Mixed sand and its preparation method and application

A technology of mixed sand and natural sand, applied in the chemical industry, can solve the problems of low product strength in the early stage, uncontrollable mortar quality, low mortar strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The present invention also provides a kind of preparation method of above-mentioned mixed sand, comprises the following steps:

[0077] The tailings, machine-made sand and natural sand are mixed.

[0078] The present invention also provides the application of the above-mentioned mixed sand. The technical solution is as follows:

[0079] A dry-mixed mortar prepared from raw materials comprising the following mass percentages:

[0080]

[0081] In one embodiment, the filler is fly ash. Fly ash mainly contains silicon dioxide (SiO 2 ), alumina (Al 2 o 3 ) and iron oxide (Fe 2 o 3 ). (1) Fly ash has a water-reducing effect, so it can reduce the water demand of mortar; the morphological effect and micro-aggregate effect of fly ash can improve the compactness, fluidity and plasticity of mortar, and reduce bleeding and segregation; The setting time of the mortar. After the fly ash is added, the mortar becomes sticky and soft, not easy to bleed, and easy to wipe, w...

Embodiment 1

[0123] This embodiment provides a mixed sand and its preparation method, dry-mixed mortar and its preparation method.

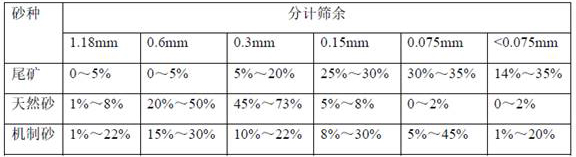

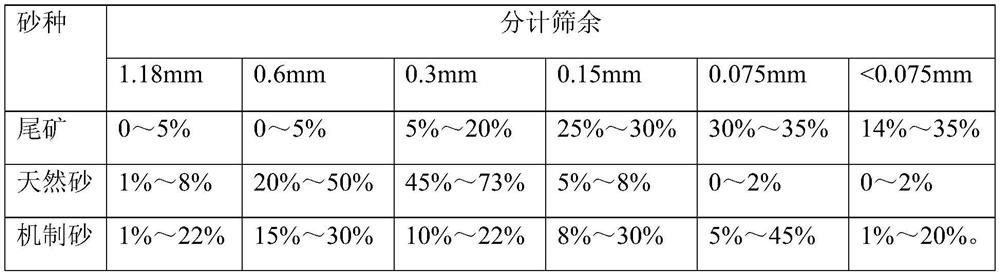

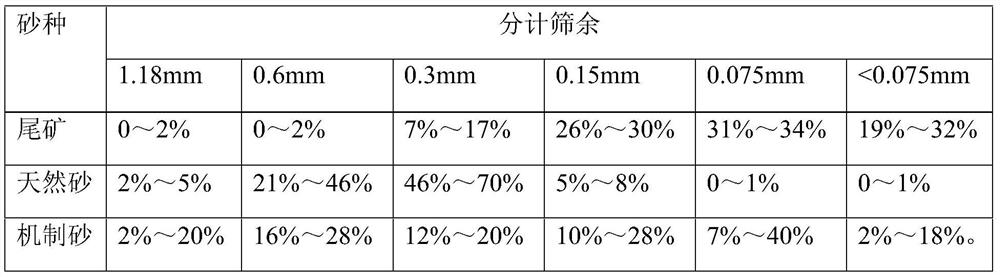

[0124] (1) Composition of mixed sand: see Table 1.

[0125] (2) Preparation of mixed sand: according to the composition ratio in Table 1, directly mix tailings, natural sand and machine-made sand evenly to obtain mixed sand.

[0126] (3) In terms of mass percentage, the composition of dry-mixed mortar is as follows:

[0127] Dry material: 9% cement, 30% fly ash, 10% bentonite, 51% mixed sand; additives: 0.02% by mass of dry material, composed of 0.005% cellulose ether, 0.01% amylase, water reducing Agent 0.005%.

[0128] (4) Preparation of dry-mixed mortar:

[0129] Cement, fly ash, lubricant and auxiliary agent (comprising cellulose ether, suspending agent and water reducer) in the dry material are dosed according to the proportioning ratio, and mixed to obtain mixture A;

[0130] Mix the mixed sand in the dry material with the mixture A, and stir evenly...

Embodiment 2

[0132] This embodiment provides a mixed sand and its preparation method, dry-mixed mortar and its preparation method.

[0133] (1) Composition of mixed sand: see Table 1.

[0134] (2) Preparation of mixed sand: according to the composition ratio in Table 1, directly mix tailings, natural sand and machine-made sand evenly to obtain mixed sand.

[0135] (3) In terms of mass percentage, the composition of dry-mixed mortar is as follows:

[0136] Dry material: 9% cement, 30% fly ash, 10% bentonite, 51% mixed sand; additives: 0.02% by mass of dry material, composed of 0.005% cellulose ether, 0.01% amylase, water reducing Agent 0.005%.

[0137] (4) Preparation of dry-mixed mortar:

[0138] Cement, fly ash, lubricant and auxiliary agent (comprising cellulose ether, suspending agent and water reducer) in the dry material are dosed according to the proportioning ratio, and mixed to obtain mixture A;

[0139] Mix the mixed sand in the dry material with the mixture A, and stir evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com