Method for realizing eccentric hoisting by matching crane and hoisting frame

A lifting frame and crane technology, applied in the direction of load hoisting components, transportation and packaging, can solve the problems of limited crane station, narrow site, and inability to complete hoisting operations, so as to save hoisting costs and achieve a safe and stable hoisting process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

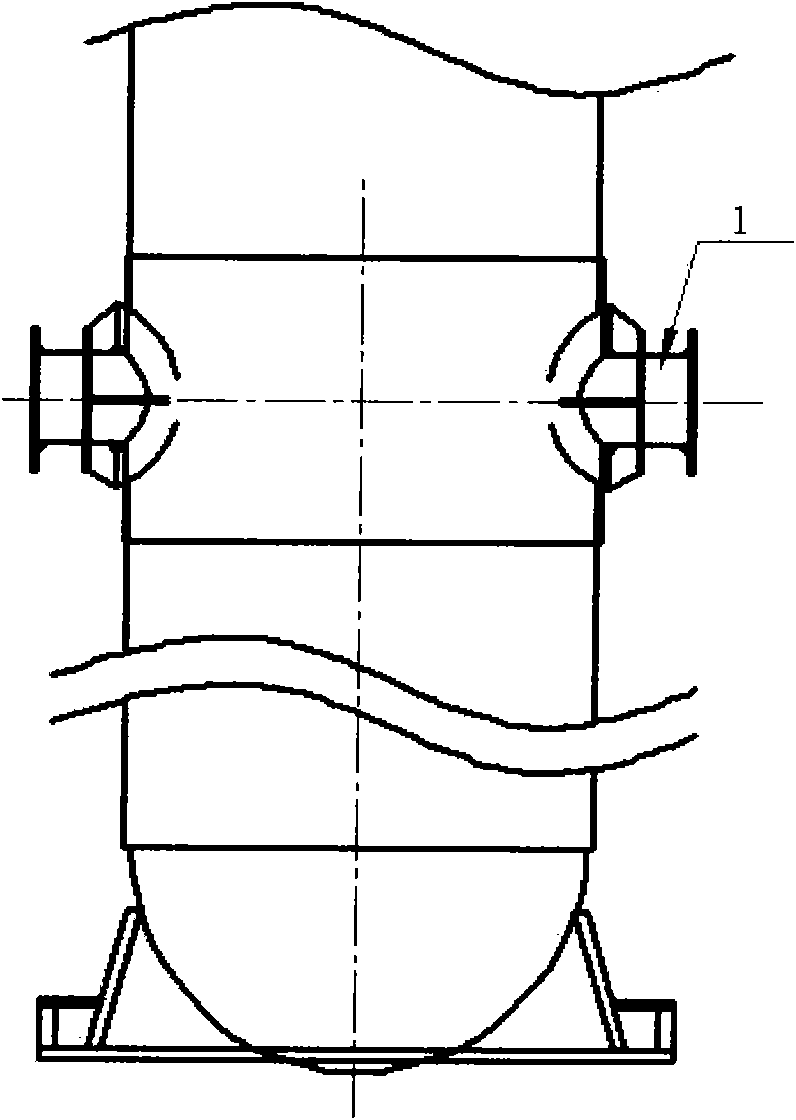

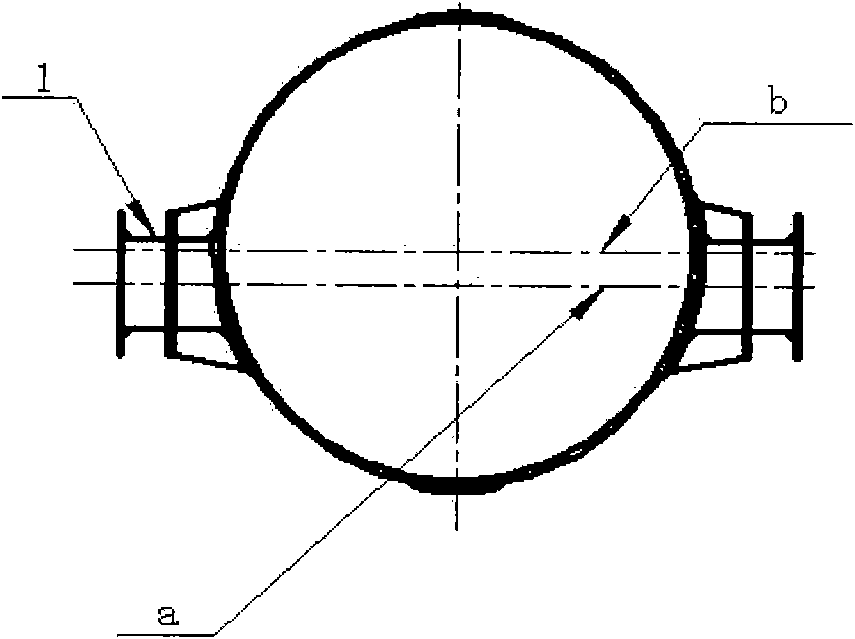

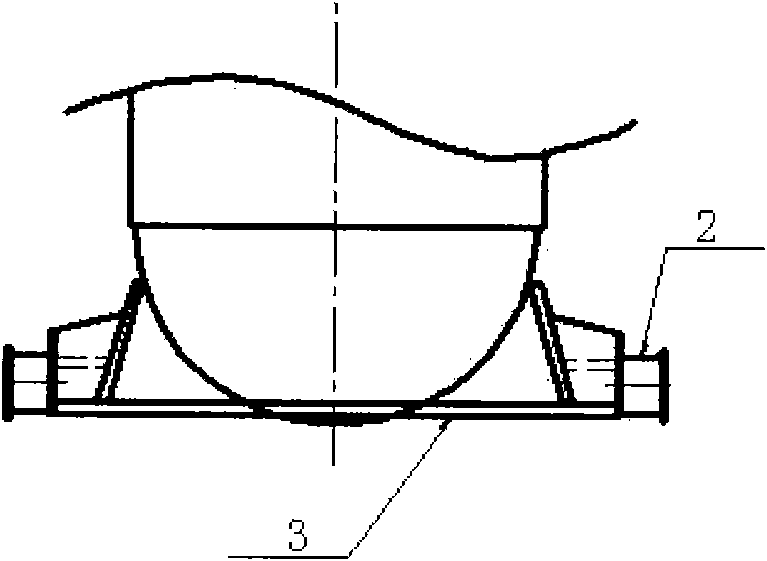

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] The present invention proposes an eccentric hoisting method in cooperation with a crane and a hoisting frame. The method includes the following steps:

[0024] The first step is to make the lifting frame. According to the hoisting capacity of the crane, carry out the load sharing calculation, determine the positions of the main hoisting point and the tail hoisting point, calculate the hoisting capacity of the hoisting frame, and design the hoisting frame.

[0025] The second step is to set up the lifting frame. A pair of lifting frames are respectively erected near the equipment installation foundation, and the two lifting frames are arranged symmetrically with respect to the center of the equipment installation foundation; the lifting frame is designed according to the mast principle: the top of the lifting frame is equipped with a main hoist block, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com