Combined multi-core high-voltage electric connector

A high-voltage, combined technology, applied in the direction of conductive connection, connection, two-component connection device, etc., can solve the problem of insufficient space for single-core electrical connectors, and achieve the effect of avoiding wrong connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

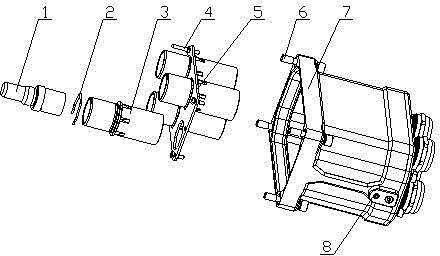

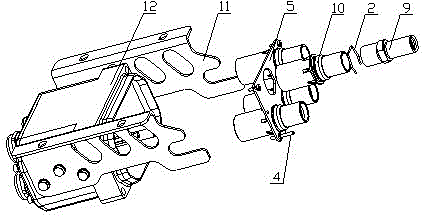

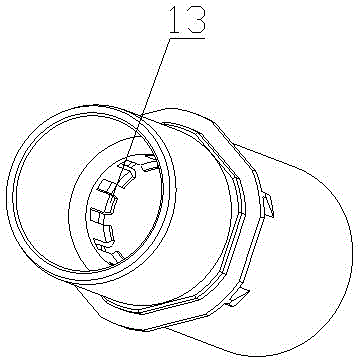

[0024] like figure 1 As shown, it is the plug part of the electrical connector, including the plug housing, the pin, the retaining spring, the anti-mistake nail, the fixing plate, the screw, the positioning block, the pin mounting part, and the claws. When installing, first insert the pin into the pin mounting piece, the pin mounting piece is cylindrical, and a claw is arranged on the inner wall of the cylindrical shape, and the outer edge of the claw is fixed with the cylindrical inner wall; such as image 3 As shown, the inner edge of the claws is a serrated reed. When the pin is inserted into the reed, the reed is reversely forced to hold the pin tightly to fix the pin. There are several through holes on the fixing plate for installing the pin mounting parts. Insert the pin mounting parts into the through holes, and set a circlip between the pin mounting parts and the through holes. The clamping force of the circlip makes the The pin mounts are firmly seated in the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com