Water-based two-component matte varnish and preparation method thereof

A two-component, clear topcoat technology, used in coatings, radiation-absorbing coatings, polyurea/polyurethane coatings, etc., to solve problems such as poor anti-discoloration performance of substrates, insufficient film compactness, and poor moisture resistance and water resistance. , to achieve good discoloration resistance, reduce discoloration, and improve water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

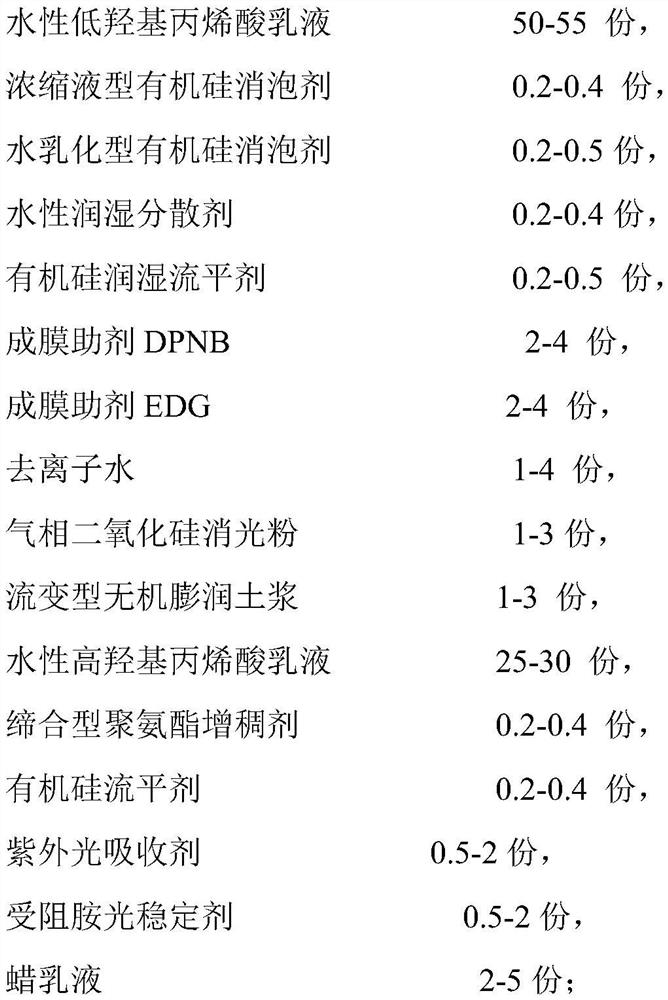

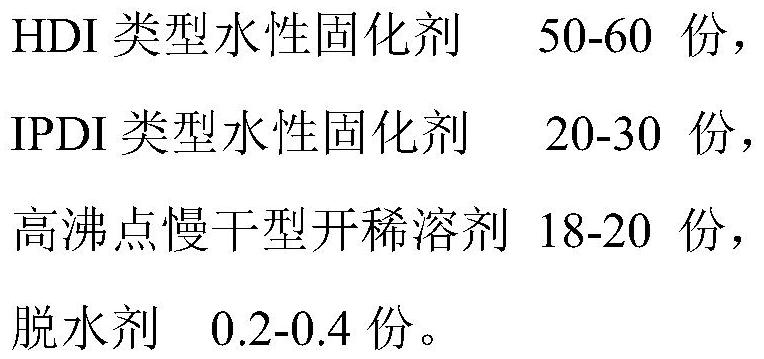

Method used

Image

Examples

Embodiment 1

[0090] Mix component A-ratio A and component B-ratio A at a ratio of 100:10 to obtain the water-based two-component matt clear finish of Example 1.

Embodiment 2

[0092] Mix component A-proportion A and component B-proportion B together in a ratio of 100:20 to obtain the water-based two-component matt clear finish of Example 1.

Embodiment 3

[0094] Mix A component-ratio A and B component-ratio C in a ratio of 100:15 to obtain the water-based two-component matt clear finish of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com