Well cementation mud flow meter device

A flowmeter and mud technology, which is applied in the field of cementing mud flowmeter devices, can solve the problems of insufficient pressure level of flowmeter, interruption of cementing, easy winding to blades, etc., to improve measurement accuracy, improve pressure safety level, and eliminate Easy to clog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

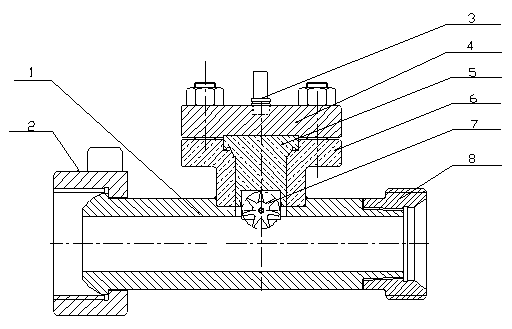

[0009] Referring to the accompanying drawings, a cementing mud flowmeter device includes a flowmeter body 1, a union nut 2, a sensor 3, an upper flange 4, a sensor seat 5, a lower flange 6, an impeller 7, and a union joint 8 , the flowmeter body 1 is respectively connected to both ends of the cement slurry pipeline through the union nut 2 and the union joint 8, and the lower flange 6 is welded in the middle part of the flowmeter body 1, and the lower flange 6 is installed with The sensor seat 5 is equipped with an impeller 7 at the lower part of the sensor seat 5; the impeller 7 is in the shape of a disc, the axis of the impeller 7 is placed vertically on the axis of the flowmeter body 1, and an upper flange is used on the lower flange 6 4 Fix the sensor seat 5 and the lower flange 6 together, and the sensor 3 is installed in the upper flange 4 . The working principle of the device is that in order to improve the wear resistance of the impeller 7, the impeller 7 is designed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com