Integrally moving on-load hydraulic lifting system without mooring rope and lifting method

A technology of hydraulic lifting and cable wind rope, which is applied in the direction of load block, load suspension components, trolley cranes, etc., can solve the problems of difficulty and construction constraints, and achieve the effect of saving hoisting costs and safe and stable hoisting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

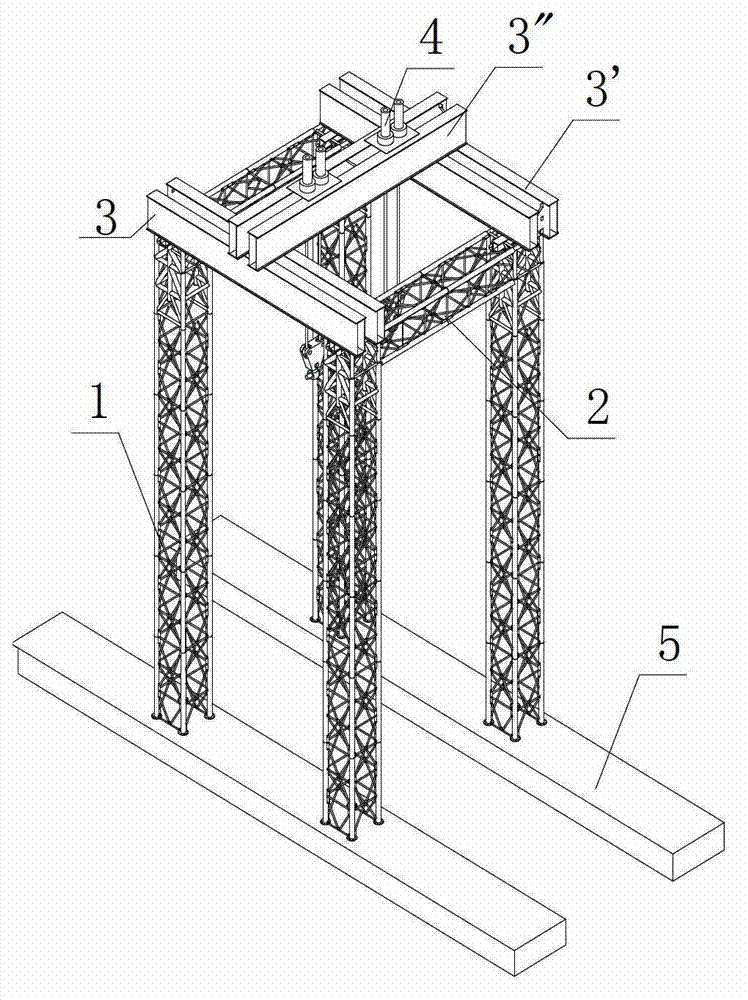

[0022] The present invention proposes an integrated mobile hydraulic lifting system with a cable-free wind rope, such as figure 1 As shown, the system includes two parallel running rails 5 and four tower columns 1, the two running rails 5 are fixed on the ground, the bottom of the tower column 1 is set in the running rails 5, and the tower The column 1 can slide along the running track 5 . Two of the tower columns 1 are arranged on one running track, and the other two tower columns 1 are correspondingly arranged on the second running track. The tops of the tower columns arranged on the same running track are respectively connected by the first hoisting beam 3 and the second hoisting beam 3'. The tower columns arranged on the two running tracks correspond to each other, and the tops of the tower columns 1 corresponding to each other are respectively connected by tower connecting beams 2 . The tower column 1 and the tower connecting beam 2 form a frame structure tower. The fi...

Embodiment 2

[0032] In this embodiment, the third hoisting beam is fixed on the upper surfaces of the first hoisting beam and the second hoisting beam, and there is no need to arrange rails on the upper surfaces of the first hoisting beam and the second hoisting beam.

[0033] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com