Precast beam maintaining apparatus and maintaining method

A technology of prefabricated beams and curing covers, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of unfavorable structural durability, unfavorable concrete maintenance, untimely covering maintenance, etc., achieve obvious durability effects, improve construction efficiency, and hoist convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

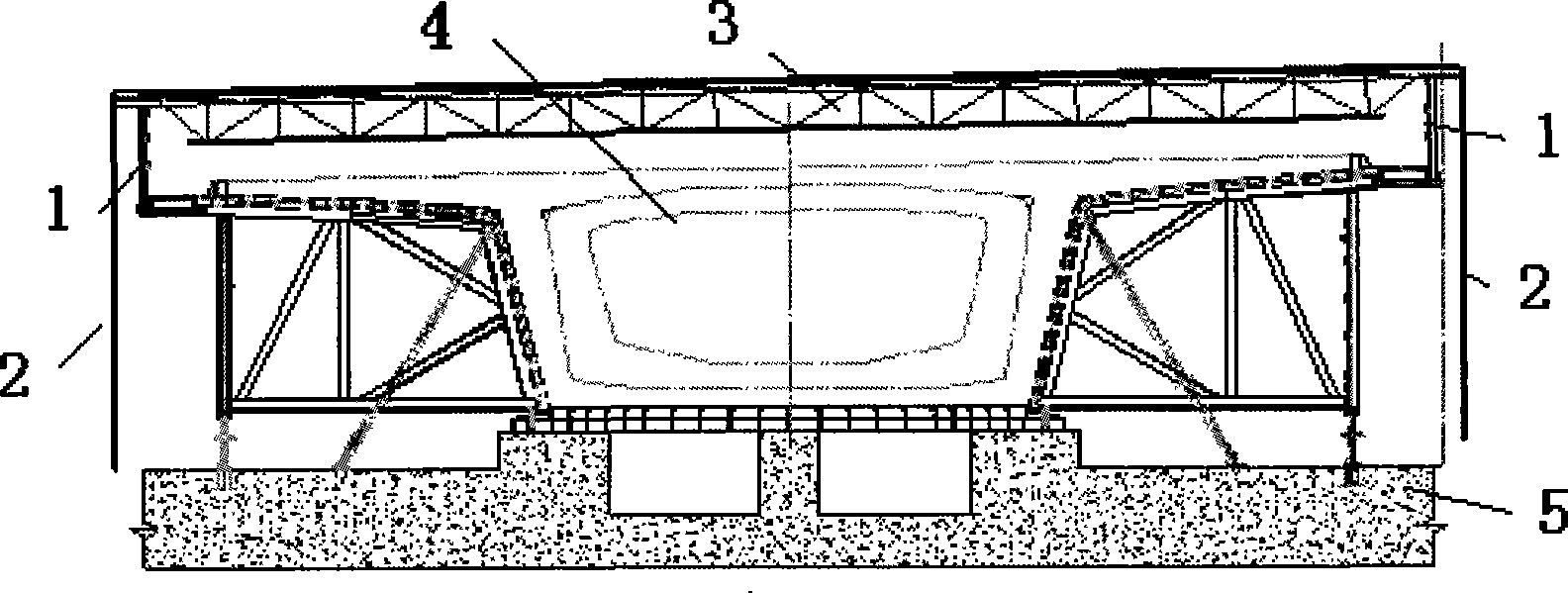

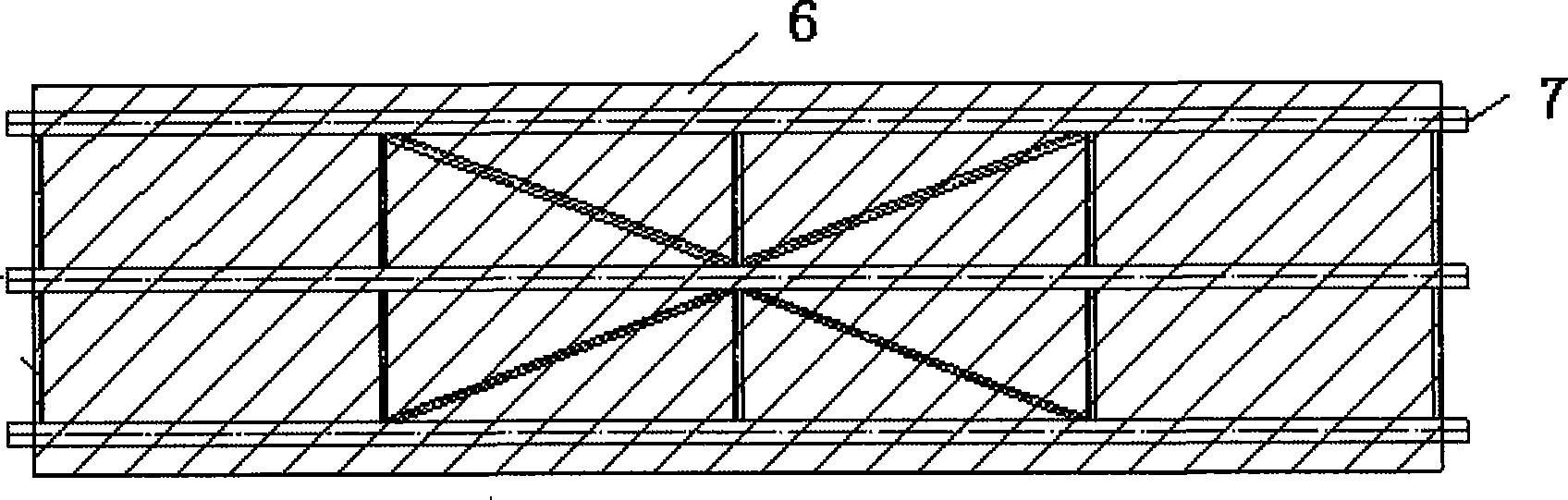

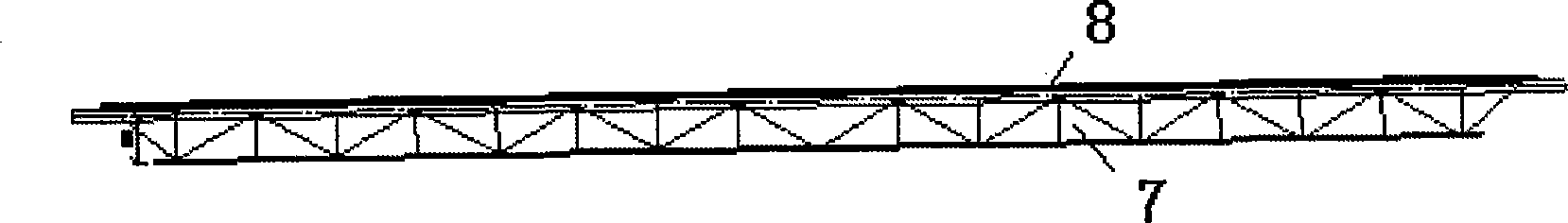

[0025] Such as figure 1 , 2 , 3, the prefabricated beam maintenance device of the present invention comprises a curing cover composed of a steam curing scaffold 3 and a three-proof tarpaulin 2 with fire prevention, heat preservation and rainproof covering around the scaffold, the size of the curing cover and the box girder The size of the pedestal is matched, and the scaffolding includes a rigid skeleton 6. The skeleton of this embodiment is 50 meters long and 18.6 meters wide. Each unit uses 3 trusses 7 with a spacing of 2.35m and a truss height of 600mm. The upper chord is made of 14# industrial steel, the lower chord is made of 50×50×5 angle steel, and the diagonal is made of 30×30×4 angle steel. The truss is equipped with a cover plate 8 made of 50mm color steel plate with thermal insulation function, and a 60cm wide sail tarpaulin is hung around the color steel plate, which is convenient to connect and close with the canvas around the model. "Anti-proof" canvas is cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com