Variable vehicle lift mechanism of engine

An engine and variable technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of engine 1 cost increase, difficulty increase, engine power loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

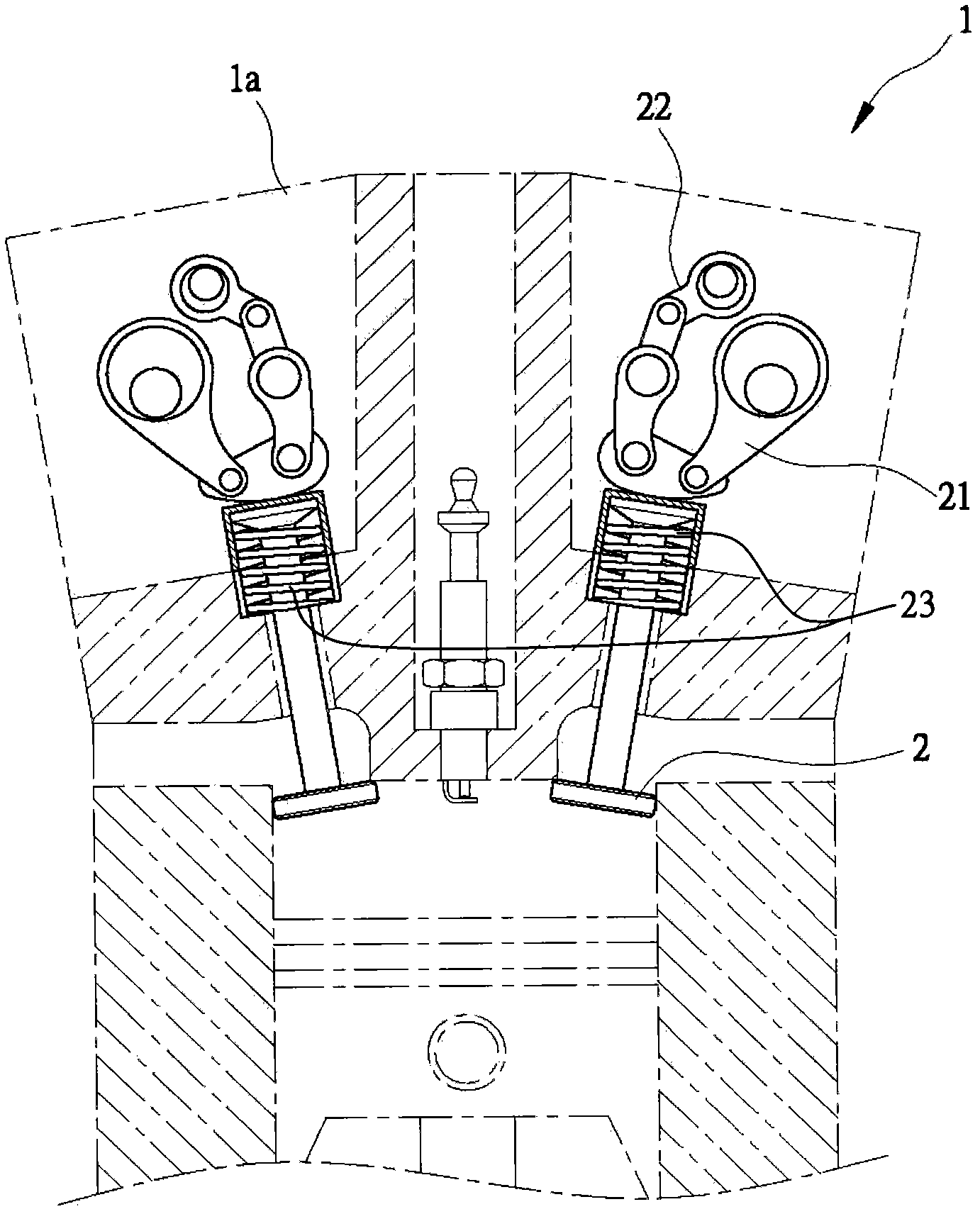

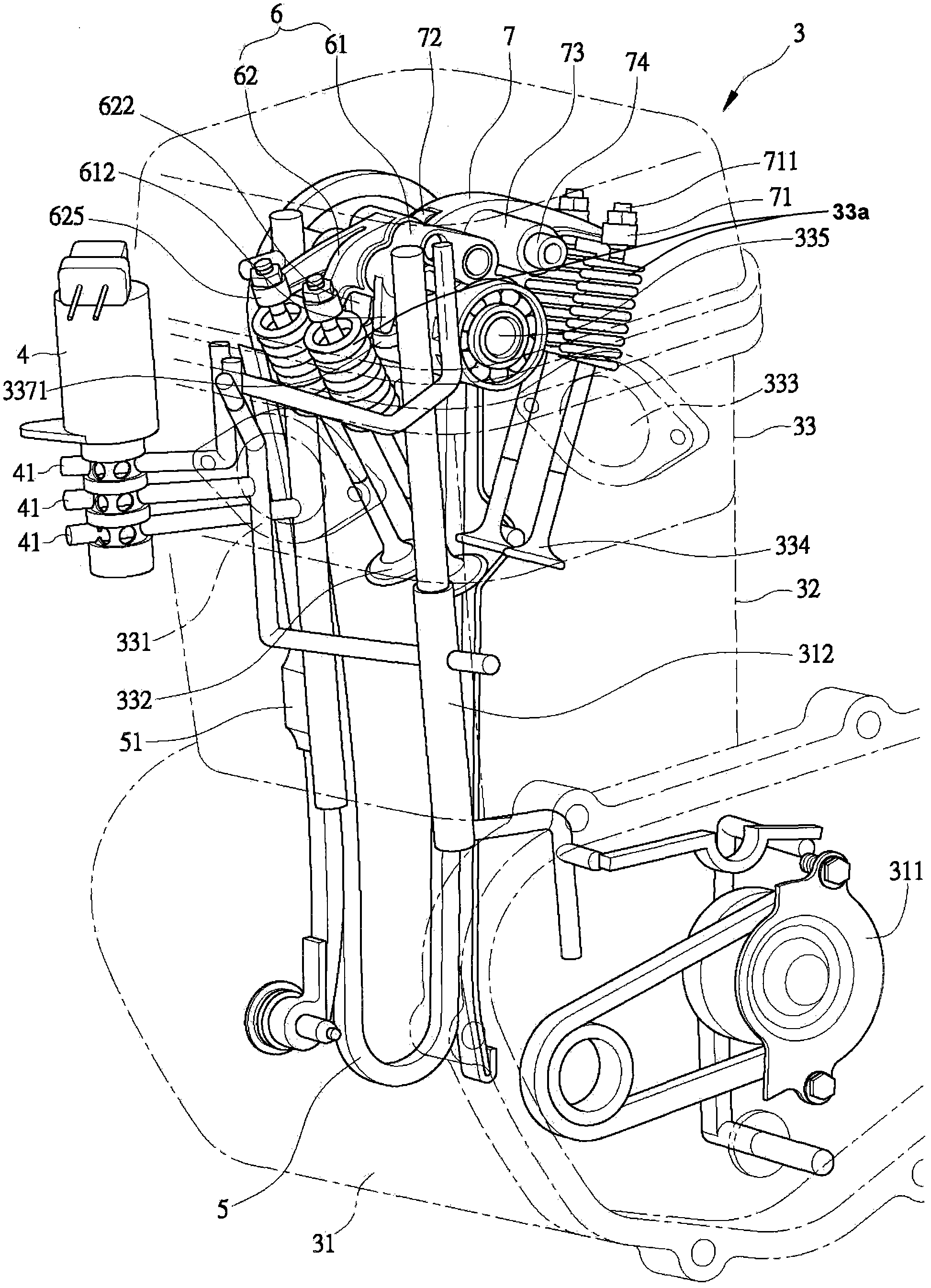

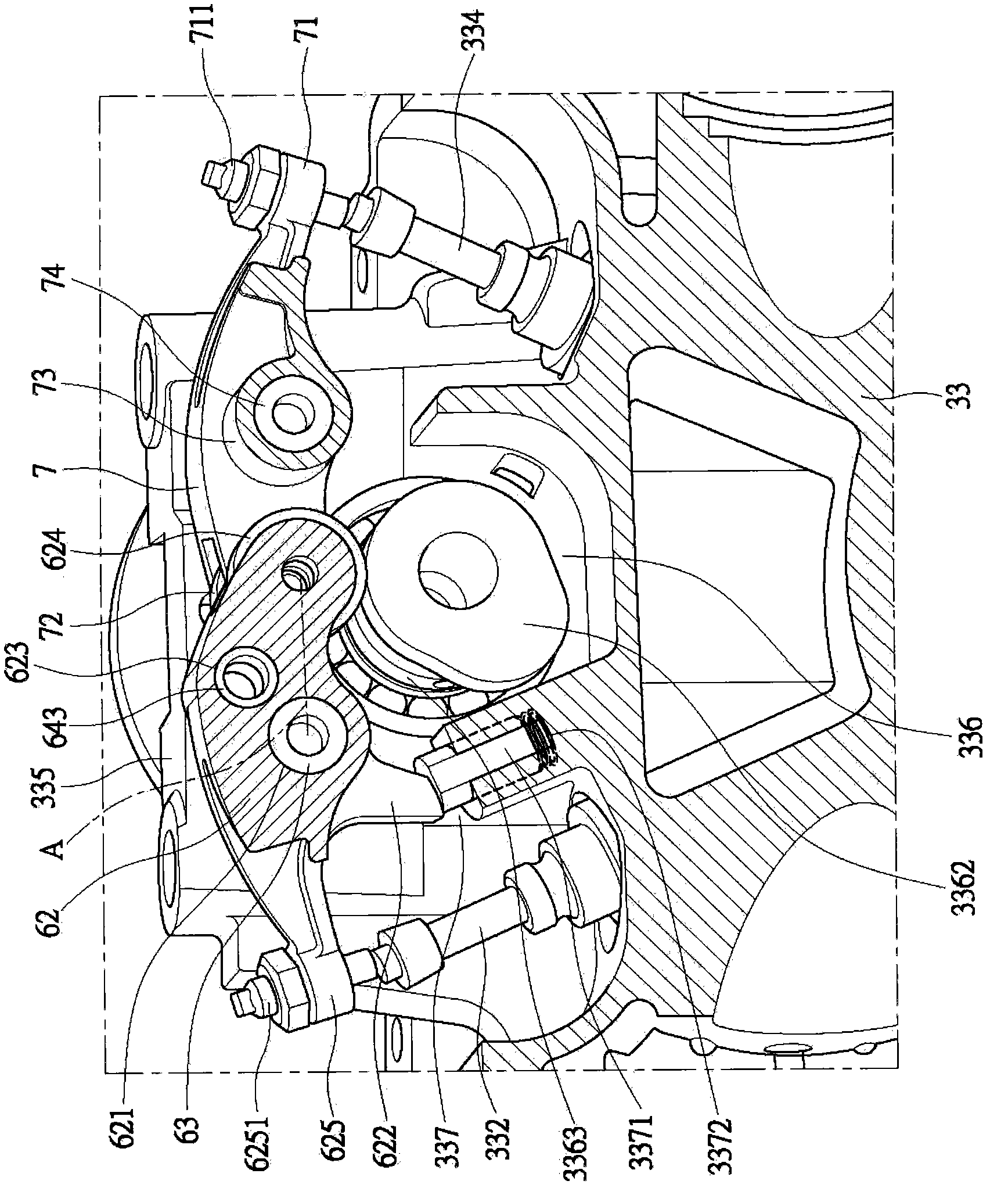

[0063] Relevant structure of the present invention and the effect that can be achieved are described as follows in conjunction with drawings:

[0064] see figure 2 Shown, engine 3 of the present invention has a crankcase 31, one group is located at the cylinder body 32 on the crankcase 31, one group is located at the cylinder head 33 on the cylinder body 32; This crankcase 31 is provided with a crankshaft ( Not shown in the drawing), and an oil pump 311, the oil pump 311 sends the oil to a main oil supply passage 312, and the main oil supply passage 312 is communicated with the crankcase 31 through the cylinder body 32 to be arranged on The oil control valve 4 of the cylinder head 33; the cylinder body 32 is arranged on the top of the crankcase 31, and can pass through the timing chain 5, wherein, the cylinder body 32 is provided with a positive When the chain tensioner 51.

[0065] The cylinder head 33 is provided with an intake port 331 and an intake valve 332 on the inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com