Finished product building block overturning table

A technology of turning tables and blocks, applied in ceramic molding machines, auxiliary molding equipment, lifting devices, etc., can solve problems such as lack of methods, and achieve the effect of improving turning efficiency, accurate action and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

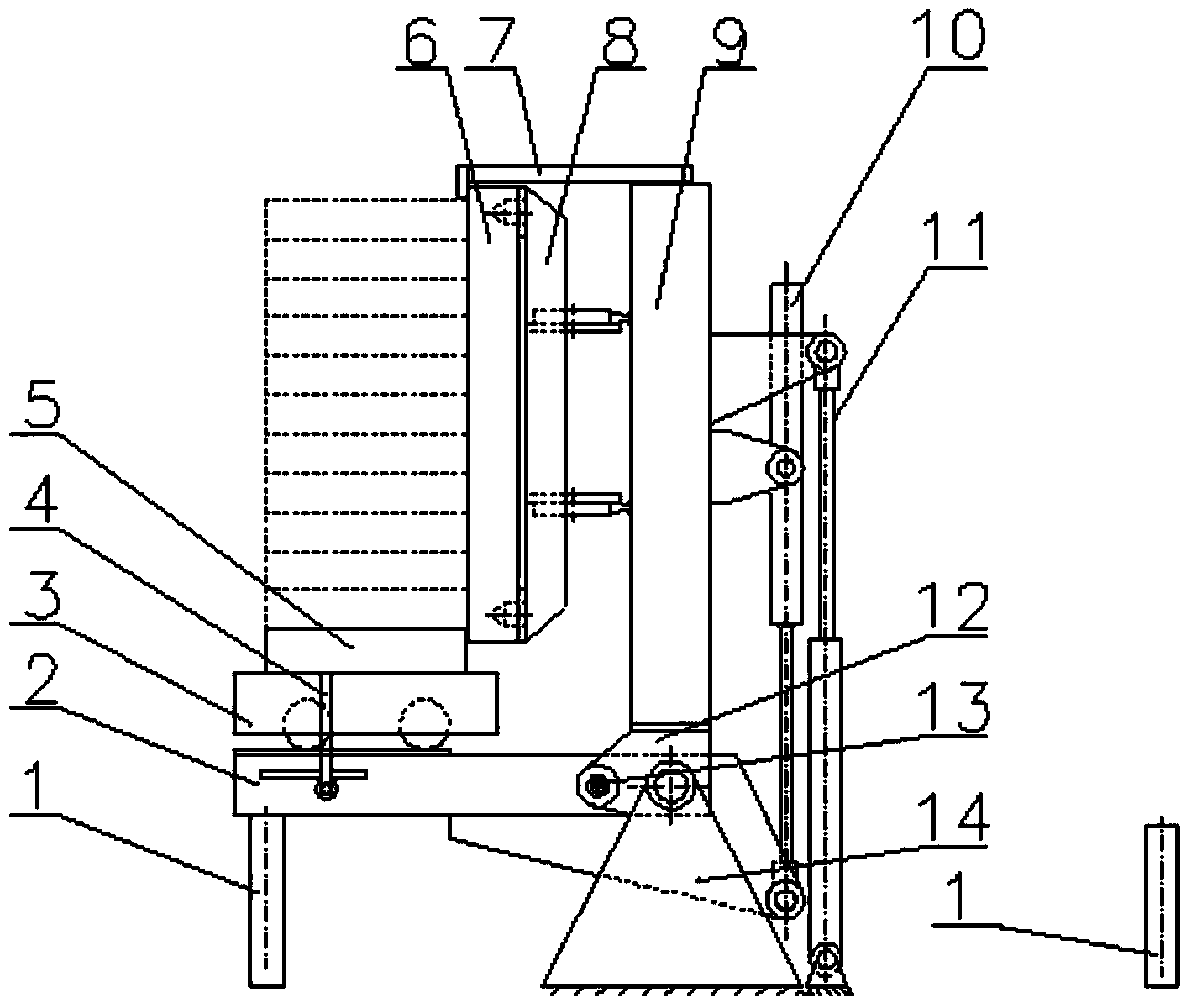

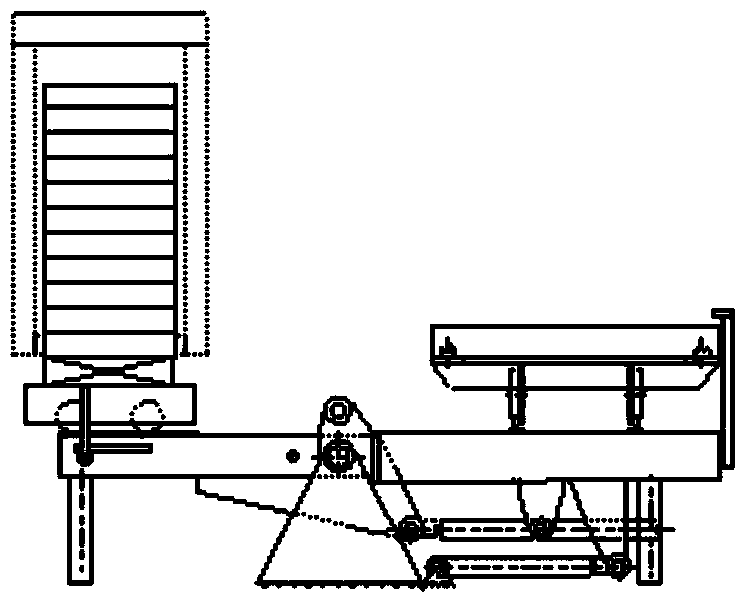

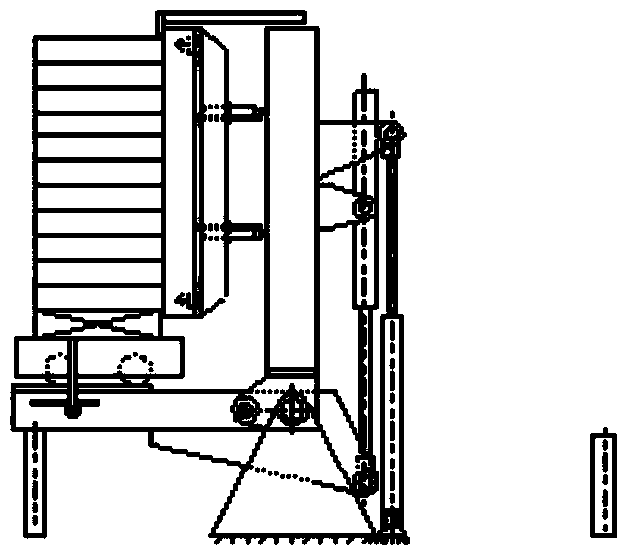

[0032] Such as figure 1 The expressed structure of the present invention is a finished block turning platform. The invention belongs to the field of aerated concrete block turning tables, in particular to the field of aerated concrete finished block turning tables.

[0033] In order to solve the problems existing in the prior art and overcome its defects, realize the purpose of the invention that the aerated concrete block is turned over 90° after being discharged from the kettle, and the recycling utilization of the steam-cured flat plate is carried out. The technical scheme adopted by the present invention is:

[0034] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com