Fabricated building construction hoisting device

A technology for building construction and hoisting devices, which is applied in the direction of safety devices, transportation and packaging, load hanging components, etc., and can solve problems such as unstable connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

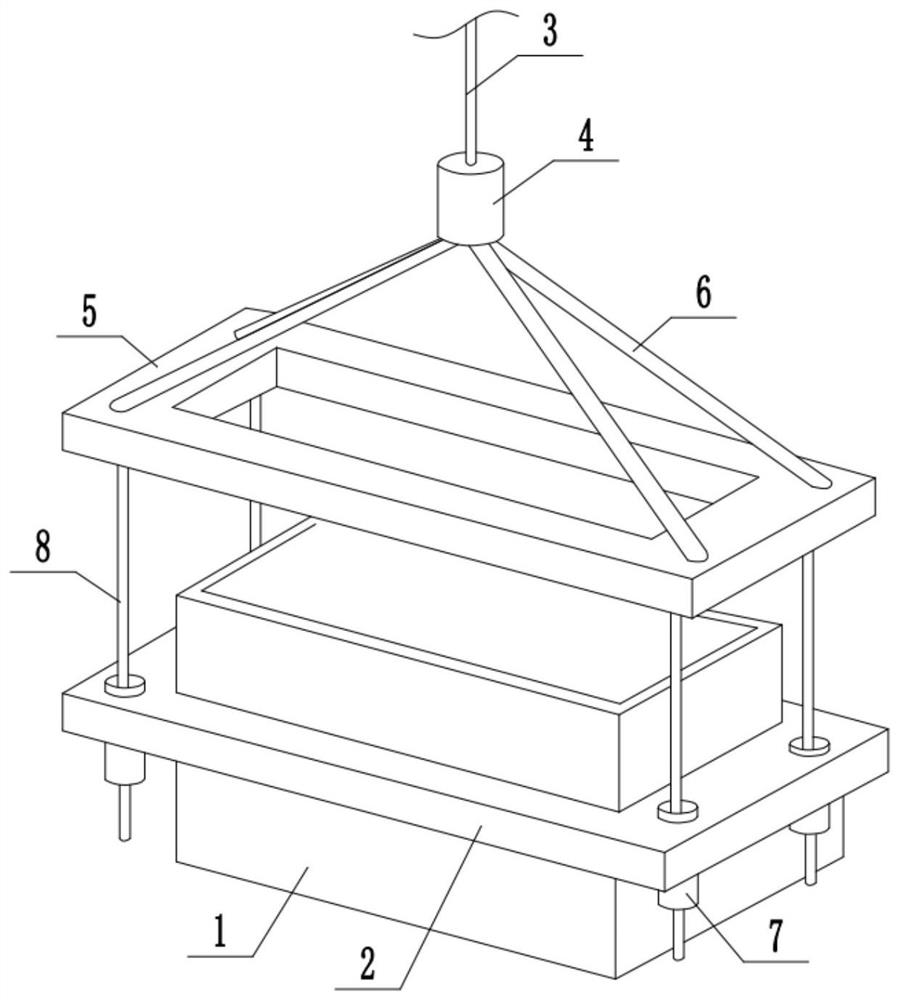

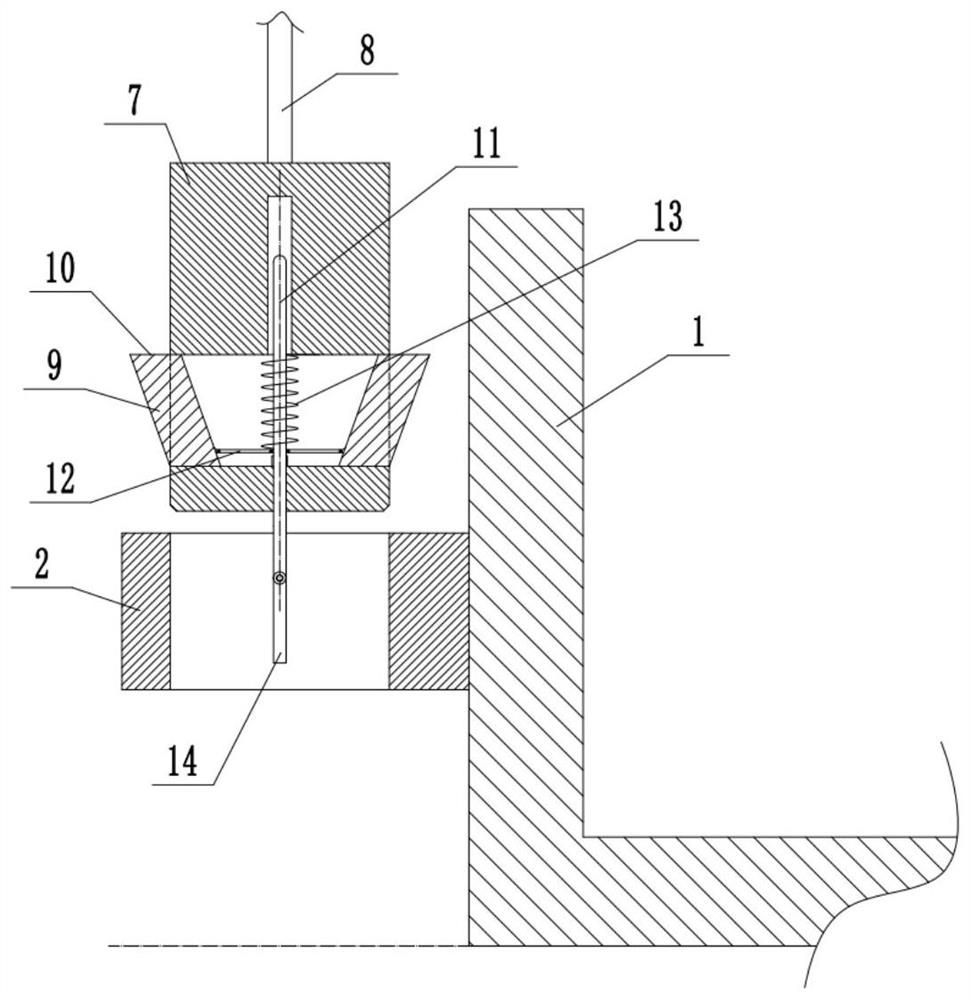

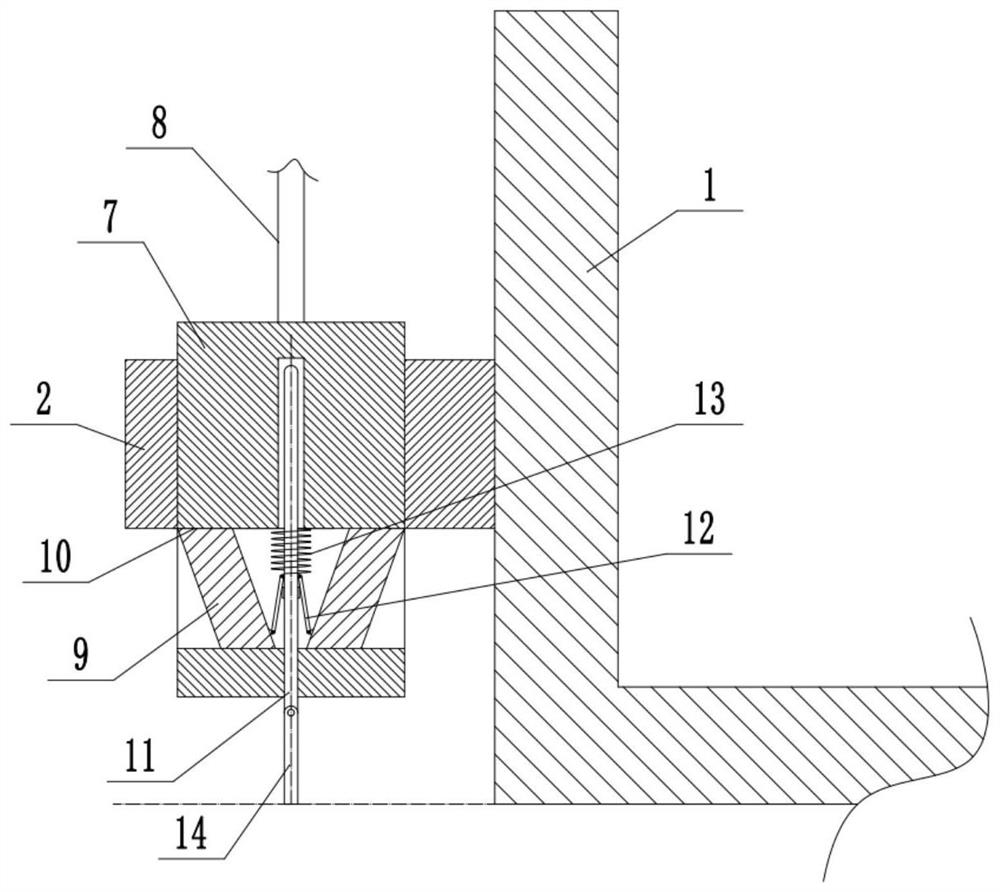

[0034] Embodiment one is basically as attached figure 1 Shown: a prefabricated building construction hoisting device, including a load-bearing frame 1 in a square hanging basket structure. The top of the hoisting mechanism is provided with a hoisting mechanism. In this embodiment, the hoisting mechanism includes a hoisting rope 3 and a hoisting head 4 fixedly connected to the bottom end of the hoisting rope 3. A square suspension frame 5 is provided below the hoisting head 4. The top of the suspension frame 5 is located at Steel wire rope 6 is fixedly connected with the lifting head 4 on the four corners, and by pulling the lifting rope 3 vertically, the wire rope 6 can be used to pull the suspension frame 5 to move in the vertical direction.

[0035] A hoisting assembly is connected between the suspension frame 5 and the load-bearing frame 1, the number of the hoisting assemblies is four and the four hoisting assemblies correspond to the four corners of the bottom of the suspen...

Embodiment 2

[0044] The difference between embodiment two and embodiment one is: as Figure 6 As shown, there is a first chamfer 15 at the bottom of the insertion slot, and the first chamfer 15 can guide the load-bearing surface 10 of the support block 9 to slide back into the insertion slot; meanwhile, on the support block 9 top surface There is a second chamfer 16 near the outside to avoid the thickness of the top surface of the support block 9 near the edge from being too small. When the load-bearing surface 10 is used to support the load-bearing frame 1, if the load-bearing surface 10 gradually slides into the fixing groove, when the load-bearing When the contact area between the surface 10 and the bottom surface of the load-bearing flange 2 is small, it may cause fracture at the top outer edge of the support block 9, but in this embodiment, by setting the second chamfer 16, the load-bearing surface 10 can be separated from the load-bearing flange 2. , the top edge of the support block...

Embodiment 3

[0046] The difference between the third embodiment and the second embodiment is that, in order to make the push rod 14 automatically rotate to the vertical state after the hoisting device is hoisted and keep the vertical state all the time, the bottom end of the push rod 14 is fixed by screws in this embodiment. A counterweight is connected, and the push rod 14 is pulled to a vertical state by the gravity of the counterweight, and the contact area between the counterweight and the ground is large, and when the hoisting device falls on the ground, it is convenient to stably push the push rod 14 and The slide bar 11 slides vertically upwards, so that the hoisting assembly is more stably separated from the load-bearing frame 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com