Assembled combining structure and mounting method thereof

A combined structure and prefabricated technology, applied in building construction, construction, building materials processing and other directions, can solve the problems of manpower and material resources, poor living comfort, slow development, etc., saving manpower, simple construction and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

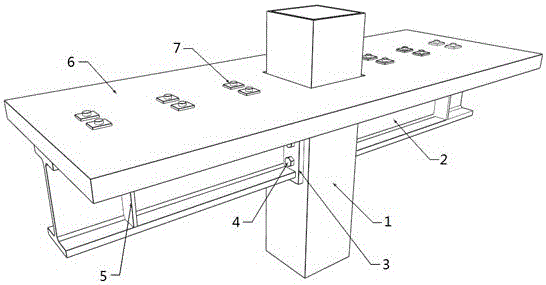

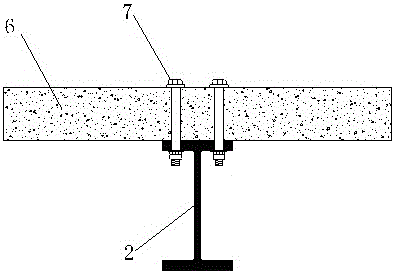

[0022] Embodiment one: if Figure 1~2 As shown, a prefabricated composite structure includes a steel pipe concrete composite column 1, the composite column 1 is composed of a steel pipe and concrete filled in the steel pipe, the side wall of the composite column is provided with an I-shaped steel beam 2, the The steel beam 2 is provided with a reinforced concrete slab 6, and the reinforced concrete slab 6 is provided with a through hole for the composite column 1 to pass through, and the reinforced concrete slab 6 is fixedly connected to the steel beam through several bolted shear connectors 7 2 on the upper flange.

[0023] In this embodiment, the cross section of the steel pipe is rectangular.

[0024] In this embodiment, the side wall of the steel pipe is connected with a flat end plate 3 by bolts 4, and the end of the steel beam is welded on the flat end plate.

[0025] In this embodiment, the reinforced concrete slab is not in contact with the composite column, and ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com