Polymer composite fireproof-type dry powder mortar smoke exhaust duct and preparation method of base material thereof

A technology of polymers and exhaust ducts, applied in vertical pipes, building structures, building components, etc., can solve problems such as irregular models, different materials used by manufacturers, disrupting the market, etc., and achieve high flexural strength and high viscosity The effect of high knot strength and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail according to the examples below.

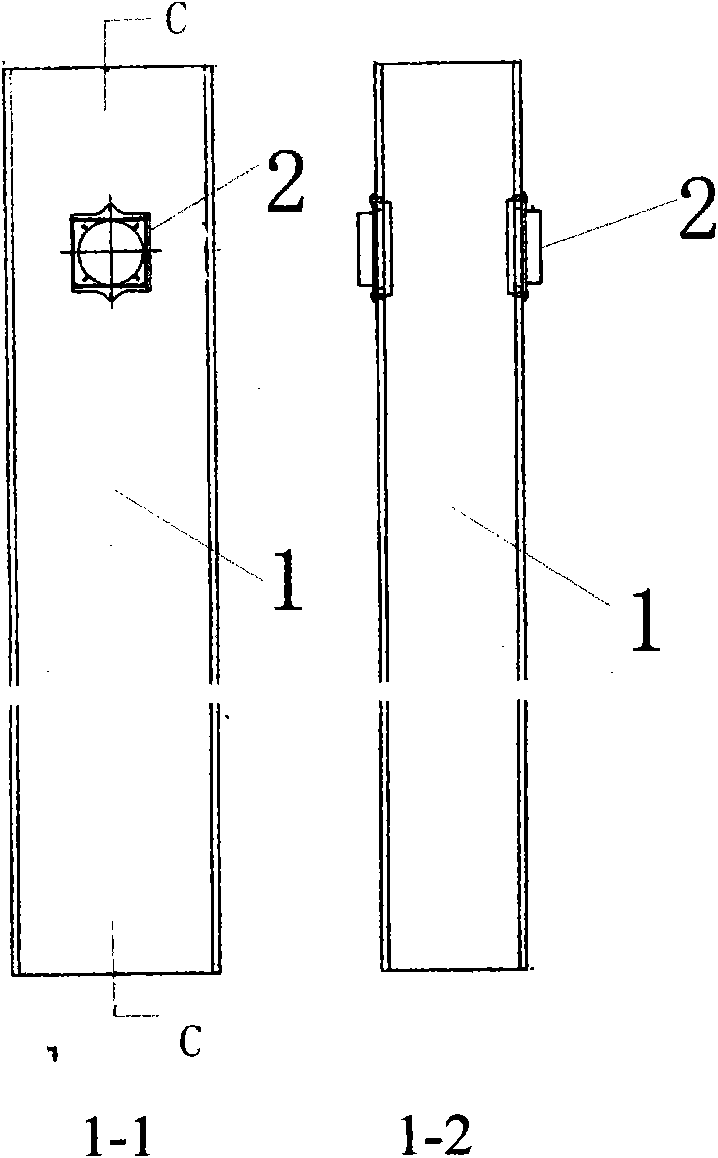

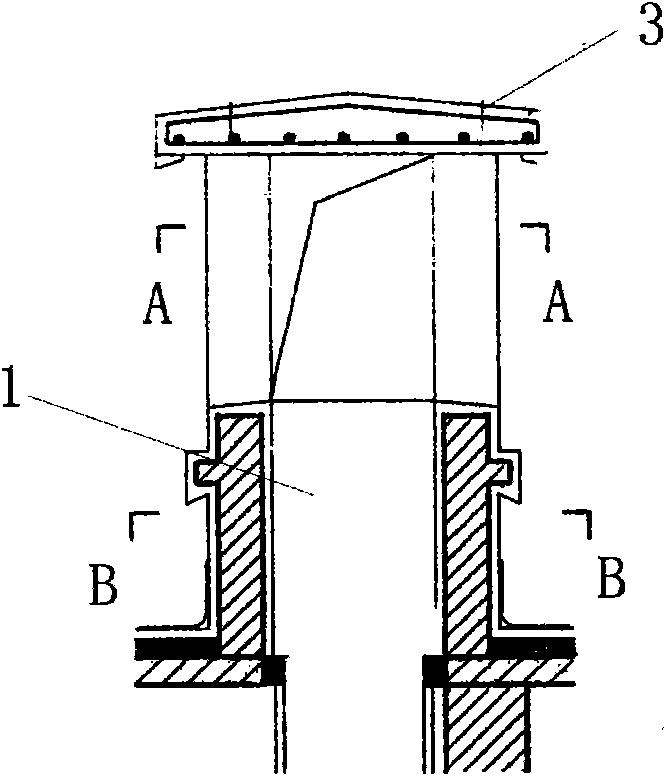

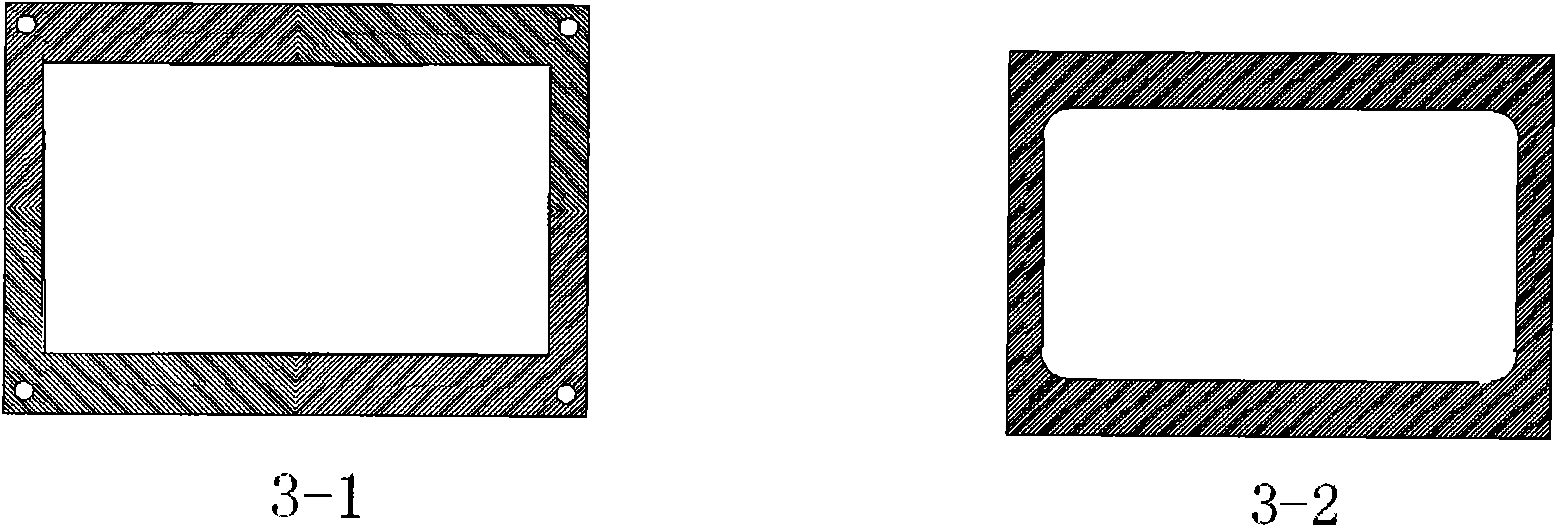

[0013] Such as Figure 1~3 As shown, the polymer composite fireproof smoke exhaust duct is composed of a range hood or exhaust fan, a fire check valve 2 and a roof hood 3 . The fire check valve 2 is arranged on the outer, middle and upper part of the exhaust duct 1, and is connected with the range hood or the exhaust fan, and the roof air cap 3 is arranged on the upper end of the exhaust duct 1. The roof hood can also be designed as a round cap.

[0014] The fire check valve 2 can prevent the flue gas from flowing back, and its valve is detachable, which is convenient for cleaning oil. At the same time, it can effectively prevent the high-temperature smoke from spreading to other floors in the event of a fire.

[0015] The preparation method of the polymer composite fire-proof flue gas duct base material is to use 35% cement, 17% sand, 22% sub-stone as aggregate, and 1.5% epo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com