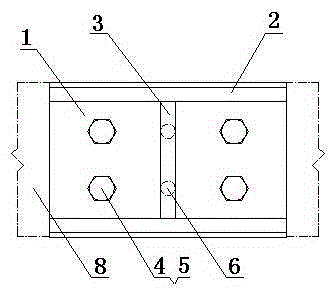

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0019] The technical scheme of the special spreader of the present invention is:

[0020] The side vertical plates (2) are respectively fixed on both sides of the flat bottom plate (1), the horizontal splint (3) is fixed in the middle of the side vertical plate (2), and two bolt holes are respectively opened on the flat bottom plates on both sides of the horizontal splint (3) ( 4), the fixing bolt (5) is installed in the bolt hole (4), and two positioning pins (6) are fixed under the flat bottom plate (1), and the distance between the two bolt holes (4) and the two positioning pins (6) is respectively It is completely consistent with the bolt hole spacing on the steel truss beam member (8) to be hoisted, and the upper part of the transverse splint (3) is provided with a hoisting hole (7);

[0021] Steel truss beam member (8) weight is less than 20 tons, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com