Moment hoisting method for three connecting rods of gantry crane

A portal crane and three-link technology, applied in cranes and other directions, can solve the problem of high hoisting costs, achieve the effects of saving hoisting costs and reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

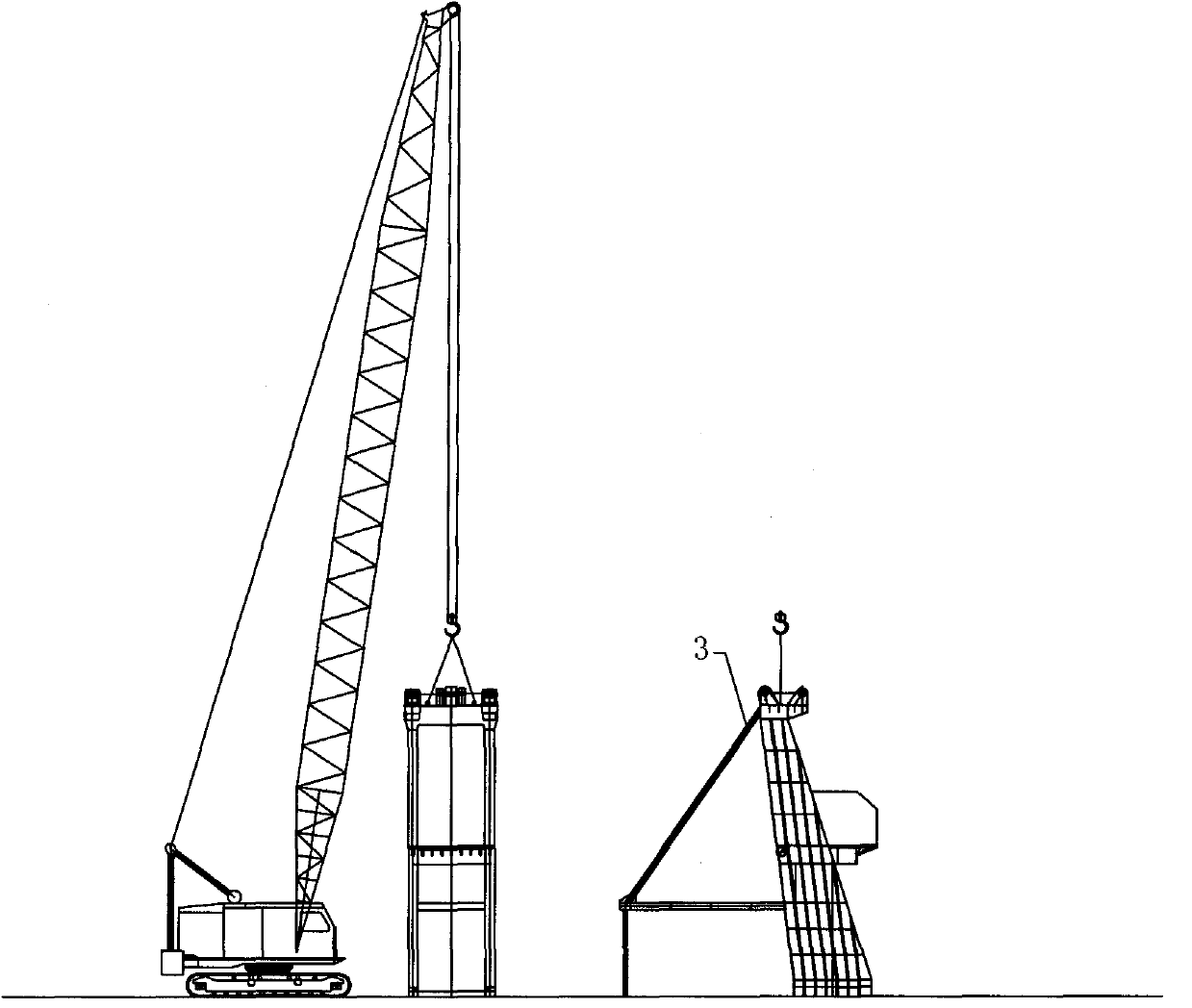

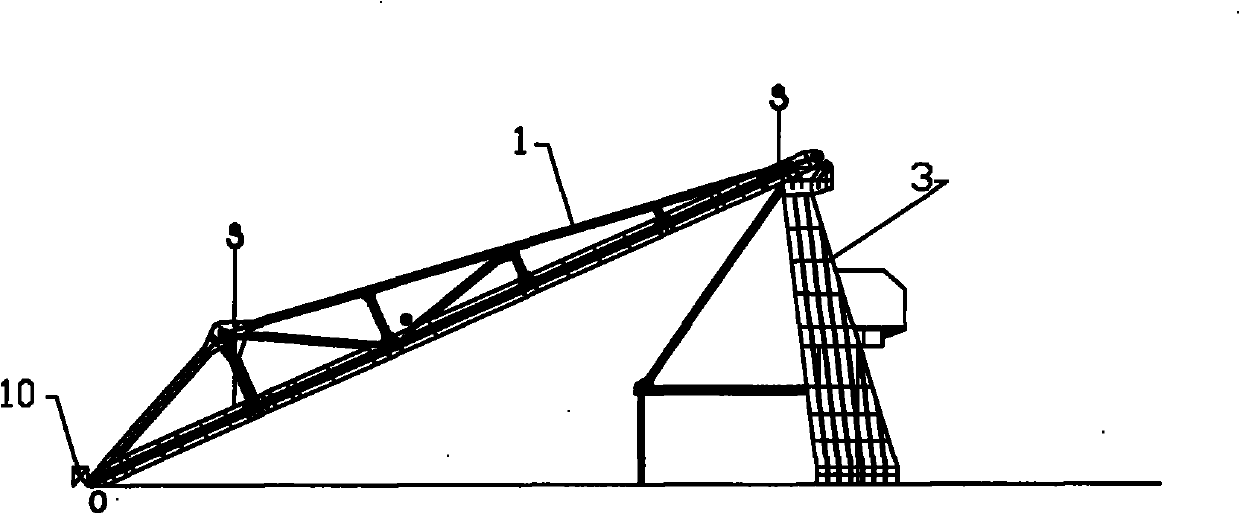

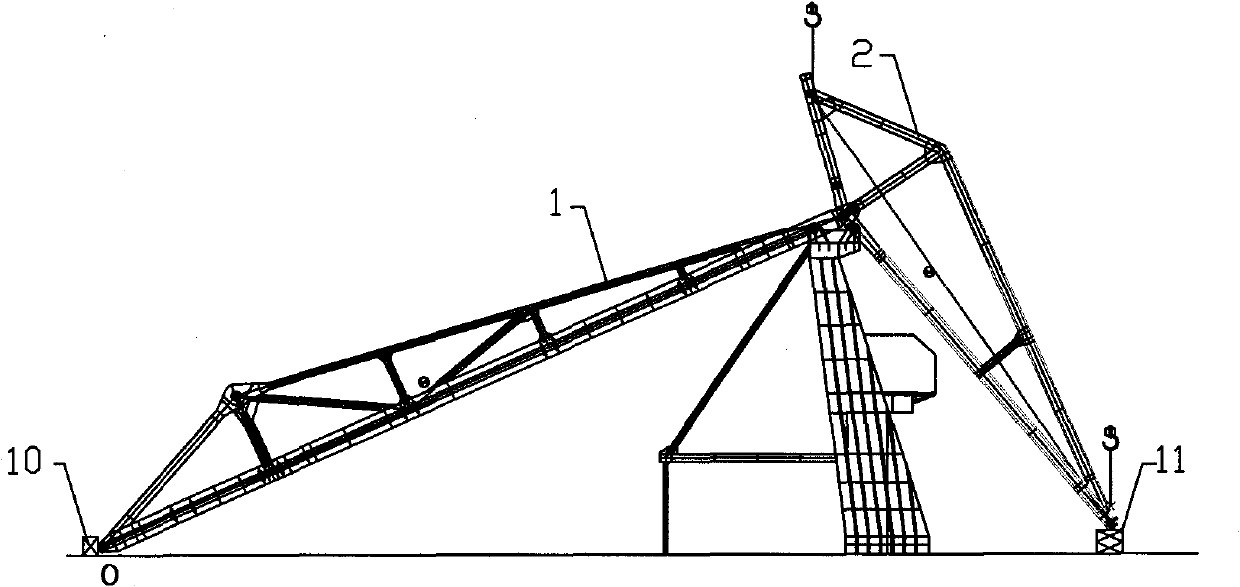

[0033] Example: such as Figure 1 to Figure 13 As shown, the three-link moment lifting method of portal crane is characterized in that it comprises the following steps:

[0034] 1) Connect the boom 1 and the elephant trunk bridge 2 at hinge points and install them.

[0035] Such as Figure 1 to Figure 3 As shown, in step 1), the upper rotating column 3 of the door machine is used as the support platform when the boom 1 and the elephant trunk beam 2 are connected and installed at hinge points, and the end connecting the arm frame 1 and the elephant trunk beam 2 is placed on the upper rotating column of the door machine. The upper end of 3, and its other end is propping up with back pile 10. That end that elephant trunk bridge 2 is connected with jib 1 is placed on the upper end of rotating column 3 on door machine, and its other end is placed on bracket 11.

[0036] 2) Fix the relative position between the boom 1 and the elephant trunk bridge 2, and form two connecting rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com