Polishing device adopting high-strength wear-resistant diamond abrasive belt

A diamond sand and polishing device technology, which is applied in the direction of grinding/polishing safety device, grinding drive device, grinding/polishing equipment, etc., can solve the problem of limited contact area between polishing abrasive belt and arc-shaped workpiece surface and time-consuming polishing operation Power consumption, large size and difficult to carry, etc., to achieve the effect of being convenient for close contact with workpiece polishing, easy to disassemble and replace, and preventing the operation from being affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

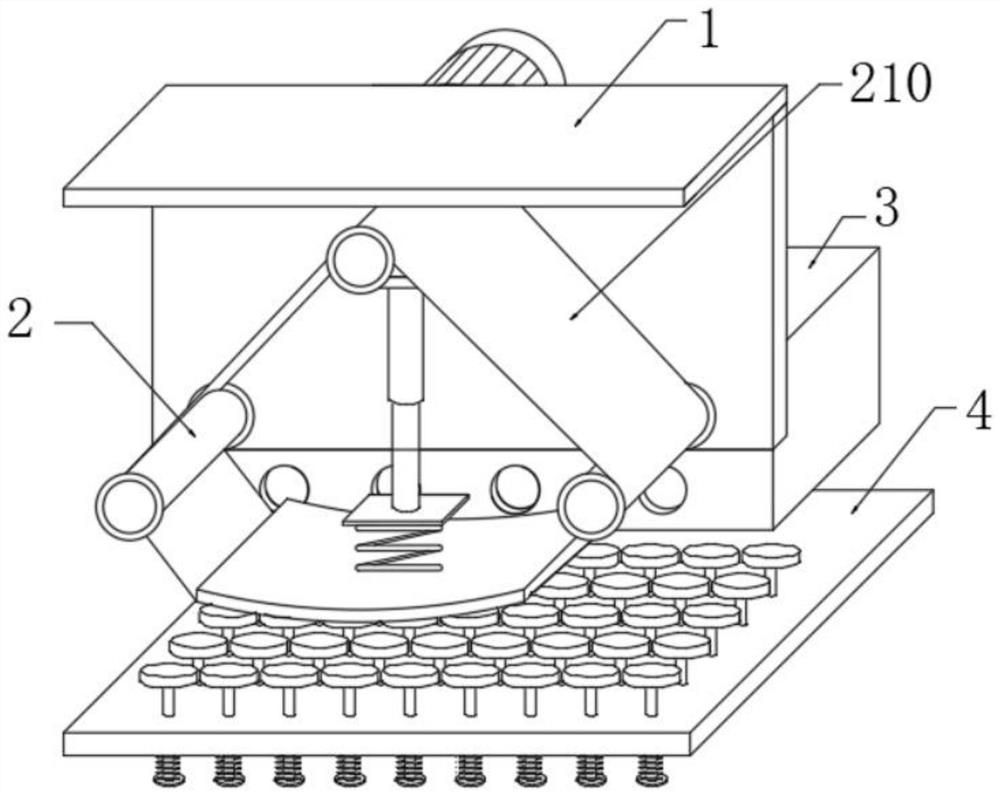

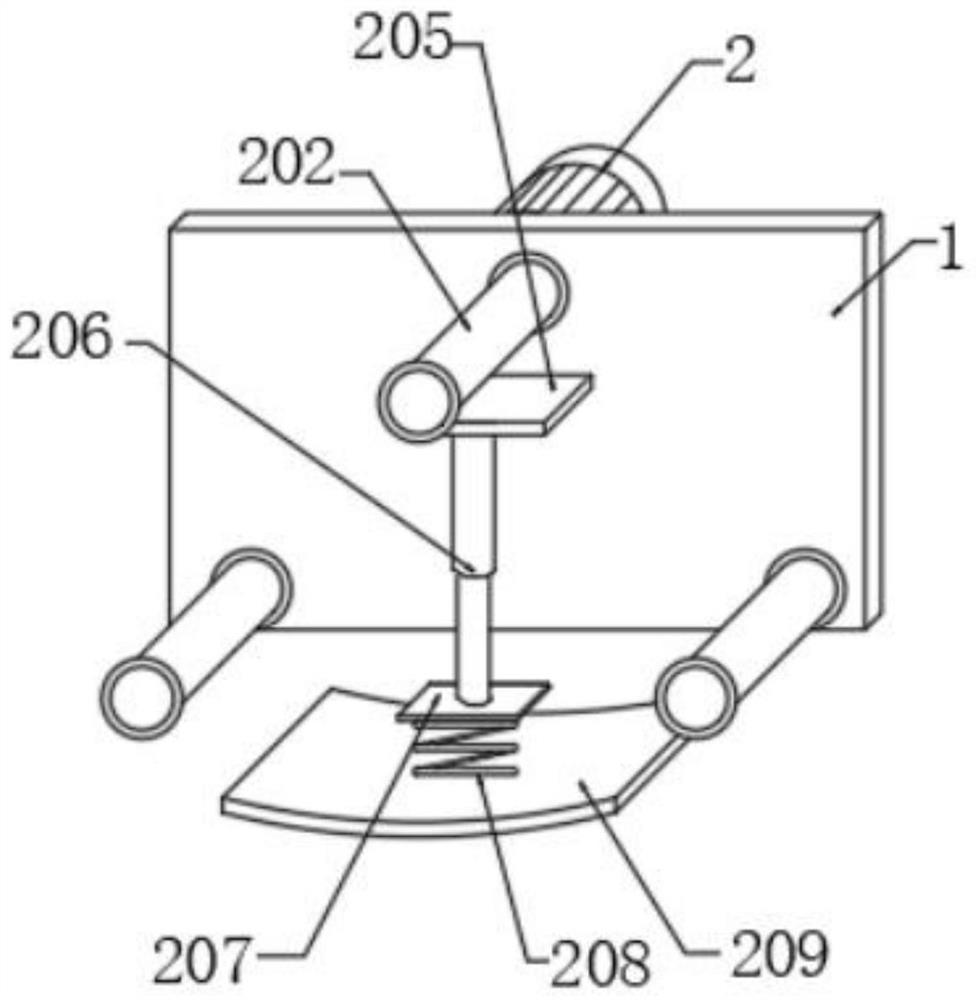

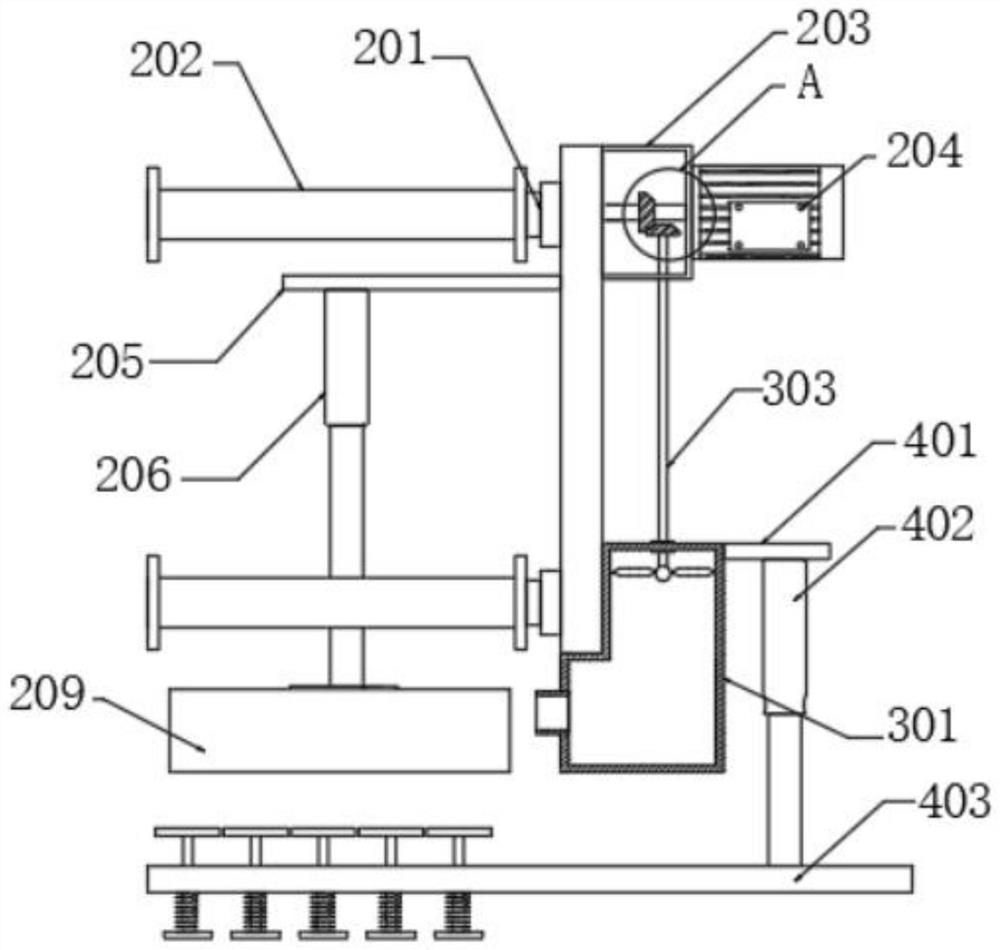

[0029] See 1- image 3 , in the embodiment of the present invention, the polishing assembly 2 includes: three first bearings 201 fixed on the front surface of the outer shell 1, the rotating ends of the three first bearings 201 are fixed with a rotating roller 202, and the surfaces of the three rotating rollers 202 are sleeved with Abrasive belt 210; the mounting frame 203 fixed on the rear end surface of the outer shell 1, the drive motor 204 is installed inside the mounting frame 203; The first cylinder 206, the output end of the first cylinder 206 is fixed with a connecting plate 207, the lower end of the connecting plate 207 is fixed with a first spring 208, the lower end of the first spring 208 is fixed with an arc plate 209, and the output end of the drive motor 204 passes through the outer shell 1. The first bearing 201 is fixedly connected with the rotary roller 202, used for the rotation of the rotary roller 202 and the abrasive belt 210, and the arc plate 209 is mova...

Embodiment 2

[0031] see Figure 3-Figure 5 The difference from Embodiment 1 is that the blower assembly 3 includes: a bellows 301 fixed on the rear end surface of the outer casing 1, the upper end of the bellows 301 is fitted with a second bearing 302, and the rotating end of the second bearing 302 is fixed with a transmission rod 303 , the extended end of the transmission rod 303 lower end is fixed with the blower fan 305 arranged in the inner cavity of the bellows 301; the pair of bevel gears 304 between the upper end of the transmission rod 303 and the output end of the drive motor 204 are fixed; An air exhaust port 306, the air exhaust port 306 is arranged opposite to the bottom of the abrasive belt 210, and is used to blow the abrasive belt 210 to polish the scattered gravel. When the output end of the driving motor 204 rotates, the transmission rod 303 can be driven to rotate by the pair of bevel gears 304 , the transmission rod 303 can drive the blower fan 305 to rotate, so that the...

Embodiment 3

[0033] see image 3 and Figure 6The difference from Embodiment 1 is that the extrusion assembly 4 includes: a second horizontal plate 401 fixed on the rear end surface of the bellows 301, a second cylinder 402 is fixed on the lower end of the second horizontal plate 401, and a set is fixed on the lower end of the second cylinder 402. The supporting plate 403 below the abrasive belt 210; and several ejector pins 404 that penetrate through the supporting plate 403, and the upper end surface of the ejector bar 404 is fixed with a tray 406, and the first pin is fixed between the ejector bar 404 and the lower end surface of the supporting plate 403 Two springs 405, the supporting plate 403 are arranged opposite to the lower end of the arc-shaped plate 209, and are used to squeeze the polishing piece to the surface of the arc-shaped plate 209, and several trays 406 move up and down in the socketed supporting plate 403 through the push rod 404, Therefore, several pallets 406 can mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com