Flexible substrate, carrier platform, flexible display and preparation method thereof

A flexible display and flexible substrate technology, applied in the direction of instrumentation, nonlinear optics, printed circuit manufacturing, etc., can solve problems affecting the flatness of flexible substrate 02, poor warping, flexible substrate 02 bubbling, etc., to reduce the phenomenon of bubbling and warpage defects, quality improvement, and effects of reducing bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

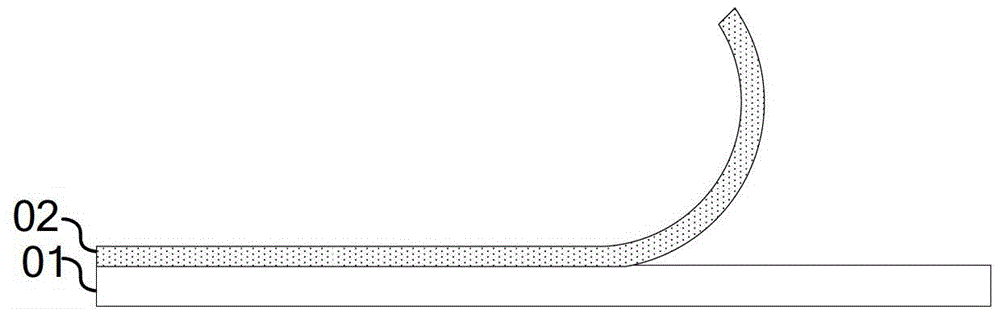

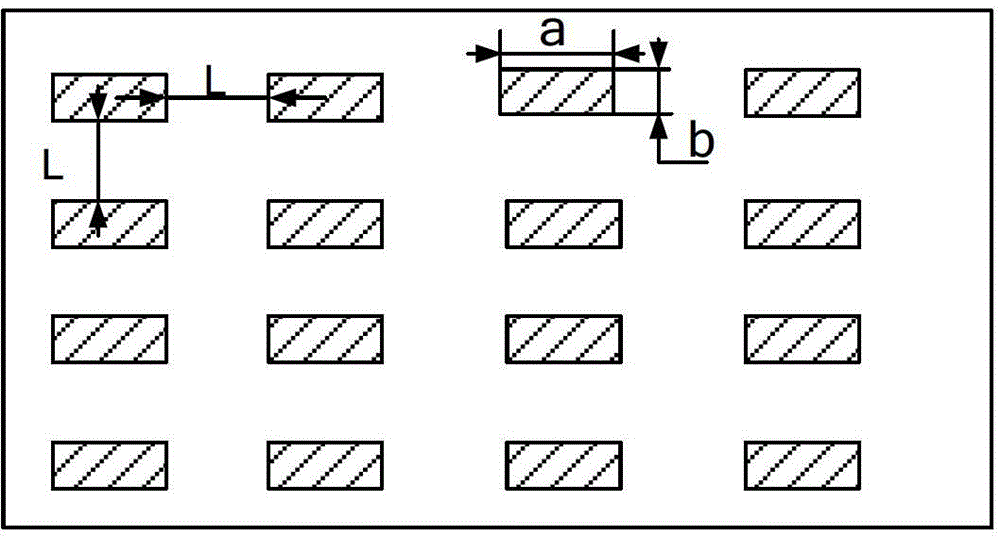

[0049] This embodiment provides a flexible substrate 2, such as figure 2 shown, including:

[0050] The spacers 3 are distributed at intervals, and the spacers 3 are located on the other side of the flexible substrate 2 opposite to the side on which the display device 5 is prepared.

[0051] When the flexible substrate 2 with the above-mentioned structure is used to prepare a flexible display, one side of the flexible substrate 2 with spacers 3 distributed at intervals is attached to the carrier platform 1, and there are spacers distributed at intervals between the flexible substrate 2 and the carrier platform 1 Object 3, the gaps between the spacers 3 distributed at intervals can make the gas existing between the flexible substrate 2 and the carrier platform 1 communicate with the gas in the surrounding environment, so as to facilitate the gas discharge between the flexible substrate 2 and the carrier platform 1 , the flatness of the flexible substrate 2 is improved, the oc...

Embodiment 2

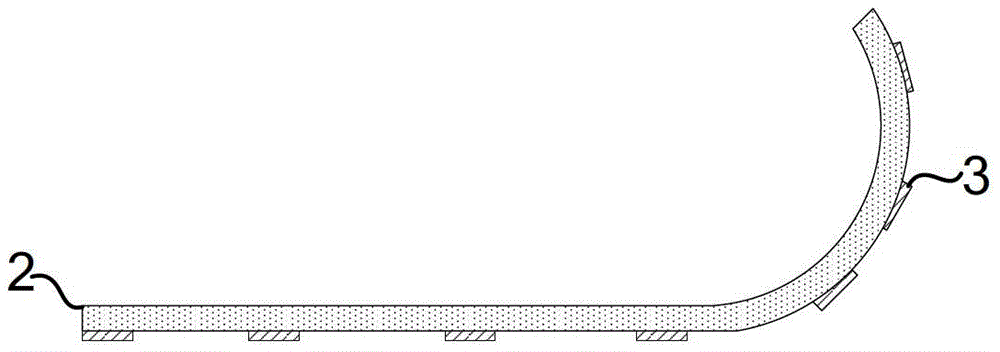

[0060] This embodiment also provides a carrier platform 1, such as Figure 5 shown, including:

[0061] The spacers 4 are distributed at intervals, and the spacers 4 are located on the side of the carrier platform 1 carrying the flexible substrate 2 .

[0062] Since the side of the attached flexible substrate 2 has spacers 4 distributed at intervals, the gaps between the spacers 4 distributed at intervals can make the gas existing between the flexible substrate 2 and the carrier platform 1 and the gas in the surrounding environment In the same way, it is beneficial for the gas between the carrier platform 1 and the flexible substrate 2 to be better discharged, and at the same time, the flatness of the side of the carrier platform 1 attached to the flexible substrate 2 is improved, so that the flexible substrate 2 is attached to the carrier platform 1. One side of the display device 5 is flat.

[0063] Therefore, using the carrier platform 1 provided by the present invention ...

Embodiment 3

[0071] This embodiment provides a flexible display, such as Figure 6 As shown, it includes the flexible substrate 2 mentioned in the above technical solution.

[0072] Since the other side of the flexible substrate 2 used in the preparation of the above-mentioned flexible display is opposite to the side for preparing the display device 5, there are spacers 3 distributed at intervals, during the preparation of the flexible display, spacers 3 distributed at intervals exist The gap can make the gas existing between the flexible substrate 2 and the carrier platform 1 communicate with the gas in the surrounding environment, facilitate the gas discharge between the flexible substrate 2 and the carrier platform 1, and reduce the drum of the flexible substrate 2 in the process of manufacturing the flexible display. The occurrence of the bubble phenomenon improves the quality of the flexible display.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com