Turnover hoisting method for gantry structure of stockyard stacker-reclaimer

A hoisting method and reclaimer technology, which are applied in the field of hoisting and overturning, can solve problems such as unstable hoisting of the gantry structure of a stacker and reclaimer in a material yard, and achieve the effects of reducing overall planning of resources, preventing equipment deformation, and avoiding dynamic loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

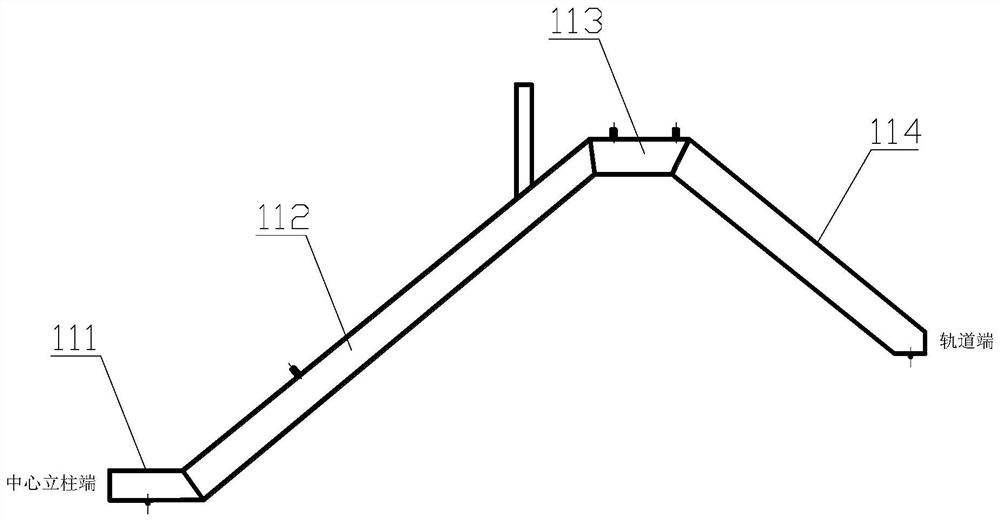

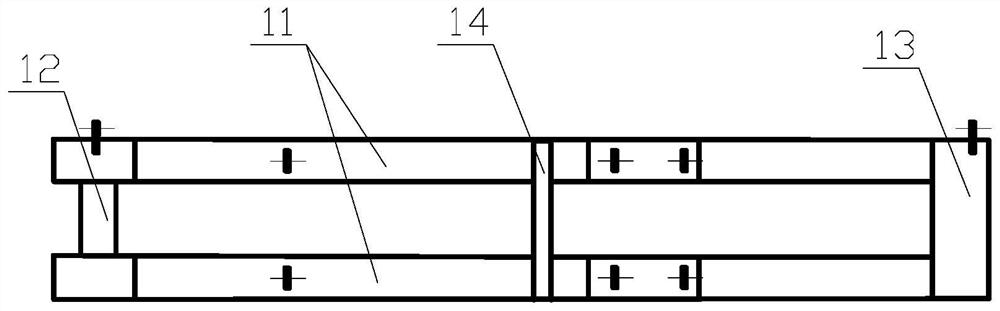

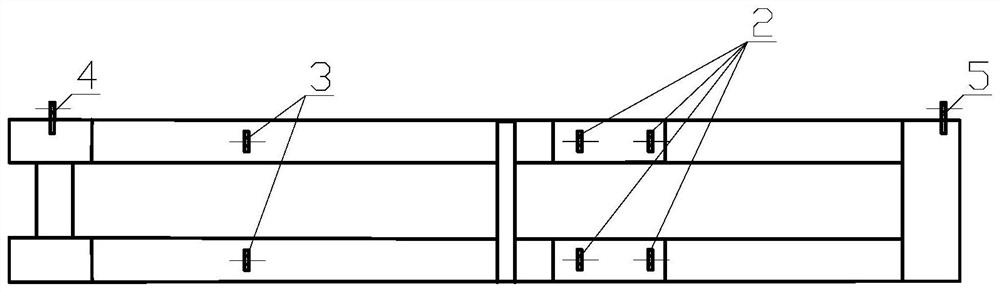

[0035] Such as figure 1 with figure 2 As shown, the stockyard stacker-reclaimer gantry structure 1 includes two single beams 11 arranged side by side in parallel according to a certain distance, and the first connecting beam 12, the second connecting beam 13, and the third connecting beam 11 are passed between the two single beams 11. The connecting beams 14 are connected, and the first connecting beam 12 , the second connecting beam 13 and the third connecting beam 14 are all perpendicular to the two single beams 11 . Wherein the first connecting beam 12 is arranged on the central column end of the stacker-reclaimer gantry structure 1 in the stockyard, the second connecting beam 13 is arranged on the track end of the stacker-reclaimer gant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com