Prefabricated bearing platform form and mounting method thereof

A prefabricated platform and installation method technology, applied in the field of building formwork, can solve problems such as affecting the foundation construction process, large on-site masonry workload, difficult quality control, etc., to achieve the effect of improving assembly efficiency, shortening construction period and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiments of the present invention will be described in detail below.

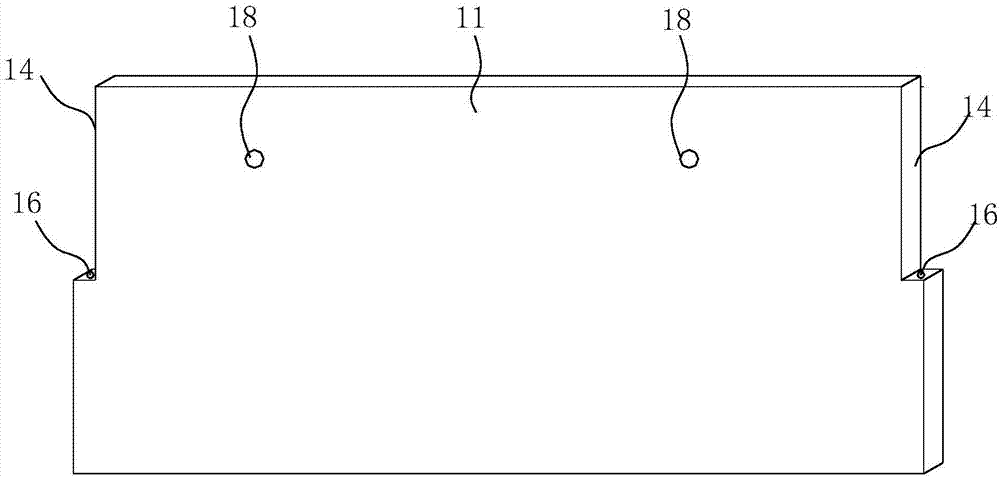

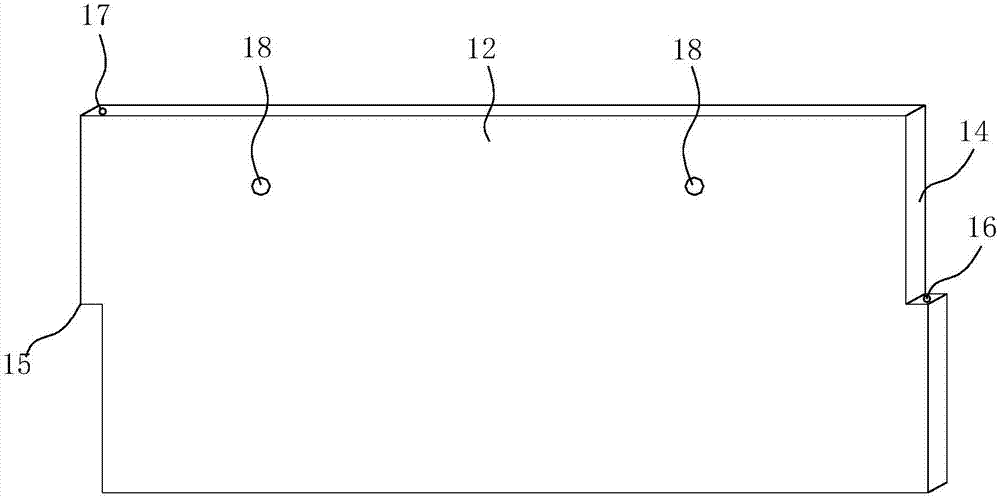

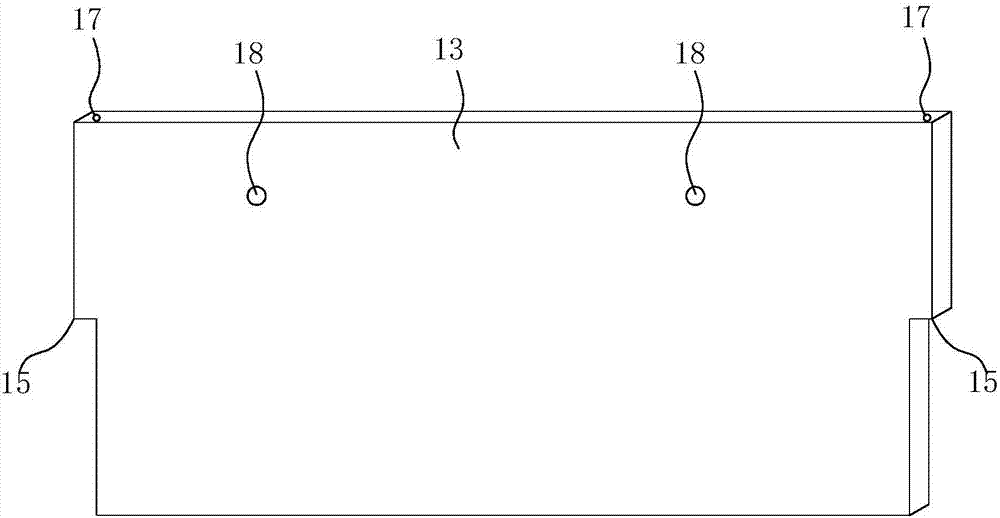

[0061] Such as Figure 1 to Figure 6 As shown, the prefabricated cap formwork includes a plurality of plate bodies which are matched and connected head to tail in sequence. The two ends of the plate body are the first end and the second end. There is an upper tenon notch 14 or a lower tenon notch 15, and the upper tenon notch 14 matches the lower tenon notch 15;

[0062] When the first end of the plate is mated with the second end of the adjacent plate, the upper concave tenon notch 14 on the end face of the first end of the plate and the second end end of the adjacent plate Lower concave tenon notch 15 is matched and assembled.

[0063] Wherein, the upper tenon notch 14 includes a half protrusion and a half through notch, the half protrusion of the upper tenon notch 14 is below, the half through notch is above, and the lower tenon notch 15 includes a half protruding part, half-side through not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com