Novel helium ion sputtering-resistant vanadium alloy and preparation method thereof

A technology of helium ion and vanadium alloy, which is applied in the field of new anti-helium ion sputtering vanadium alloy and its preparation, can solve the problems of affecting the performance of the alloy, easy oxidation, and not suitable for large-scale production, so as to improve the yield and cost-effective , Blistering and Peeling Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] The invention provides a novel anti-helium ion sputtering vanadium alloy, which is a V-Cr-Ti-Y alloy, and the weight percentages of various components are: Cr (chromium): 3.0-6.5%, Ti (titanium) : 3.0 to 6.5%, Y (yttrium): 0.1 to 2.0%, V (vanadium): balance.

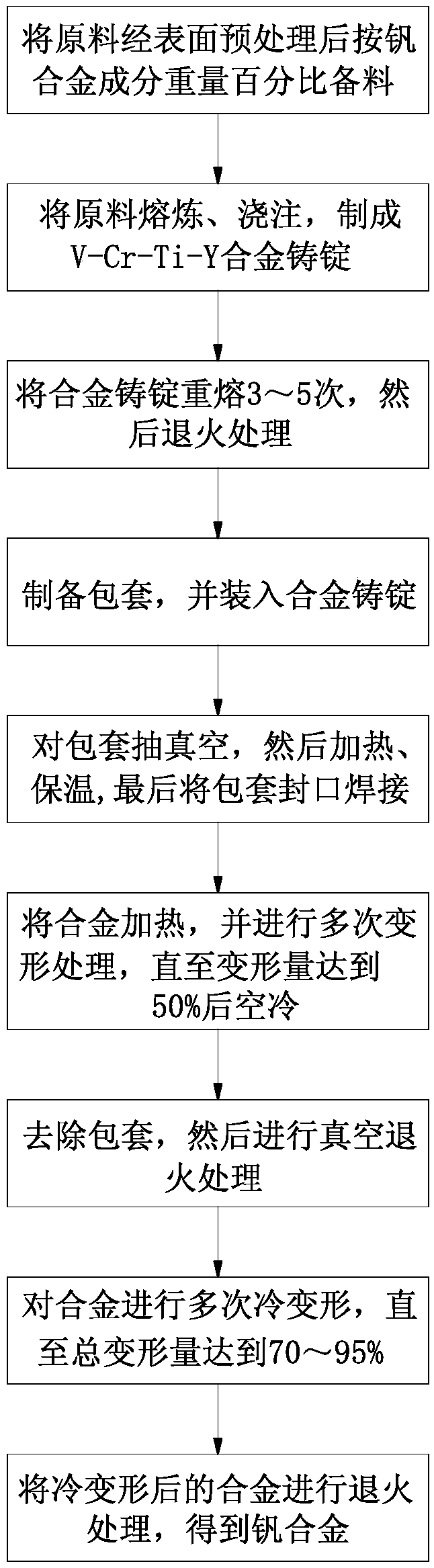

[0056] Such as figure 1 Shown, the present invention prepares the method for this kind of novel anti-helium ion sputtering vanadium alloy as follows:

[0057] (1) Using pure vanadium dendrites, pure titanium particles, pure chromium particles, and titanium-yttrium master alloy as raw materials, after surface pretreatment, prepare materials respectively according to the weight percentage of the vanadium alloy composition;

[0058] (2) Mix various raw materials, then use non-consumable arc melting furnace or consumable arc melting furnace to melt the mixed raw materials, and make V-Cr-Ti-Y alloy ingots through casting; this implementation In the example, the smelting and pouring of the alloy are carried out under ...

example 1

[0069] (1) Select the V-4.4Cr-4.3Ti-0.3Y alloy composition ratio to form a vanadium alloy. The preparation method includes the following steps:

[0070] 1) Ingredients: Pure V dendrites (99.9wt.%), pure Ti particles (99.9wt.%), pure Cr particles (99.9wt.%), Ti-20Y master alloy (the actual detection content of yttrium is 20.3wt.%) ) is alloying raw material, carries out batching according to the weight percentage of above-mentioned vanadium alloy;

[0071] 2) Melting: Melting, stirring, cooling and solidifying in a non-consumable arc melting furnace under an argon protective atmosphere with a purity higher than 99.99% to prepare alloy ingots;

[0072] 3) Homogenization treatment: cast the alloy ingot obtained in the previous step in a vacuum degree better than 1×10 -3 Homogenization annealing under the condition of Pa, the annealing temperature is 900°C, the time is 10 hours, and the heating time is 90min;

[0073] 4) Sheath: Prepare a stainless steel sheath for encapsulating...

example 2

[0081] (1) Select the V-4.4Cr-4.3Ti-0.5Y alloy composition ratio to form a vanadium alloy. The preparation method includes the following steps:

[0082] 1) Ingredients: Pure V dendrites (99.9wt.%), pure Ti particles (99.9wt.%), pure Cr particles (99.9wt.%), Ti-20Y master alloy (the actual detection content of yttrium is 20.3wt.%) ) is alloying raw material, carries out batching according to the weight percentage of above-mentioned vanadium alloy;

[0083] 2) Melting: Melting, stirring, cooling and solidifying in a non-consumable arc melting furnace under an argon protective atmosphere with a purity higher than 99.99% to prepare alloy ingots;

[0084] 3) Homogenization treatment: cast the alloy ingot obtained in the previous step in a vacuum degree better than 1×10 -3 Homogenization annealing under the condition of Pa, the annealing temperature is 900°C, the time is 10 hours, and the heating time is 90min;

[0085] 4) Sheath: Prepare a stainless steel sheath for encapsulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com