Preparation method of impact-resistant glass with coating

A technology of impact resistance and glass, applied in the direction of coating, application, ink, etc., can solve problems such as shedding, limited impact resistance of impact-resistant ink, soft hardness, etc., to improve toughness and elasticity, strong impact resistance, and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

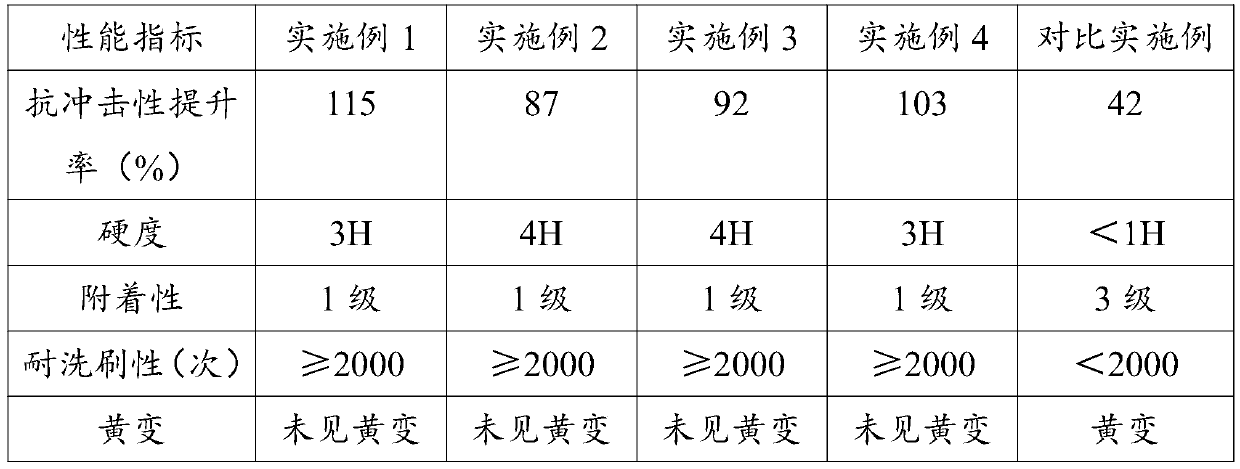

Embodiment 1

[0028] A preparation method of coated impact-resistant glass, comprising the following steps:

[0029] S1. Dissolve 25 parts of T-methyl silicone resin in 30 parts of ethyl acetate in parts by weight, and stir magnetically for 1 hour until the T-methyl silicone resin is completely dissolved in ethyl acetate; Add 5 parts of methyl vinyl silicone resin, 4 parts of aminopropyltriethoxysilane (KH-550), 0.5 parts of polyether-modified silicone and another 30 parts of ethyl acetate, and stir magnetically for 2 hours After the stirring is completed, add 1 part of 1-hydroxy-cyclohexyl-phenyl ketone and 1 part of dibutyltin dilaurate, and magnetically stir for 0.5 hours to obtain an impact-resistant coating;

[0030] S2. Preheat the glass substrate to 40°C, use an automatic air spray gun to evenly spray the anti-impact coating prepared in step S1 on the surface of the preheated glass substrate, the film thickness of the initial spraying is 2.5 microns, and keep it warm for 7 minutes; ...

Embodiment 2

[0033] A preparation method of coated impact-resistant glass, comprising the following steps:

[0034] S1. Dissolve 30 parts of T-phenyl silicone resin in 30 parts of ethyl acetate in parts by weight, and stir magnetically for 1 hour until the T-phenyl silicone resin is completely dissolved in ethyl acetate; Add 2 parts of methylphenyl vinyl silicone resin, 5 parts of γ-mercaptopropyltrimethoxysilane (KH-590), 1 part of polyester modified silicone and another 30 parts of ethyl acetate, magnetic Stir for 2 hours; after the stirring is completed, add 0.5 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 0.5 parts of ethyl orthosilicate, and magnetically stir for 0.5 hours to obtain an impact-resistant coating;

[0035] S2. Preheat the glass substrate to 40°C, use an automatic air spray gun to evenly spray the anti-impact coating prepared in step S1 on the surface of the preheated glass substrate, the film thickness of the initial spraying is 1.5 microns, and keep warm for 7 m...

Embodiment 3

[0038] A preparation method of coated impact-resistant glass, comprising the following steps:

[0039] S1. Dissolve 28 parts of T-methyl silicone resin in 30 parts of ethyl acetate in parts by weight, and stir magnetically for 1 hour until the T-methyl silicone resin is completely dissolved in ethyl acetate; Add 3 parts of methyltrifluoropropylvinyl fluorosilicone resin, 1 part of γ-mercaptopropyltriethoxysilane (KH-580), 0.1 part of polyether modified silicone and another 30 parts of acetic acid Ethyl ester, magnetically stirred for 2 hours; after the stirring was completed, 1.5 parts of 1-hydroxy-cyclohexyl-phenyl ketone and 1.5 parts of dibutyltin dilaurate were added, and magnetically stirred for 0.5 hour to obtain an impact-resistant coating;

[0040] S2. Preheat the glass substrate to 40°C, use an automatic air spray gun to evenly spray the anti-impact coating prepared in step S1 on the surface of the preheated glass substrate, the film thickness of the initial spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com