A method for refining the grain size of magnesium alloys

A grain size, magnesium alloy technology, applied in the field of refined magnesium alloy grain size, can solve the problems of reducing the corrosion resistance of magnesium alloys, increasing the cost of use, hindering the application and promotion, and achieving the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention discloses a method for refining the grain size of a magnesium alloy, which comprises the following steps:

[0029] S1: Preheat the resistance furnace with cast iron crucible to 660°C-680°C; put the alloy composition weighed by weight percentage into the preheating furnace for preheating, the preheating temperature is 200°C-300°C; Both resistance furnace and preheating furnace adopt gas protection;

[0030] S2: put the industrially pure magnesium weighed by weight percentage into the cast iron crucible;

[0031] S3: After the industrial pure magnesium is completely melted in the cast iron crucible, add the preheated alloy composition into the cast iron crucible;

[0032] S4: After the alloy composition is melted, raise the temperature of the resistance furnace to 725°C-735°C;

[0033] S5: Add the block-cut Al-B master alloy into the cast iron crucible, stir fully after the Al-B master alloy melts, and let it stand for 8-12 minutes; wherein, the Al-B maste...

Embodiment 2

[0039] The method and process parameters for refining the grain size of the magnesium alloy included in this example are basically the same as those in Example 1, except that in step S1, the alloy composition includes Al and Mg-5Mn, and the weight of Al in the magnesium alloy The percentage is 0.5-5.5 wt%, and the weight percentage of Mg-5Mn in the magnesium alloy is 1.0-10.0 wt%. The alloy composition and industrial pure magnesium are mixed and melted to form Mg-Al-Mn series magnesium alloy.

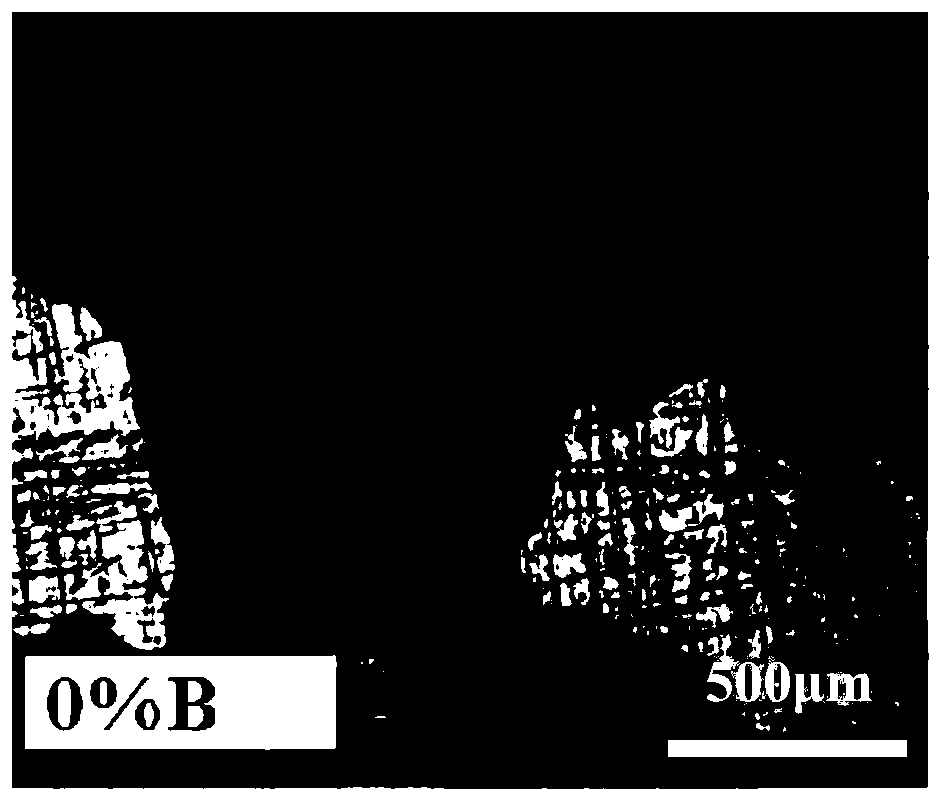

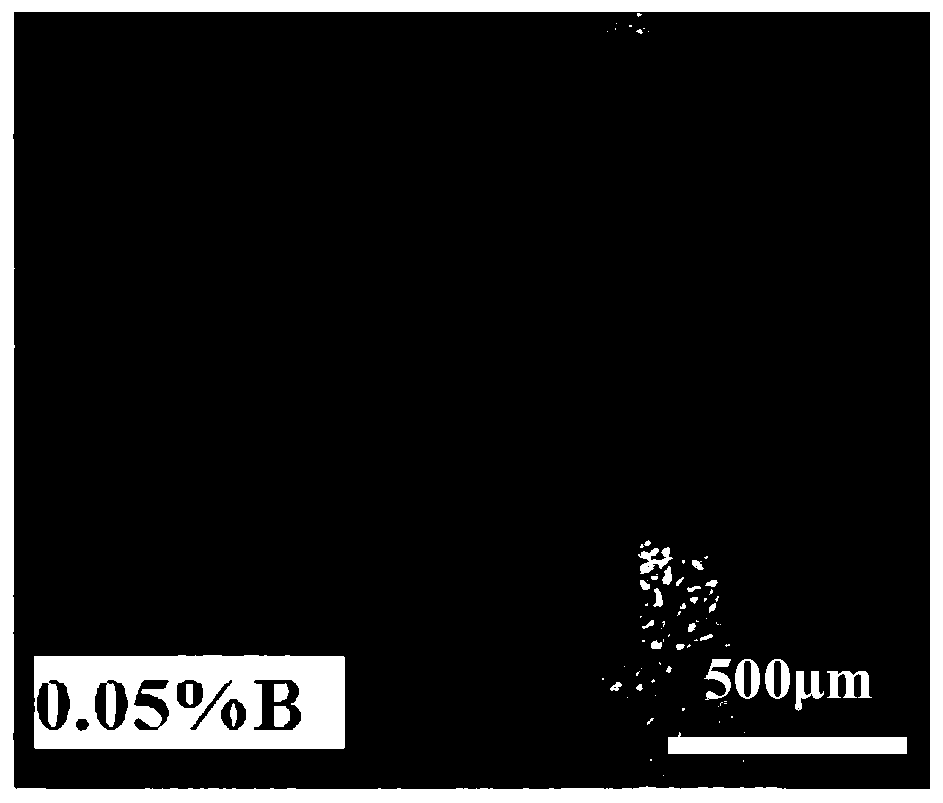

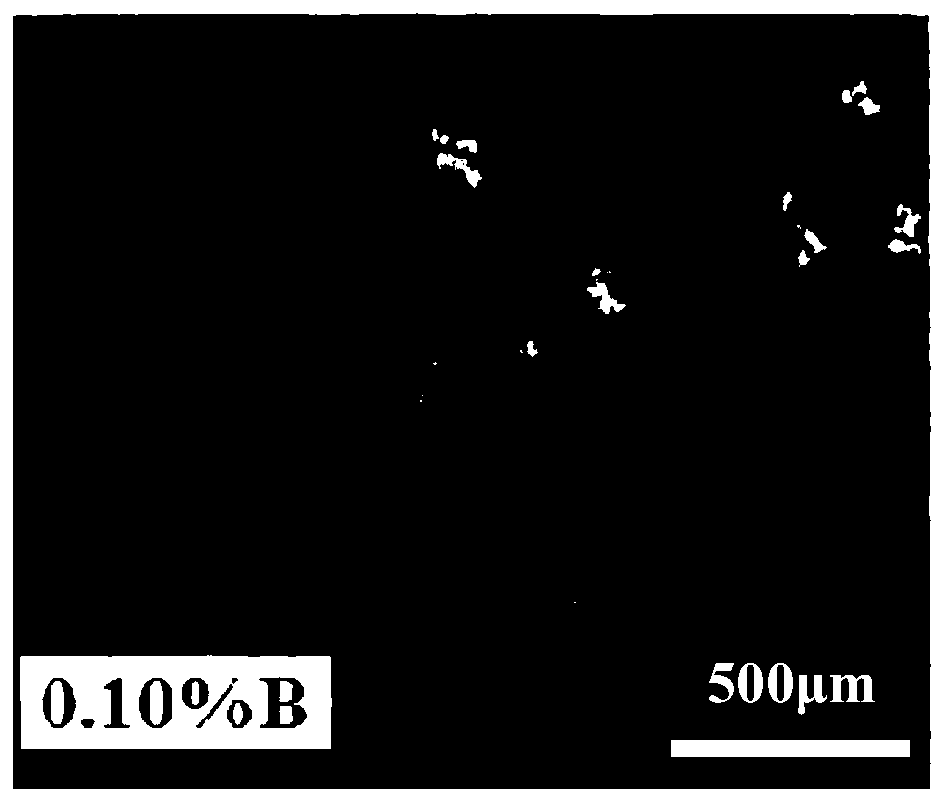

[0040] When the Al-B master alloy is added to the Mg-Al-Mn series magnesium alloy, the grain size of the magnesium alloy corresponding to the different weight percentage of B also changes. like Figure 1 to Figure 4 As shown, the grain size in the original AM50 without adding B was 550±150 μm; when adding 0.05wt% B, the grain size was significantly reduced to 320±96 μm; when the addition amount reached 0.1wt% B, the grain size was significantly reduced reduced to about 140 μm; when th...

Embodiment 3

[0042] The method and process parameters for refining the grain size of magnesium alloys included in this embodiment are basically the same as in embodiment 1 or embodiment 2, except that in step S1, CO2 and SF are used in the resistance furnace and the preheating furnace. The mixed gas is protected in the whole process according to the volume ratio V(CO2):V(SF6)=99:1. The mixed gas of CO2 and SF6 can effectively prevent the magnesium melt in the resistance furnace and the alloy composition in the preheating furnace from being oxidized by air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com