Method of fast inserting type test wire connection for fuel cell set

A fuel cell stack and fuel cell technology, applied in the direction of conductive connection, connection, circuit, etc., can solve the problem of not finding the connection method of the fuel cell inspection line, loose contact between the inspection line and the metal needle, and affecting the normal operation of the fuel cell and other problems to achieve the effect of avoiding abnormal operation, ensuring firmness and avoiding looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

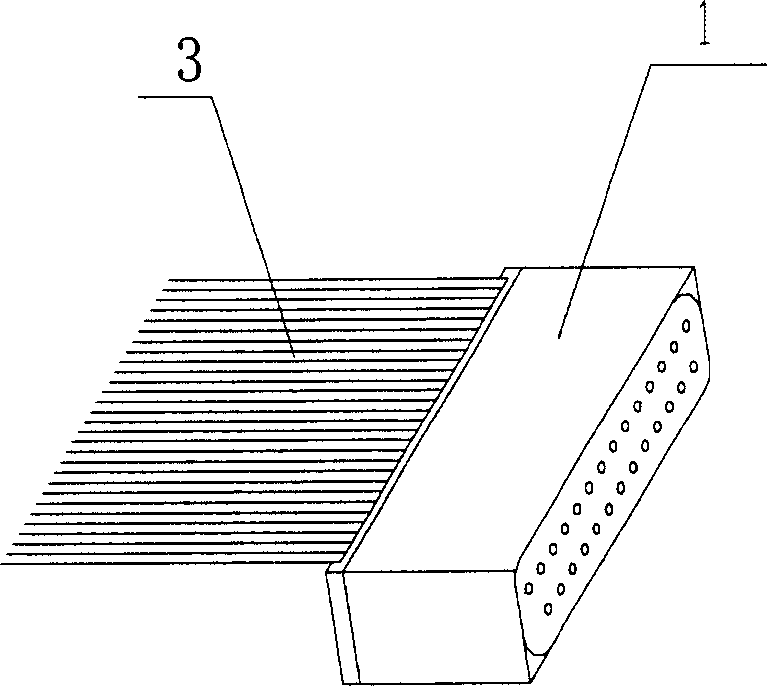

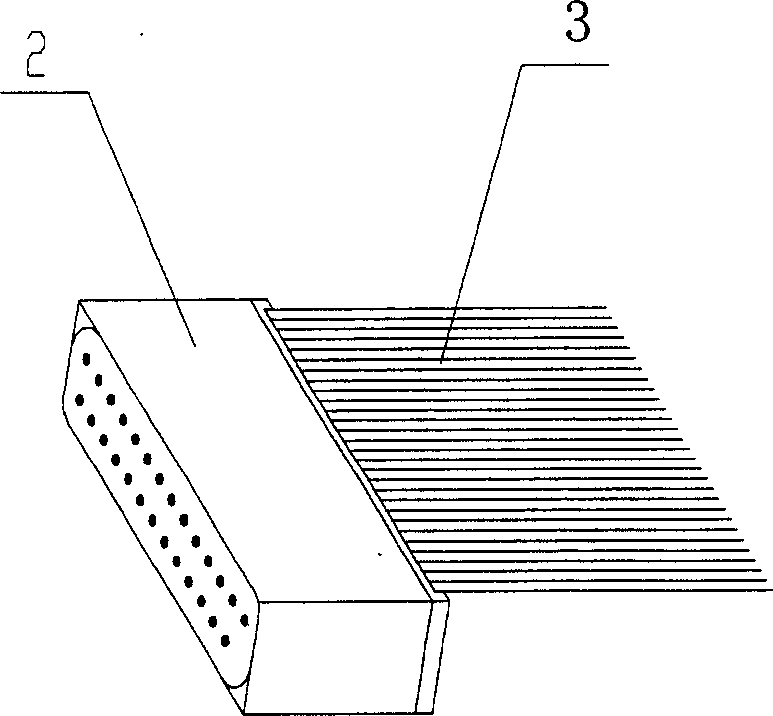

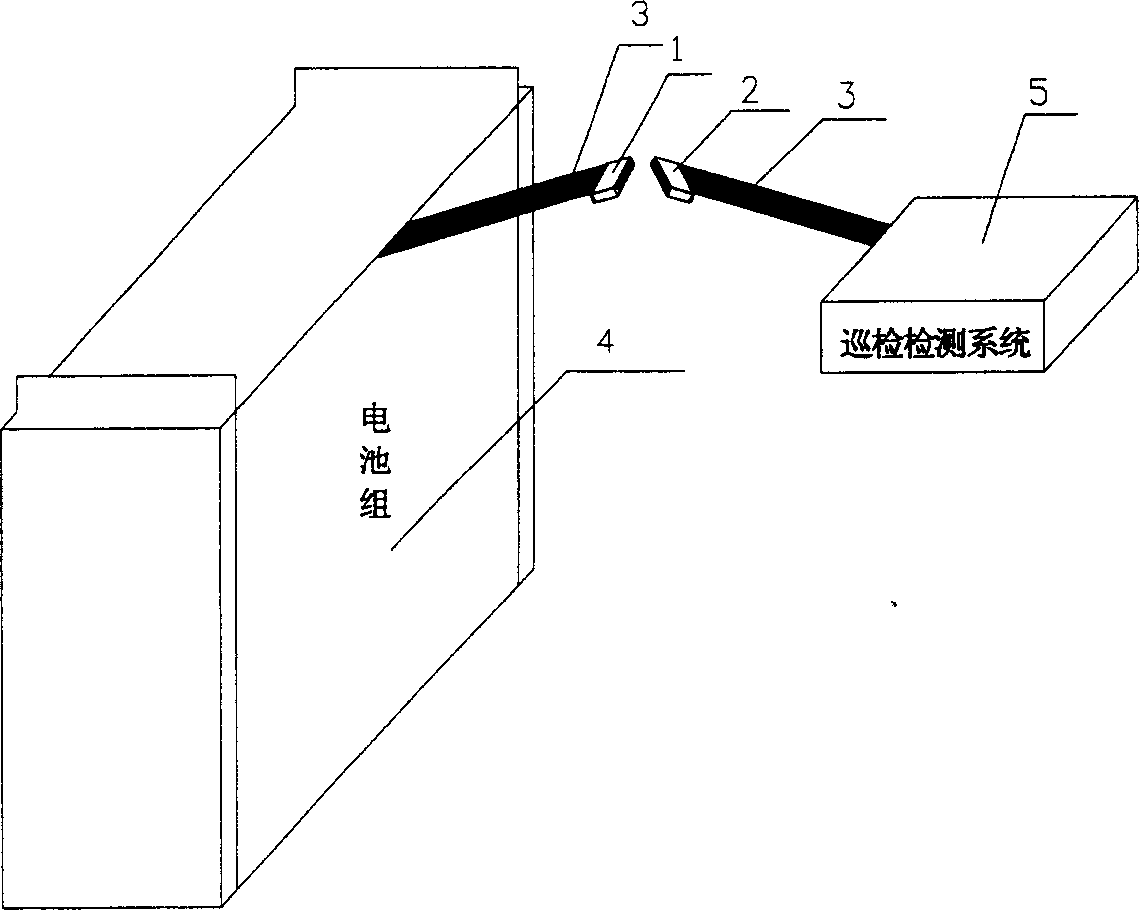

[0019] Application of fuel cell quick-plug inspection interface in fixed test platform: assemble a 50kW fuel cell stack with 180 cells. Use the 20-channel line row 3 and the multi-channel D-type connector element 1 to press into a 20-channel quick-plug inspection interface element, and connect the other end of the multiple quick-plug inspection interface element lines to the fuel cell bipolar Plates (including collector plates) are welded together in sequence. Place the battery pack with quick-plug inspection interface components on the fuel cell test platform to connect the pipelines and lines; then connect the fuel cell quick-plug inspection interface with the quick-plug inspection Check the interface for plugging. Various performance tests of fuel cells are carried out. The test shows that using this method to connect the fuel cell group and the detection system, there is no phenomenon that the inspection line falls off during battery operation, the connection between the...

Embodiment 2

[0021] Application of quick-plug inspection interface in dynamic fuel cell performance test: Two 50kW fuel cell stacks (180 cells / set) using this connection method are assembled into a fuel cell power generation system with a net output of 60kW as The engine of the 863 fuel cell city bus. The 863 project team headed by Tsinghua University conducted a 3,000-kilometer actual running performance test on this fuel cell city bus. During the test, there was never any bad contact between the inspection line and the battery pack, which laid the foundation for the stable operation of the fuel cell engine. good foundation. At the same time, because the inspection line is connected to the fuel cell detection system by quick plug (the battery pack can be quickly disconnected and connected to the inspection system), it provides great convenience for the maintenance of the fuel cell engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com