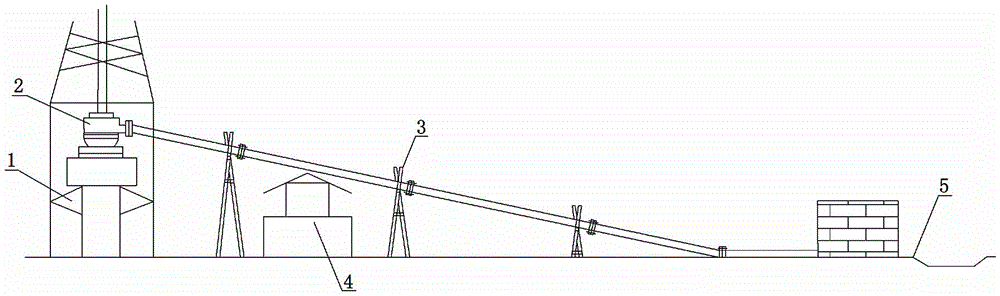

Novel supporting device for gas drilling sand draining pipe

A technology of gas drilling and supporting devices, which is applied in the direction of pipeline support, earthwork drilling, and flushing of boreholes, etc. It can solve the problems of difficult hoisting, large suspension span, and long distance from the combustion pit path, and achieves the goal of improving suspension stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

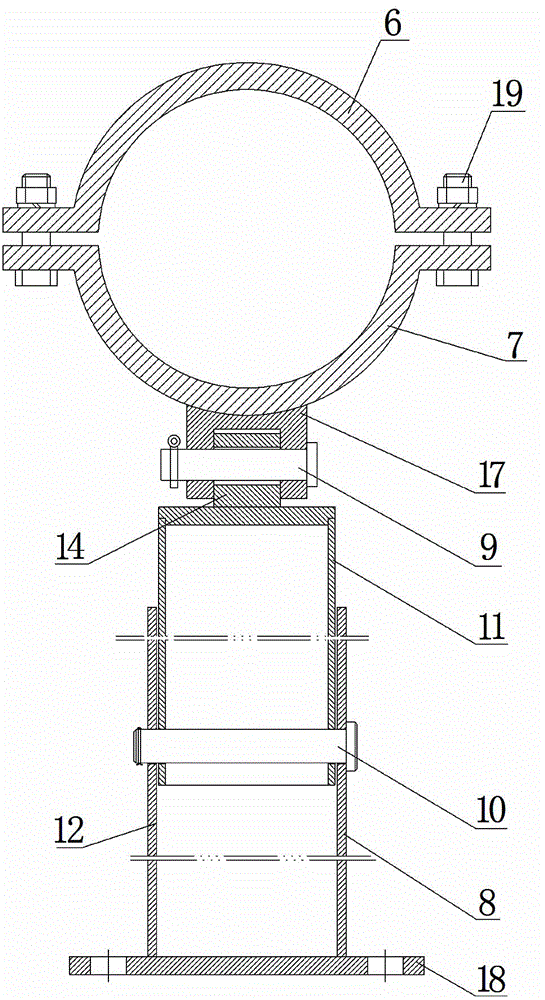

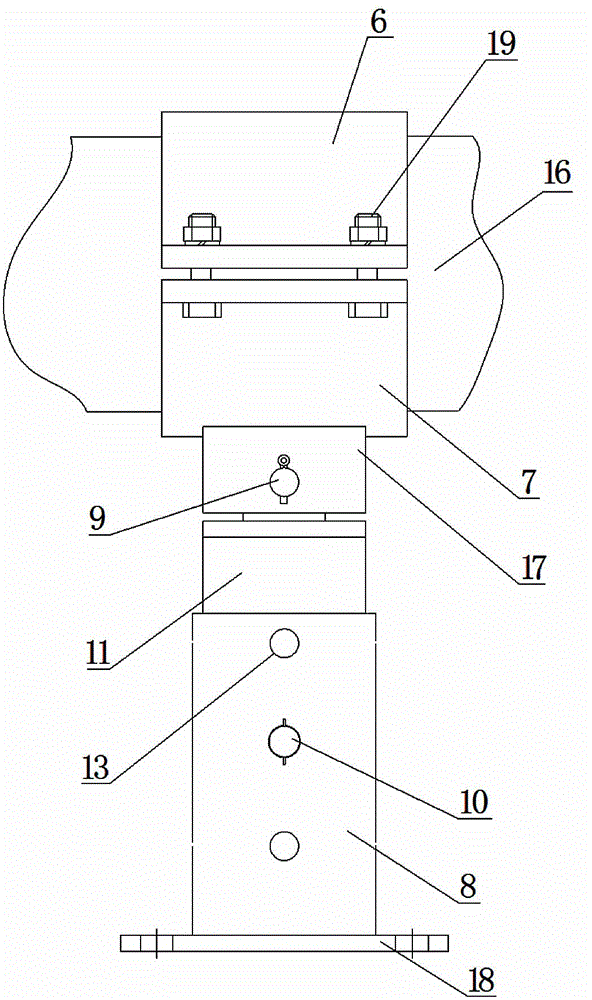

[0025] Such as figure 2 , 3 , 4, 9, 10, 11, 12, and 13, a new type of support device for gas drilling sand discharge pipeline, which includes an upper pressure sleeve 6, a lower support sleeve 7, a support base 8, an angle rotation pin 9, a fixed height The pin 10 and the height adjustment sleeve 11, the support base 8 is columnar, the top of the support base 8 is provided with a cavity 12, and a plurality of penetrating supports are provided on the cylindrical surface of the support base 8 and along the length direction of the support base 8 The through hole I13 of the base 8, the top of the height adjustment sleeve 11 is provided with a double-hole hinged seat 14, the cylindrical surface of the height adjustment sleeve 11 and along the length direction of the height adjustment sleeve 11 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com