Method for hoisting rolling mill housing

A rolling mill archway, hoisting method technology, applied in the direction of transportation and packaging, load hanging components, etc., to achieve the effect of safe hoisting, safe operation, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

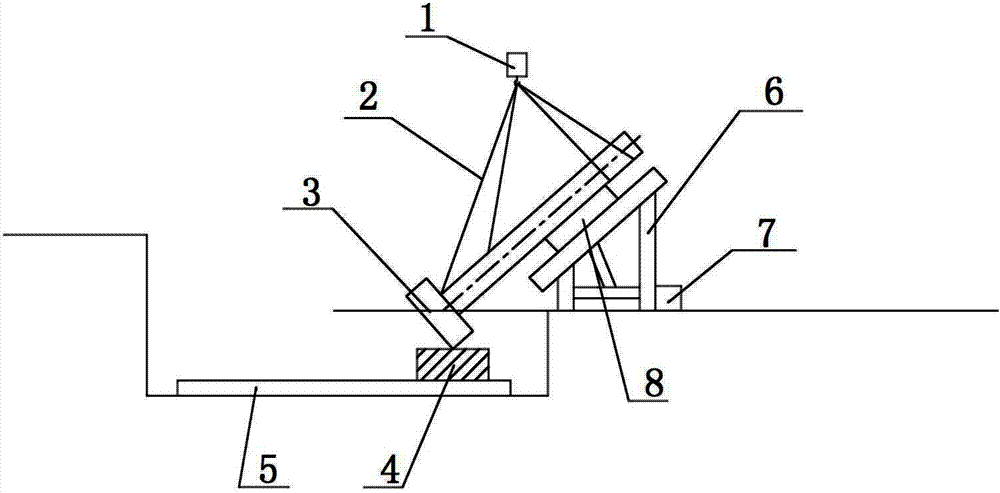

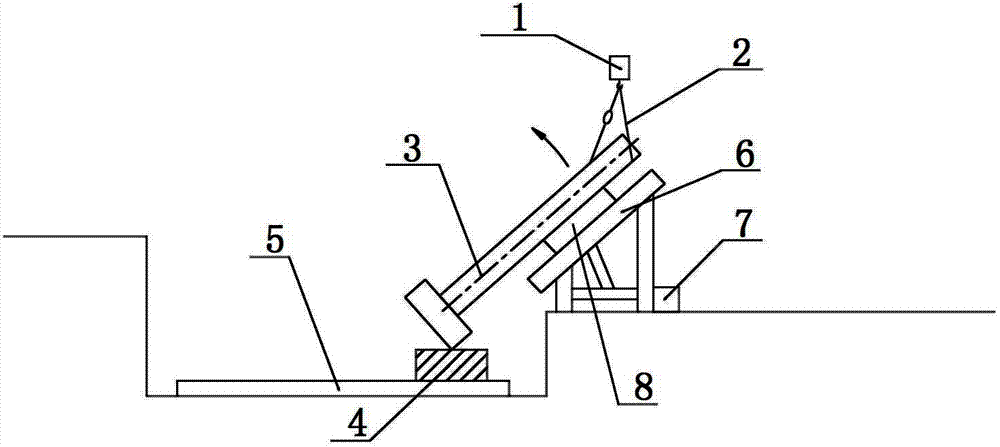

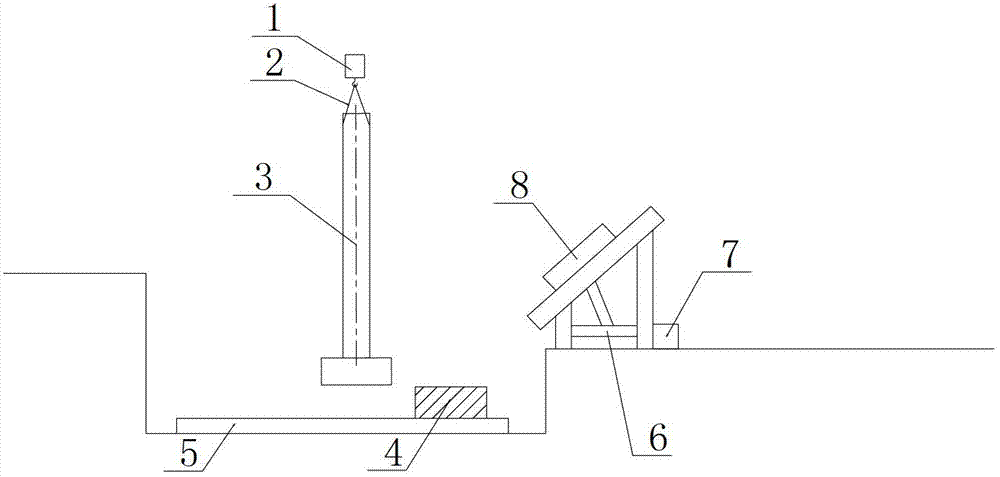

[0014] see Figure 1 ~ Figure 3 , a hoisting method for a rolling mill archway, comprising the following steps:

[0015] 1) Before hoisting the archway of the rolling mill, fix an archway support frame 6 on the track of the rolling mill roll changing trolley, and set a stopper 7 at the end far away from the bottom plate 5 of the rolling mill to prevent the archway support frame 6 from moving and the archway support The frame 6 is provided with an inclined support panel 8, and the inclination angle of the inclined support panel 8 is preferably the same as the hoisting inclination angle of the rolling mill archway 3; a sleeper 4 is placed on the rolling mill floor 5;

[0016] Use the crane 1 and the sling 2 to lift the rolling mill archway 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com