Technological method for hoisting special large-sized equipment using rotary balance process

A technological method and a technology of rotational balance, applied in hoisting devices, hoisting devices, transportation and packaging, etc., can solve the problems of slow construction progress and high hoisting operation costs, and achieve the effects of convenient operation, shortened construction period, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

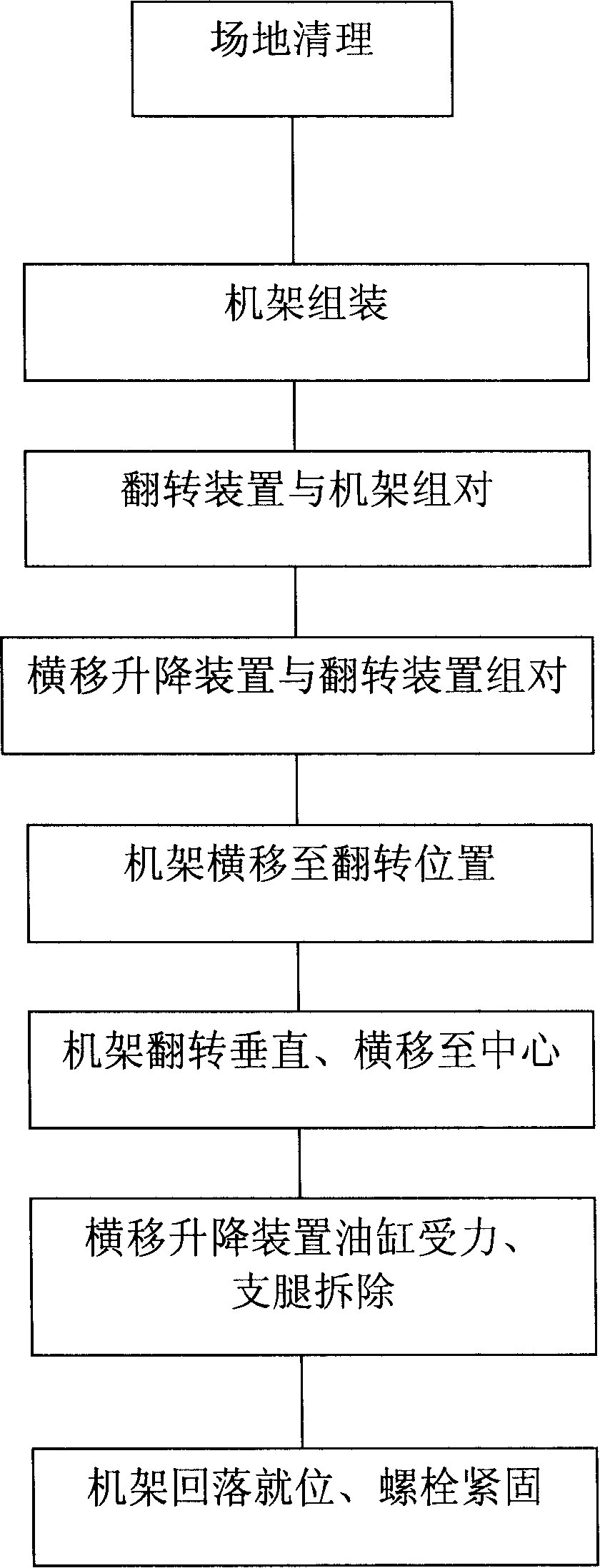

[0027] See figure 1 , A process method for hoisting extra-large equipment by rotating balance method is:

[0028] In the workshop near the hoisting installation position, the frame assembly platform 7 and the slide rail 8 of the super large equipment are positioned and fixed on the foundation embedded parts. The slide rail 8 is made horizontal under the support of the track leg 9 and moves horizontally. The device 3 is located on the slide rail 8.

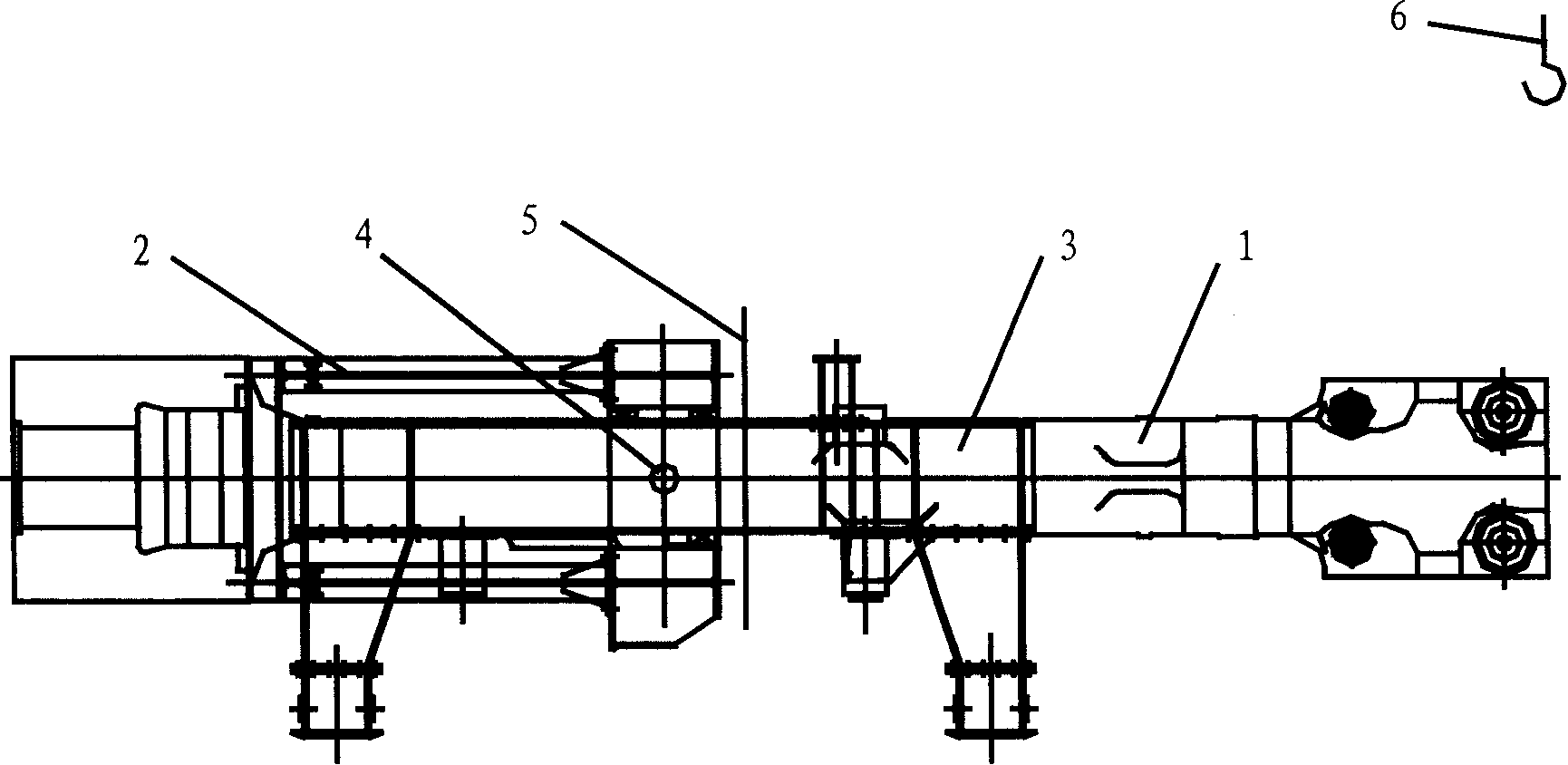

[0029] Use the workshop crane 6 to hoist the parts of the extra-large rack to the assembly platform 7, adjust and assemble the rack 1 into a whole in a horizontal state, see Figure 5 .

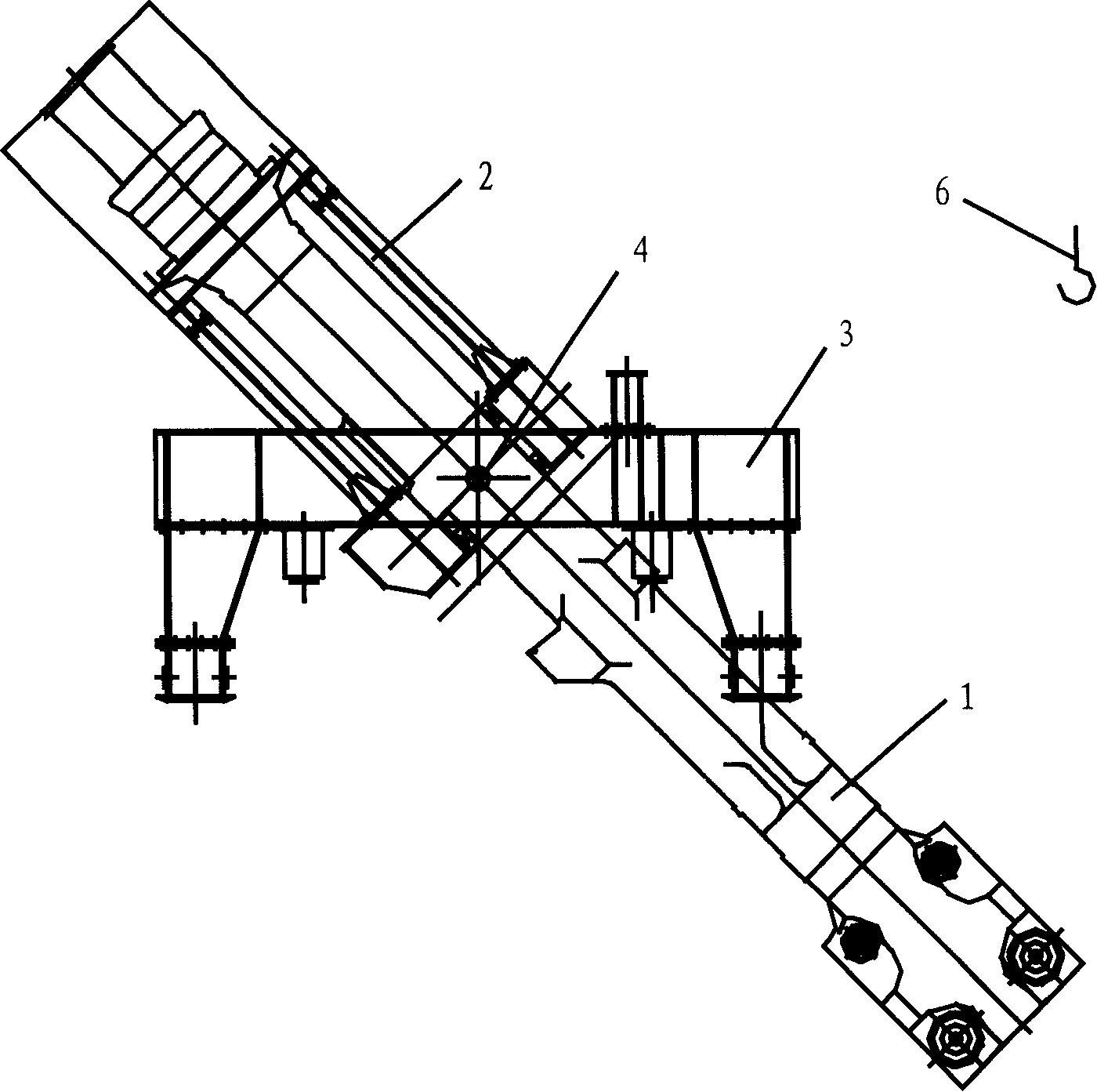

[0030] Then clamp the frame turning device 2 and frame 1, see Figure 5 , Figure 6 , Figure 7 . The frame turning device 2 includes a frame turning frame 21, a rotation pin 4, a positioning pin 22, and a connecting bolt 23. The frame turning frame 21 includes left and right end beams 24, a rear beam 25, a front beam 26, and a stop beam 27. The fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com