Post-cast strip supporting structure and construction method thereof

A support structure and construction method technology, applied in the field of building support, can solve the problems of post-cast belt damage, inadequate management, long construction period, etc., and achieve the effects of saving construction period and labor, facilitating chisel cleaning, and improving turnover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A construction method for a post-cast belt support structure, comprising the following steps:

[0043] S01: material selection, select materials for the support tube 1 and the head plate 2 according to the actual situation;

[0044] Among them, the support pipe 1 selects a large-diameter steel pipe with a diameter of 200mm and a wall thickness of 3mm and a large-diameter steel pipe with a diameter of 100mm and a wall thickness of 3mm, and the head plate 2 selects a steel plate with a specification of 250*250 and a thickness of 10mm and 150 *150 gauge steel plate with a thickness of 10mm;

[0045] The selected material is tested by a vernier caliper, and the wall thickness deviation of the support tube 1 is ±12.5%; the raw material is re-inspected on site, and can only be used if it is qualified.

[0046] S02: Determine the position, calculate the position of the pre-embedded support pipe 1 through field investigation, set a support pipe 1 with a diameter of 200mm at th...

Embodiment 2

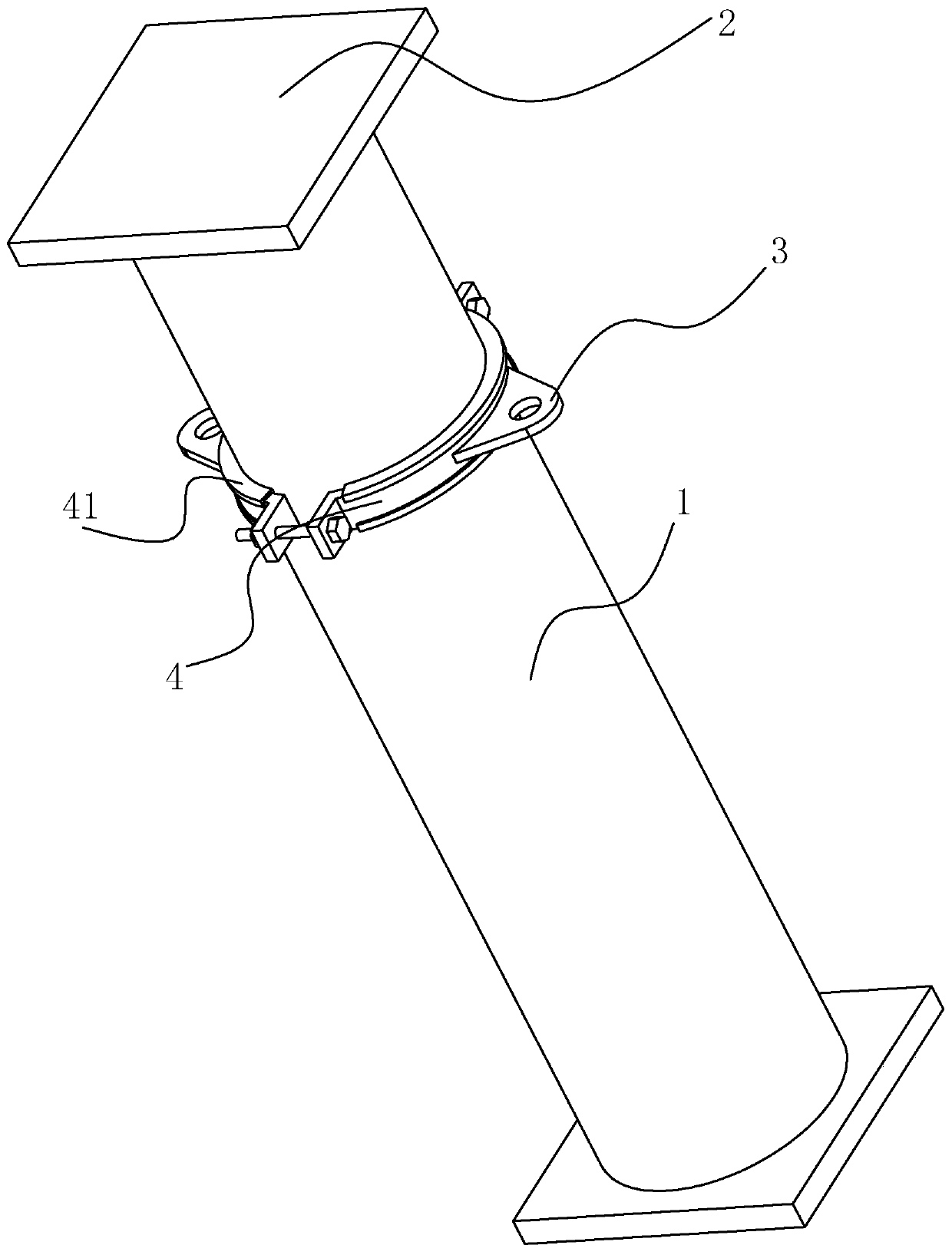

[0056] A post-cast belt support structure, refer to figure 1 , including several different types of support tubes 1, the two ends of the support tube 1 are welded with head plates 2; the support tube 1 is respectively selected from a large-diameter steel pipe with a diameter of 200 mm and a wall thickness of 3 mm and a steel pipe with a diameter of 100 mm and a wall thickness of 3 mm. For the large-diameter steel pipe, the head plate 2 is selected from a steel plate with a specification of 250*250 and a thickness of 10 mm and a steel plate with a specification of 150*150 and a thickness of 10 mm.

[0057] The support tube 1 is symmetrically provided with lifting lugs 3, and the two lifting lugs 3 are welded with hoops 4, the lifting lugs 3 are located on the outer wall of the hoops 4, the hoops 4 are set on the support tube 1, and the hoops 4 It is arranged as a gap fit with the support tube 1, and the edge of the hoop 4 is sleeved with a protective strip 41. The protective st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com