Hoisting structure and hoisting method for prefabricated panel with high height-thickness ratio

A technology of prefabricated wall panels and hoisting methods, which is applied in the direction of clockwork mechanism, hoisting device, transportation and packaging, etc., can solve the problems of increased hoisting weight, prone to rollover, and poor hoisting safety, so as to improve safety and Stability, improvement of accuracy and safety, safe and stable hoisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

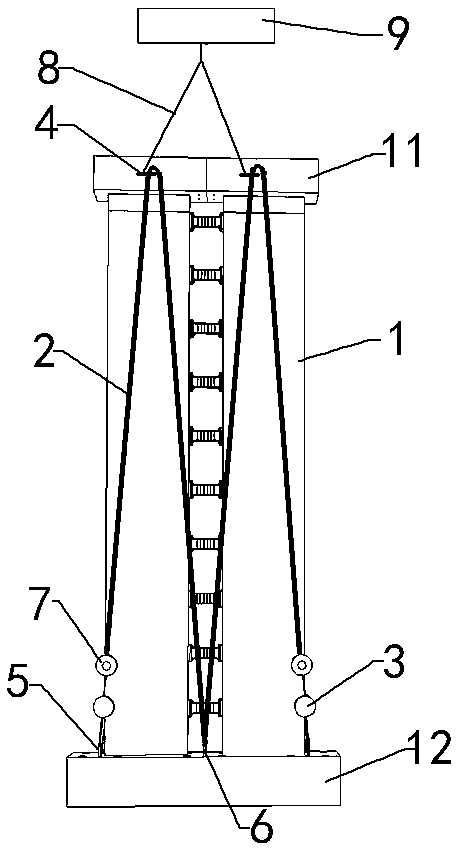

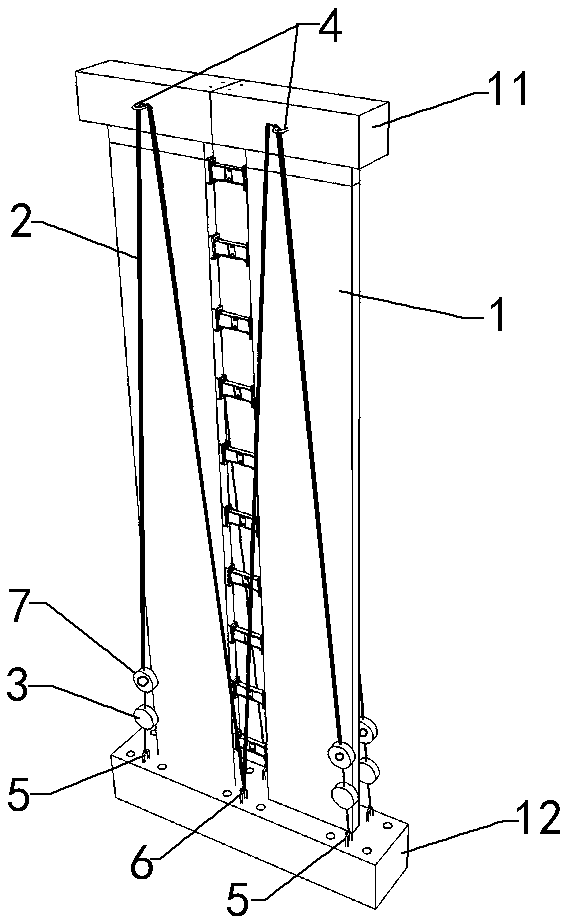

[0035] like figure 1 and figure 2 As shown, the hoisting structure of the prefabricated wallboard with a large height-thickness ratio of the present invention is suitable for the hoisting of the prefabricated wallboard 1 with a height-thickness ratio greater than 30, including the pretensioning device arranged on the prefabricated wallboard 1 and the lifting equipment for the prefabricated wallboard 1 9.

[0036] The pre-tightening devices are respectively arranged on the opposite side panels of the prefabricated wall panel 1, and the pre-tightening devices on the same side panels include two sets of pre-tightening units arranged horizontally side by side, and the two sets of pre-tightening units are symmetrically arranged along the mid-perpendicular line of the panel ; Each group of pre-tightening units includes a pre-tightening rope 2, a chain block 3, a first suspension ring 4 arranged on the top beam 11 of the prefabricated wall panel 1, a second suspension ring 5 arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com